Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Guaranteed diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron-base desulfurizer for catalyzing, translating and absorbing carbonyl sulfur at middle-low temperature and preparation thereof

InactiveCN101054538AHigh breakthrough sulfur capacityHigh precisionCombustible gas purificationSyngasSecondary component

The invention relates to a preparation of catalyzing and transforming-absorbing Fe-desulphurizer by high accuracy carbonyl sulfur at medium and low temperature, which has a good hydrogenation effect to the carbonyl sulfur and absorbs the produced carbonyl sulfur. The invention can be used to accurately remove the carbonyl sulfur in the ammonia material gas, coke oven gas, natural gas and composed gas. The desulphurizer is provided with primary active components Fe2O3, CeO2, MnO2, Ni2O3, and secondary components CuO, ZnO, MgO, K2O and etc, and the carriers are Al2O3, ZrO2, and residual binding agent and expanding drilling agent, and water. The process has a reacting temperature of 150-350 DEG C, an airspeed of 500-2000h-1, a carbonyl sulfur concentration in the gas from minim to 5000ppm. The inventive desulphurizer has a high catalytic transforming capacity with a carbonyl sulfur converting ratio more than 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

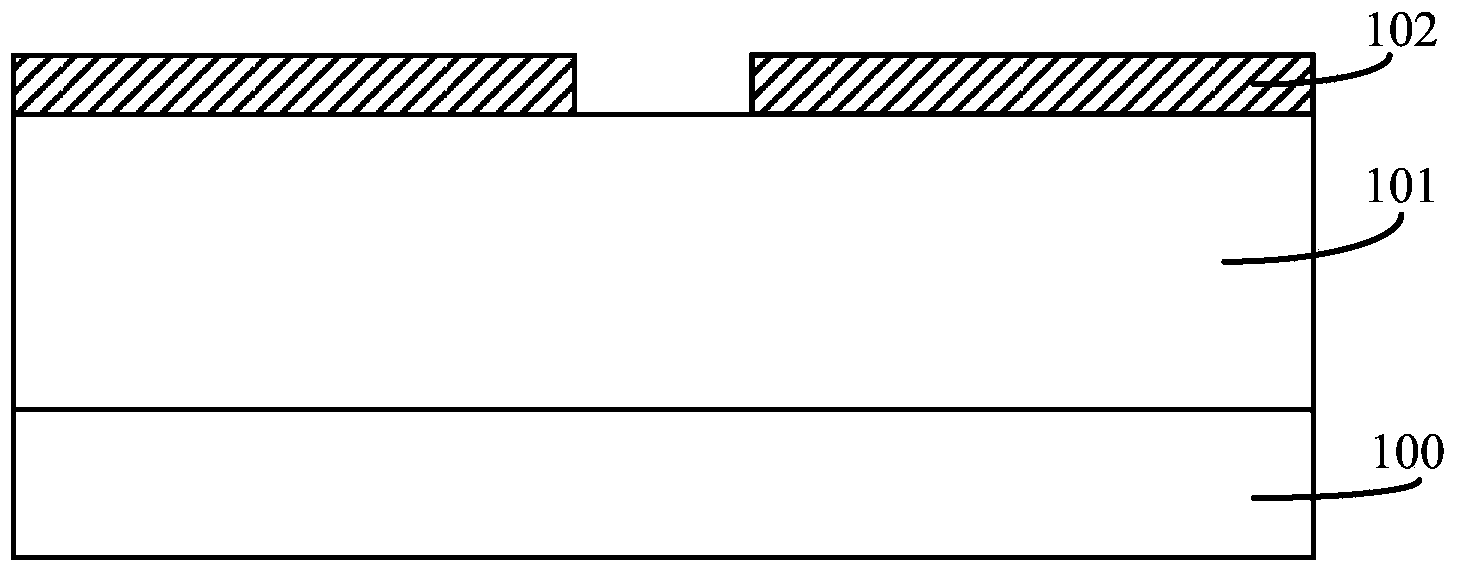

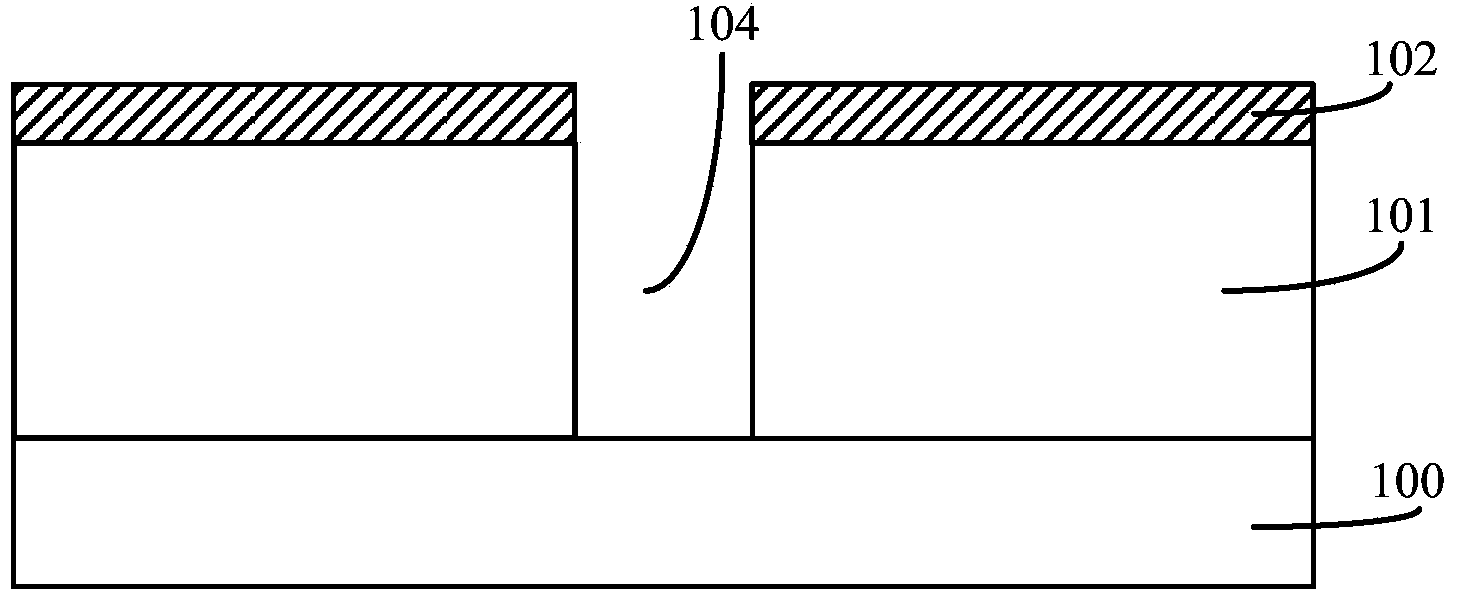

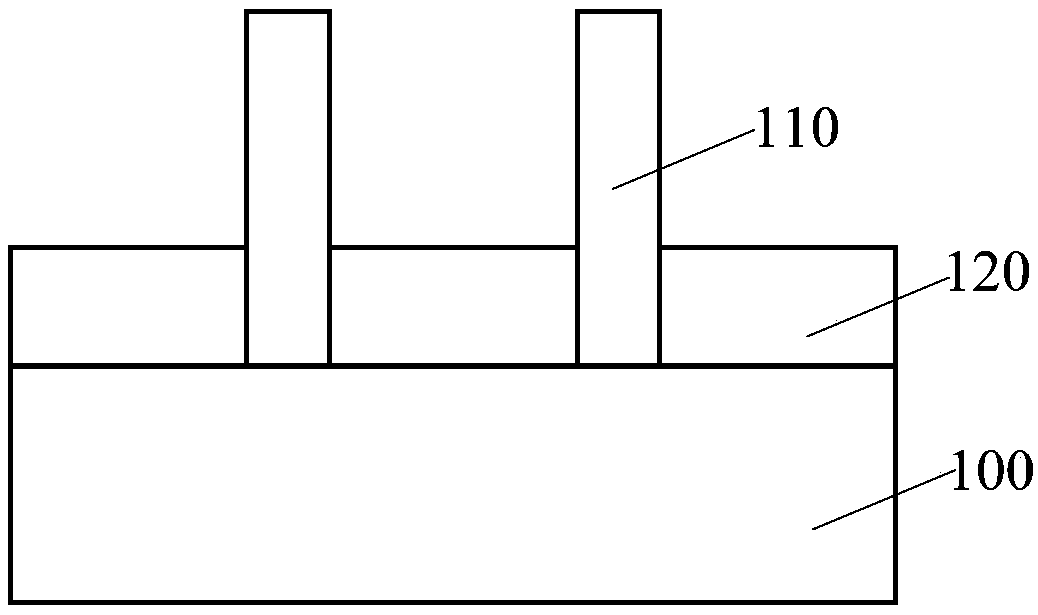

Method for forming semiconductor structure

ActiveCN103400762AReduce reactivityLow etch impactSemiconductor/solid-state device manufacturingSemiconductor structureRadio frequency signal

The invention discloses a method for forming a semiconductor structure, comprising the steps: providing a substrate, wherein the surface of the substrate is provided with a layer to be etched; forming a mark layer on the layer to be etched, wherein a part of the mark layer is exposed out of the surface of the layer to be etched; performing plasma etching on the layer to be etched by using the mark layer as a mark to form an opening in the layer to be etched, wherein a radio frequency signal output from a bias radio frequency power source in the plasma etching is a pulse signal, the duty cycle of the pulse signal is reduced along with the increasing of the etching depth, when the bias radio frequency power source is powered on, a part of the layer to be etched is etched to form an etching hole in which an etching byproduct is provided, and when the bias radio frequency power source is powered off, the etching byproduct diffuses from the etching hole. The size of the opening formed by the plasma etching process is precious and even, and the opening etching rate is high.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Preparation method of neodymium iron boron permanent magnet material

The invention provides a preparation method of neodymium iron boron permanent magnet material. The method includes: attaching attachment on the surface of a neodymium iron boron magnet parent, sintering under the protection of vacuum or inert gases, and performing aging treatment. The attachment comprises (R1xR2y)aTbMcAdHe alloy powder, wherein R1 is Dy and / or Tb, R2 is at least one of La, Ce, Pr, Nd, Sm, Ho, Y and Sc, T is iron and / or cobalt, M is at least one of Al, Cu, Zn, Sn, Ga, Ge, Nb, V, W, Ti, Ni, Zr, Ta, Mn, Cd and Mo, A is boron and / or carbon, H is hydrogen, 40wt%< / =a< / =80wt%, 1wt%< / =c< / =20wt%, 0wt%< / =d< / =5wt%, 0.2wt%< / =e< / =1wt%, the balance of b, x> / =10wt%, y> / =0wt%, x+y=100wt%, and the oxygen content of the (R1xR2y)aTbMcAdHe alloy powder is lower than 1000ppm. Compared with the prior art, the neodymium iron boron permanent magnet material has the advantages that the residual magnetism (Br), coercive force (Hcj) and maximum magnetic energy product ((BH)max) are increased.

Owner:BYD CO LTD

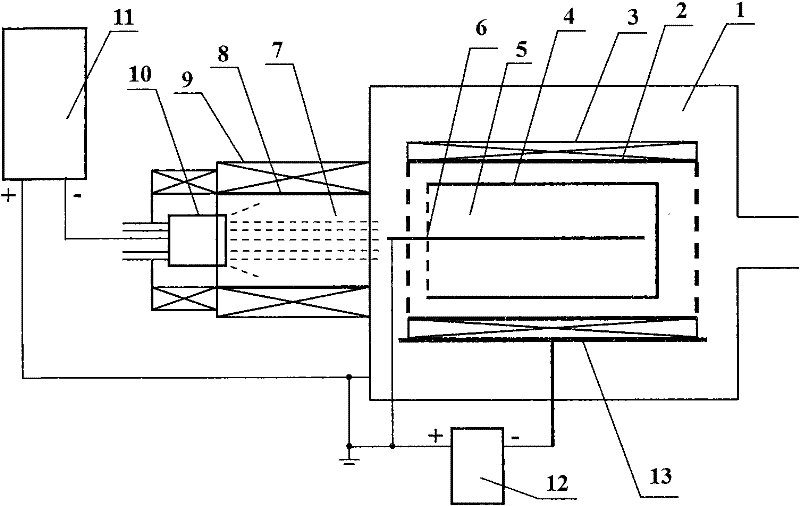

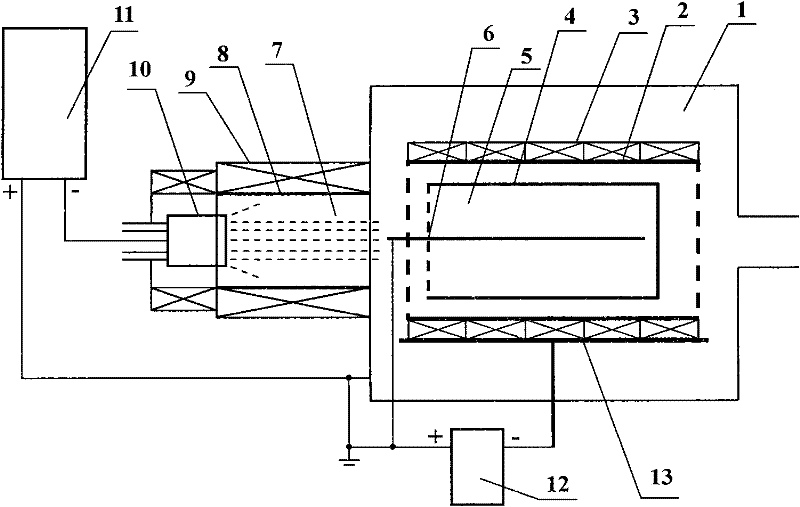

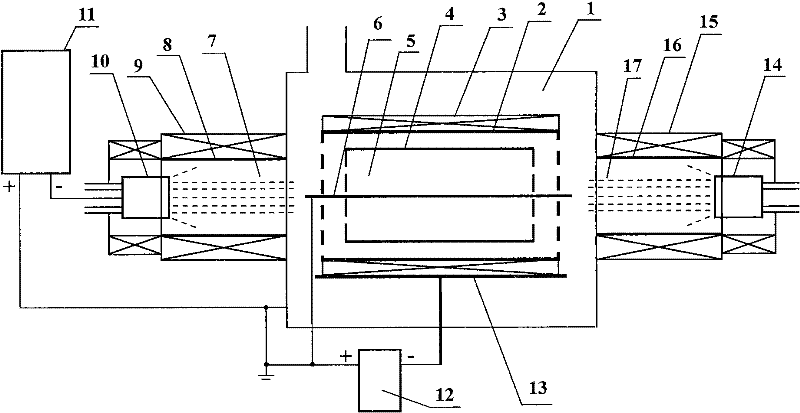

Magnetic field for plating on inner wall of long pipe and field-enhanced arc ion plating device

ActiveCN102345097AGuaranteed Utilization EfficiencyParameters are adjustable and convenientVacuum evaporation coatingSputtering coatingTransmission channelVacuum chamber

The invention, belonging to the field of surface modification on materials, relates to a magnetic field for plating on inner wall of long pipe and a field-enhanced arc ion plating device, characterized in that: the magnetic field is used to restrain and control the plasma beam motion trail in the arc ion plating process, two sets of magnetic field generators are arranged in an arc ion plating deposition device, one set is arranged on the plasma transmission channel outside a vacuum chamber for using the magnetic field to focus the plasma beam and restrain the diameter of cross section and transmission efficiency when transmitting the plasma beam, and the other set is arranged on the outside of a tubular workpiece in the vacuum chamber for guiding the plasma beam to diffuse along with the central axial direction of the tubular workpiece; field enhancement is used in arc ion plating for using the magnetic field to realize accelerated directional flow of plasma, a pulsed electric field is arranged in the workpiece; the magnetic field and electric field are used to restrain and control the plasma beam, so as to realize the coating deposition of the plasma on the inner wall of the tube. The invention is suitable for depositing coatings on the inner wall of tubular workpiece which is used as the service surface.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rotary continuous microwave drier

The rotary continuous microwave drier includes one microwave drying oven with inner cavity with wall painted with one layer of PTFE, right and left parallel vertical baffles of metal plates surface painted with PTFE on the two sides of the oven, one 4-20 deg inclined rotary container with material feeding pipe and air exhaust pipe extending beyond the side oven all at the high end and material discharge pipe and air intake pipe extending beyond the side oven wall at the lower end, microwave suppressors set at the joints between each of the said pipes and the side oven wall. The apparatus dries material inside the container continuously and automatically, and the evaporated water vapor is limited inside the container and thus has no influence on the circuit, resulting in long service life and high operation safety of the equipment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

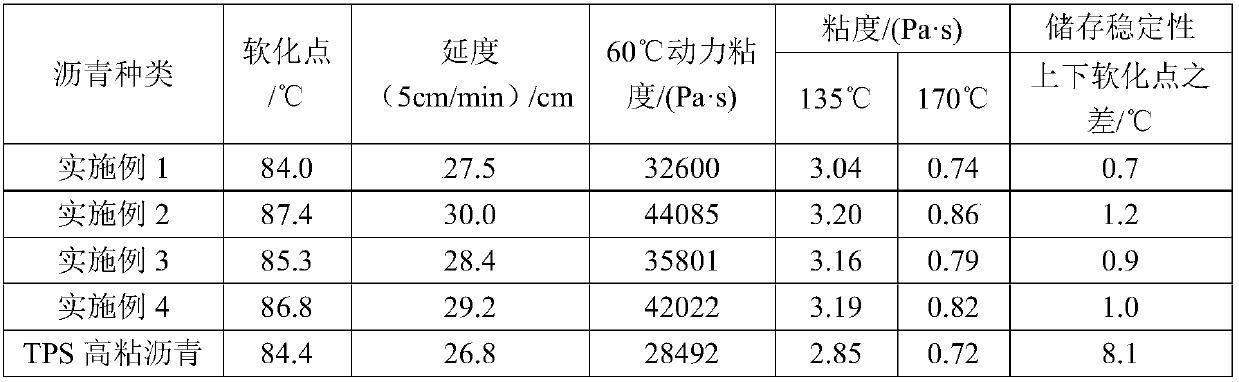

High-viscosity modified asphalt based on SBS/polyurethane compounding and preparation method thereof

InactiveCN109553991AImproved high temperature and bonding propertiesGood storage stabilityBuilding insulationsPrepolymerCarbamate

The invention discloses high-viscosity modified asphalt based on SBS / polyurethane compounding and a preparation method thereof. The preparation method includes: a) heating matrix asphalt to molten, adding a SBS modifier and uniformly mixing the components to make a mixture A, thus providing SBS-modified asphalt with incomplete swelling development; b) shearing the mixture A to obtain swelling-developed SBS-modified asphalt, adding a stabilizer to guarantee stability of a mixture B; c) adding a chain extender and a coupling agent, wherein the chain extender is a key factor of forming binding force after a curing reaction on a polyurethane prepolymer, and the coupling agent can reduce the chemical reactions between the polyurethane compound and micro amount of water in air, thus reducing theinfluence on storage stability and modification effect on the asphalt due to generated gas; d) finally, adding the polyurethane prepolymer, of which a molecular structure contains an active isocyanate group, which can react with a hydroxyl group, in the asphalt, to generate a carbamate group, therefore, a chemical reaction is carried out with amino groups in the matrix asphalt to generate allophanate.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS +1

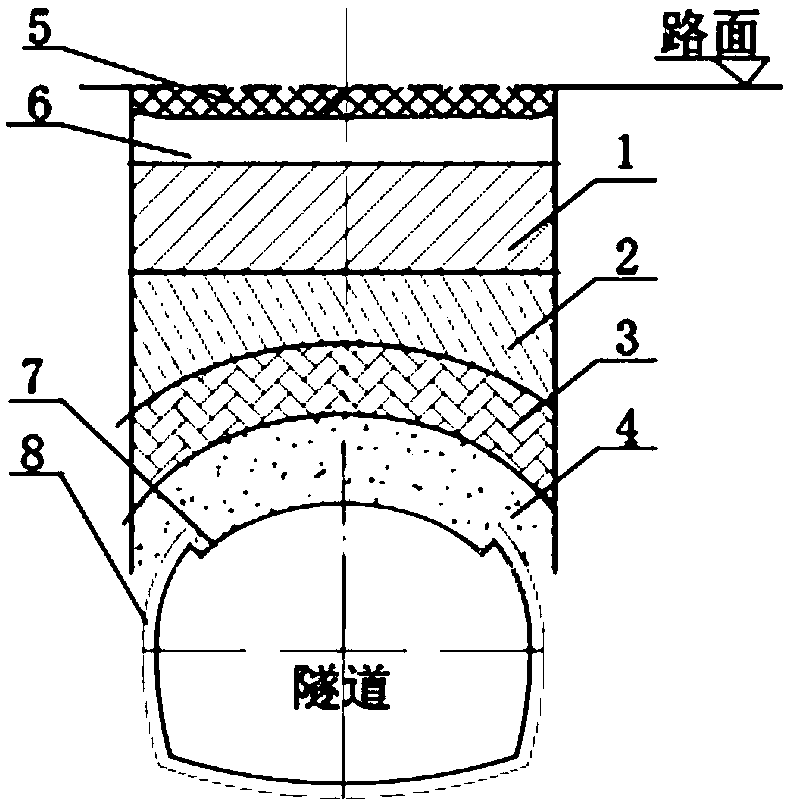

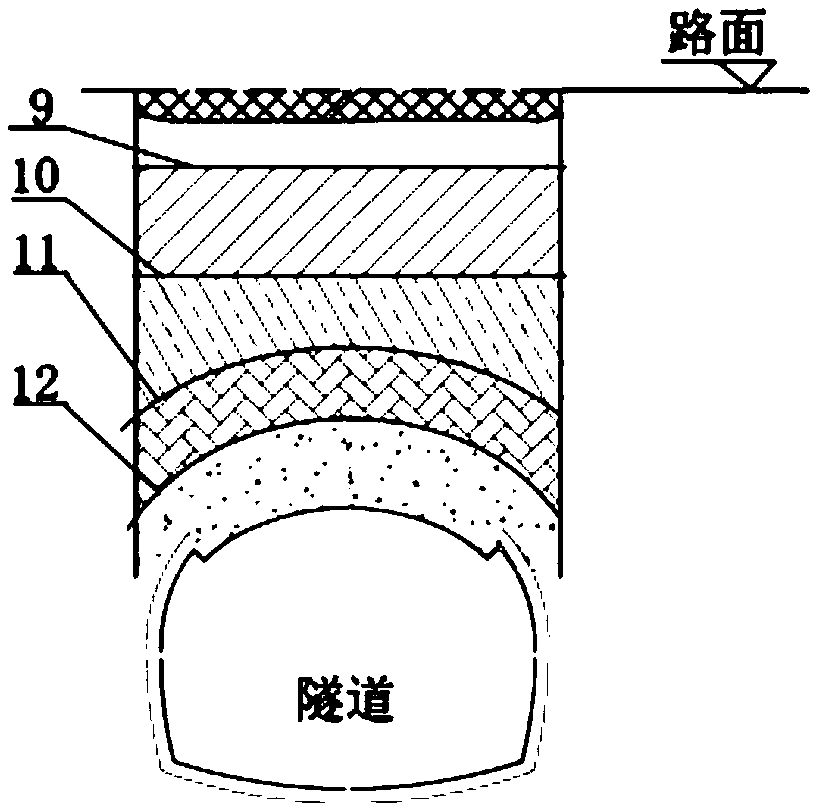

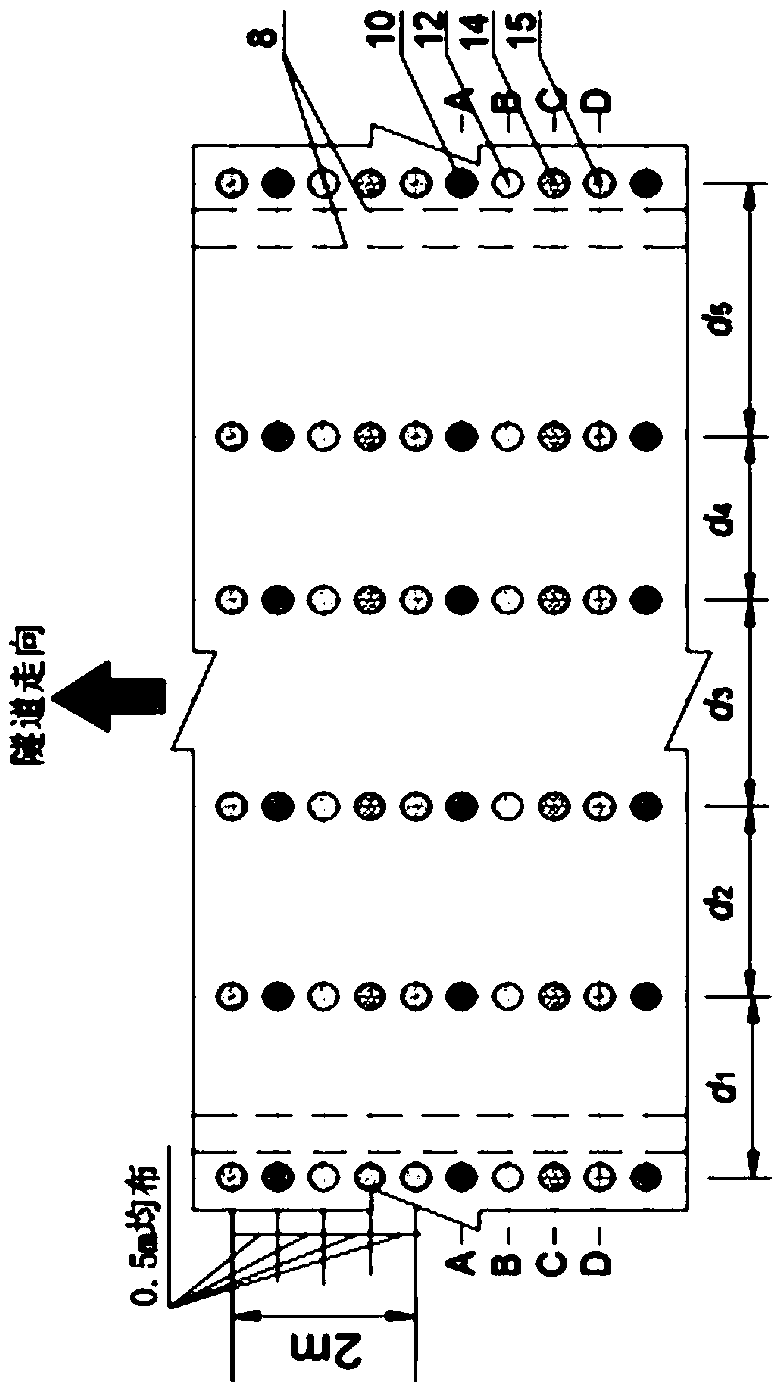

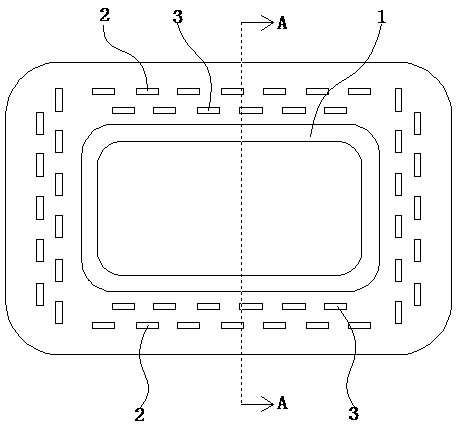

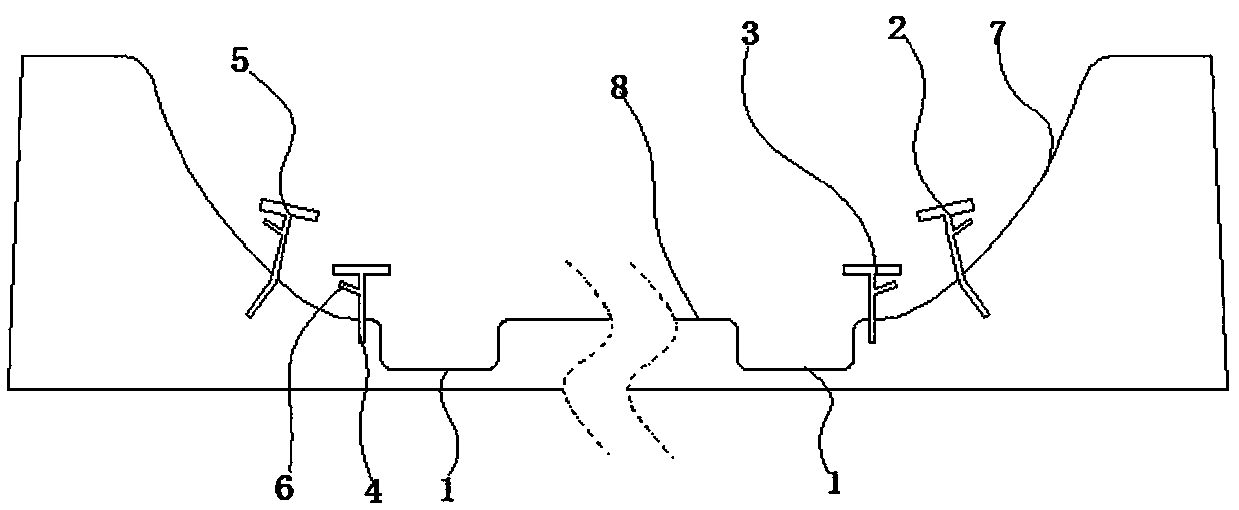

Layered and sequential grouting reinforcement treatment method for sunk vault of urban tunnel

ActiveCN108843345APrevent leakageGuaranteed diffusionUnderground chambersTunnel liningGeomorphologySlurry

The invention discloses a layered and sequential grouting reinforcement treatment method for the sunk vault of an urban tunnel. Through gaps between various pipelines under the ground, drilling is carried out on the ground in the range of a sunk area of the tunnel; through the drilling depths and the grouting-stop depths in holes in different positions, grouting is carried out in surrounding rockbelow the grouting-stop depths, specifically, the surrounding rock from the vault of the tunnel to the ground is divided into a shallow slurry-blocking layer, an intermediate reinforcement layer, a vault reinforcement layer and a vault grouting-stop layer, and grouting is carried out layer by layer in the sequence of the shallow slurry-blocking layer, the vault grouting-stop layer, the vault reinforcement layer and the intermediate reinforcement layer under different controllable slurry initial setting time and final grouting pressure, and overall system reinforcement of the upper formation ofthe tunnel is achieved.

Owner:SHANDONG UNIV

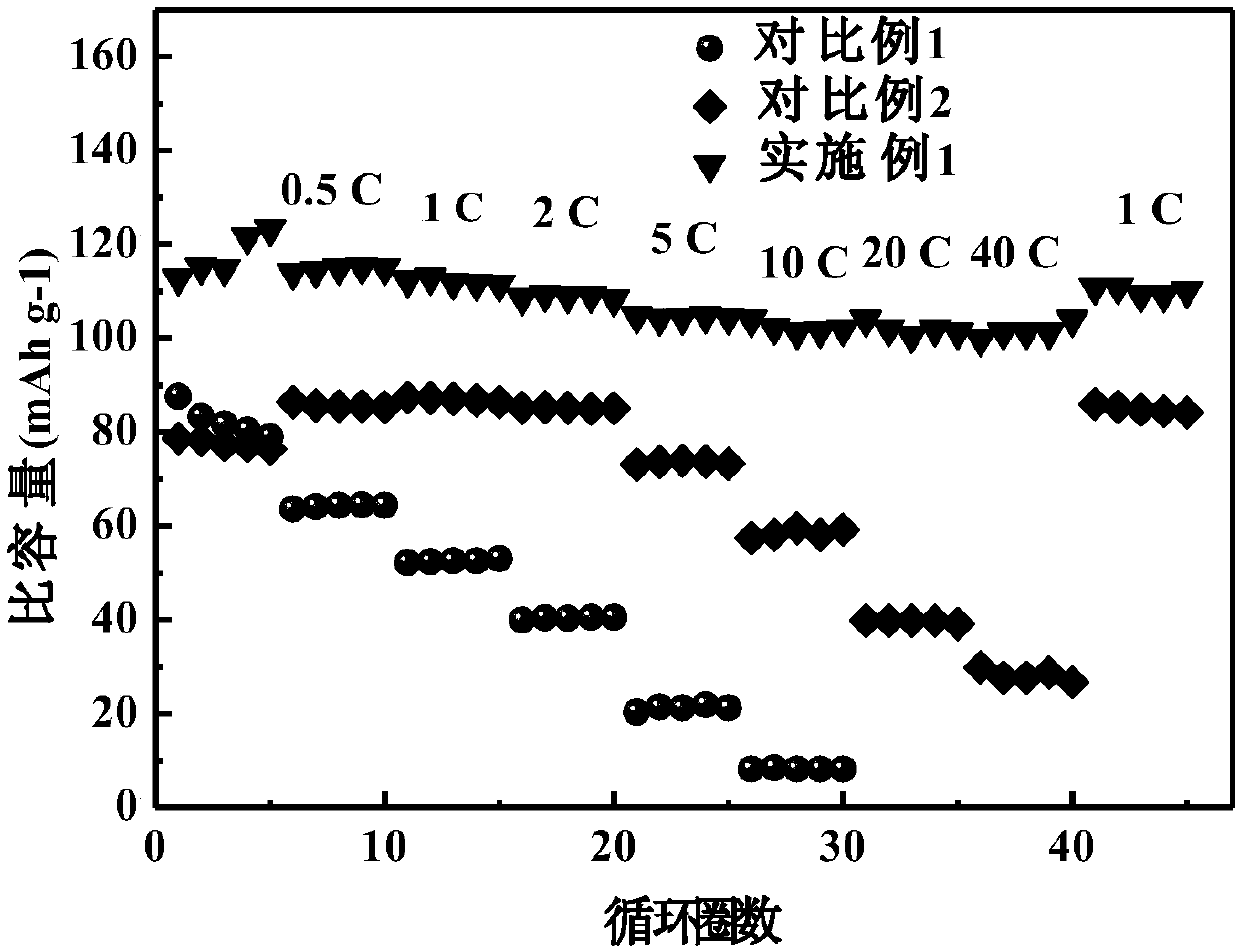

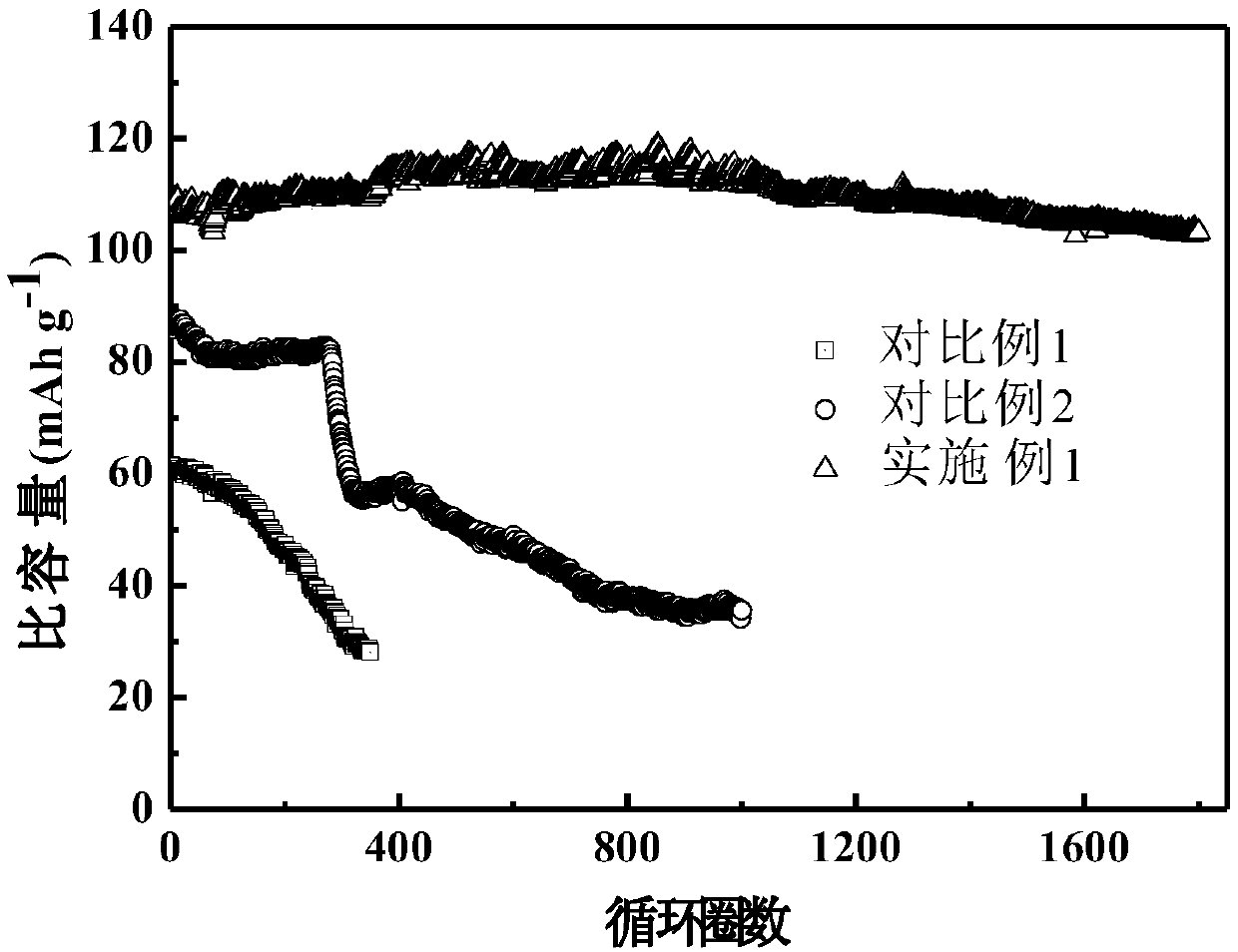

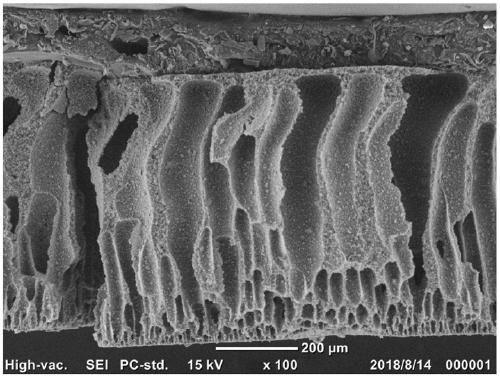

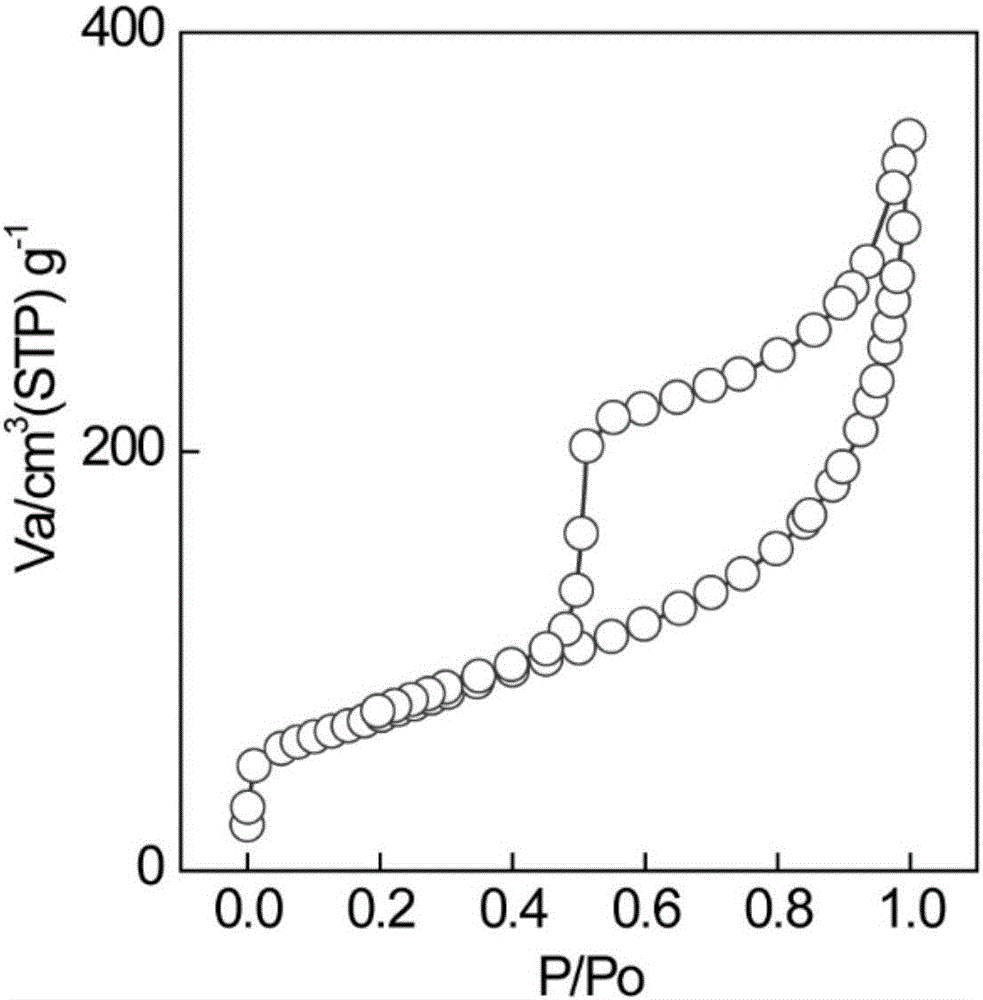

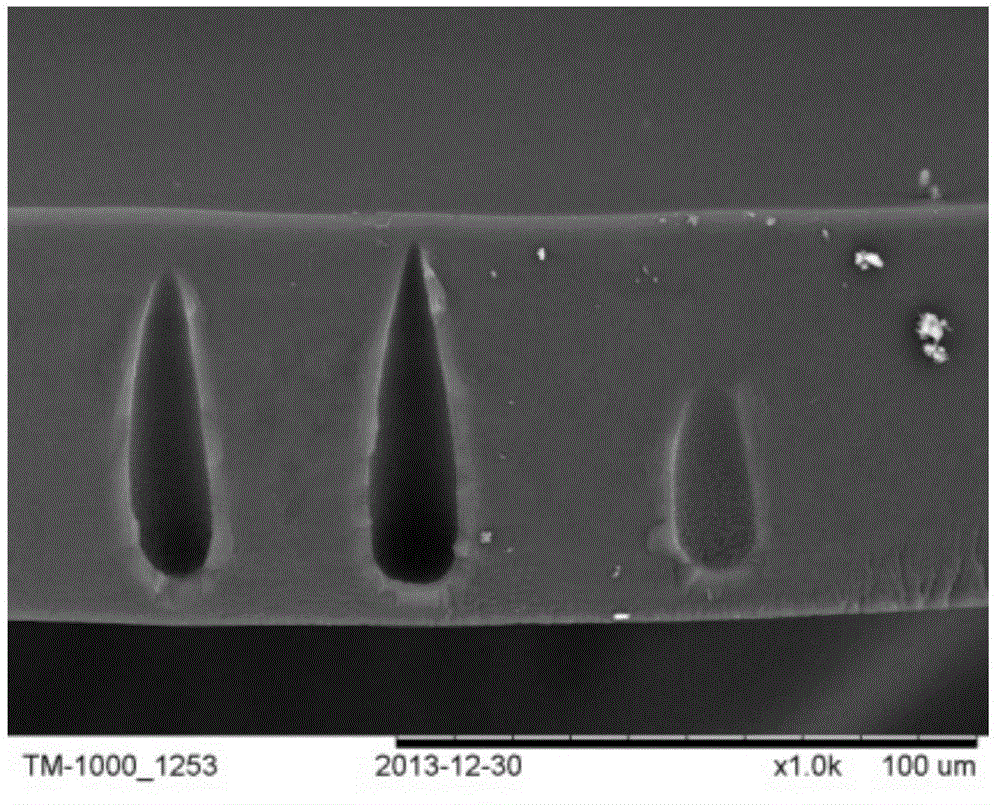

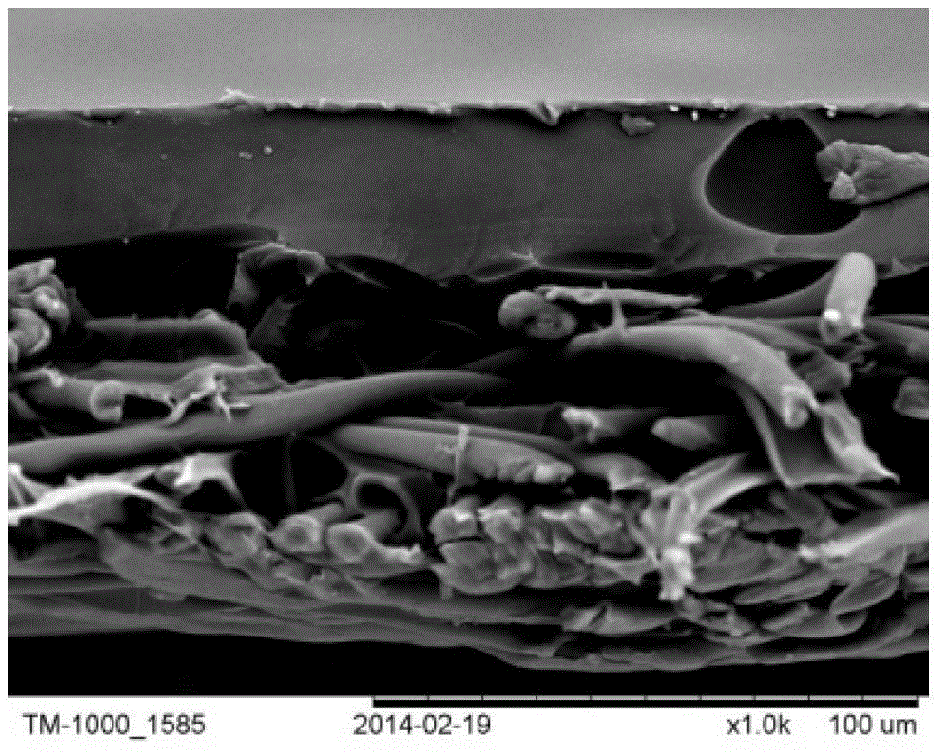

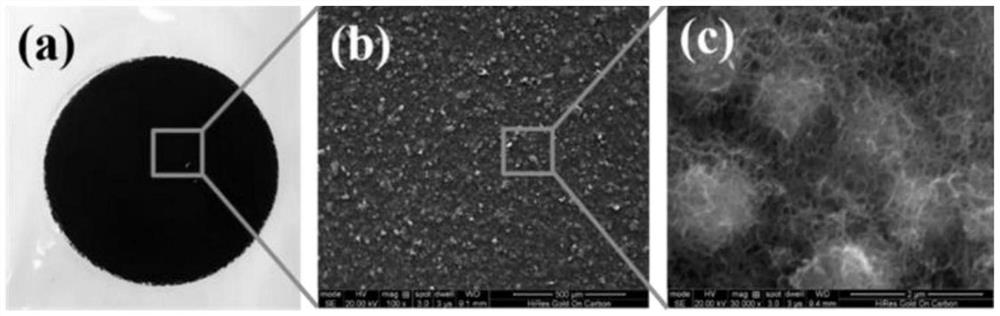

Preparation of high-loading self-supporting thick electrode and application of high-loading self-supporting thick electrode in sodium ion battery

ActiveCN111106312AIncrease energy densityIncrease the mass ratioSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryEngineering

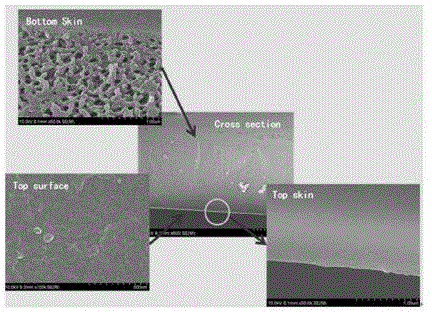

The invention belongs to the field of electrode materials, and discloses a high-loadng self-supporting thick electrode prepared through phase inversion and a preparation method and application thereof. The electrode prepared by the process has the following advantages: 1) a current collector, a binder and additional conductive carbon are not needed, so that the overall energy density of the electrode is greatly improved; 2) the thickness of the electrode is 300-3000 [mu]m, the loading capacity is 8-55 mg cm <-2 >, the thick electrode can improve the proportion of active materials in the wholeenergy storage equipment, and the energy density of the whole energy storage equipment is improved; 3) compared with a thin electrode, under the condition of achieving the same energy storage capacity, the high-loading thick electrode has fewer preparation steps and is lower in production cost; and 4) the electrode is provided with micron-sized finger-shaped holes communicated with the surfaces ofthe two electrodes and hundred-nanometer-sized holes dispersed in the whole electrode, and the holes ensure that the electrode has excellent rate capability even under a high loading capacity. The method promotes the industrial application and mass production of the high-loading self-supporting thick electrode.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

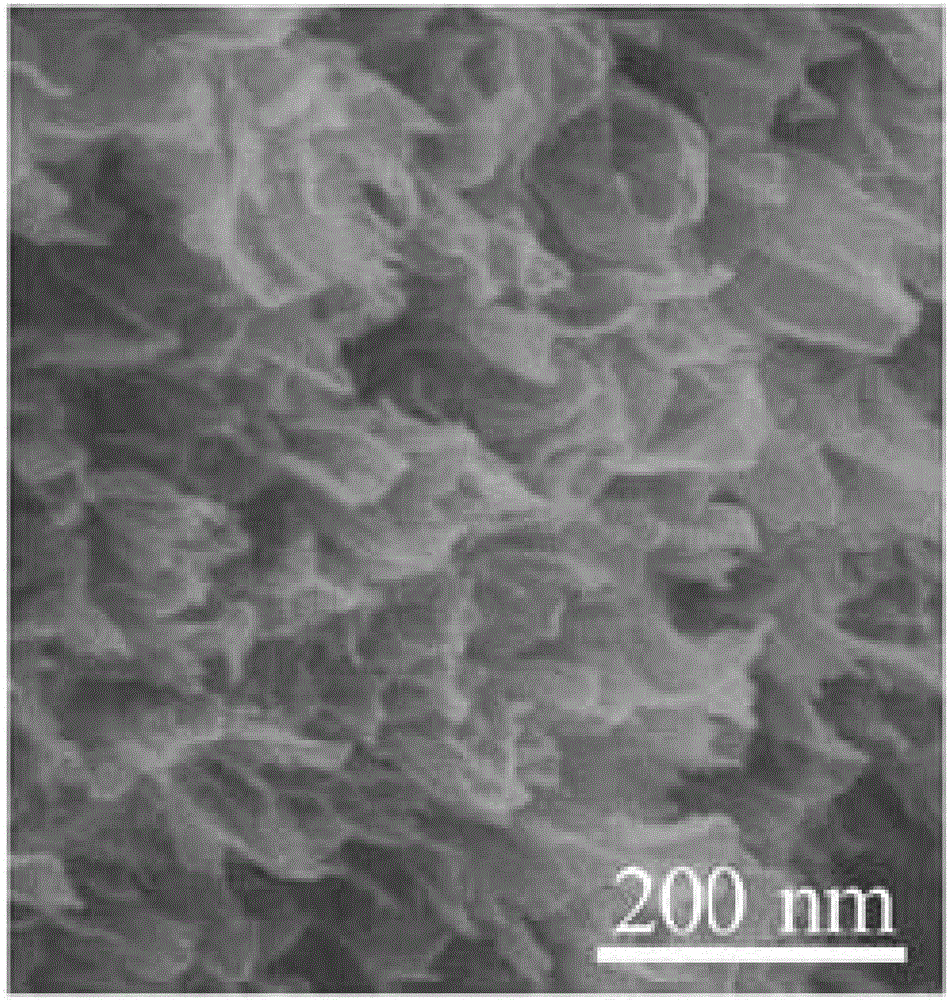

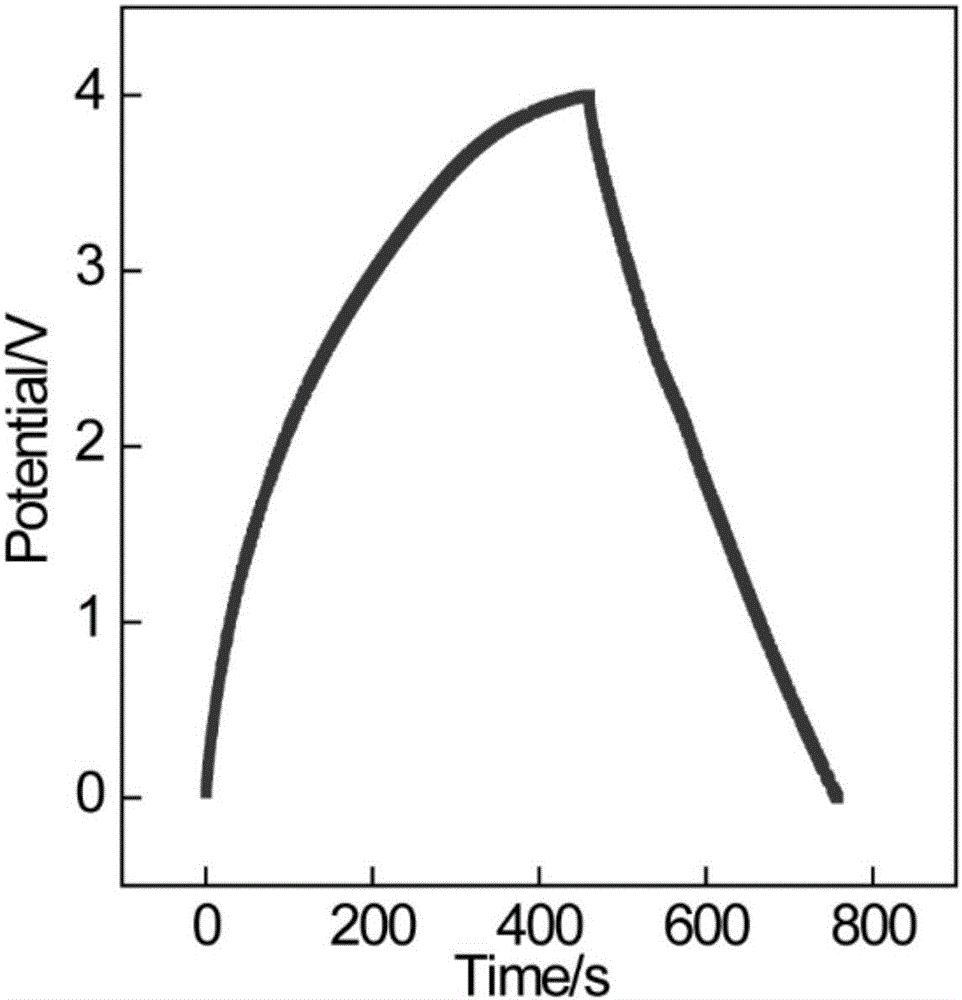

Method for regulating and controlling three-dimensional graphene holes with aid of sulfur used as template

InactiveCN106829932AAchieve dense shrinkageMild method conditionsCell electrodesGraphenePorous grapheneCvd graphene

The invention belongs to the technical field of graphene, and particularly relates to a method for regulating and controlling three-dimensional graphene holes with the aid of sulfur used as a template. The method at least includes steps of adding sulfur-containing substances and acid into graphene dispersion liquid and sufficiently stirring the sulfur-containing substances, the acid and the graphene dispersion liquid to obtain mixed dispersion liquid; adding the mixed dispersion liquid obtained at the first step into a hydrothermal reaction kettle and carrying out hydrothermal reaction; sufficiently soaking hydrogel obtained at the second step in deionized water, removing impurities and then removing water; carrying out desulfurization treatment on to-be-treated products obtained at the third step to obtain three-dimensional porous graphene macroscopic bodies. Compared with the prior art, the method has the advantages that the sulfur is led into the three-dimensional graphene macroscopic bodies as the template in hydrothermal procedures, and the pore sizes of the three-dimensional graphene macroscopic bodies can be increased after the sulfur is removed by means of simple heat treatment; the leading quantity of the sulfur is accurately controlled, accordingly, pore structures of the macroscopic bodies can be accurately regulated and controlled on a large scale, and the macroscopic bodies can be applied to different energy storage devices.

Owner:TIANJIN UNIV

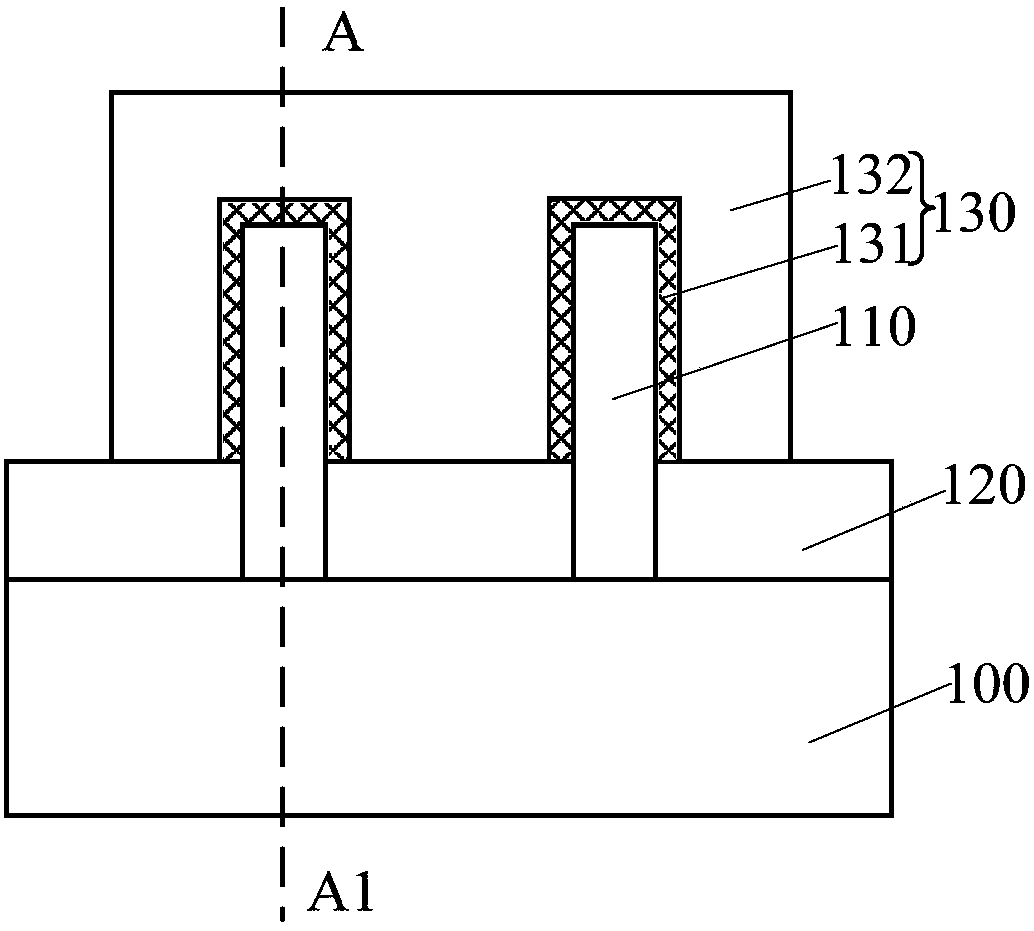

Forming method of semiconductor device

ActiveCN107919324AImprove compactnessIncreased etch resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesIonPower semiconductor device

The invention discloses a forming method of a semiconductor device, and the method comprises the steps: providing a semiconductor substrate which is provided with a fin part and an isolation structure, wherein the isolation structure covers a part of side walls of the fin part; forming a first pseudo-gate structure across the fin part on the isolation structure, wherein the first pseudo-gate structure comprises a first pseudo-gate medium layer and first pseudo-gate electrode layers, the first pseudo-gate medium layer covers a part of the top surface and a part of side wall surfaces of the finpart, and the first pseudo-gate electrode layers are located on the first pseudo-gate medium layer and a part of isolation structure; forming interlayer medium layers on the isolation structure and the fin part, wherein the interlayer medium layers cover a part of side walls of the first pseudo-gate structure; removing the first pseudo-gate electrode layers, and forming an opening; carrying out the doping of modified ions in the isolation structure at the bottom of the opening, and forming a modified layer in the isolation structure, wherein the modified structure is aligned with the surface of the modified layer; and removing the first pseudo-gate medium layer through etching. The method can reduce the loss of the isolation structure, enables the isolation performances of the isolation structure and the modified layer for the fin part to be improved, and meets the demands of the technological design.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Polyculture pond and polyculture method for penaeus monodon, holothuria scabra and siganus oramin

PendingCN107897096ACompatible with growing conditionsGood economic farming modelClimate change adaptationPisciculture and aquariaAlgaeEngineering

The invention discloses a polyculture pond and a polyculture method for penaeus monodon, holothuria scabra and siganus oramin. The circumferential inner edge of the polyculture pond is provided with aslope. The polyculture pond is characterized in that several inhabitation piles are arranged close to the bottom of the slope and are alternately distributed around the edge of the polyculture pond,each inhabitation pile comprises a column and a ceiling located at the top of the column, and an impoundment cover is arranged around the middle of the column and faces the slope. Holothuria scabra isstocked in the impoundment covers, at the same time, penaeus monodon and siganus oramin are cultured in water in the polyculture pond together, and penaeus monodon is fed with bait regularly. By culturing holothuria scabra and siganus oramin together in the polyculture pond where penaeus monodon is mainly cultured, bottom mud dirt and water algae in the polyculture pond can be effectively controlled respectively, it is guranateed that both the bottom of the polyculture pond and water in the polyculture pond can meet growth conditions of penaeus monodon all the time, and polyculture in this way provides a good economical culture mode.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

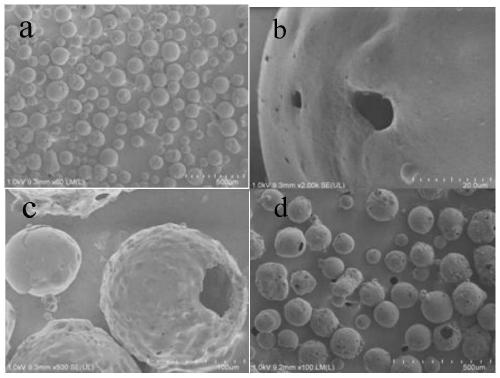

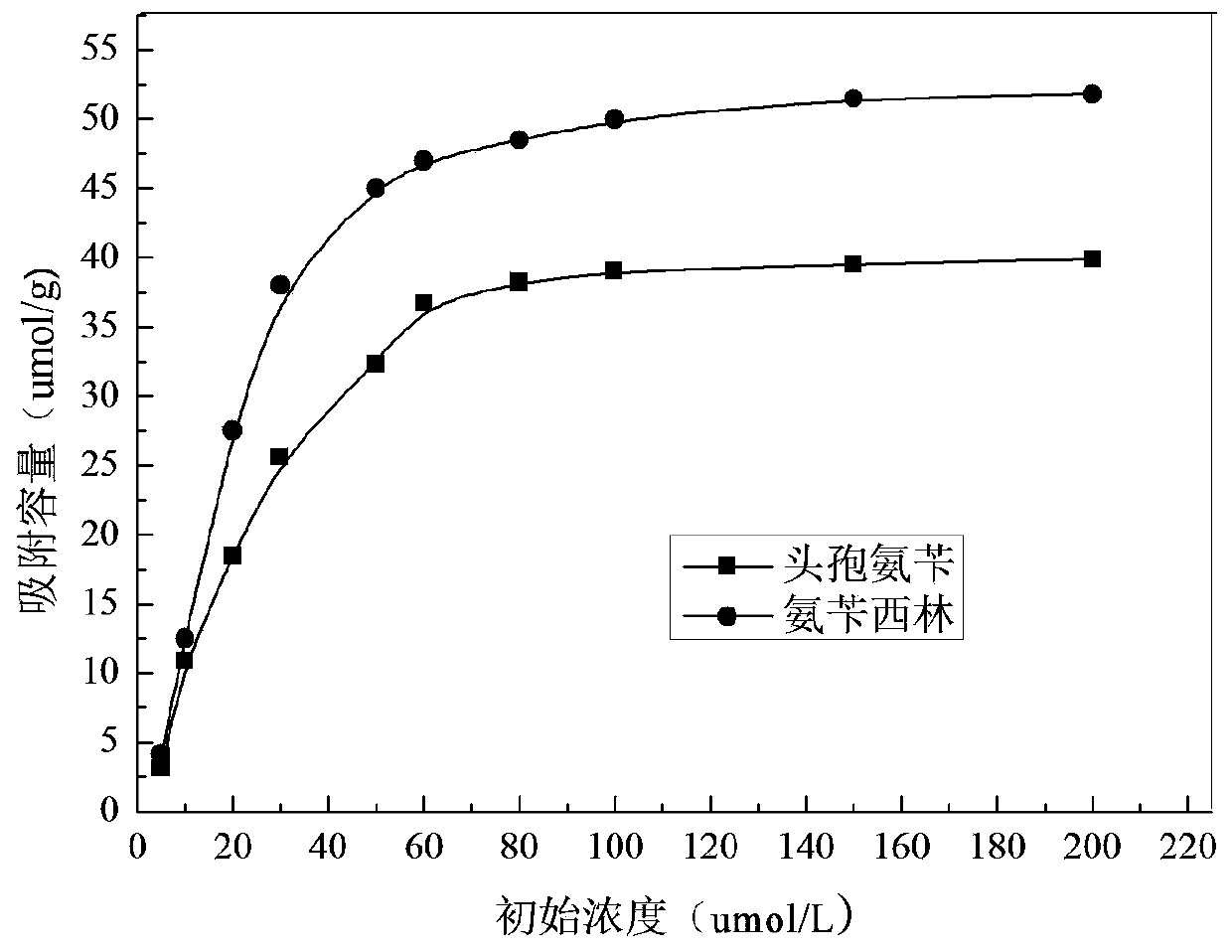

Spherical bead like walnut shell based porous carbon adsorption material and preparation method and applications thereof

PendingCN110252247AFacilitate internal diffusionLarge specific surface areaOther chemical processesWater contaminantsActivation methodPorous carbon

The invention discloses a preparation method of a spherical bead like walnut shell based porous carbon adsorption material. The preparation method comprises following steps: at first, activating walnut shell powder by phosphoric acid, preparing a uniform solution, wrapping the surface of cenospheres by the solution, filling the solution into the cavities of the cenospheres , carrying out carbonization, removing fly ash to obtain a hollow structure of fly ash, and finally generating micro holes by a high temperature alkali activation method to obtain the hierarchical porous carbon material with a high specific surface area. Cheap agricultural wastes namely walnut shells are taken as the carbon source, solid industrial wastes namely fly ash cenospheres (FACs) are taken as the hard template, and the prepared hierarchical porous carbon material is used to process sewage of beta-lactam antibiotics, and the processing effect is good.

Owner:HENAN UNIV OF URBAN CONSTR

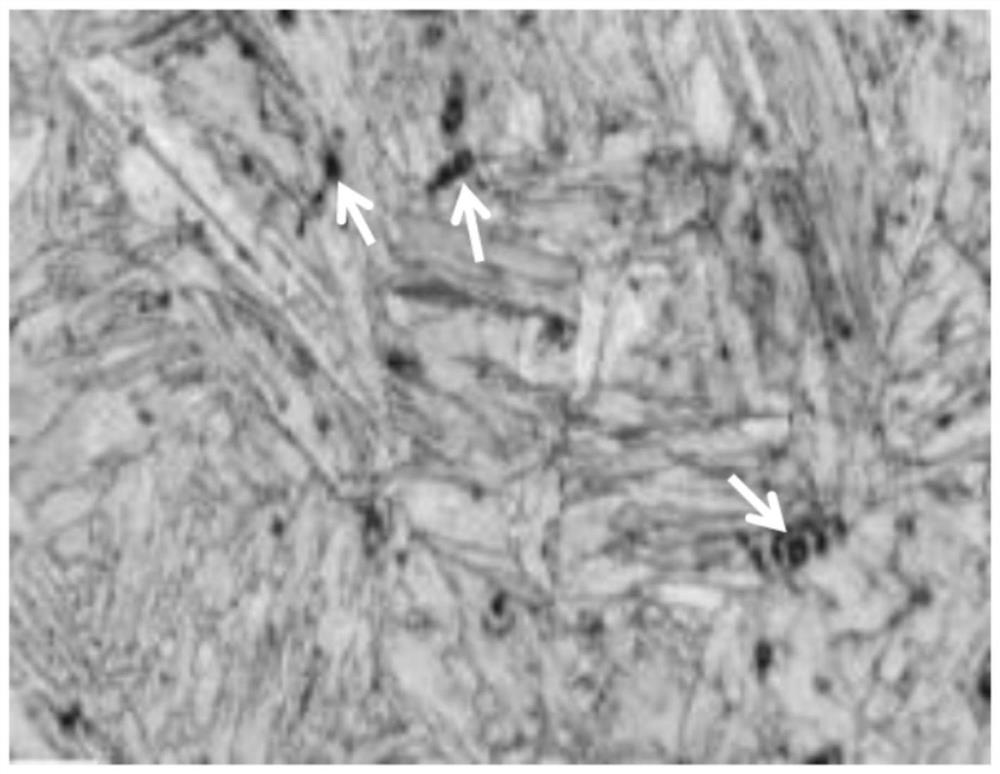

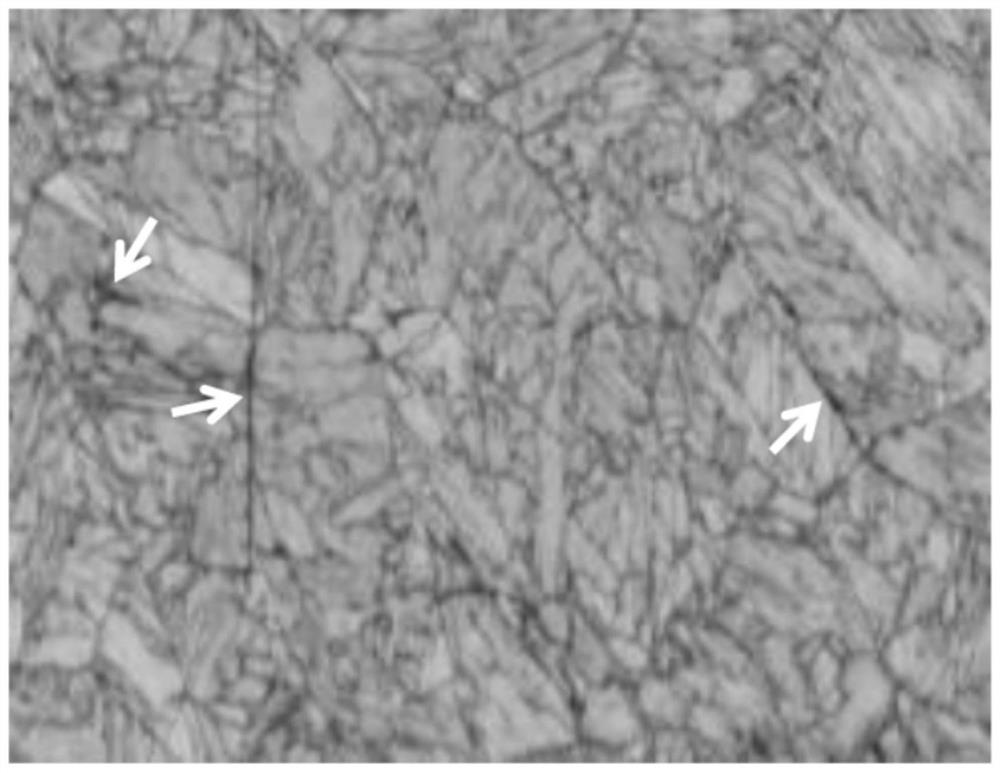

Method for preparing super martensitic stainless steel EBSD sample

ActiveCN112160018ASpeed up the flowFast dissolutionPreparing sample for investigationElectrolytic agentMetallurgy

The invention discloses a method for preparing a super martensitic stainless steel EBSD sample. The method comprises the steps of polishing solution preparation, sample grinding, electrolytic polishing and polished surface cleaning; a polishing solution is prepared by mixing HCLO4, CH3COOH and C2H5OH according to the volume ratio of (1 + / -0.1): (3 + / -0.1): (6 + / -0.1), a stainless steel sheet is used as a cathode, and the super martensitic stainless steel sample serves as an anode; then an electrolysis device is placed on a magnetic stirrer, liquid nitrogen is used for cooling the electrolyte,and the power voltage is adjusted; finally, a stainless steel clamp is used for immersing the sample into the electrolyte, the grinding face is parallel to the cathode stainless steel sheet, the powercurrent is adjusted, and polishing is started; and after polishing is completed, the sample is taken out to be wiped and dried. According to the method, the polishing time is short, the polishing efficiency is high, and the EBSD collecting and calibrating rate can reach 95% or above.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Acid, alkali and organic solvent resisting diaphragm material, and preparation method and application thereof

ActiveCN105435659AStrong chemical stability and mechanical propertiesAvoid the decrease of hydrophilicitySemi-permeable membranesOrganic moleculesBismuth

The invention discloses an acid, alkali and organic solvent resisting diaphragm material, and a preparation method and an application thereof. The diaphragm material is prepared from hydrophilic and hydrophobic block copolymers, and has a nano-pore structure. The nano-pore structure in the diaphragm material is prepared through an inorganic filler structure preparation method or an immersion phase separation method. The acid, alkali and organic solvent resisting diaphragm material has polar hydrophilic groups, and the surface of a diaphragm can be further grafted with other organic molecules with permselective functional groups by using above active groups, so realization of diaphragm functionalization is facilitated to meet various separation requirements. The diaphragm material can be applied in cation separating systems, such as separation of ions of lithium, copper, gold, platinum, palladium, silver, boron, rubidium, cesium, antimony, bismuth, nickel, mercury and other metals.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

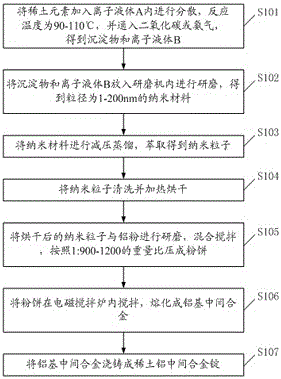

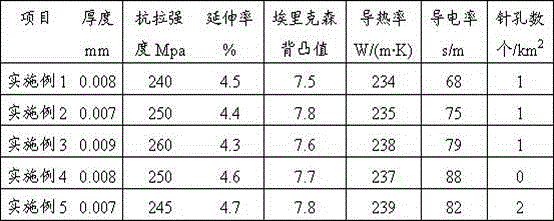

Aluminum foil applicable to lithium ion battery and preparation method for aluminum foil

ActiveCN105977494AIncreased strength and mechanical performance indicatorsLower bandgapElectrode rolling/calenderingMaterial nanotechnologyRare-earth elementThermal conductivity

The invention discloses a preparation method for an aluminum foil applicable to a lithium ion battery. The preparation method comprises the steps of 1, grinding rare earth elements to obtain a nanometer rare earth material with the particle diameter of 1-200nm, enabling the nanometer rare earth material to be ground, mixed and stirred with aluminum powder, pressing the mixture into pressed powder, and then melting the pressed powder and casting to obtain a rare earth aluminum intermediate alloy ingot; 2, adding the rare earth aluminum intermediate alloy ingot and the aluminum ingot into a smelting furnace to be smelted to obtain a blank material; 3, performing cast rolling on the smelted blank material to obtain an aluminum plate blank material; 4, performing annealing and heat treatment on the aluminum plate blank material; 5, performing continuous cold rolling on the aluminum plate blank material to obtain a primary product; and 6, performing finish rolling on the primary product to obtain the aluminum foil. Correspondingly, the invention also discloses the aluminum foil prepared by the method. The aluminum foil is high in intensity, thermal conductivity and electric conductivity, good in mechanical performance and resistant to electrochemical corrosion.

Owner:佛山金兰铝厂有限公司

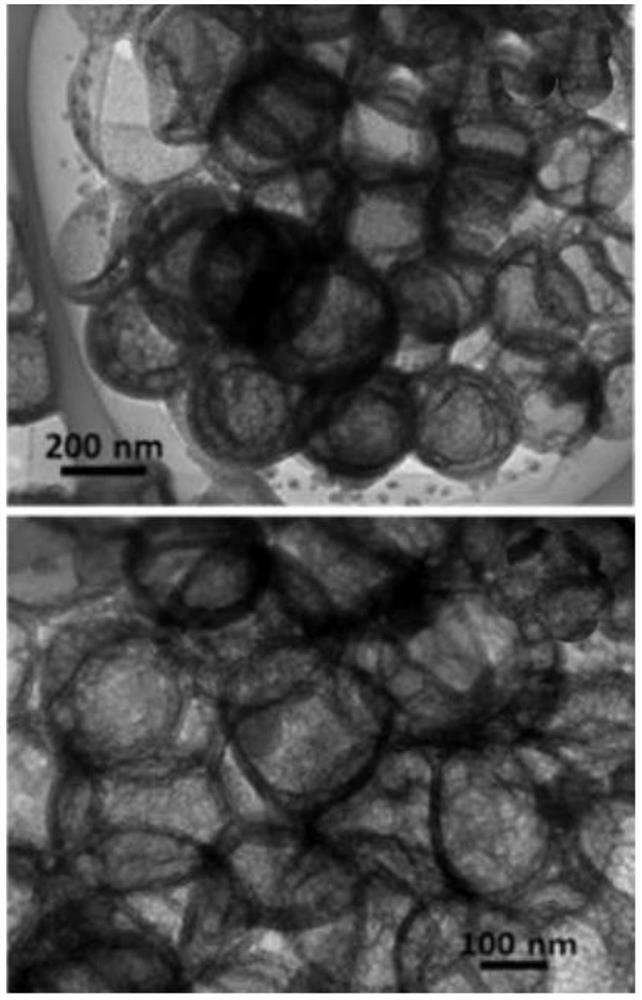

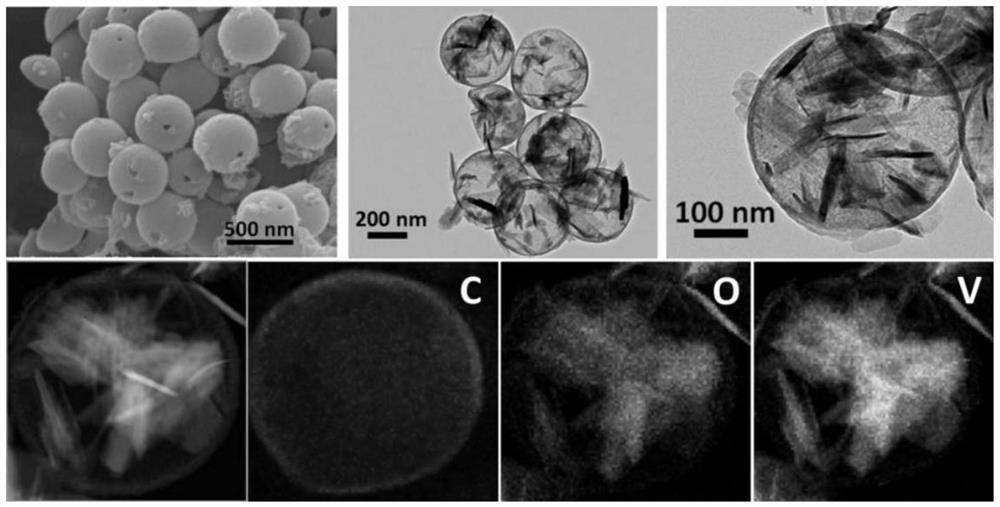

Porous carbon sphere packaged vanadium oxide heterogeneous core-shell sphere structure material and preparation method thereof, lithium-sulfur battery diaphragm and lithium-sulfur battery

ActiveCN113036311AReduce manufacturing costEasy to operateLi-accumulatorsCell component detailsElectrical batteryPorous carbon

The invention belongs to the field of electrochemical materials, and provides a porous carbon sphere packaged vanadium oxide heterogeneous core-shell sphere structure material and a preparation method thereof, a lithium-sulfur battery diaphragm and a lithium-sulfur battery. The preparation method of the porous carbon sphere encapsulated vanadium oxide heterogeneous core-shell sphere structure material comprises the following steps: stirring water, ethanol, ammonia water, tetraethyl orthosilicate, resorcinol and formaldehyde, carrying out a stirring reaction to obtain a carbon-coated silicon dioxide core-shell structure, carbonizing the carbon-coated silicon dioxide core-shell structure, adding the carbon-coated silicon dioxide core-shell structure into a sodium hydroxide solution to obtain a hollow porous carbon sphere, mixing ammonium metavanadate, ethanol and nitric acid to obtain a vanadium oxide solution, adding the hollow porous carbon spheres into the vanadium oxide solution, and carrying out ultrasonic treatment and hydrothermal reaction to obtain a product. According to the invention, the amount of a vanadium oxide precursor entering porous carbon spheres is controlled by adjusting ultrasonic time so as to achieve manual control of a nano structure, and the product takes the non-polar carbon spheres as a surface layer so as to achieve an adsorption effect on polysulfide and show high conversion efficiency when sulfur exists in the inner layer.

Owner:TONGJI UNIV

Device for detecting heat dissipation performance of phase change material, and method for detecting heat dissipation performance of graphene-paraffin composite material

InactiveCN106556621AEliminate interference from cooling resultsGuaranteed diffusionMaterial heat developmentHeating filmParaffin oils

The invention discloses a device for detecting the heat dissipation performance of a phase change material. The device comprises a heat insulating plate, a sheet heating film, a phase change material cube module and thermocouples, so that the heat insulating plate and the phase change material cube module form a wrapping structure on the sheet heating film, and the temperature of the phase change material cube module is detected through the thermocouples. The invention also discloses a method for detecting the heat dissipation performance of a graphene-paraffin composite material. The device for detecting the heat dissipation performance of the phase change material is adopted, one side with a graphene-paraffin sample is upturned, a connecting circuit applies constant heat power to the heating film, the temperature change of every thermocouple is detected and recorded at regular intervals, and statistic analysis of data is carried out to analyze the temperature change curve of the graphene-paraffin composite at a given power. The heat dissipation effects of the graphene-paraffin composite material with different ratios can be conveniently and accurately detected, and the heat dissipation performances of graphene-paraffin composite material with different ratios can be serially compared and analyzed.

Owner:SHANGHAI UNIV

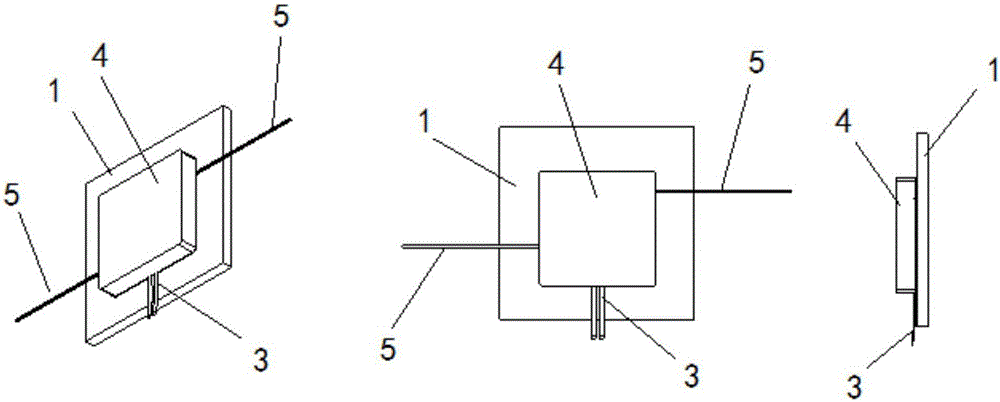

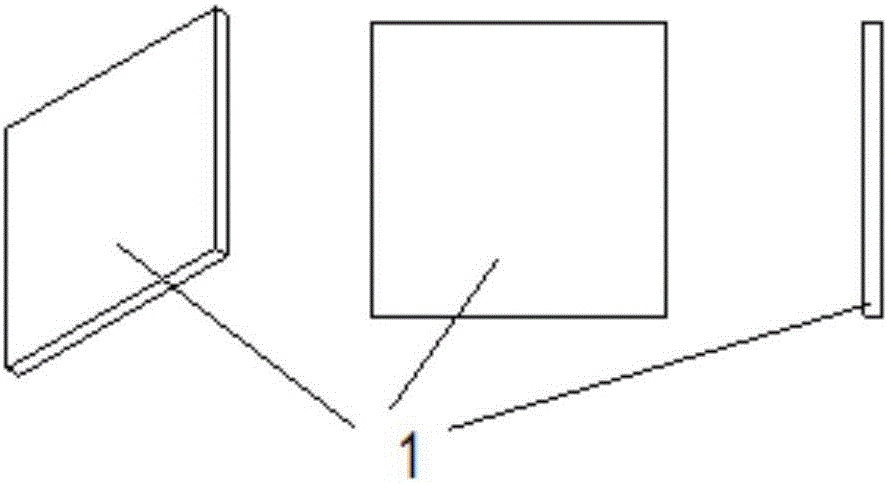

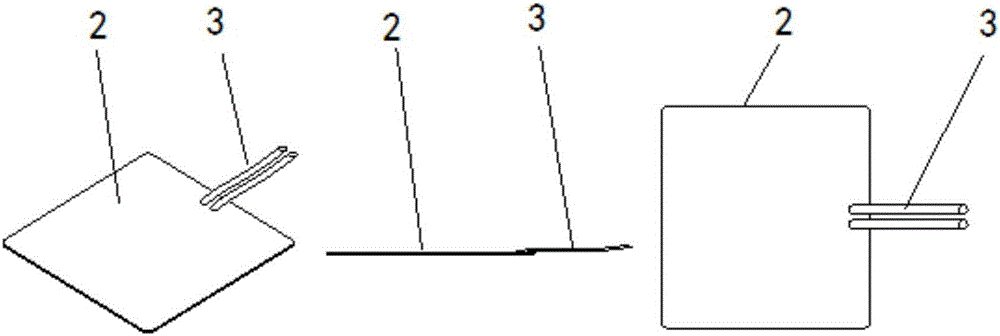

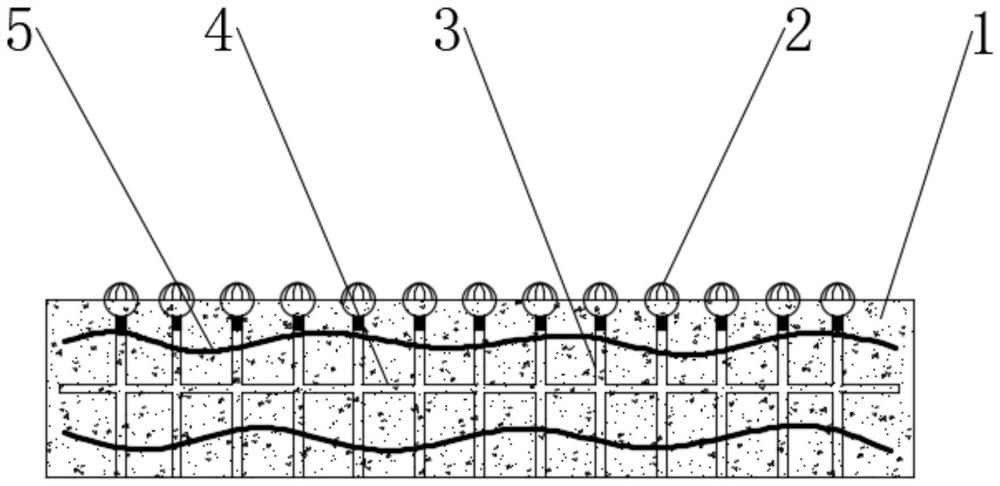

Foam concrete roof insulation board capable of detecting internal humidity and manufacturing method thereof

PendingCN111734056AImprove internal moistureFacilitated DiffusionRoof covering insulationsFoam concretePetal

The invention discloses a foam concrete roof insulation board capable of detecting internal humidity and a manufacturing method thereof and belongs to the technical field of construction. A humidity sensing framework can be introduced into a foam concrete insulation board body. Once water enters the foam concrete insulation board body, the humidity sensing framework can sense humidity quickly andconduct water to a humidity display and damp removal ball. After a water accumulating sponge ball in the humidity display and damp removal ball is diffused autonomously, a display propelling expansionball absorbs moisture to expand, so that a humidity display petal blooms by imitating a flower petal, so that on the one hand, a user can be prompted that the foam concrete insulation board body is affected with damp internally and on the other hand, water diffusion and release of water in the water accumulating sponge ball can be accelerated and an evaporation-assisting water absorbing fluff canbe driven to transfer water outward for efficient evaporation to improve the damp affecting condition in the foam concrete insulation board body based on high frequency jittering by means of a disintegration automatic ball specially arranged in the water accumulating sponge ball as the disintegration automatic ball is disintegrated quickly after encountering with water.

Owner:支琴芳

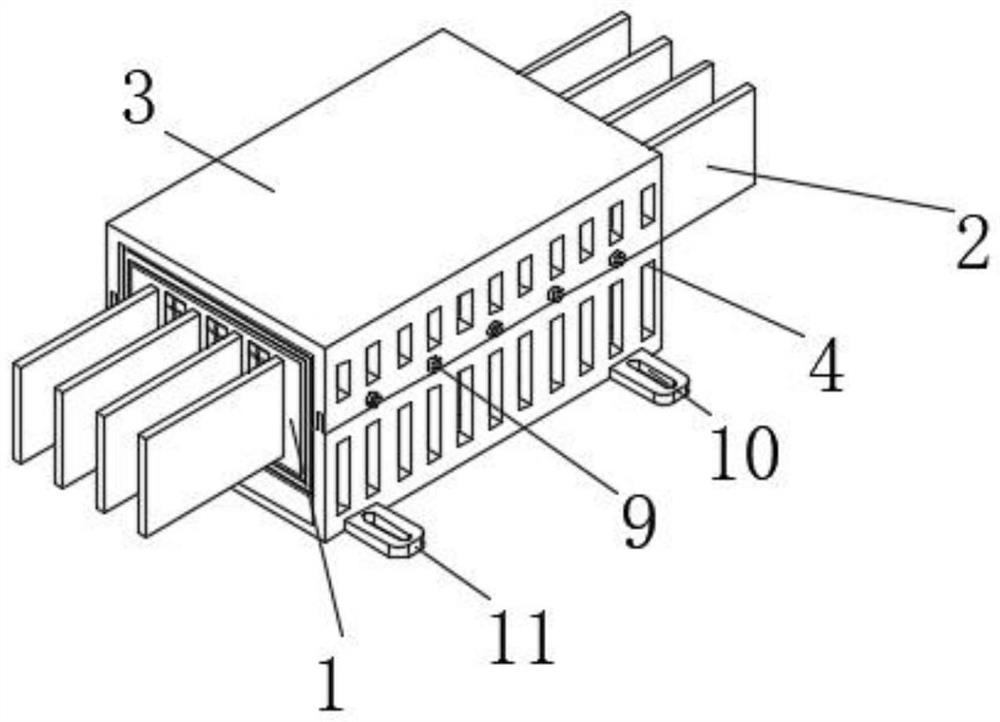

High-protection pouring bus duct

PendingCN111725754AImprove cooling efficiencyAvoid Cooling FeaturesCooling bus-bar installationsTotally enclosed bus-bar installationsStructural engineeringMechanical engineering

Owner:杰铭电气科技(镇江)有限公司

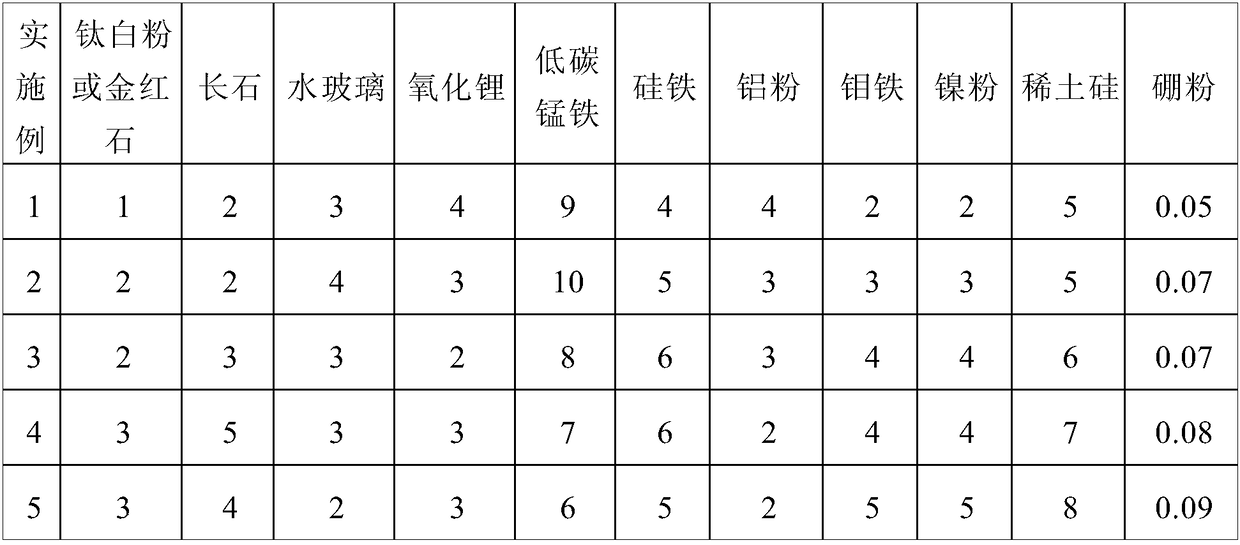

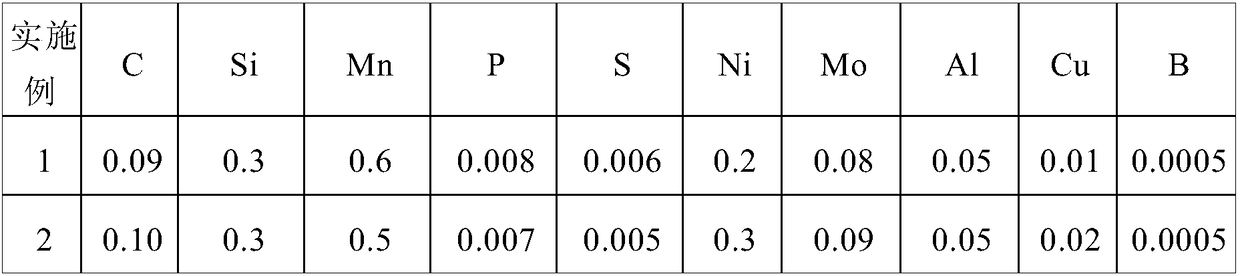

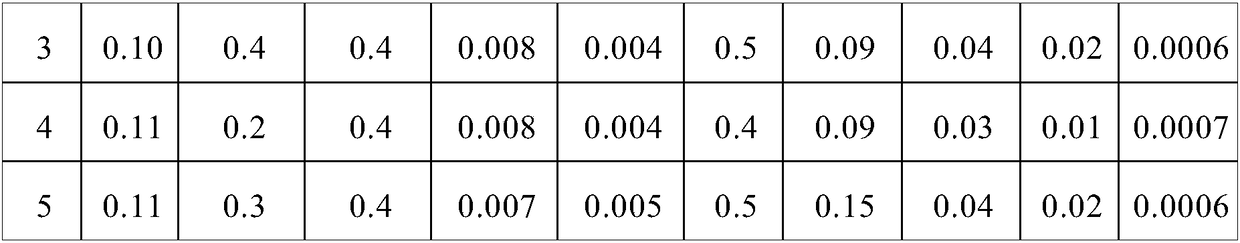

Structure homogenizing mechanism based large-heat-input gas electrical vertical welding gas shielded flux cored wire

ActiveCN109128585AGood welding performanceGood comprehensive mechanical propertiesWelding/cutting media/materialsSoldering mediaFerrosiliconMechanism based

Owner:BAOSHAN IRON & STEEL CO LTD

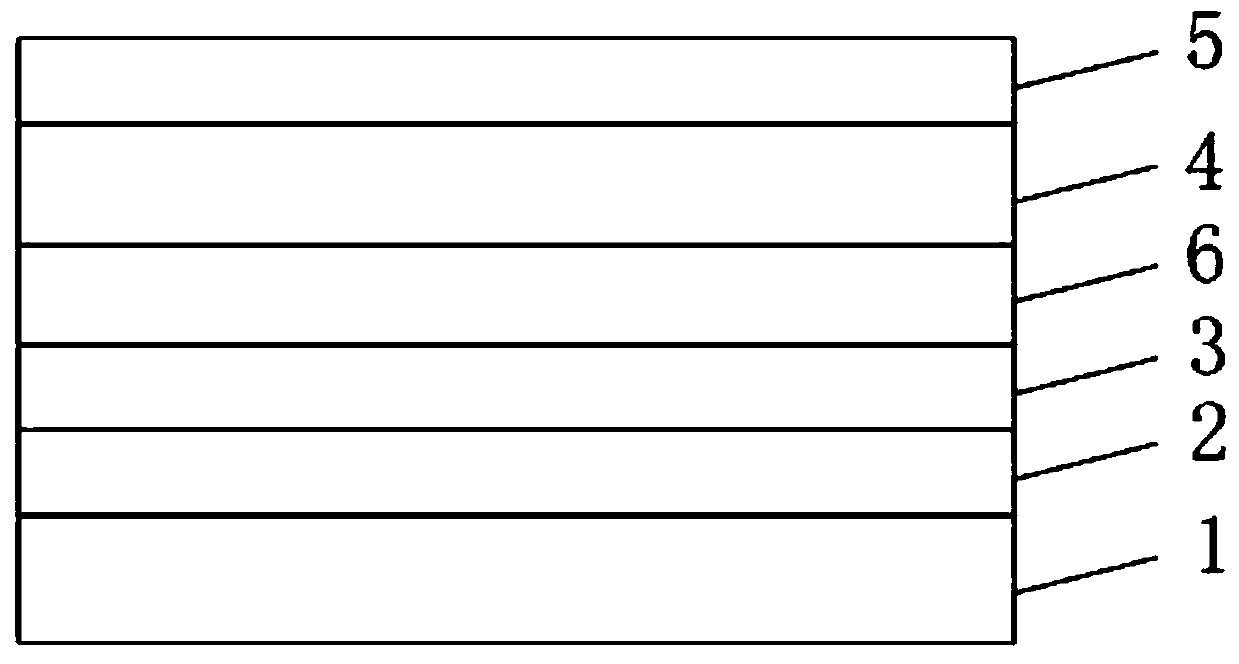

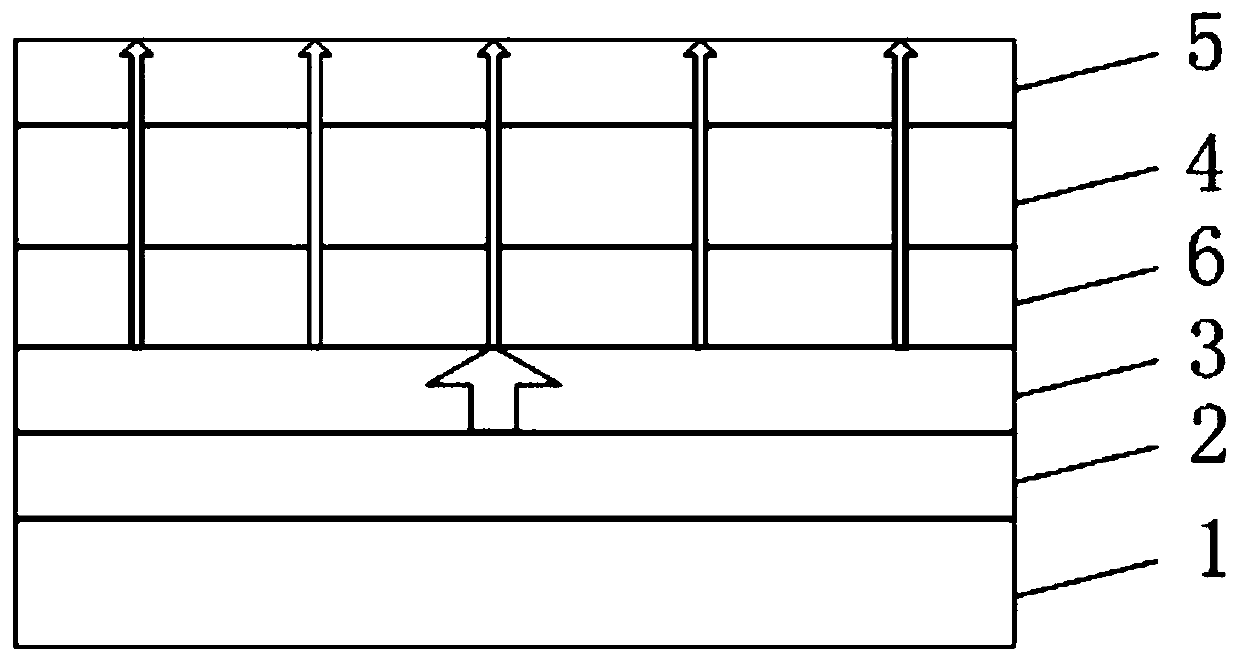

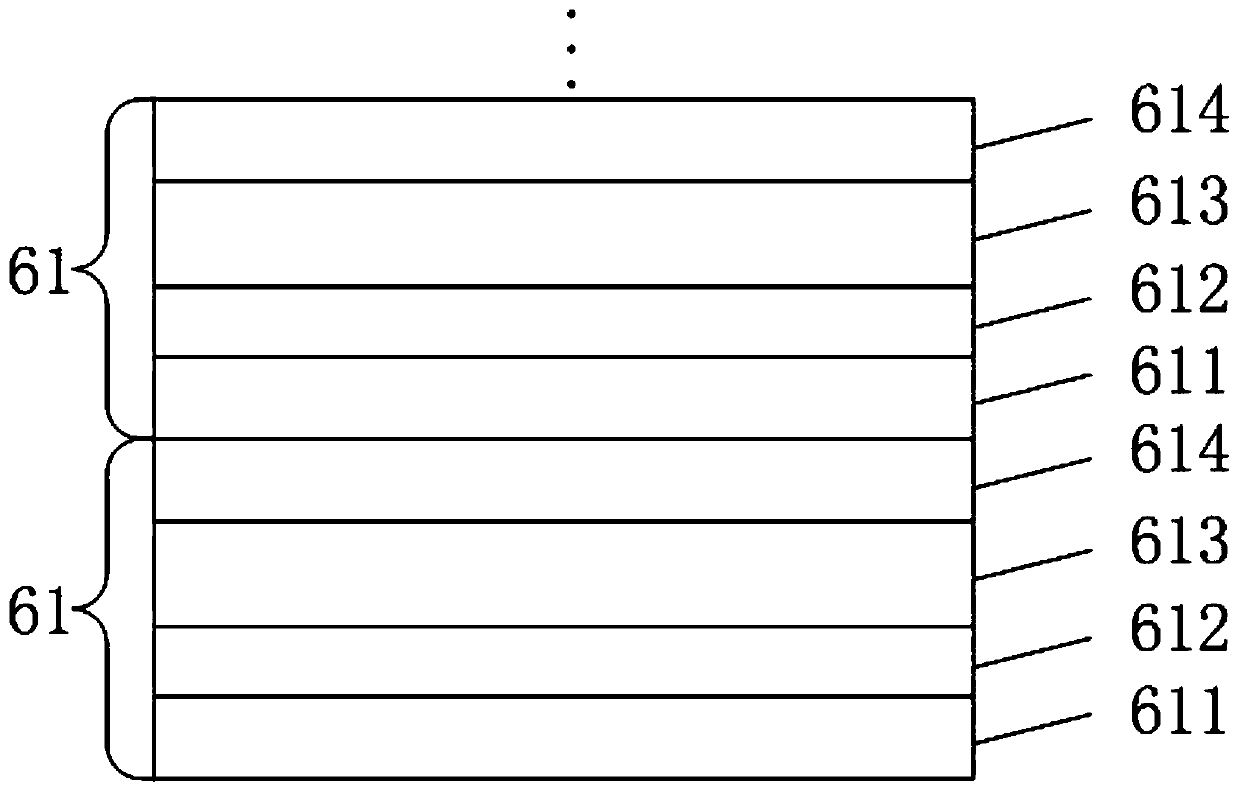

Antistatic epitaxial structure and manufacturing method thereof

PendingCN110364603AImprove electrostatic propertiesPrevent breakdownSemiconductor devicesActive layerSilicon

The invention discloses an antistatic epitaxial structure and a manufacturing method thereof. The epitaxial structure comprises a buffer layer, an N-type GaN layer, an active layer and a P-type GaN layer which are sequentially arranged on a substrate, characterized in that it is characterized in that it comprises, a composite layer is arranged between the N-type GaN layer and the active layer; thecomposite layer comprises a plurality of silicon concentration changing GaN layers. The silicon concentration change GaN layer comprises a first GaN layer, a second GaN layer arranged on the first GaN layer, a third GaN layer arranged on the second GaN layer, and a fourth GaN layer arranged on the third GaN layer. Wherein the doping concentration of silicon in the first GaN layer is zero, and thedoping concentration of silicon in the second GaN layer and the fourth GaN layer is smaller than the doping concentration of silicon in the third GaN layer. According to the invention, the compositelayer is arranged between the N-type GaN layer and the active layer, and the current can be uniformly distributed to the whole epitaxial structure after passing through the composite layer, so that the current cannot be concentrated on a certain region or point, the antistatic capability of the epitaxial structure is improved, and the active layer is prevented from being broken down by static electricity.

Owner:FOSHAN NATIONSTAR SEMICON

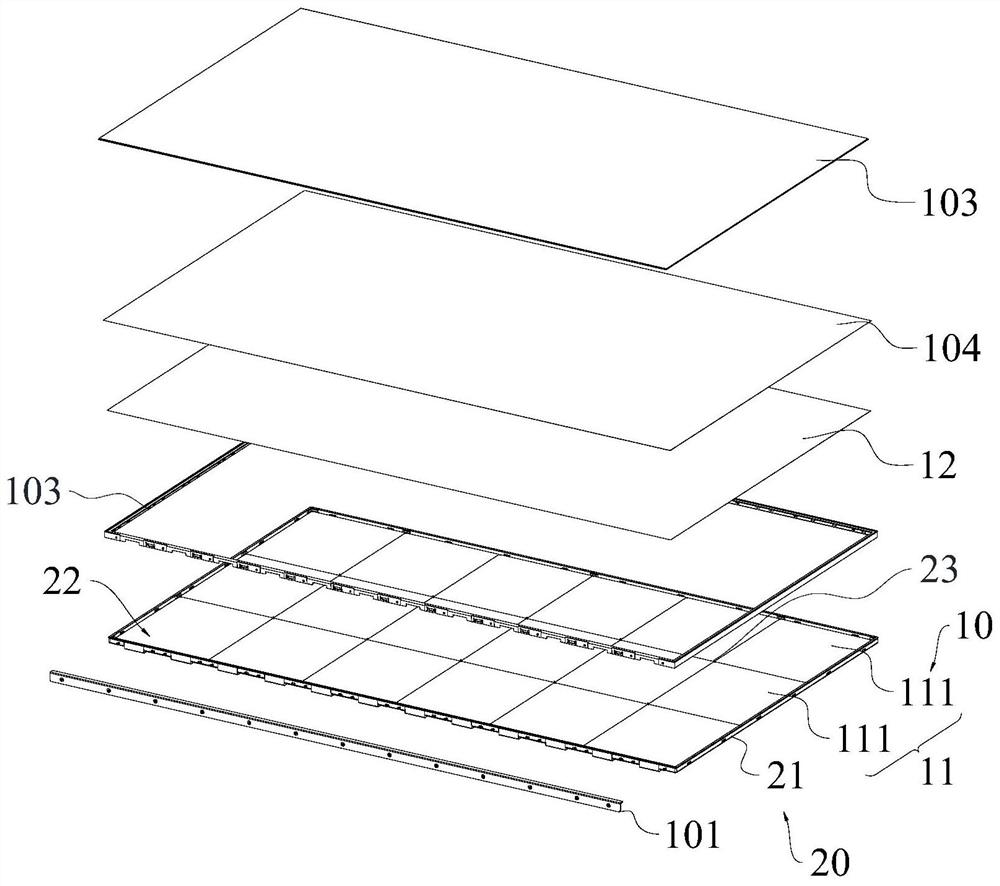

Backlight module and display

PendingCN113109970AAvoid thermal expansionGuaranteed OD valueNon-linear opticsLiquid-crystal displayDisplay device

The invention belongs to the field of liquid crystal display technical equipment, and particularly relates to a backlight module and a display. The backlight module comprises a supporting structure and a light source structure. The supporting structure comprises a back plate and supporting pieces, the back plate is provided with a containing cavity, and the containing cavity is provided with an opening. The light source structure is located in the containing cavity and comprises a diffusion plate and a lamp panel arranged to project light rays to the diffusion plate, the lamp panel is laid in the containing cavity, the diffusion plate is stacked relative to the lamp panel, an avoiding hole is formed in the lamp panel, one end of each supporting piece penetrates through the avoiding hole and is connected with the cavity bottom of the containing cavity, and the other end of each supporting piece abuts against and supports the diffusion plate, so that the diffusion plate is arranged relative to the lamp panel in a clearance manner; the multiple supporting pieces are arranged at intervals. The diffusion plate can be prevented from being expanded when heated, the OD value of the diffusion plate is guaranteed, meanwhile, light diffusion is guaranteed, and therefore the uniformity of light rays on the diffusion plate is improved.

Owner:HKC CORP LTD

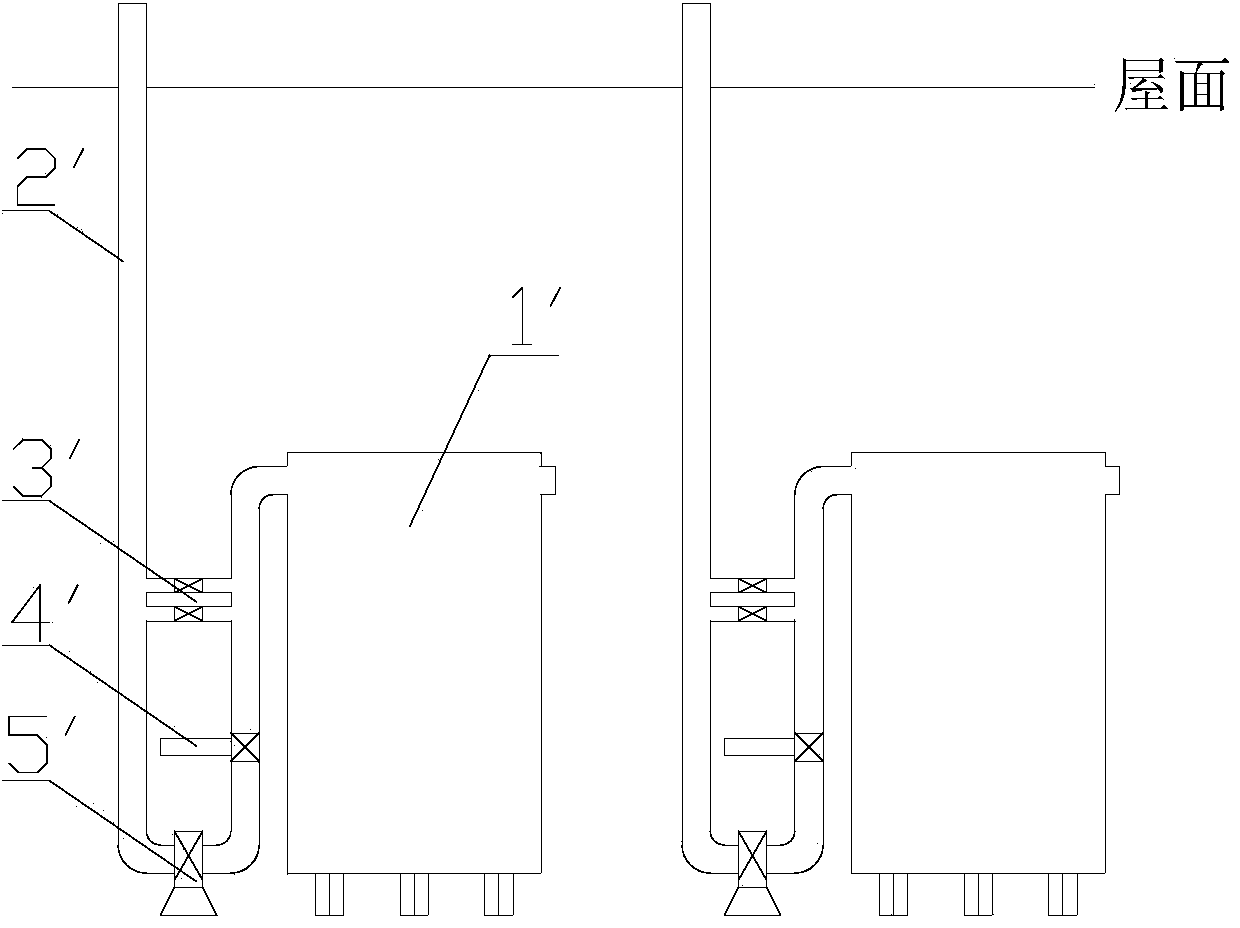

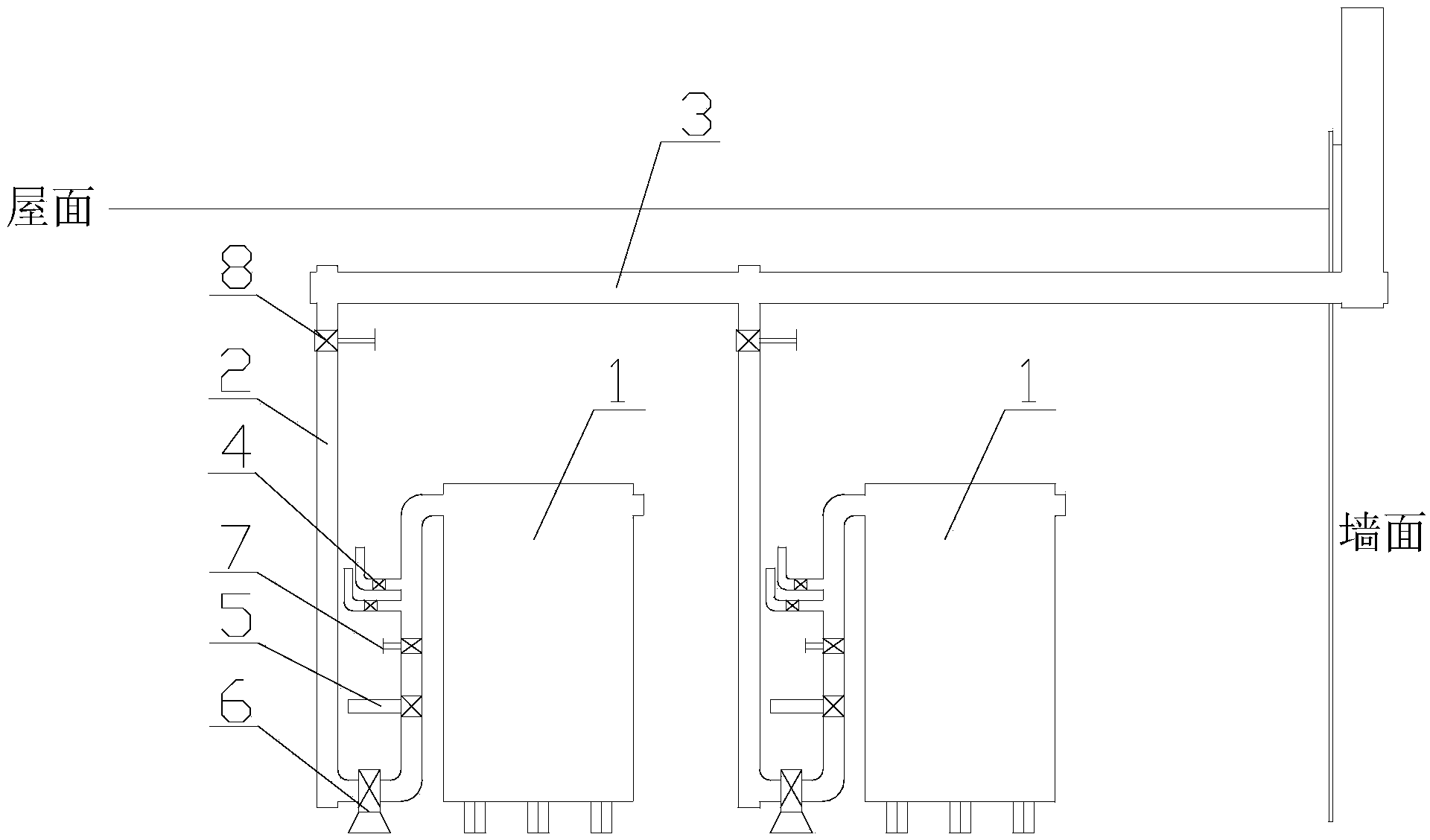

Exhaust device for elevator furnace system

InactiveCN104075562AImprove cleanlinessGuaranteed aestheticsMaintainance of heating chambersBell type furnacesPneumatic valveExhaust gas

The invention discloses an exhaust device for an elevator furnace system. The elevator furnace system comprises M elevator furnaces. The exhaust device comprises M branch exhaust pipelines and one main exhaust pipeline, wherein the air inlet ends of the M branch exhaust pipelines are connected to the air outlets of the M elevator furnaces respectively; the air outlet ends of the M branch exhaust pipelines are connected to the main exhaust pipeline respectively; the main exhaust pipeline passes through a wall surface, and is fixed on the wall surface through a fastening mechanism; along an exhaust direction from the air inlet ends of the branch exhaust pipelines to the air outlet ends, a safety pneumatic pressure-reducing valve, an electromagnetic pneumatic valve and an exhaust fan are arranged in sequence on each branch exhaust pipeline; the outlets of the safety pneumatic pressure-reducing valves are directly communicated with the outside; first manual valves are arranged on the branch exhaust pipelines of the safety pneumatic pressure-reducing valves and the electromagnetic pneumatic valves; second manual valves are arranged on the branch exhaust pipelines at the air outlet ends from the exhaust fans to the branch exhaust pipelines.

Owner:ZHONGDE ELECTRONICS

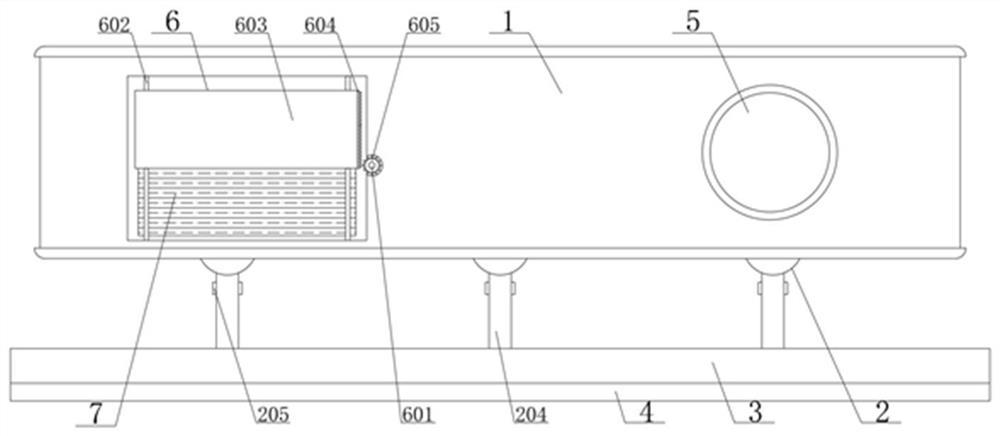

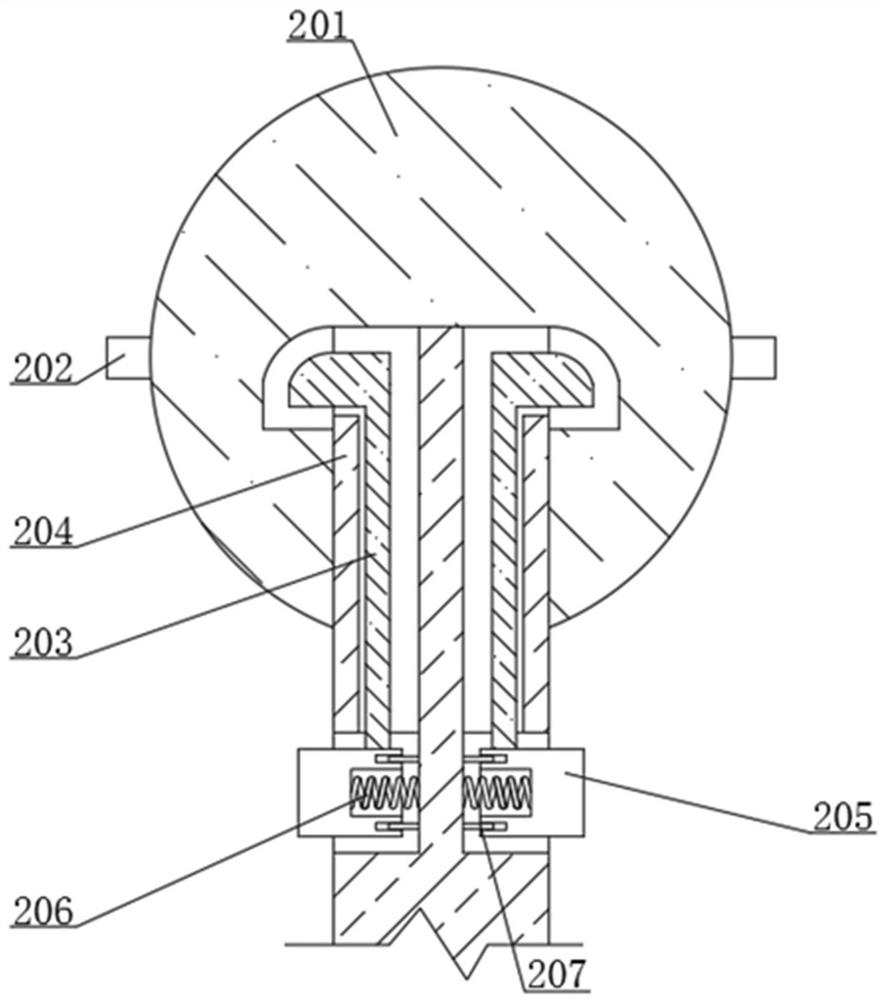

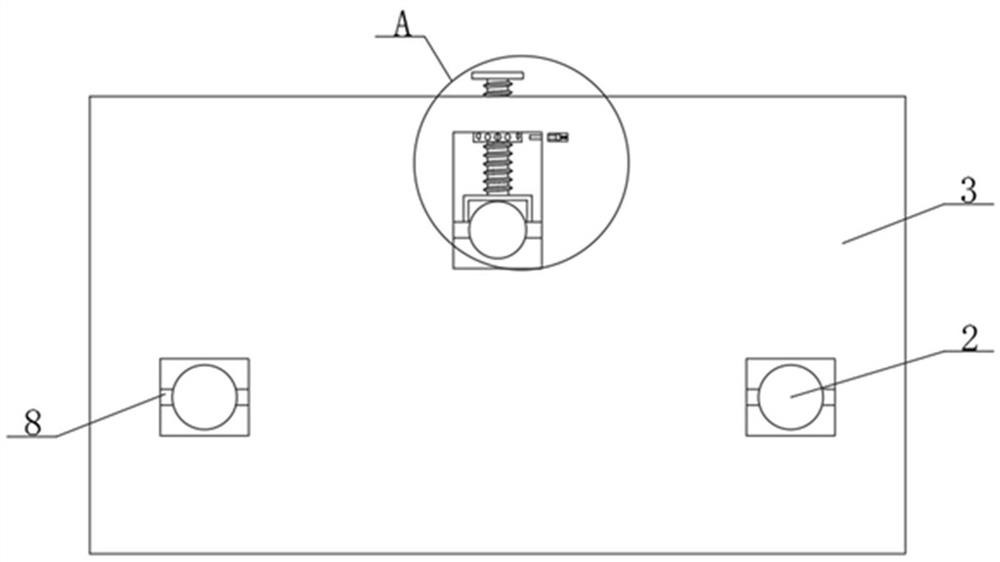

Vehicle-mounted projector with fine adjustment mechanism and using method thereof

PendingCN111913341AEasy to disassembleEasy to installProjectorsRecord information storageIn vehicleEngineering

The invention relates to the technical field of projection equipment, in particular to a vehicle-mounted projector with a fine adjustment mechanism and a using method thereof. The vehicle-mounted projector comprises a vehicle-mounted projector body and a base, a sound playing hole is fixedly connected to the left side of the front end face of the vehicle-mounted projector body, a shielding deviceis arranged at the front side of the sound playing hole, and the outer side of the shielding device is fixedly connected with the vehicle-mounted projector body. A lens is fixedly connected to the right side of the front end face of the vehicle-mounted projector body, a supporting device is rotatably connected to the lower end face of the vehicle-mounted projector body, a rotating shaft is arranged on the lower end face of the supporting device, and the base is arranged at the outer side of the rotating shaft. According to the vehicle-mounted projector, by arranging a rotating ball, the supporting shaft, a sliding clamping plate, the supporting rod, the sliding block, a telescopic spring and a limiting rod, the vehicle-mounted projector can be conveniently disassembled and assembled through the rotating ball and the supporting rod, the overall disassembly is not needed, and great convenience is achieved; the rotating ball is spherical, so that it is guaranteed that the vehicle-mountedprojector can rotate, and the inclination angle of the vehicle-mounted projector can be conveniently adjusted.

Owner:DIMOND WALKER COMMERCE CO LTD

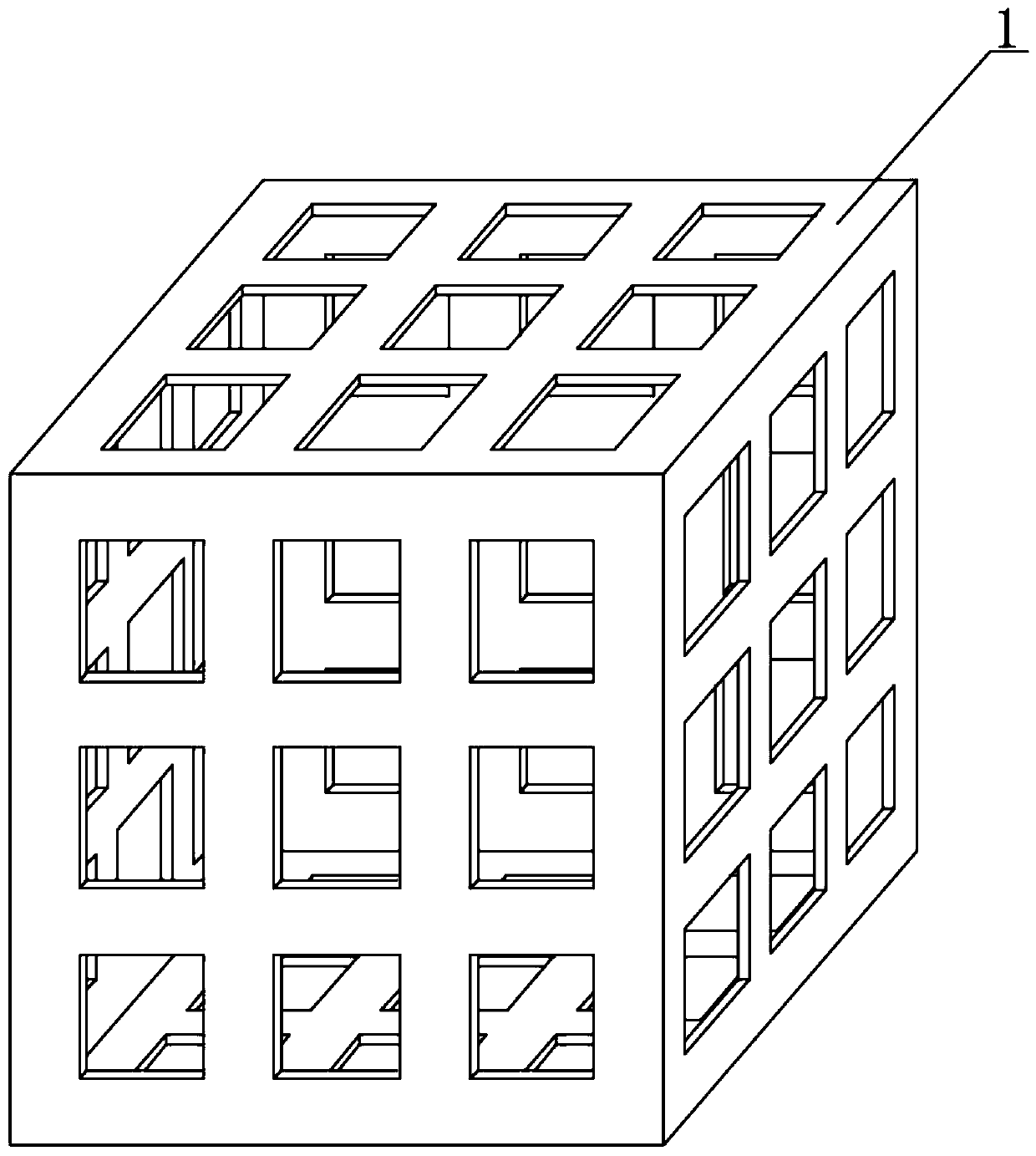

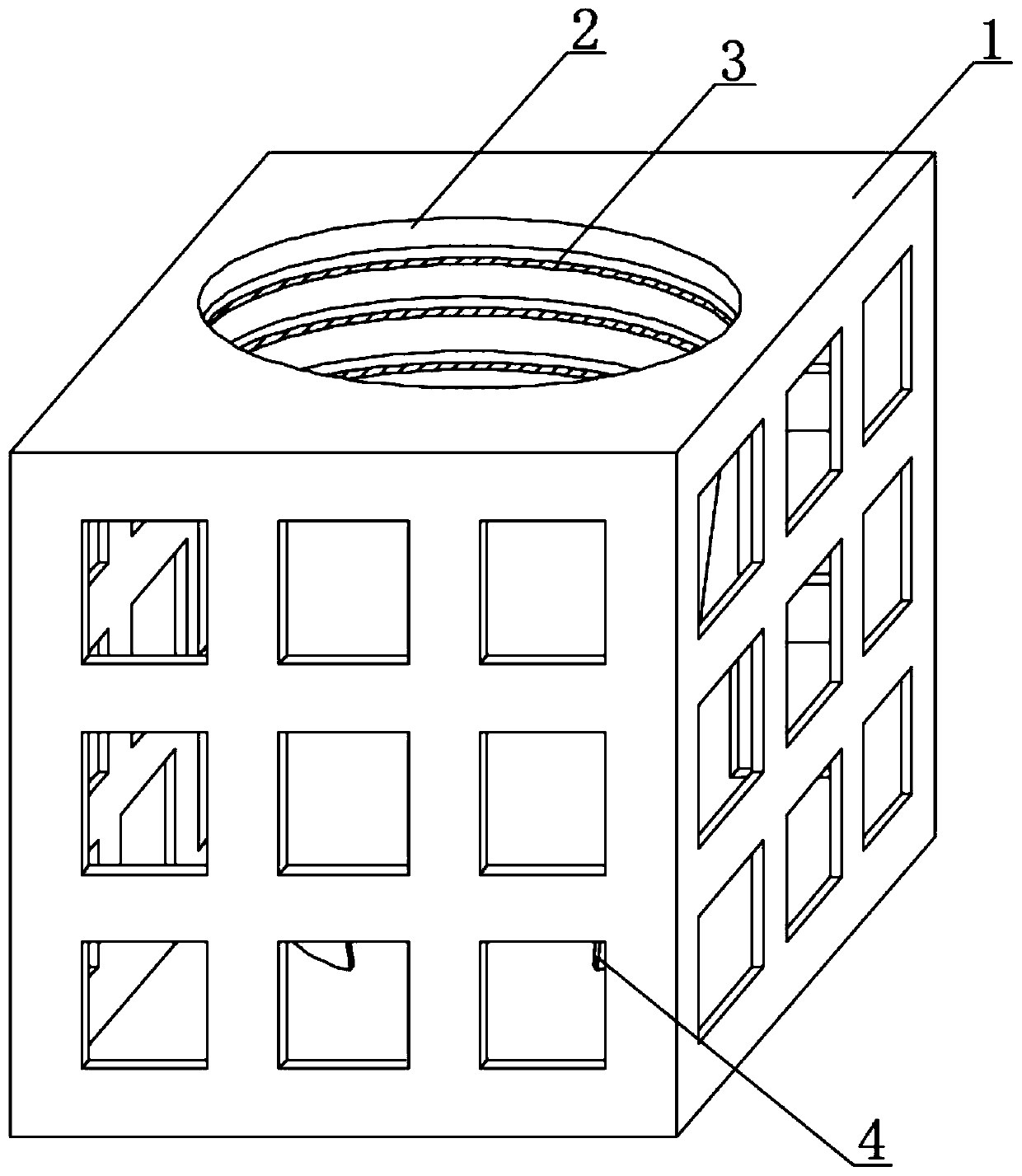

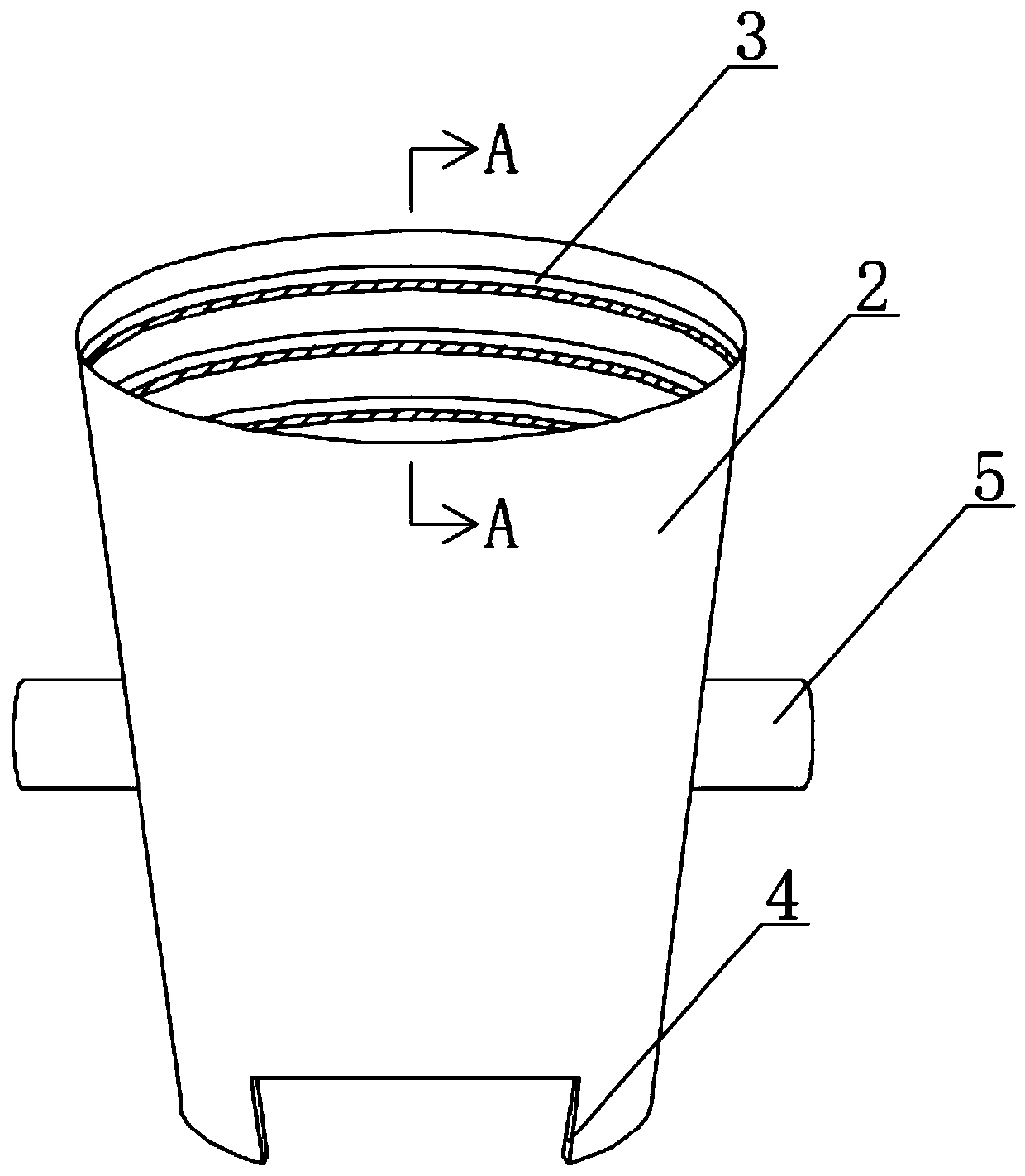

Artificial fish reef with high proliferation effect

ActiveCN110506685AGuaranteed diffusionRapid aggregate growthClimate change adaptationPisciculture and aquariaSeawaterNutrient content

The invention relates to the technical field of aquaculture, and discloses an artificial fish reef with a high proliferation effect. The artificial fish reef comprises a fish reef frame, a spiral cylinder is arranged in the fish reef frame, and the spiral cylinder is fixedly connected with the inner wall of the fish reef frame through a connecting rod. According to the artificial fish reef with the high proliferation effect, the spiral cylinder is additionally arranged in a traditional artificial fish reef so that seawater can actively enter the spiral cylinder through a water inlet by using the self-flowing of the seawater; a groove wall is formed in the inner part of the spiral cylinder, spiral rising of the seawater entering the spiral cylindrical can be promoted along the groove wall by means of a spiral rising structure of the groove wall, generated vortex water flow can efficiently drive nutrients of the seabed to move towards the middle upper layer of the seawater along with therising water flow, the maximum diffusion of the nutrients in the middle upper layer of the water area can be ensured through a larger outlet in the top, the rapid gathering and growth of bait are guaranteed, and therefore a better fish swarm gathering effect is achieved.

Owner:浙江龙谱科技有限公司

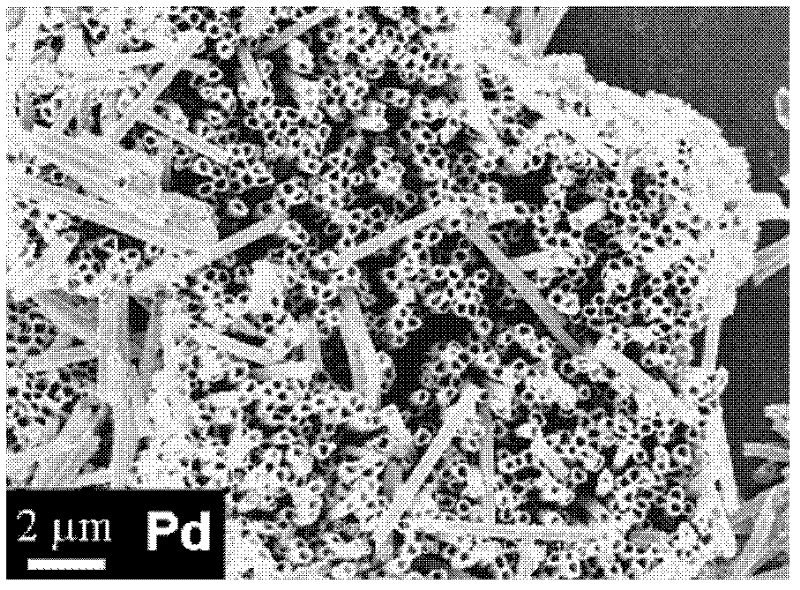

Preparation method of tubular metal catalyst

InactiveCN102407106APromote formationSlow down the spreadCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectrochemical windowSolvent

The invention discloses a preparation method of tubular metal catalyst comprising dissolving metal salt and sodium nitrate in dimethyl sulfoxide to obtain mixed solution; taking aluminum oxide porous template with nano path as template, conducting electrochemical deposition of the mixed solution at the nano path, and removing the template to obtain the tubular metal catalyst. The invention takes polar aprotic solvent dimethyl sulfoxide (DMSO) as solvent and electrolyte, since DMSO contains S group with weak absorption effect to metal surface, when metal is reduced to particles, DMSO moleculeswill absorb on the particle surface to inhibit the particle from growing large to make the prepared tubular metal catalyst wall thin and to increase the activated area. Furthermore, DMSO with relatively wide electrochemical window, high dielectric constant and high viscosity can ensure the prepared tubular metal catalyst wall is thin and made of particles, the length diameter ratio is high and the wall is uniform.

Owner:UNIV OF SCI & TECH OF CHINA

High temperature resistant electromagnetic shielding copper wire

PendingCN110246610AGuaranteed service lifeReduce wear and tearInsulated cablesDetails of conductive coresCopper wireCopper matrix

The invention discloses a high temperature resistant electromagnetic shielding copper wire, comprising a copper wire. The copper wire comprises an inner copper core. The outer part of the copper core is sleeved with a tin plating layer. The outer part of the tin plating layer is sleeved with a fixed layer. The outer part of the fixed layer is sleeved with a waterproof layer. The outer part of the waterproof layer is sleeved with a fireproof layer. The outer part of the fireproof layer is sleeved with a flame retardant layer. As for the high temperature resistant electromagnetic shielding copper wire, a separation layer is disposed between the copper core and the tin plating layer so that the copper matrix can be effectively prevented from diffusing into the tin plating layer; the waterproof layer is arranged to effectively prevent the internal structure from being eroded and rusted; at the same time, the fireproof layer and the flame retardant layer are provided, which can effectively protect the internal structure from fire; and an electromagnetic isolation layer is provided, which can effectively prevent external electromagnetic interference when the tinned copper wire is used. The plurality of protective layers are provided so that the internal structure is protected, the service life of the tinned copper wire is prolonged, and the waste of resources is reduced, which can effectively solve the problems in the background art.

Owner:山东天厚新材料科技有限公司

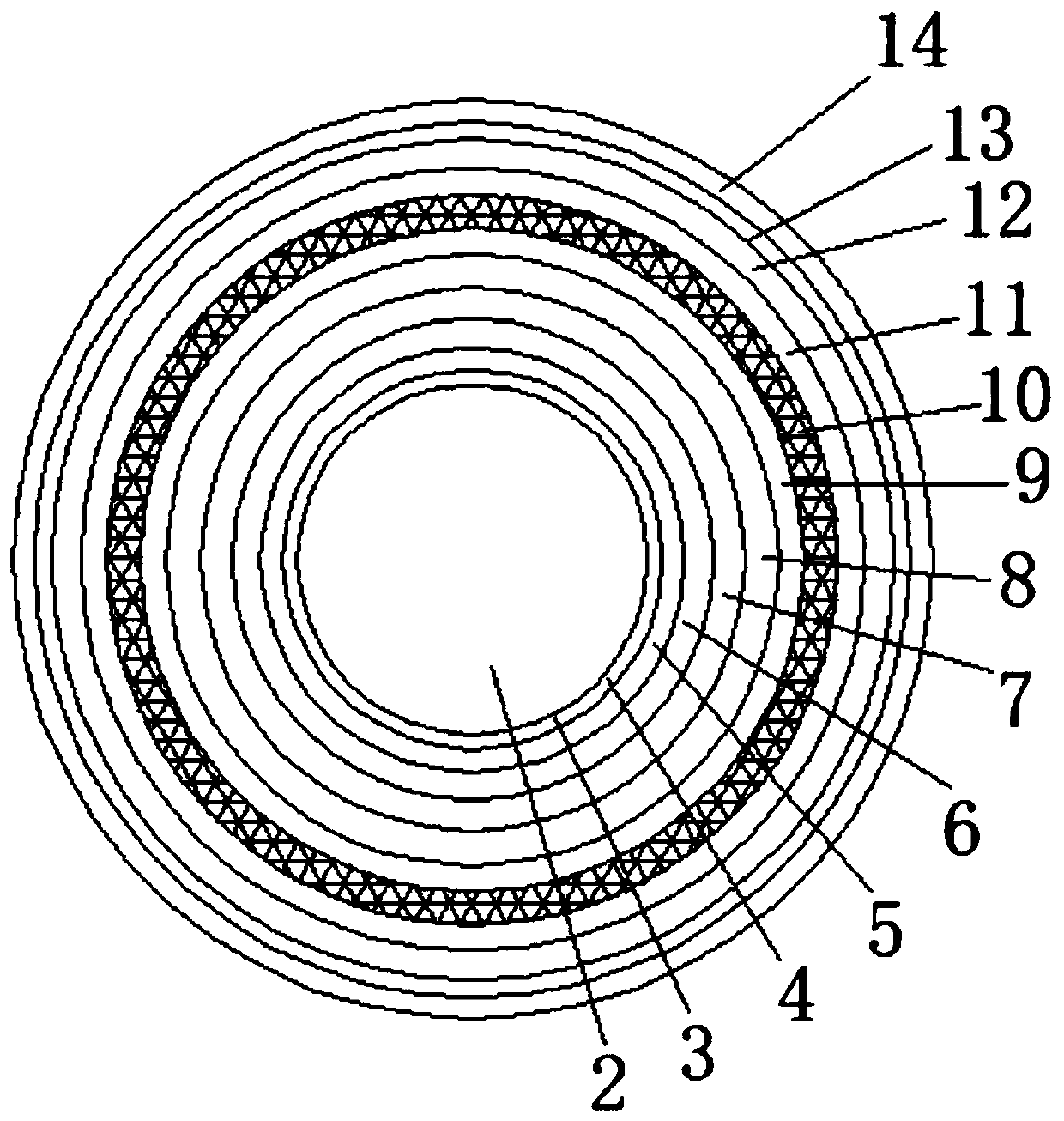

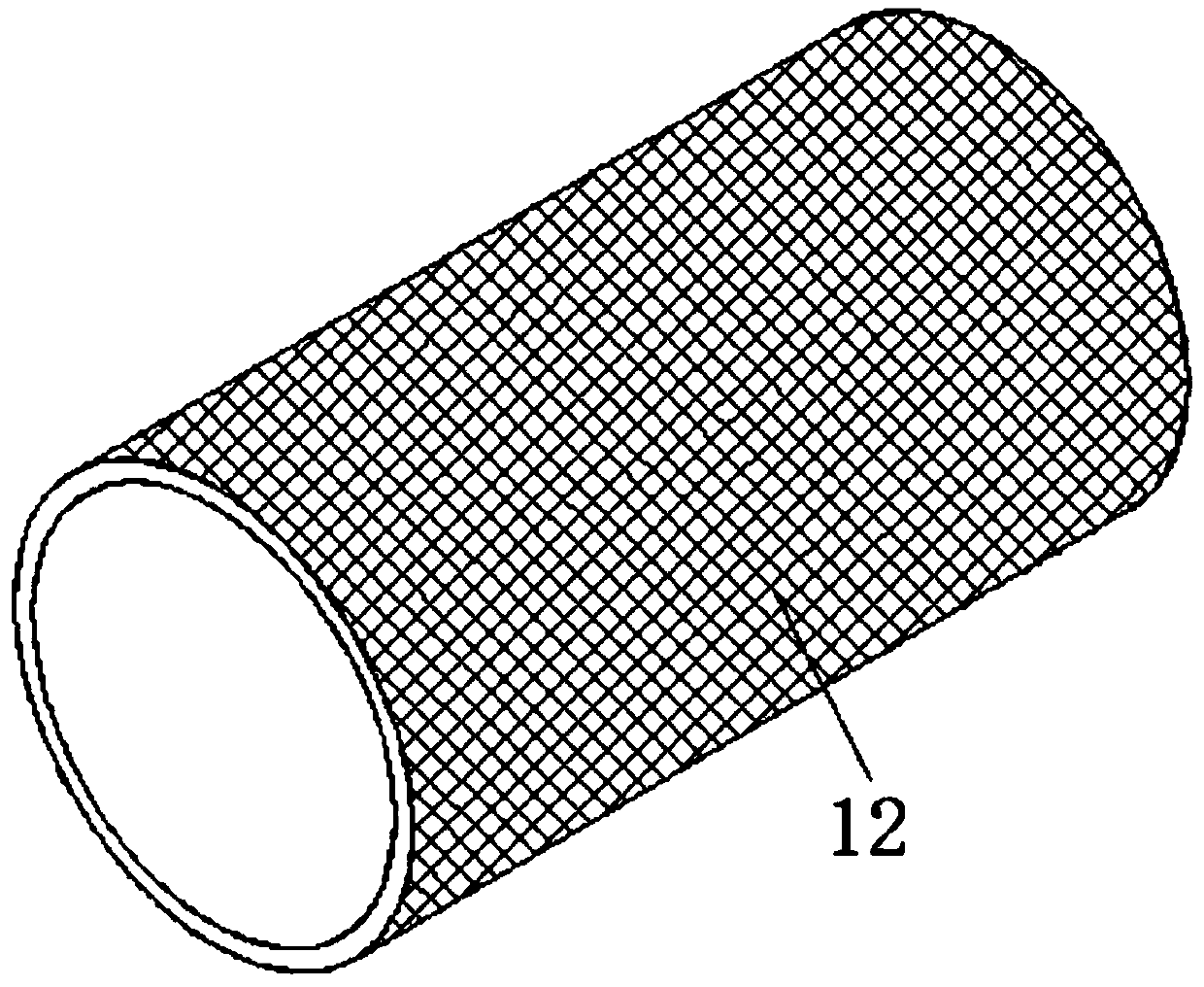

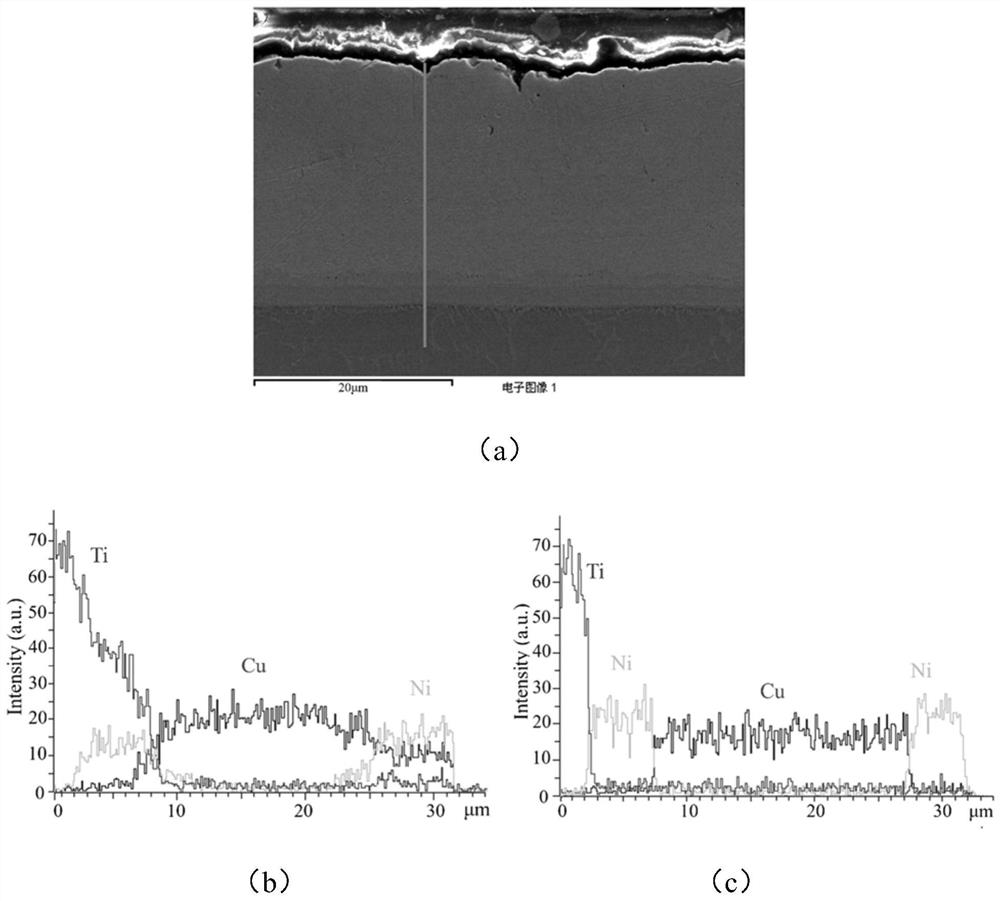

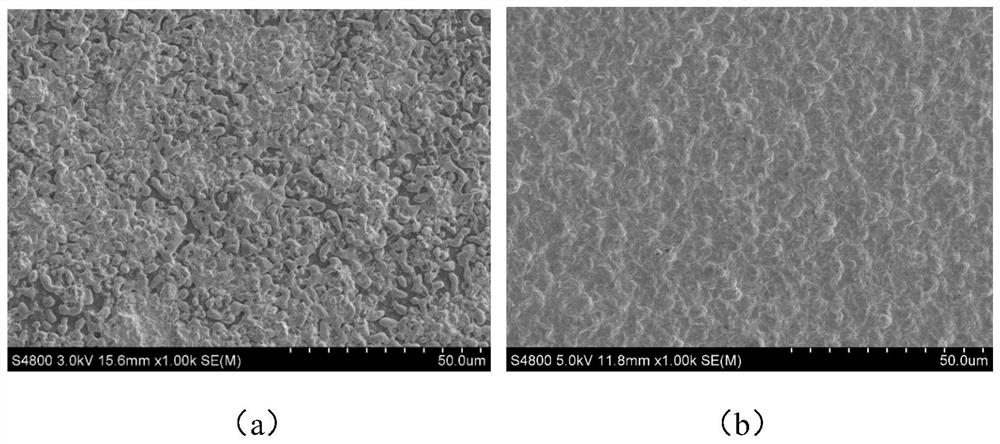

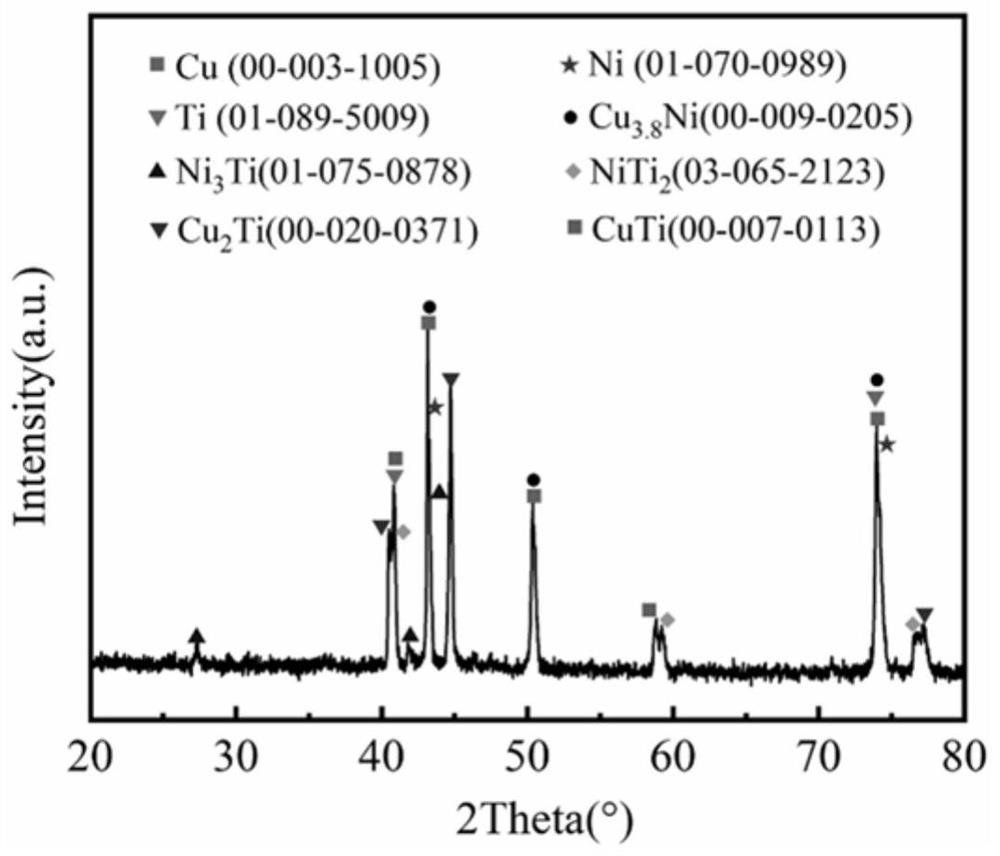

Composite film layer with sandwich structure and preparation method of composite film layer

The invention discloses a composite film layer with a sandwich structure and a preparation method of the composite film layer, and belongs to the field of titanium alloy coatings. According to the preparation method, a titanium alloy is electroplated with a Ni / Cu / Ni composite coating of the sandwich structure, and then vacuum circulation heat treatment is conducted, so that titanium atoms, nickelatoms and copper atoms in the composite coating diffuse mutually, and holes formed by transition and migration of the atoms are gathered; the temperature is increased from 300-350 DEG C to 500-550 DEGC, heat preservation is conducted for 30-40 min, so that the titanium atoms, the nickel atoms and the copper atoms form NixTiy and CuxTiy intermetallic compounds, and stress concentration and microcracks caused by interatomic rapid phase change are avoided; the temperature is increased from 500-550 DEG C to 750-800 DEG C, and heat preservation is conducted for 30-40 minutes, so that the intermetallic compounds further grow, disperse and diffuse; and cooling with a furnace is conducted, and the compact sandwich structure film layer in which the NixTiy and CuxTiy intermetallic compounds are dispersedly distributed is formed.

Owner:XINDA KECHUANG TANGSHAN PETROLEUM EQUIP CO LTD

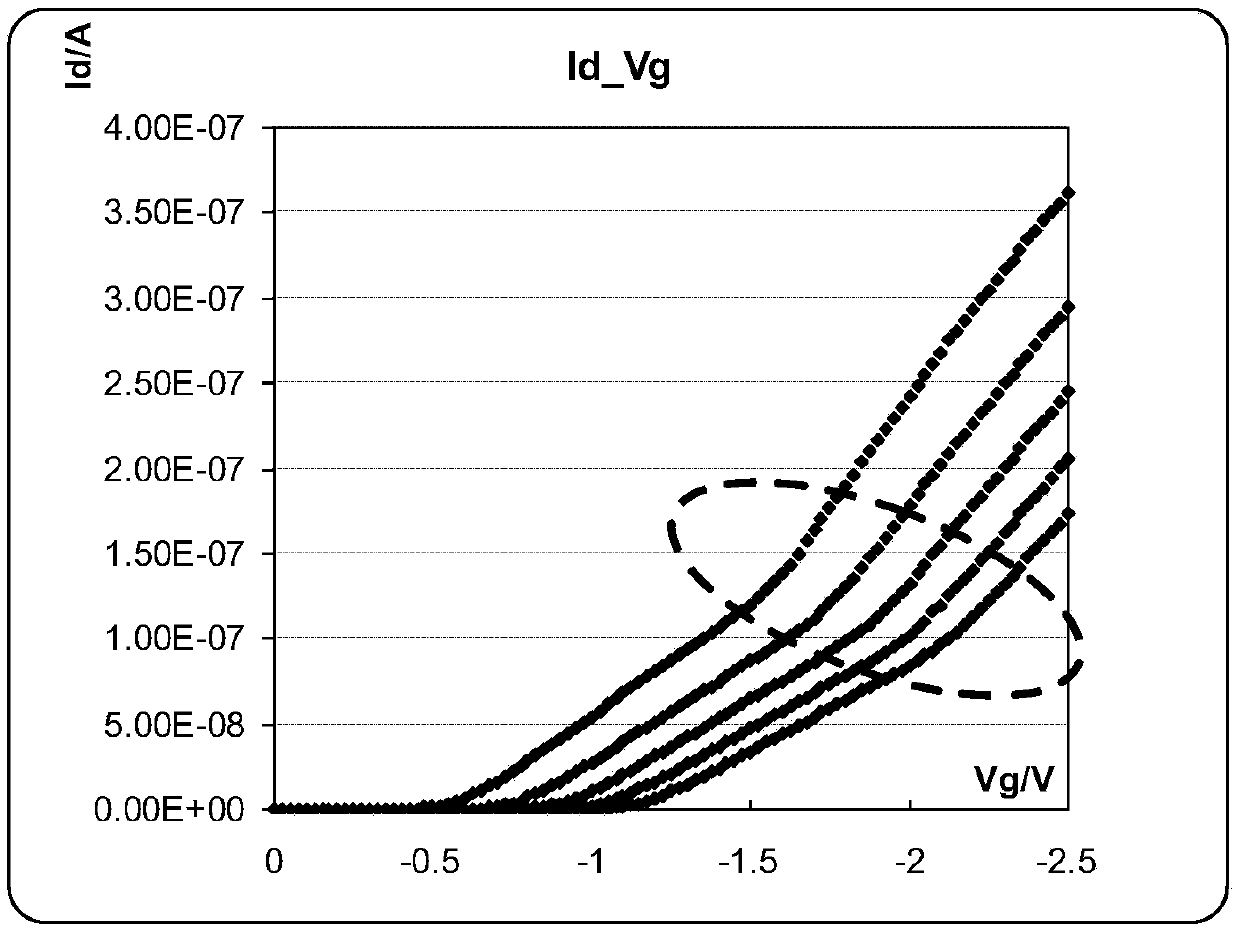

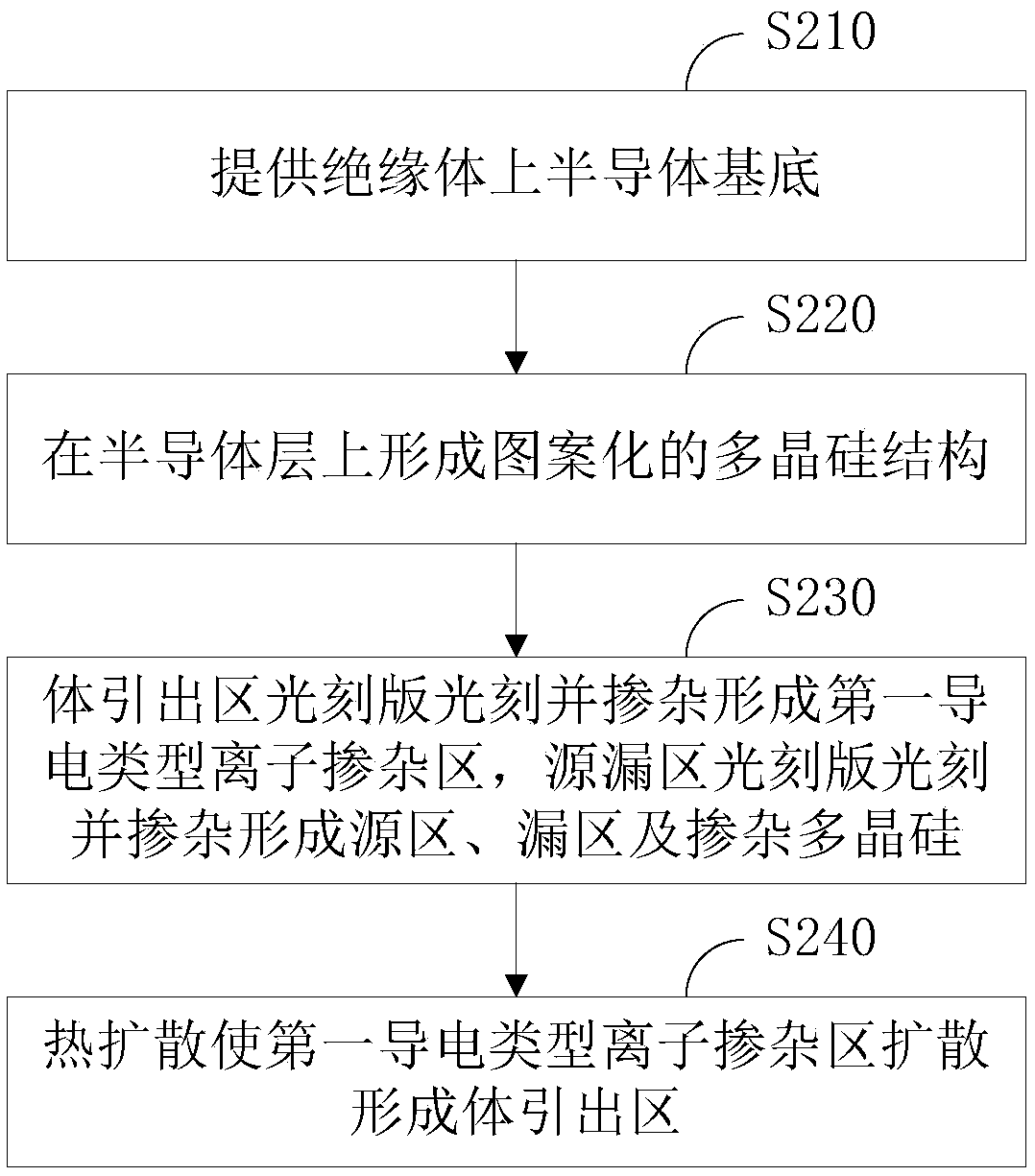

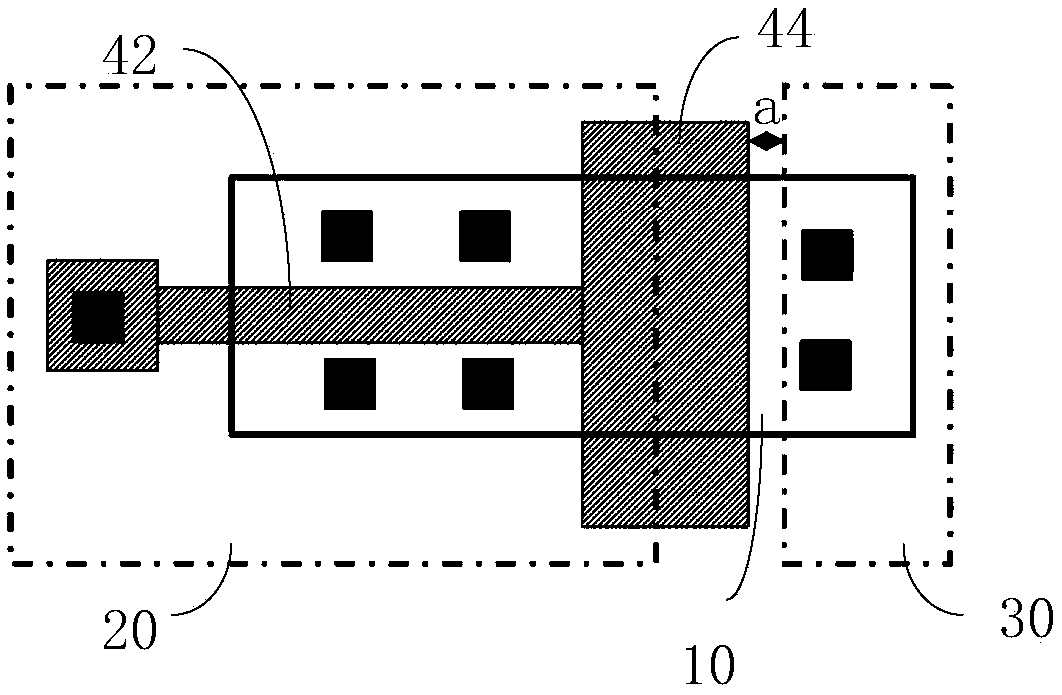

Semiconductor-on-insulator device and manufacturing method thereof

ActiveCN111146278AAvoid the hump phenomenonGuaranteed diffusionSemiconductor/solid-state device manufacturingSemiconductor devicesBody regionElectrically conductive

The invention relates to a semiconductor-on-insulator device and a manufacturing method thereof. The method comprises the following steps: providing a semiconductor-on-insulator substrate; forming a patterned polycrystalline silicon structure on the semiconductor layer; photoetching and doping the body leading-out region photoetching plate to form a first conductive type ion doped region, and photoetching and doping the source-drain region photoetching plate to form a source region, a drain region and doped polycrystalline silicon; and carrying out thermal diffusion to enable the first conductive type ion doped region to diffuse to form a body lead-out region. According to the invention, the polycrystalline silicon structure has no work function difference, so that the turn-on voltage of aparasitic channel is consistent with that of a main channel region, and the hump phenomenon of a narrow-channel device can be avoided; and when the body leading-out region is doped, the doping windowis separated from the body region isolation polycrystalline silicon by a proper distance, so that the impurities in the active region can be diffused to the poly boundary, and a good body region leading-out effect can be ensured.

Owner:CSMC TECH FAB2 CO LTD

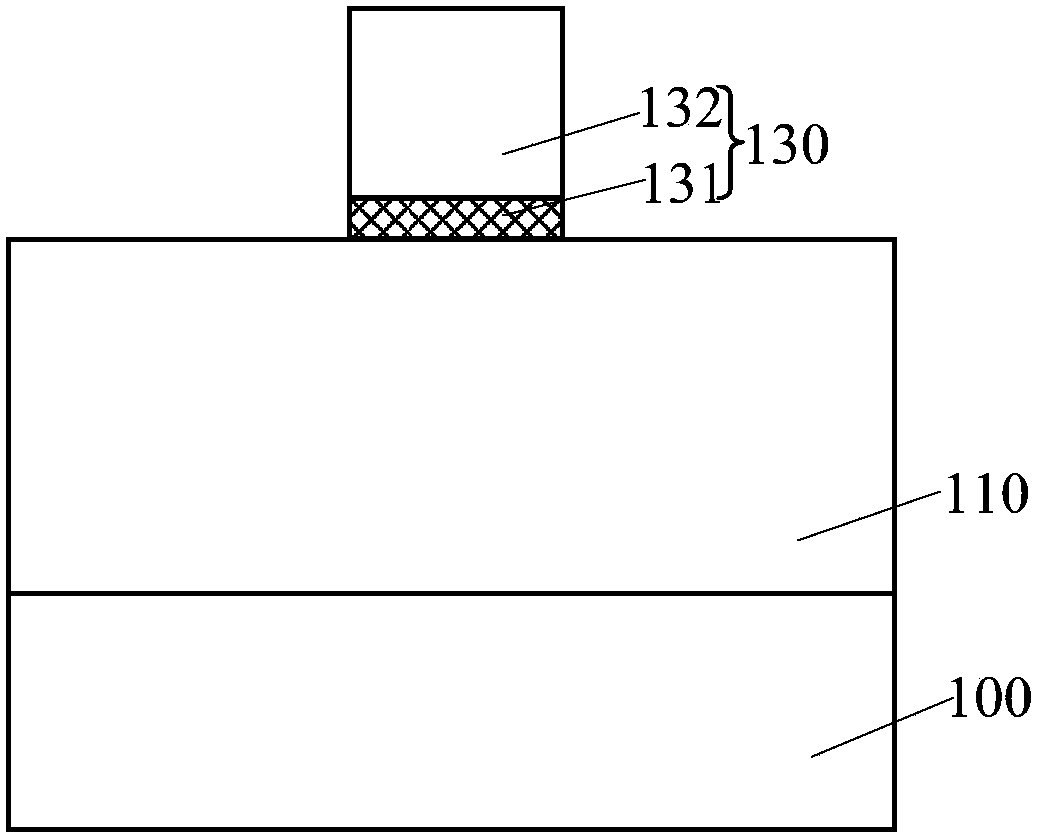

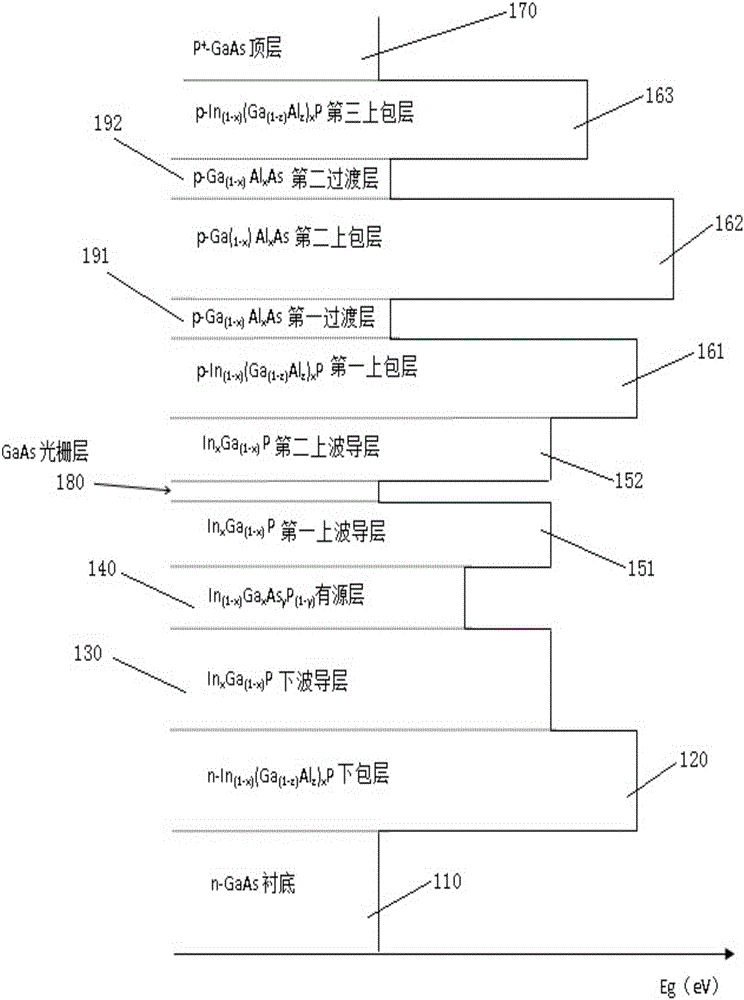

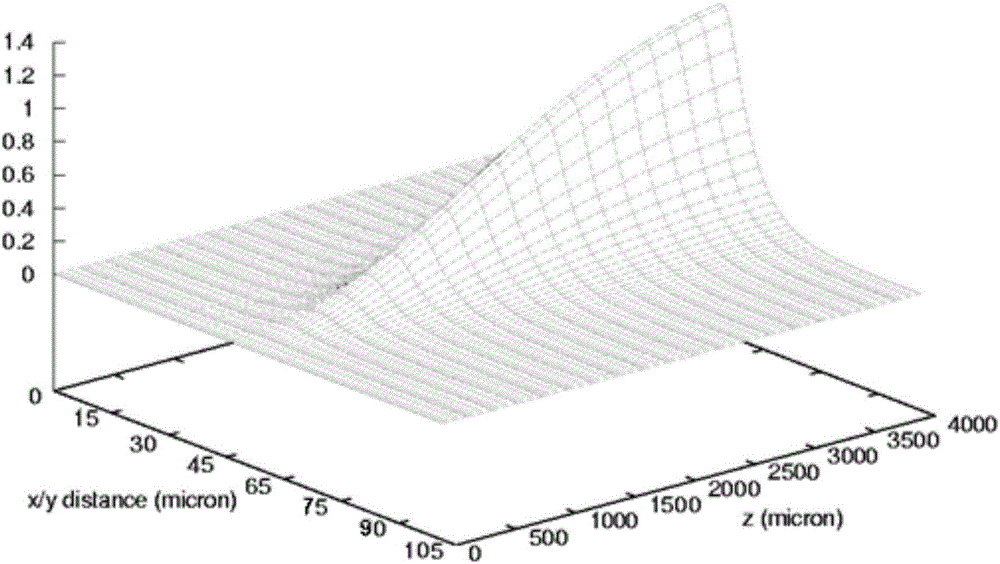

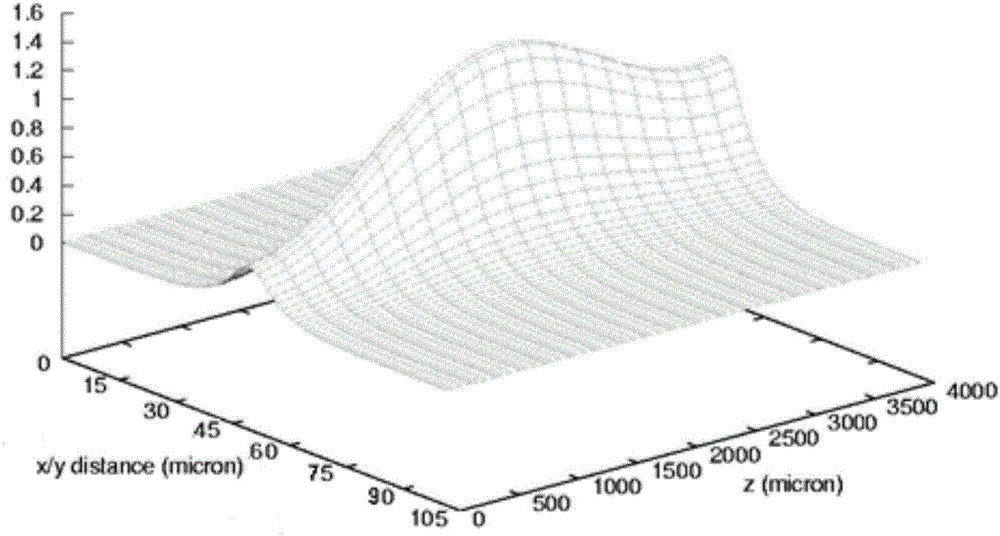

Semiconductor laser with internal optical grating

ActiveCN106329312AImproved spectral quality and temperature stabilityReduce size and power consumptionOptical wave guidanceLaser detailsPhysicsSemiconductor laser theory

The invention provides a semiconductor laser with internal optical grating. The semiconductor laser comprises a substrate, a lower covering layer, a lower waveguide layer, an active layer, an upper waveguide layer, an upper covering layer and a top layer sequentially from bottom to top. The upper waveguide layer comprises a first upper waveguide layer and a second upper waveguide layer, the first upper waveguide layer is positioned above the active layer adjacently, the second upper waveguide layer is positioned below the upper covering layer adjacently, and a optical grating layer is arranged between the first upper waveguide layer and the second upper waveguide layer. By the optical grating layer between the first upper waveguide layer and the second upper waveguide layer, spectrum quality and temperature stability of the semiconductor laser can be greatly improved, and power consumption and size of the laser can be reduced.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com