High-performance conducting resin and preparation method thereof

A conductive adhesive, high-performance technology, used in conductive adhesives, adhesives, epoxy resin adhesives, etc., can solve the problems of not meeting high temperature conditions, endangering human health, and poor workability, and achieving excellent resistance to atmospheric aging. , easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

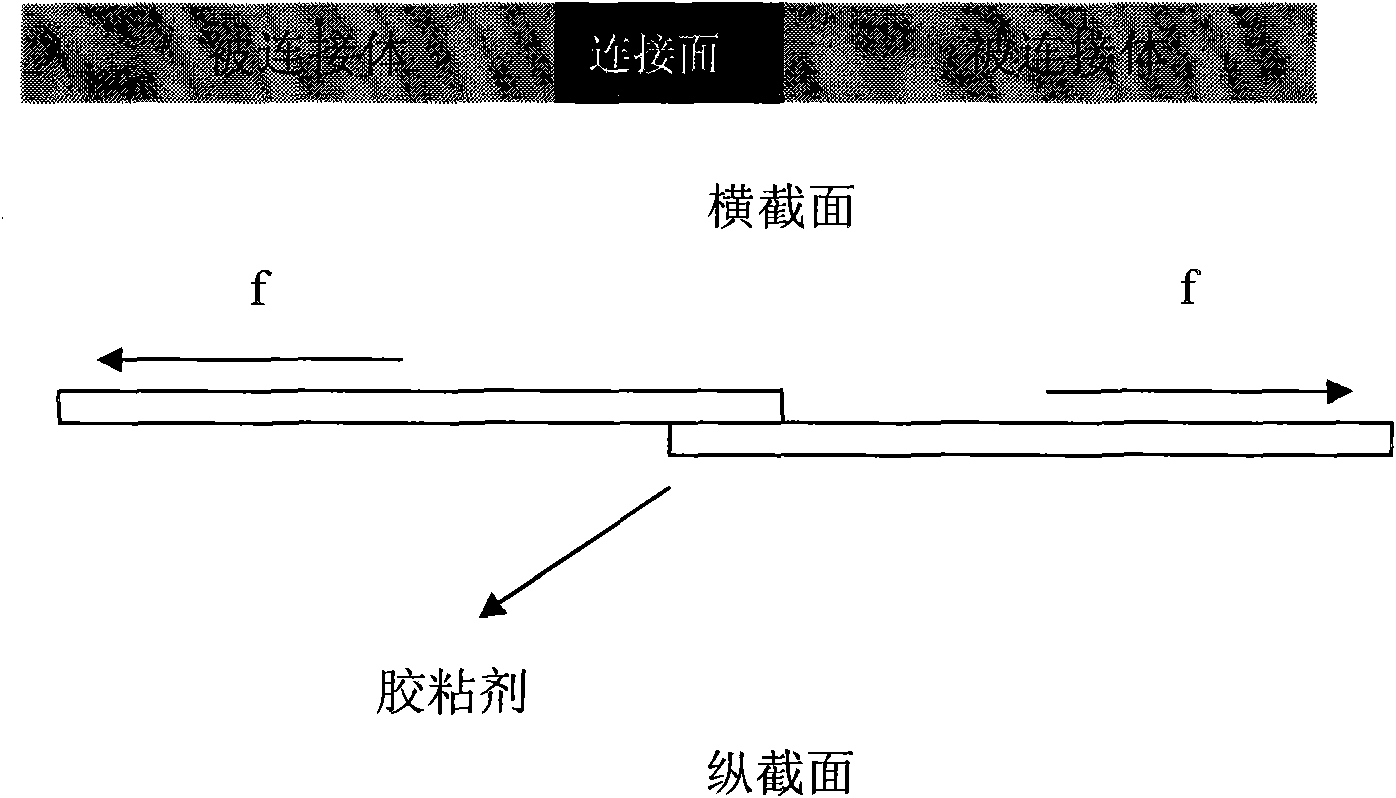

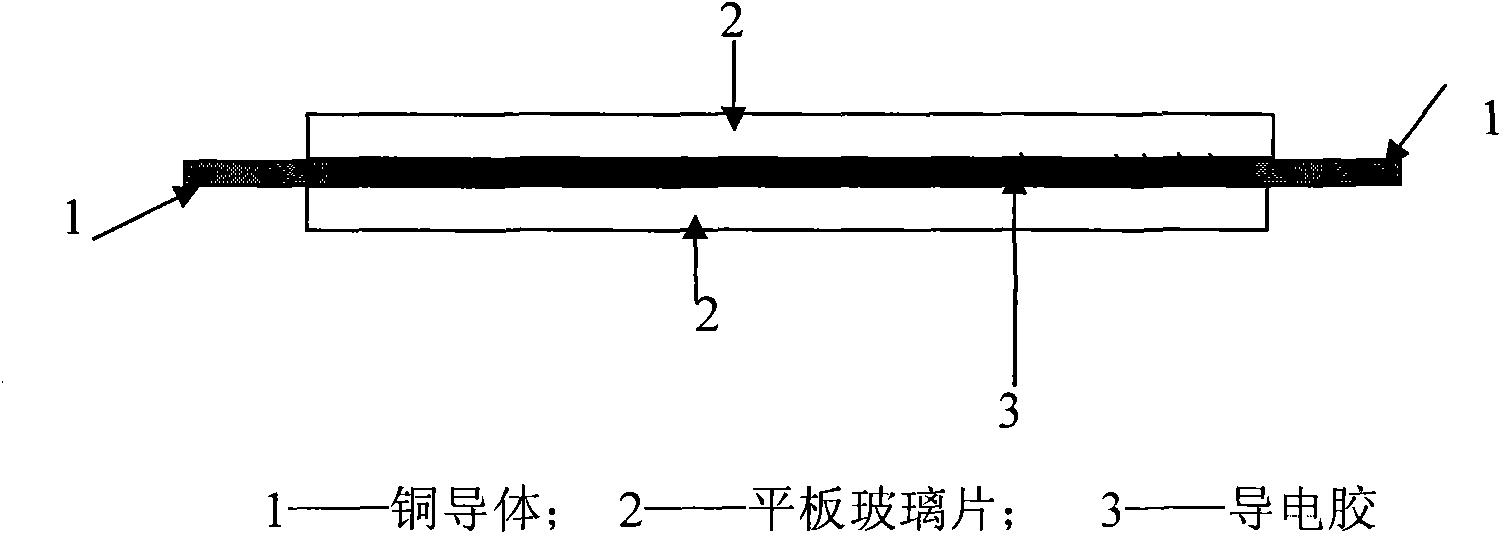

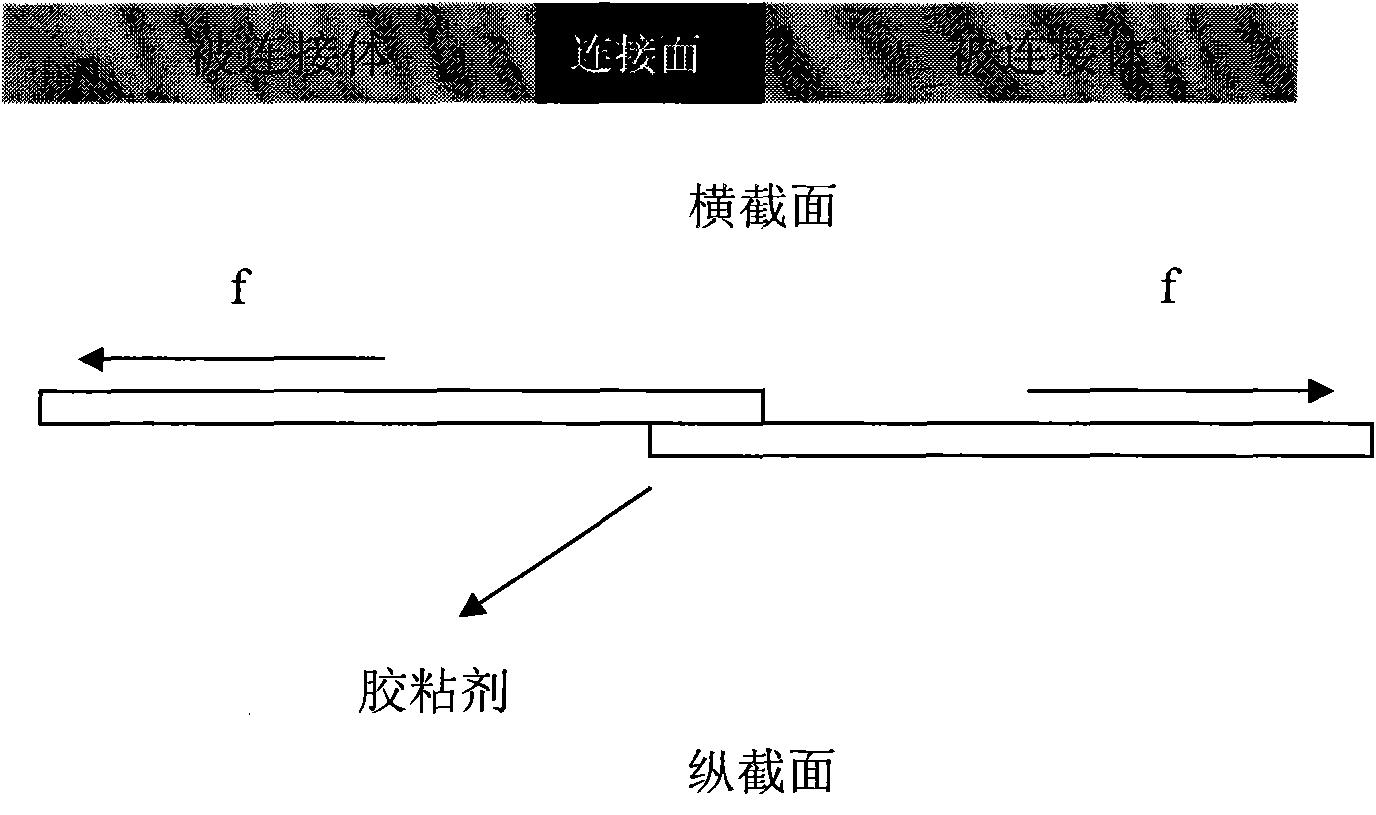

Method used

Image

Examples

Embodiment 1

[0036] Put 100 grams of silver powder into 500 milliliters of ethanol solution (mass percentage concentration is 0.5%) containing 3-glycidyl ether oxypropyl trimethoxysilane coupling agent, stir for 1-2 hours, filter, dry, obtain through Surface-treated conductive particles are denoted as A-1.

[0037] Put 30.0 grams of ES216 epoxy resin, 16.0 grams of CE127 epoxy resin, and 2.0 grams of carboxy-terminated nitrile rubber active toughening agent into the reaction bottle, react at a temperature of 80 ° C to 90 ° C for 0.5 hours, and add 4.0 at 50 ° C gram of dicyandiamide latent curing agent, after being stirred evenly, a solvent-free adhesive is obtained, which is denoted as SLA-1.

[0038] Take 26.0 grams of the above-mentioned SLA-1 solvent-free adhesive, add 74.0 grams of surface-treated conductive particles A-1, stir evenly, vacuum defoam, weigh and pack to obtain a high-performance conductive adhesive, which is designated as ECA-1.

[0039] Take an appropriate amount of E...

Embodiment 2

[0046] Put 100 grams of silver powder into 500 milliliters of ethanol solution (mass percent concentration: 1.0%) containing terminal aminopropyltriethoxysilane coupling agent, stir for 1-2 hours, filter, and dry to obtain a surface-treated conductive silver powder. Particles, denoted as A-2.

[0047] Put 20.0 grams of ES216 epoxy resin, 2.0 grams of E-51 epoxy resin, 2.0 grams of YAG-80 epoxy resin, 16.0 grams of CE127 epoxy resin, and 3.0 grams of amino-terminated polyetherimide resin active toughening agent into the reaction In the bottle, react at a temperature of 80°C to 90°C for 0.5 hours, add 4.0 grams of phenyl-substituted dicyandiamide latent curing agent and 2.0 grams of adipic acid dihydrazide latent curing agent at 50°C, and stir evenly to obtain Solvent-free adhesive, denoted as SLA-2.

[0048] Take 24.5 grams of the above-mentioned SLA-2 solvent-free adhesive, add 75.5 grams of surface-treated conductive particles A-2, stir evenly, vacuum defoam, weigh and pack ...

Embodiment 3

[0056] Put 100 grams of silver-plated copper powder into 500 milliliters of ethanol solution (mass percentage concentration is 0.8%) containing isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate coupling agent, stir After 1-2 hours, filter and dry to obtain surface-treated conductive particles, which are designated as A-3.

[0057] 20.0 grams of ES216 epoxy resin, 2.0 grams of E-44 epoxy resin, 2.0 grams of YAG-80 epoxy resin, 16.0 grams of CE127 epoxy resin, 0.5 gram of hydroxyl-terminated nitrile rubber and 1.5 gram of carboxyl-terminated nitrile rubber activity enhancer Put the toughening agent into the reaction bottle, react at 80°C to 90°C for 0.5 hours, add 3.0 g of dicyandiamide and 1.0 g of 2-ethyl-4-methylimidazole latent curing agent at 50°C, and stir evenly Finally, a solvent-free adhesive is obtained, denoted as SLA-3.

[0058] Take 23.0 grams of the above SLA-3 solvent-free adhesive, add 77.0 grams of surface-treated conductive particles A-3, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com