High-viscosity modified asphalt based on SBS/polyurethane compounding and preparation method thereof

A technology of modified asphalt and polyurethane, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of poor storage stability and high price of high-viscosity modified asphalt, and achieves the improvement of storage stability and reduction of polymer blending. The effect of good quantity and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

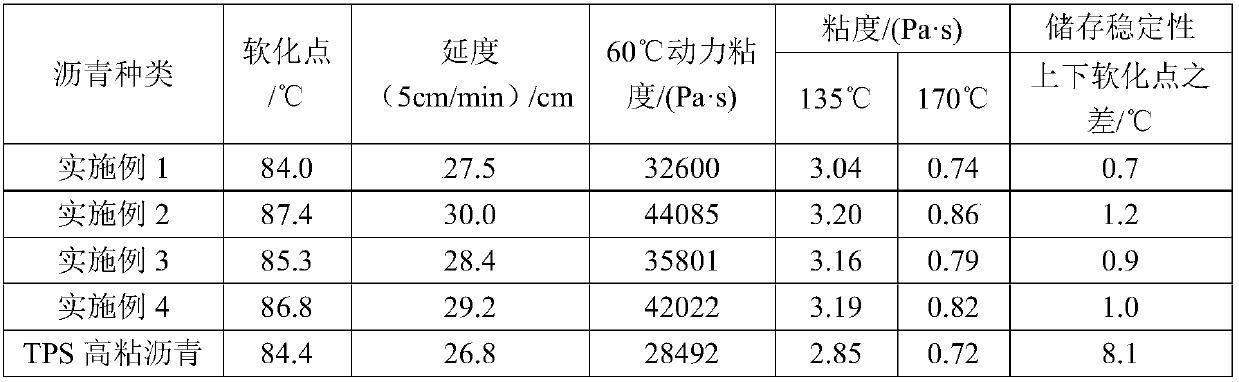

Examples

Embodiment 1

[0044] A high-viscosity modified asphalt based on SBS / polyurethane composite, in parts by mass, is composed of the following materials: 3 parts of polyurethane prepolymer H2122A, 3 parts of star-shaped SBS modifier, 100 parts of 70# matrix asphalt, Chain agent MOCA 0.4 part and coupling agent KH550 2 parts, sulfur-free compound stabilizer is 1.0‰ of the mass of SBS modifier.

[0045] The composite modified asphalt of the present embodiment is prepared according to the following steps:

[0046] (1) Slowly add SBS modifier after heating 70# base asphalt to 155°C, and use a mixer to stir at low speed, stir and swell for 30min after adding SBS, and keep the temperature at 155°C;

[0047] (2) After rapidly heating the mixture of asphalt and SBS modifier to 165°C, use a high-speed shearing machine for processing, the rotational speed is 4000r / min, the time is 30min, and the temperature of the mixture during the shearing process is 165°C;

[0048] (3) adding a stabilizer to the shea...

Embodiment 2

[0053] A high-viscosity modified asphalt based on SBS / polyurethane composite, in parts by mass, is composed of the following materials: 4 parts of polyurethane prepolymer H2122A, 4 parts of star-shaped SBS modifier, 100 parts of 70# matrix asphalt, 0.6 part of chain agent MOCA and 3 parts of coupling agent KH550, sulfur-free compound stabilizer is 1.0‰ of the mass of SBS modifier.

[0054] The composite modified asphalt of the present embodiment is prepared according to the following steps:

[0055] (1) Slowly add SBS modifier after heating the 70# base asphalt to 160°C, and stir at a low speed with a stirrer, stir and swell for 30min after the addition of SBS, and keep the temperature within the range of 160°C;

[0056] (2) After rapidly heating the mixture of asphalt and SBS modifier to 170°C, use a high-speed shearing machine for processing, the rotational speed is 4500r / min, the time is 45min, and the temperature of the mixture during the shearing process is 170°C;

[005...

Embodiment 3

[0062] A high-viscosity modified asphalt based on SBS / polyurethane composite, in parts by mass, is composed of the following materials: 5 parts of polyurethane prepolymer H2133A, 4 parts of linear SBS modifier, 100 parts of 70# matrix asphalt, 0.6 part of chain agent M-OEA and 2 parts of coupling agent KH550, sulfur-free compound stabilizer is 1.0‰ of the mass of SBS modifier.

[0063] The composite modified asphalt of the present embodiment is prepared according to the following steps:

[0064] (1) Slowly add SBS modifier after heating 70# base asphalt to 165°C, and use agitator to stir at low speed, stir and swell for 30min after adding SBS, and keep the temperature within the range of 165°C;

[0065] (2) After rapidly heating the mixture of asphalt and SBS modifier to 175°C, use a high-speed shearing machine for processing, the rotational speed is 3500r / min, the time is 50min, and the temperature of the mixture during the shearing process is 175°C;

[0066] (3) Add stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com