Composite film layer with sandwich structure and preparation method of composite film layer

A composite film and sandwich technology, which is applied in the field of titanium alloy coating, can solve the problems of poor wear resistance of the film layer and easy agglomeration of intermetallic compounds, etc., and achieve the effect of fast and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

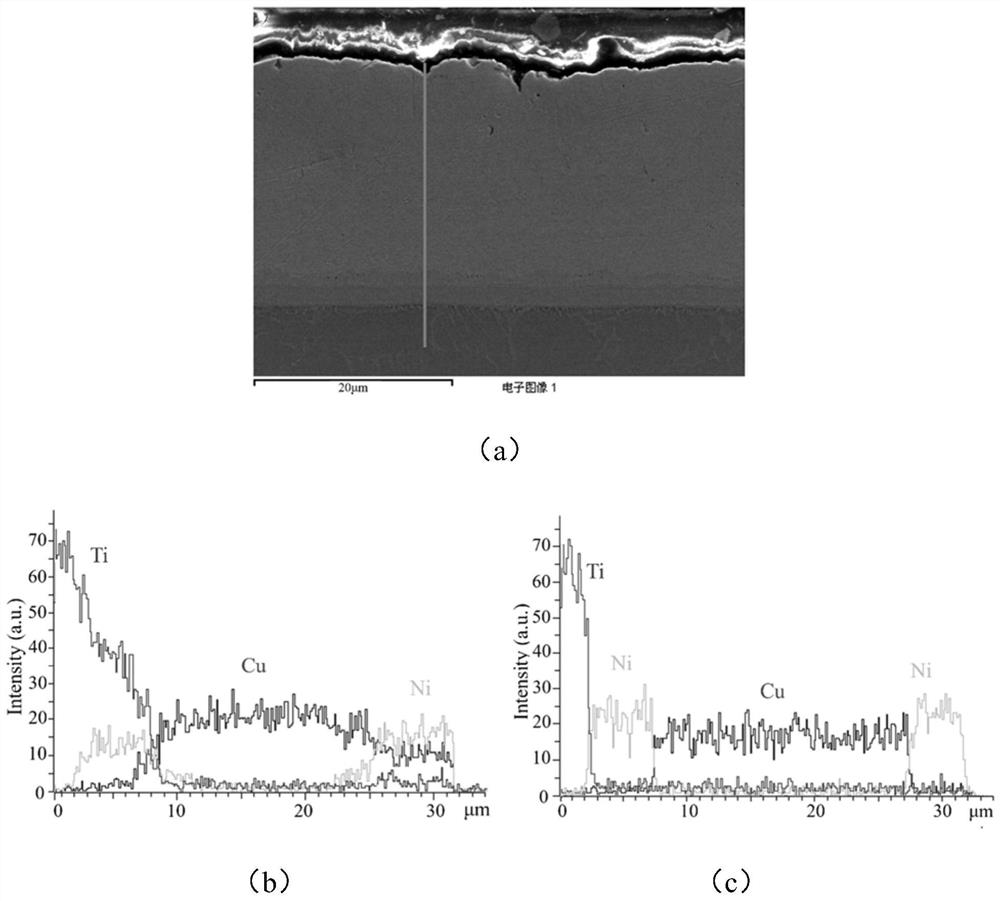

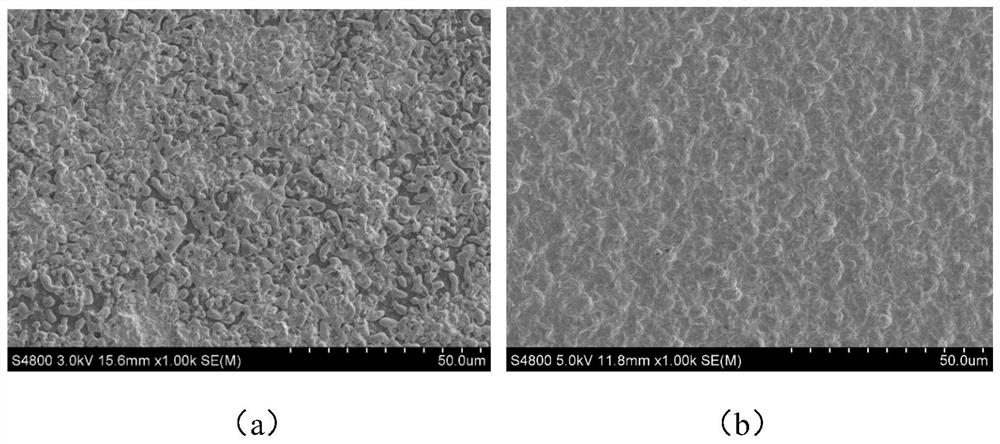

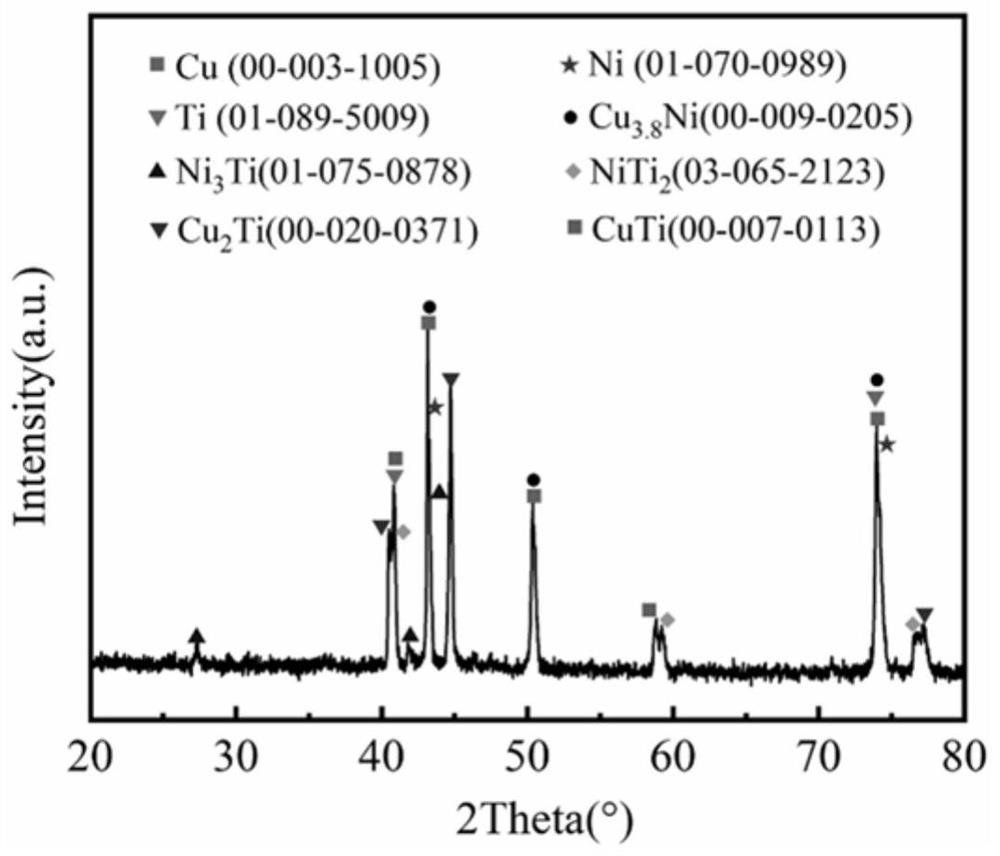

Embodiment 1

[0044] 1) Clean the TC4 titanium alloy sample

[0045] Put the alkali of TC4 titanium alloy sample in the cleaning solution to remove the surface grease;

[0046] 2) Ni plating

[0047] Put the TC4 titanium alloy in the electroplating solution for electroplating, and then wash it with running water to deposit Ni coating on the surface of the TC4 titanium alloy; the electroplating conditions are: temperature is room temperature, electroplating voltage is 3V, electroplating time is 10min; per 1L 80g Ni in the plating solution 2 SO 4 , 70g Na 2 SO 4 , 30g MgSO 4 , 30g NaCl and 30g H 3 BO 3 ;

[0048] 3) Vacuum heat treatment

[0049] Vacuum heat treatment was carried out on the TC4 titanium alloy deposited with Ni coating on the surface, the vacuum heat treatment temperature was 350° C., and the time was 30 min.

[0050] 4) Electroplating Cu

[0051] Place the heat-treated sample in the electroplating solution for electroplating, and after washing with running water, t...

Embodiment 2

[0072] 1) Clean the TC4 titanium alloy sample

[0073] Put the alkali of TC4 titanium alloy sample in the cleaning solution to remove the surface grease;

[0074] 2) Ni plating

[0075] Put the TC4 titanium alloy in the electroplating solution for electroplating, and then wash it with running water to deposit Ni coating on the surface of the TC4 titanium alloy; the electroplating conditions are: temperature 30°C, electroplating voltage 3V, electroplating time 10min; 80g Ni in 1L electroplating solution 2 SO 4 , 70g Na 2 SO 4 , 30g MgSO 4 , 30g NaCl and 30g H 3 BO 3 ;

[0076] 3) Vacuum heat treatment

[0077] Vacuum heat treatment was carried out on the TC4 titanium alloy with Ni coating deposited on the surface. The vacuum heat treatment temperature was 300°C, the time was 40min, and the pressure was 1×10 -2 Pa.

[0078] 4) Electroplating Cu

[0079] Place the heat-treated sample in the electroplating solution for electroplating, and after washing with running water...

Embodiment 3

[0092] 1) Clean the TC4 titanium alloy sample

[0093] Put the alkali of TC4 titanium alloy sample in the cleaning solution to remove the surface grease;

[0094] 2) Ni plating

[0095] Place the TC4 titanium alloy in the electroplating solution for electroplating, and then wash it with flowing water to deposit Ni coating on the surface of the TC4 titanium alloy; the electroplating conditions are: temperature 35°C, electroplating voltage 3V, electroplating time 10min; 80g Ni in 1L electroplating solution 2 SO 4 , 70g Na 2 SO 4 , 30g MgSO 4 , 30g NaCl and 30g H 3 BO 3 ;

[0096] 3) Vacuum heat treatment

[0097] Vacuum heat treatment was performed on the TC4 titanium alloy deposited with Ni coating on the surface, the vacuum heat treatment temperature was 33° C., and the time was 35 min.

[0098] 4) Electroplating Cu

[0099] Place the heat-treated sample in the electroplating solution for electroplating, and after washing with running water, the Ni / Cu coating can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com