Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

268 results about "Titanium atom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the periodic table of elements, Titanium is atomic number 22, meaning that an atom of titanium has 22 protons in its nucleus. By definition, atoms have no overall electrical charge, therefore they have an equal number of protons and electrons.

Method for photocatalytically hydrophilifying surface and composite material with photocatalytically hydrophilifiable surface

InactiveUS6090489AImproved oil repellencyEasy to disassembleOther chemical processesPretreated surfacesAtmospheric airSolid acid

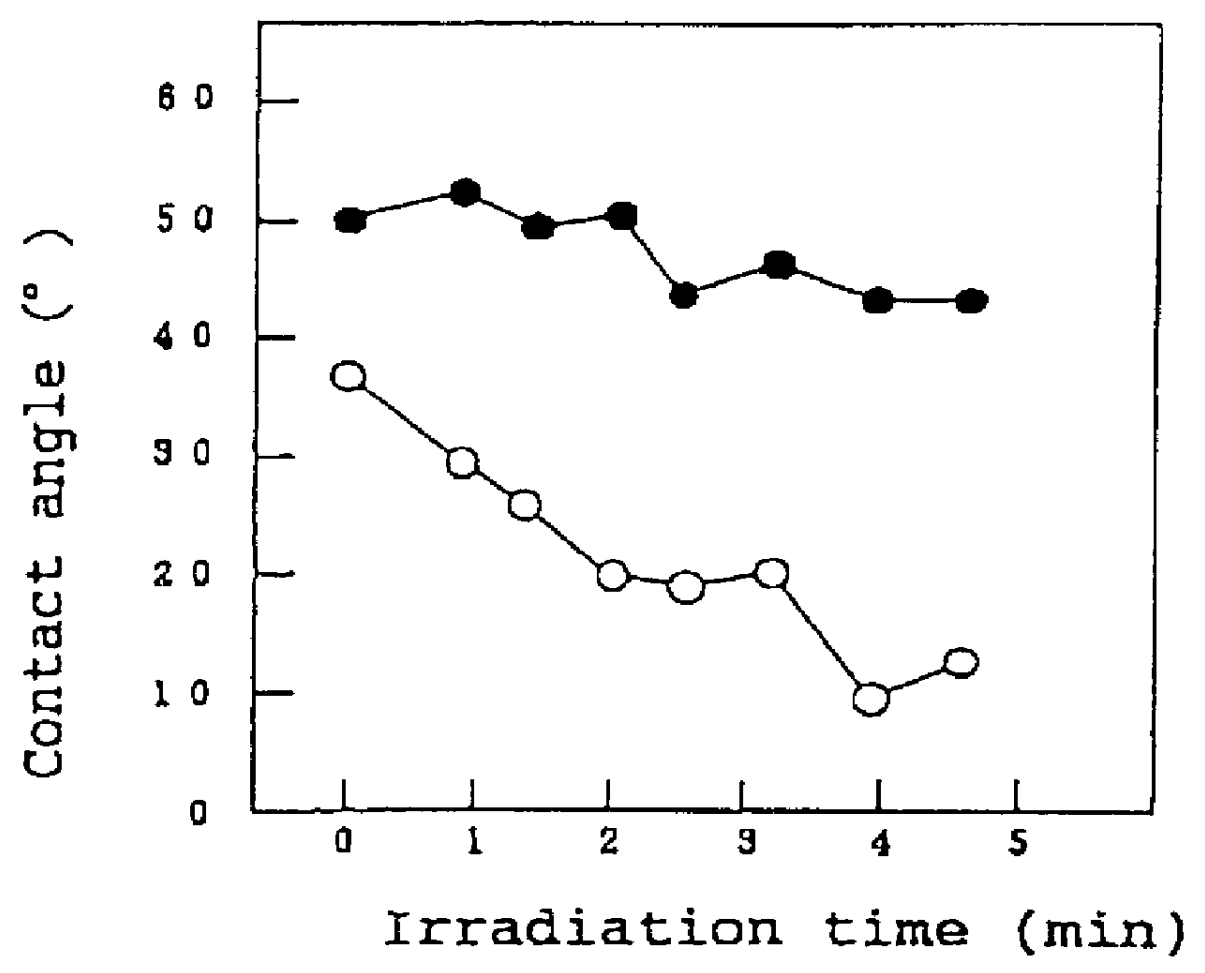

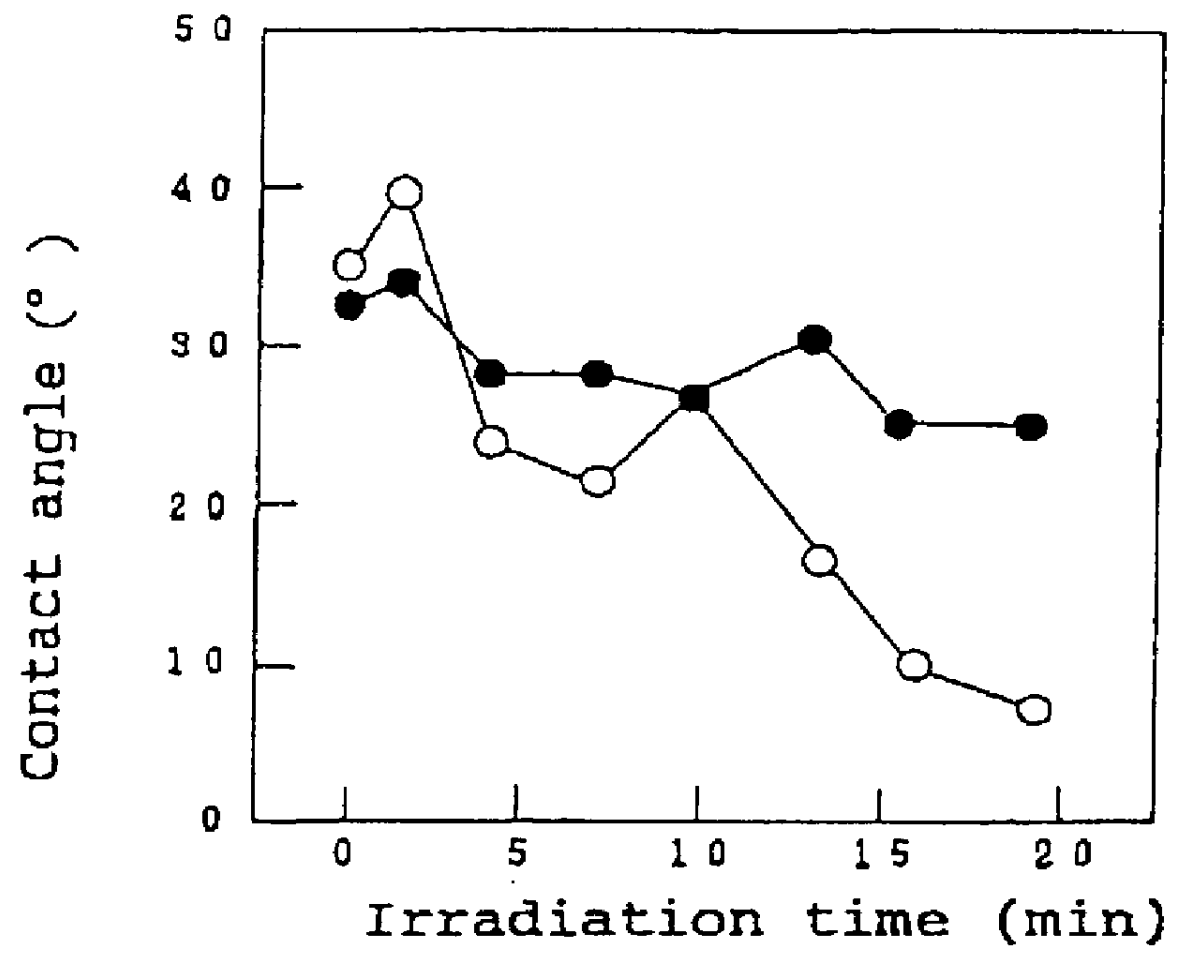

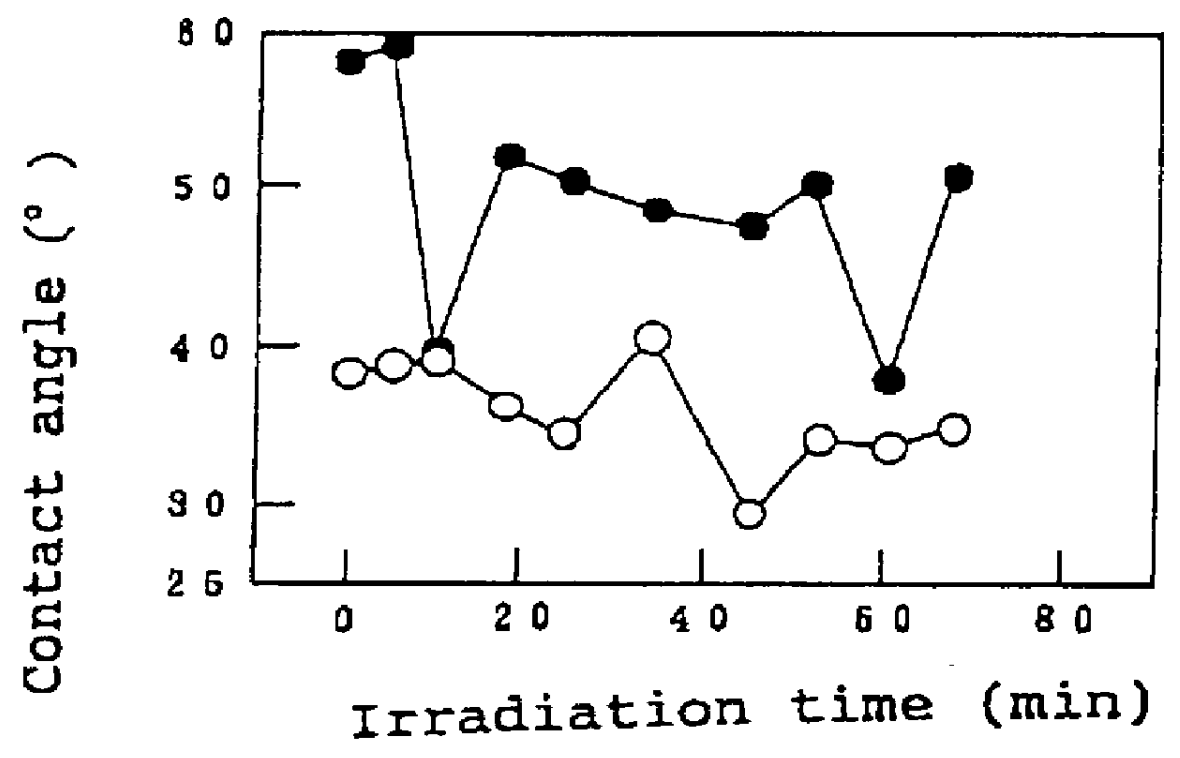

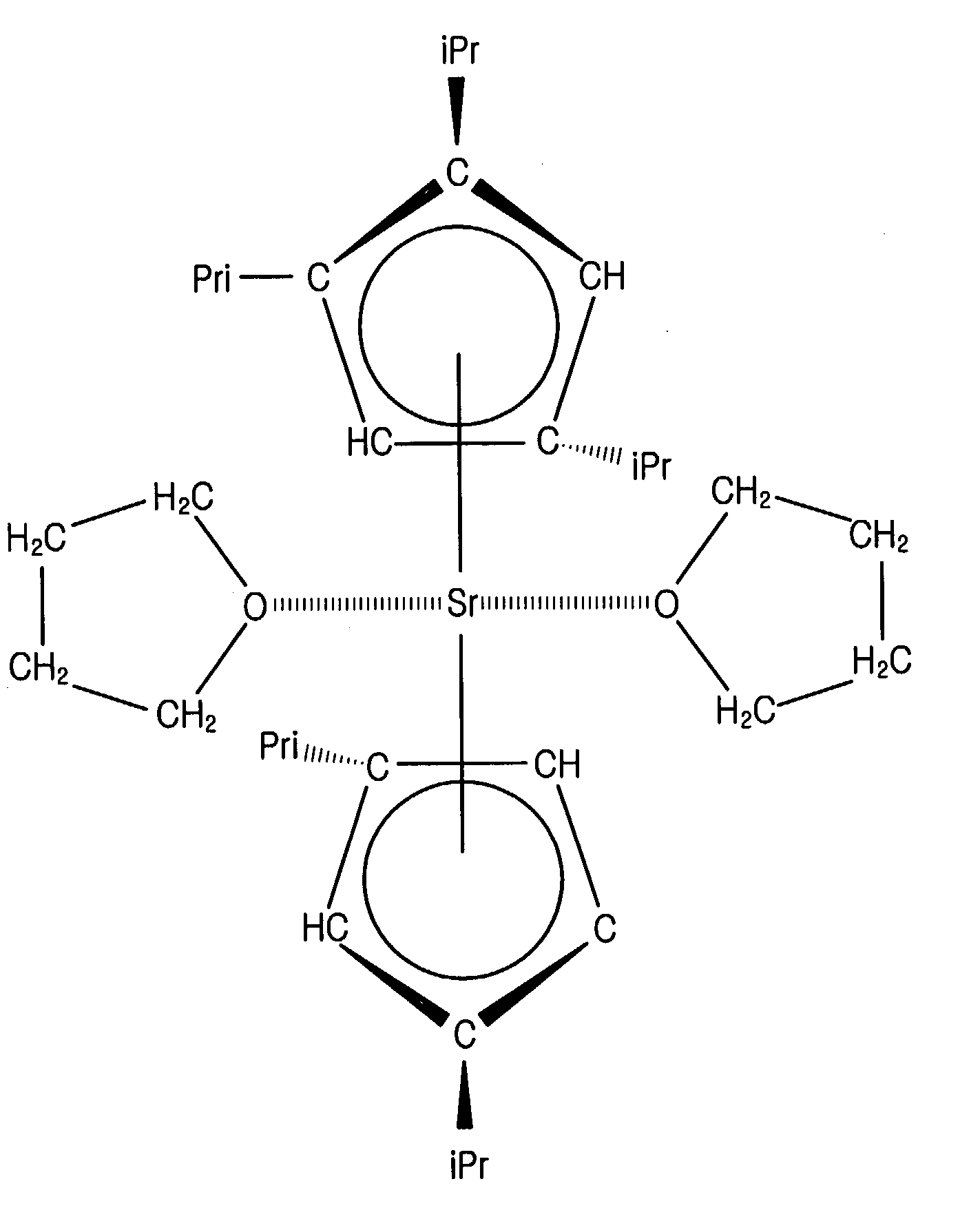

A method for hydrophilifying the surface of a substrate by taking advantage of photocatalytic action. The substrate has a photocatalytic titania coating (10). The surface of the photocatalytic coating (10) bears the solid acid that increases a hydrogen bond component ( gamma Sh) in the surface energy in the solid / gas interface of the coating. Photoexcitation of the photocatalyst enhances the hydrogen bond component ( gamma Sh) in the surface energy of the photocatalytic coating (10), accelerating the physical adsorption of molecules of water in the atmosphere through a hydrogen bond (16) onto hydrogen atoms in a terminal OH group (12), bonded to a titanium atom, and a bridge OH group (14) on the surface of the coating. This results in the formation of a high density, physically adsorbed water layer (18) on the surface of the photocatalytic coating (10), thus permitting the surface of the substrate to be easily hydrophilified. The method is applicable to antifogging, antifouling, selfcleaning and cleaning of articles.

Owner:TOTO LTD

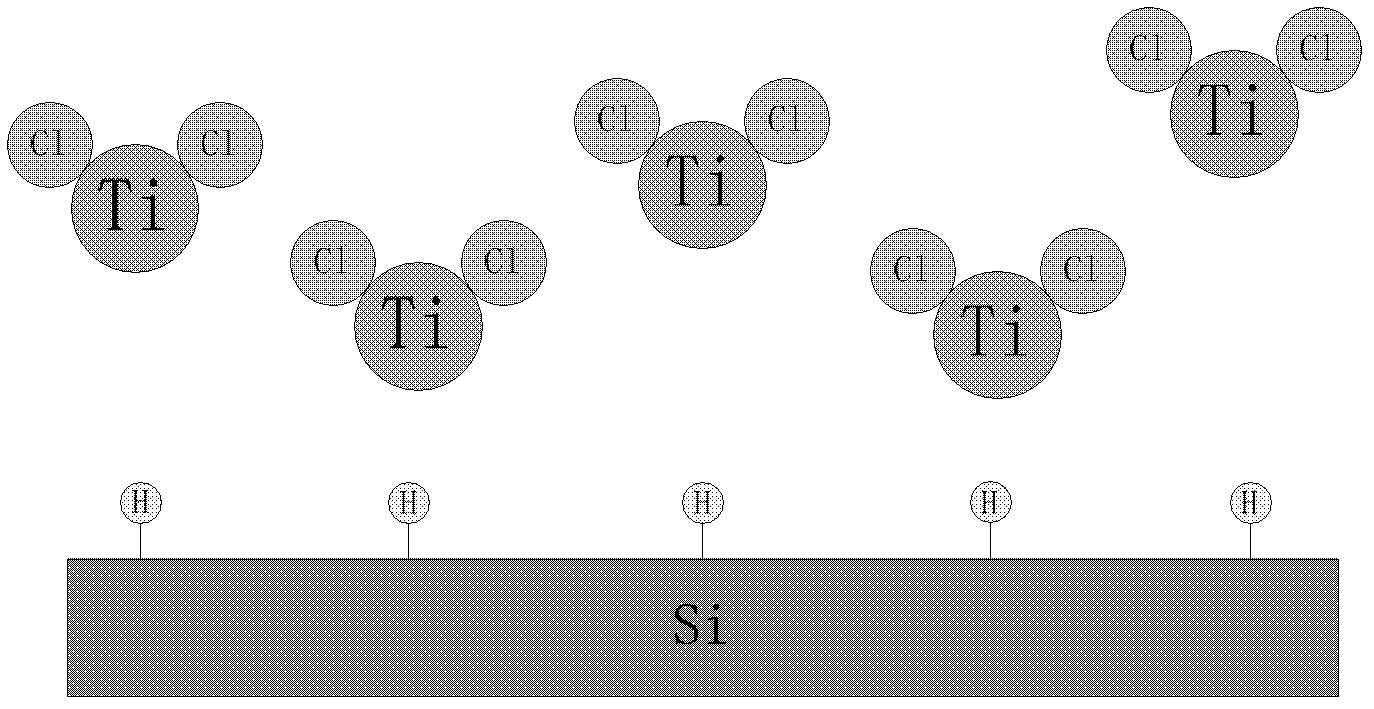

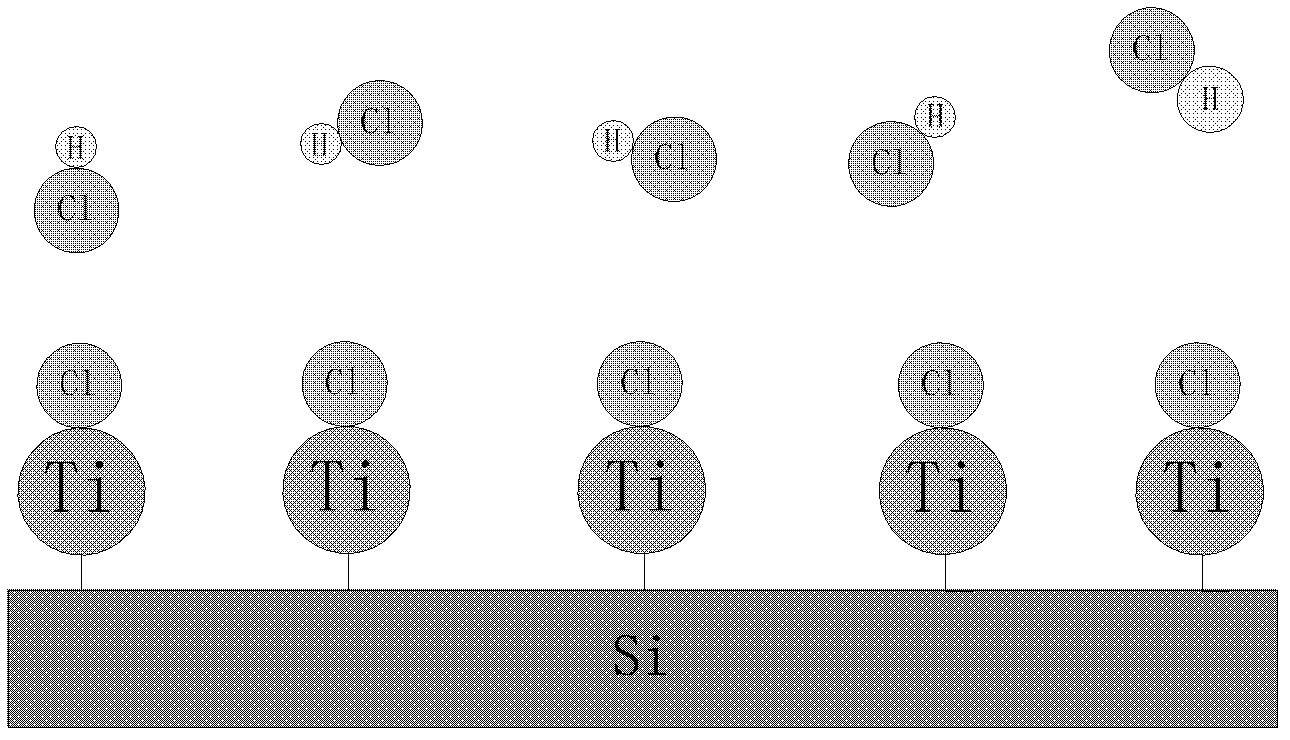

Method for forming high dielectric layers using atomic layer deposition

InactiveUS20030113480A1Favorable reaction kineticsImprove responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOxygenDielectric layer

A method for manufacturing semiconductor device is disclosed which forms a high dielectric layer using atomic layer deposition (ALD). The method for forming a high dielectric layer having a first metal element, a titanium atom and an oxygen atom includes: a) preparing a substrate where a predetermined bottom layer is formed; b) on a surface of the substrate, adsorbing a first organism source combining a ligand, wherein the ligand includes at least oxygen and C-H combination in the first metal element; c) on the surface of the substrate, forming an atomic layer of the first metal element and the oxygen by inducing reduction reaction of the first organism source and a NH3 gas, which are adsorbed on the surface of the substrate; d) on the surface of the substrate where the atomic layer is formed, adsorbing a second organism source combining a ligand, wherein the ligand includes at least oxygen and C-H combination on the titanium; and e) on the surface of the substrate, forming an atomic layer of the titanium and the oxygen by inducing reduction reaction of the second organism source and the NH3 gas, which are adsorbed on the surface of the substrate.

Owner:SK HYNIX INC

Polyester compositions which comprise cyclobutanediol ethylene glycol, titanium, and phosphorus with improved color and manufacturing processes therefor

Described as one aspect of the invention are polyester compositions comprising at least one polyester which comprises: (a) a dicarboxylic acid component comprising: (i) about 90 to about 100 mole % of terephthalic acid residues; (ii) about 0 to about 10 mole % of aromatic and / or aliphatic dicarboxylic acid residues having up to 20 carbon atoms; and (b) a glycol component comprising: (i) about 1 to less than 90 mole % 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and (ii) about 0 to about 89 mole % cyclohexanedimethanol residues; (iii) greater than 10 mole % ethylene glycol residues, and (iv) less than about 2 mole % of a modifying glycol having from 3 to 16 carbon atoms; (c) titanium atoms and phosphorus atoms, wherein the total mole % of the dicarboxylic acid component is 100 mole %, and wherein the total mole % of the glycol component is 100 mole %; and wherein the inherent viscosity of the polyester is from 0.50 to 1.2 dL / g as determined in 60 / 40 (wt / wt) phenol / tetrachloroethane at a concentration of 0.25 g / 50 ml at 25° C. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

Polyester resin and catalyst for polyester production, process for producing polyester resin with the catalyst, polyester resin obtained with the catalyst, and hollow molded container comprising the polyester resins

InactiveUS20050107576A1Increase chanceProduced in advanceSynthetic resin layered productsDomestic footwearSolubilityProduction rate

The object of the present invention is to provide a high quality polyester resin having high productivity, stability and safety, a catalyst for polyester production with high catalytic activity, a method for producing the polyester resin with the catalyst, a polyester resin obtained with the catalyst, and a hollow molded container comprising the polyester resin. The polyester resin of the present invention satisfies specific parameters regarding polymerizability, stability, and metal content. The catalyst for polyester production satisfies specific parameters. The catalyst particularly preferably comprises: (a) a solid titanium-containing compound which has a maximum solubility in ethylene glycol of 1,000 ppm or more in terms of converted titanium amount when dissolved in ethylene glycol with heating at 150° C., and which comprises titanium, oxygen, carbon, and hydrogen, and optionally alkali metal, and has a Ti—O—C bond; and (b) an alkali metal compound, the molar ratio of the alkali metal atoms to the titanium atom in the catalyst being in the range of 20 / 1 to 0.1 / 1.

Owner:MITSUI CHEM INC

Solid catalyst component and catalyst for olefin polymerization, and process for producing olefin polymer

InactiveUS6903041B2Reduce contentLow component requirementsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorOlefin polymerization

There are provided;[0001](i) a solid catalyst component obtained by contacting a trivalent titanium atom-containing solid catalyst component precursor (C) with a halogeno compound (A) of the 13 or 14 group of elements in the periodic table of the elements and an electron donor (B), or a solid catalyst component obtained by contacting an intermediate product with a titanium-halogen bond-carrying compound (D), the intermediate product being obtained by contacting the solid catalyst component precursor (C) with a halogeno compound (A′) of the 14 group of elements in the periodic table of the elements and the electron donor (B), or a solid catalyst component comprising a magnesium atom, a titanium atom, a halogen atom and an electron donor and having a relative surface area of not more than 30 m2 / g, the catalyst component being superior in a particle form, and[0002](ii) a catalyst comprising the solid catalyst component and an organoaluminum compound, the catalyst being high in polymerization activity.

Owner:SUMITOMO CHEM CO LTD

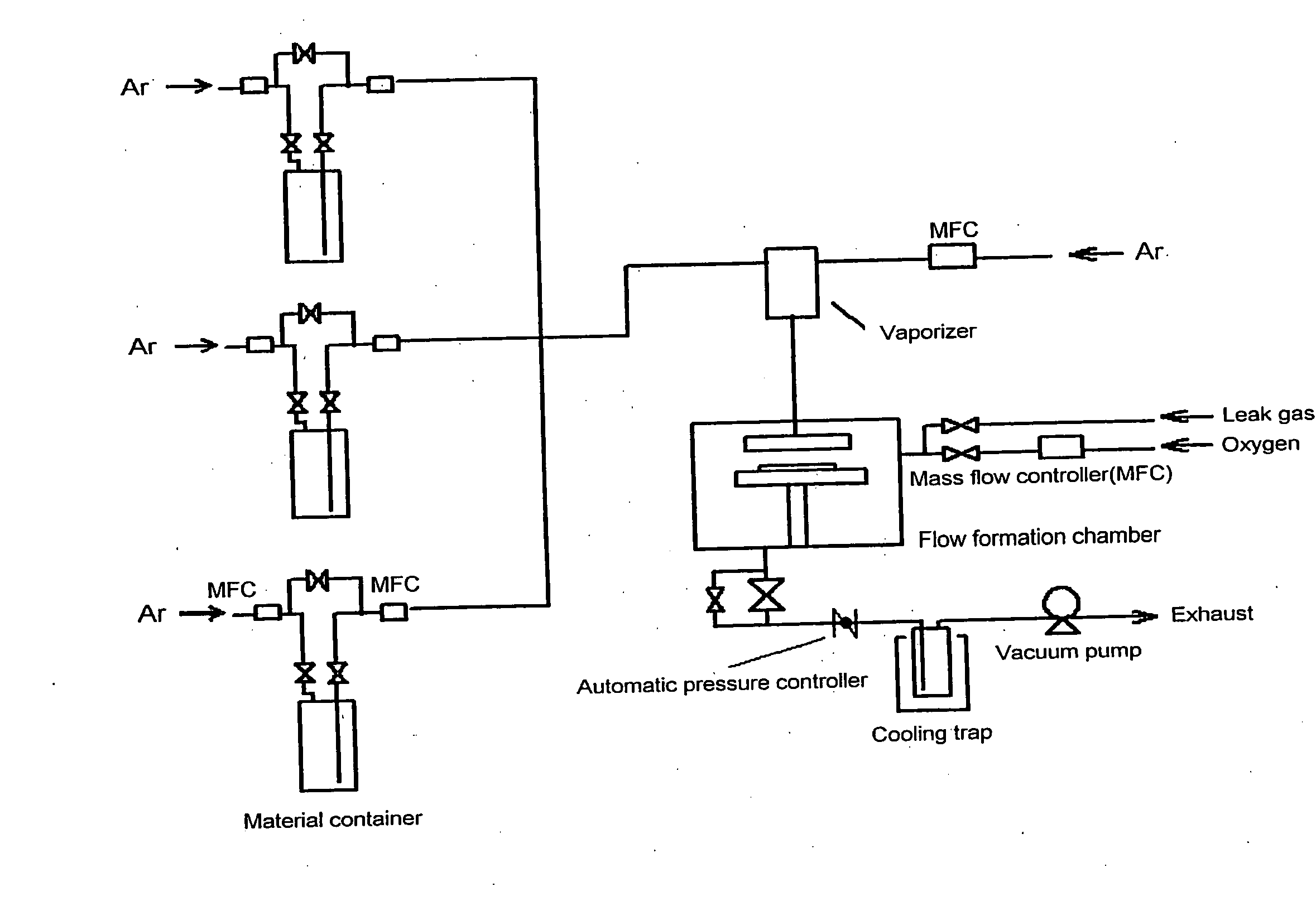

Metal compound, material for thin film formation, and process of forming thin film

InactiveUS20070122947A1Group 4/14 organic compounds without C-metal linkagesSemiconductor/solid-state device manufacturingChemical reactionLiquid state

A metal compound represented by general formula (I): wherein R1, R2, R3, and R4 each represent an alkyl group having 1 to 4 carbon atoms; A represents an alkanediyl group having 1 to 8 carbon atoms; M represents a lead atom, a titanium atom or a zirconium atom; n represents 2 when M is a lead atom or 4 when M is a titanium or zirconium atom. The metal compound has a low melting point and is therefore deliverable in a liquid state, has a high vapor pressure and is therefore easy to vaporize, and, when mixed with other metal compound, undergoes no denaturation due to a chemical reaction. The metal compound is suitable as a material of thin film formation processes involving vaporization of a metal compound, such as CVD.

Owner:ADEKA CORP

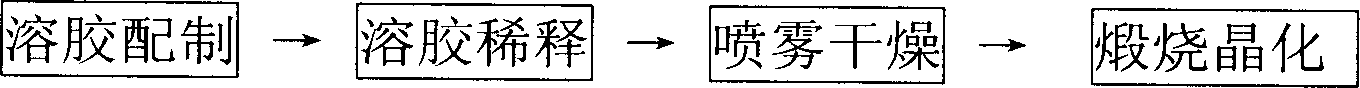

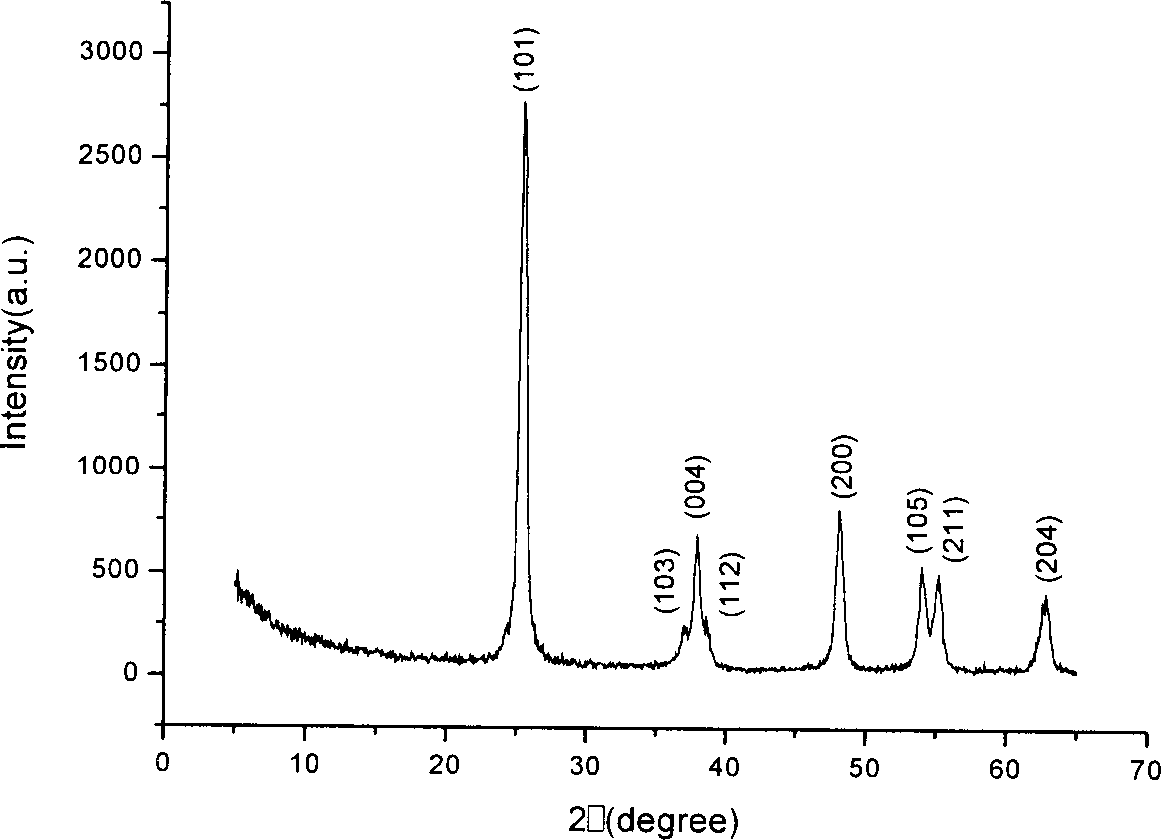

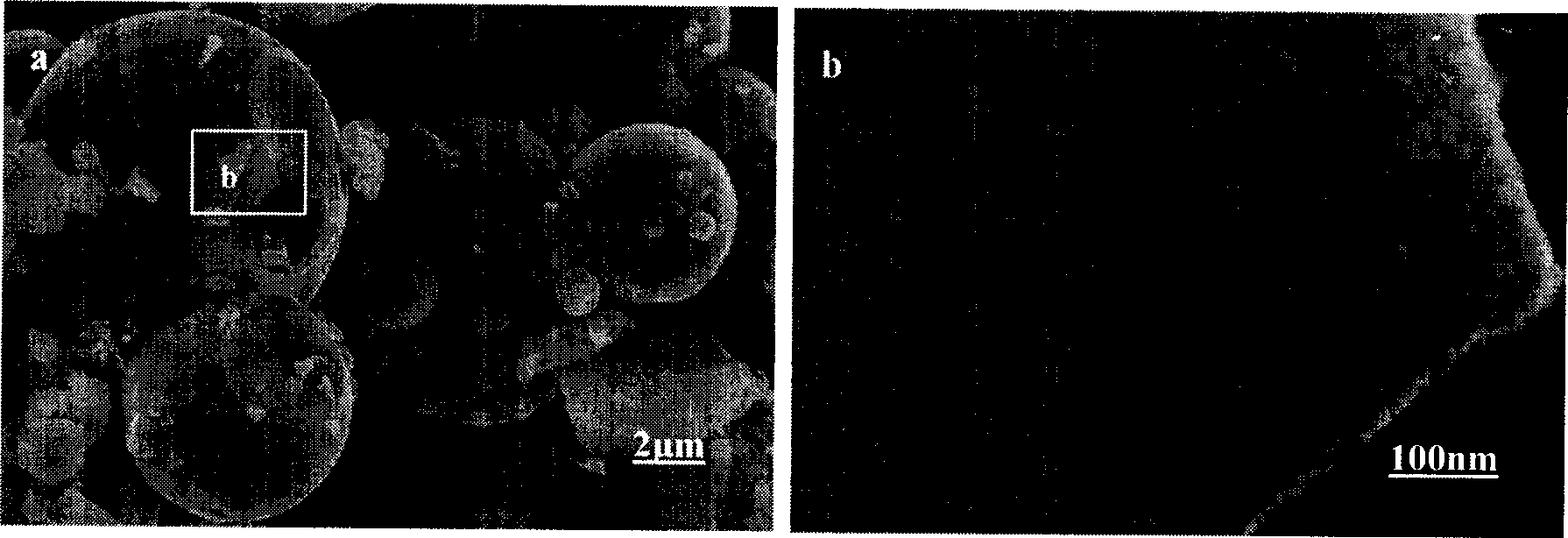

Prepn. process of mesic hole hollow ball-shape titania powder

This invention relates to a method to prepare mezoporous empty-centered titanium dioxide powders, which comprises following steps: titanium chloride is made into hydrosol with pure water, diluted and introduced into a spray dryer for spray drying. The subsequent product is empty-centered ball-shaped powder made up of nanosized titanium dioxide particles and the preceding titanium chloride is titanium tetrachloride or titanium trichloride. The titanium dioxide particles prepared in this invention all have mezoporous empty-centered ball-shaped structure and the empty-centered wall is made up of nanosized titanium dioxide particles and mezopores, on the surface of which titanium atoms possess a fraction of as high as 70%. As only titanium tetrachloride is adopted as precursor and no other reagent is necessary, the product is highly pure and has excellent photocatalytic properties. This method has the advantages of high yield, low cost, easily controlled technique and convenience for magnification experiment. Besides, there are not severe requirements for facilities and this method is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

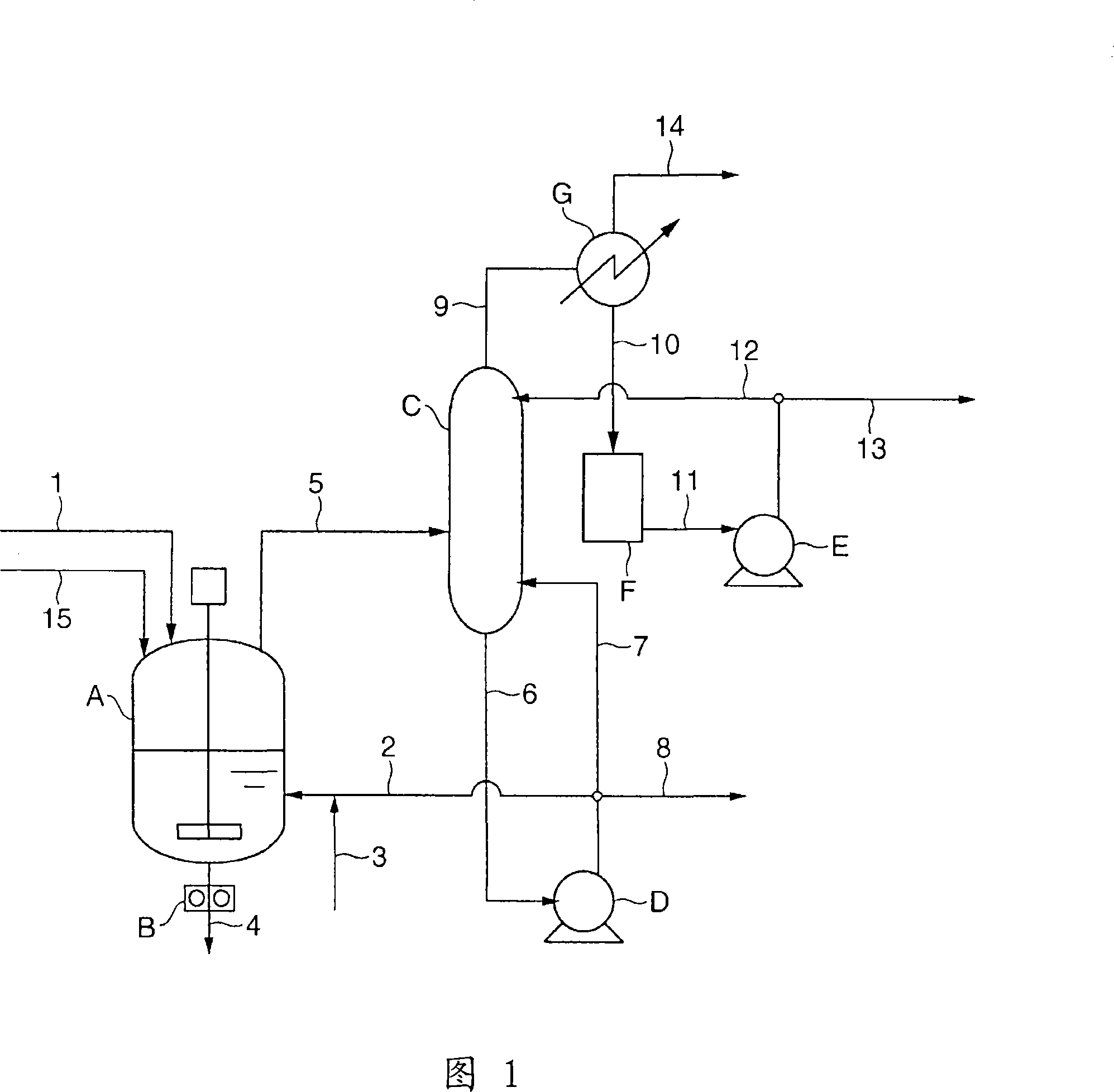

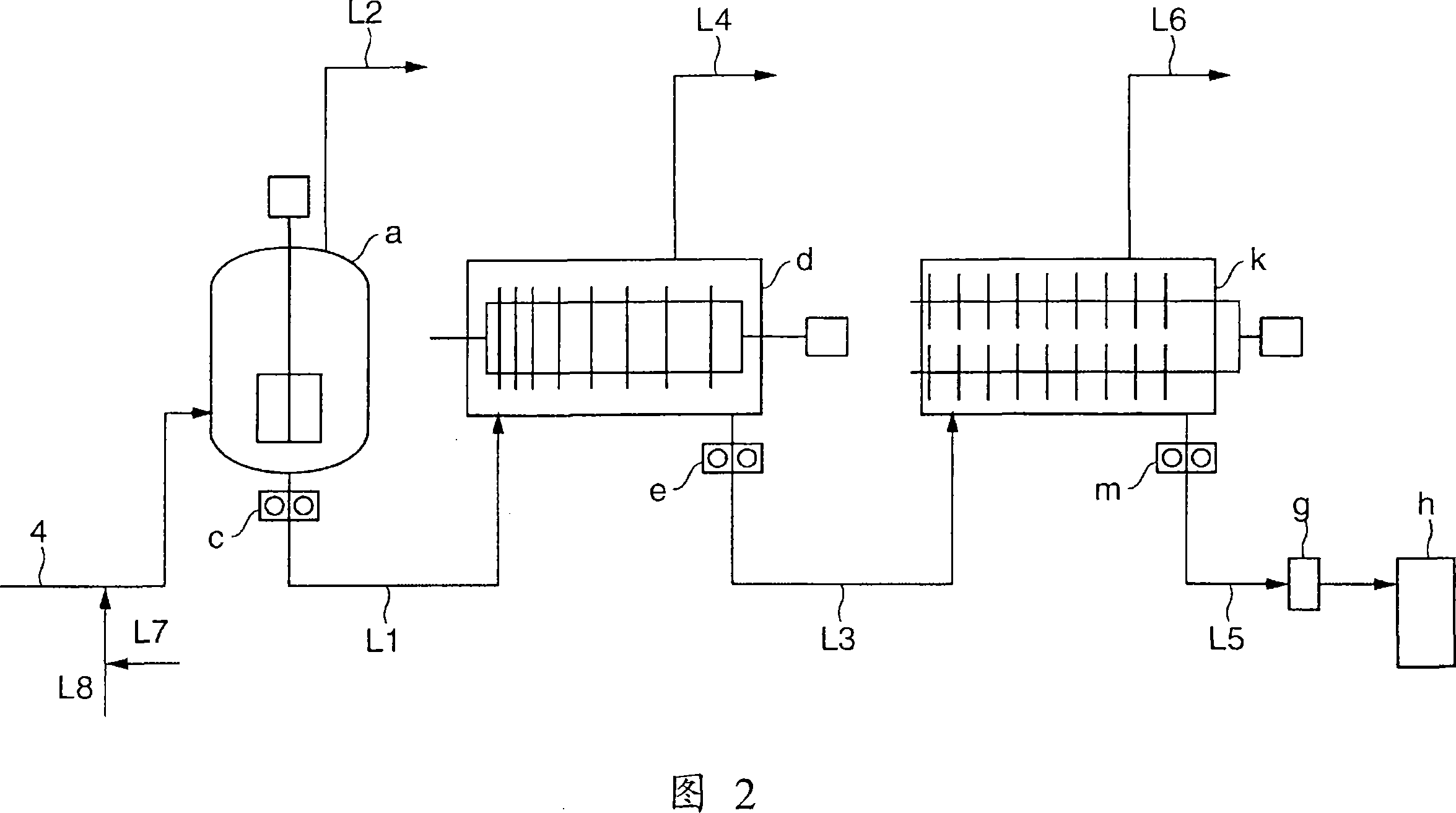

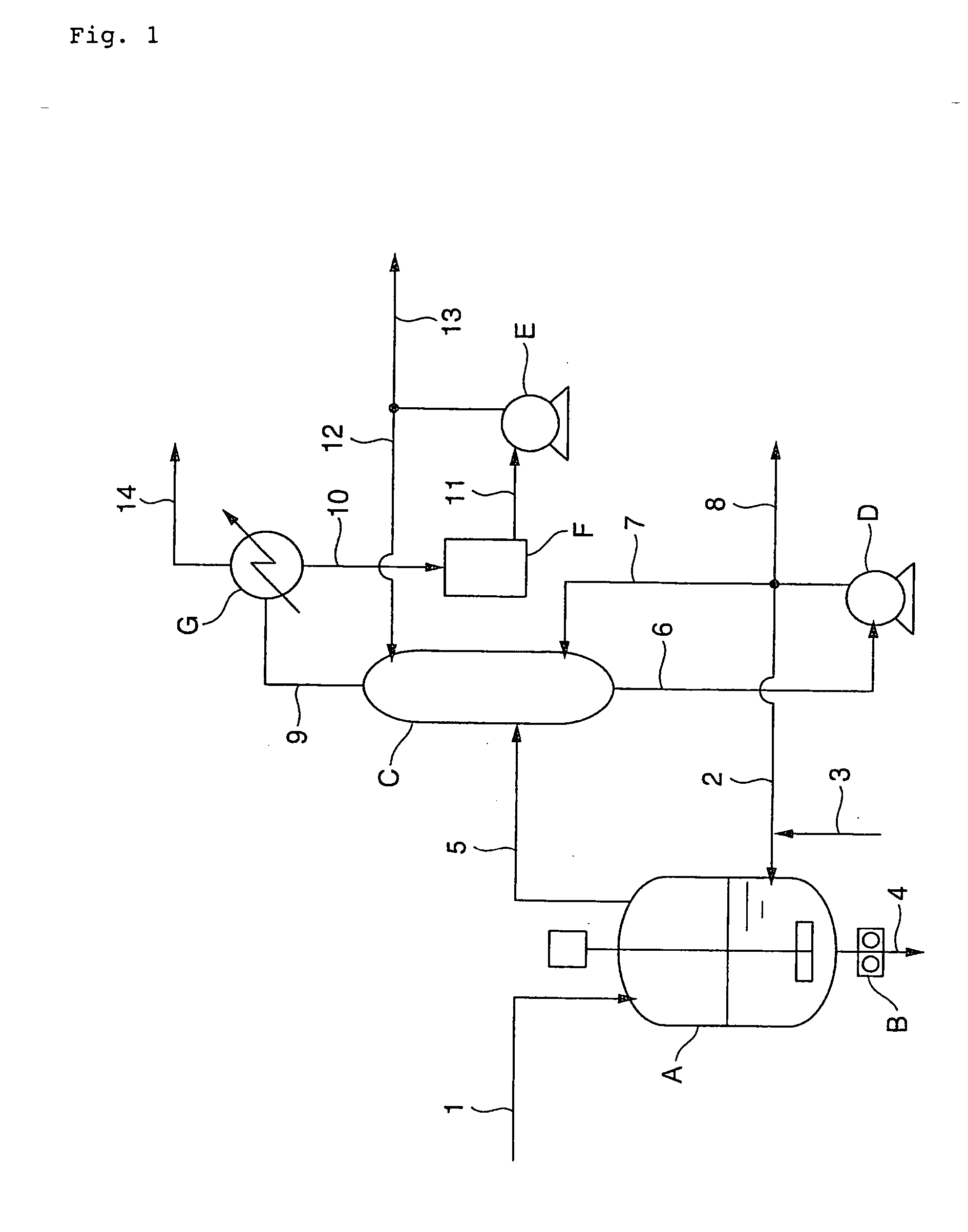

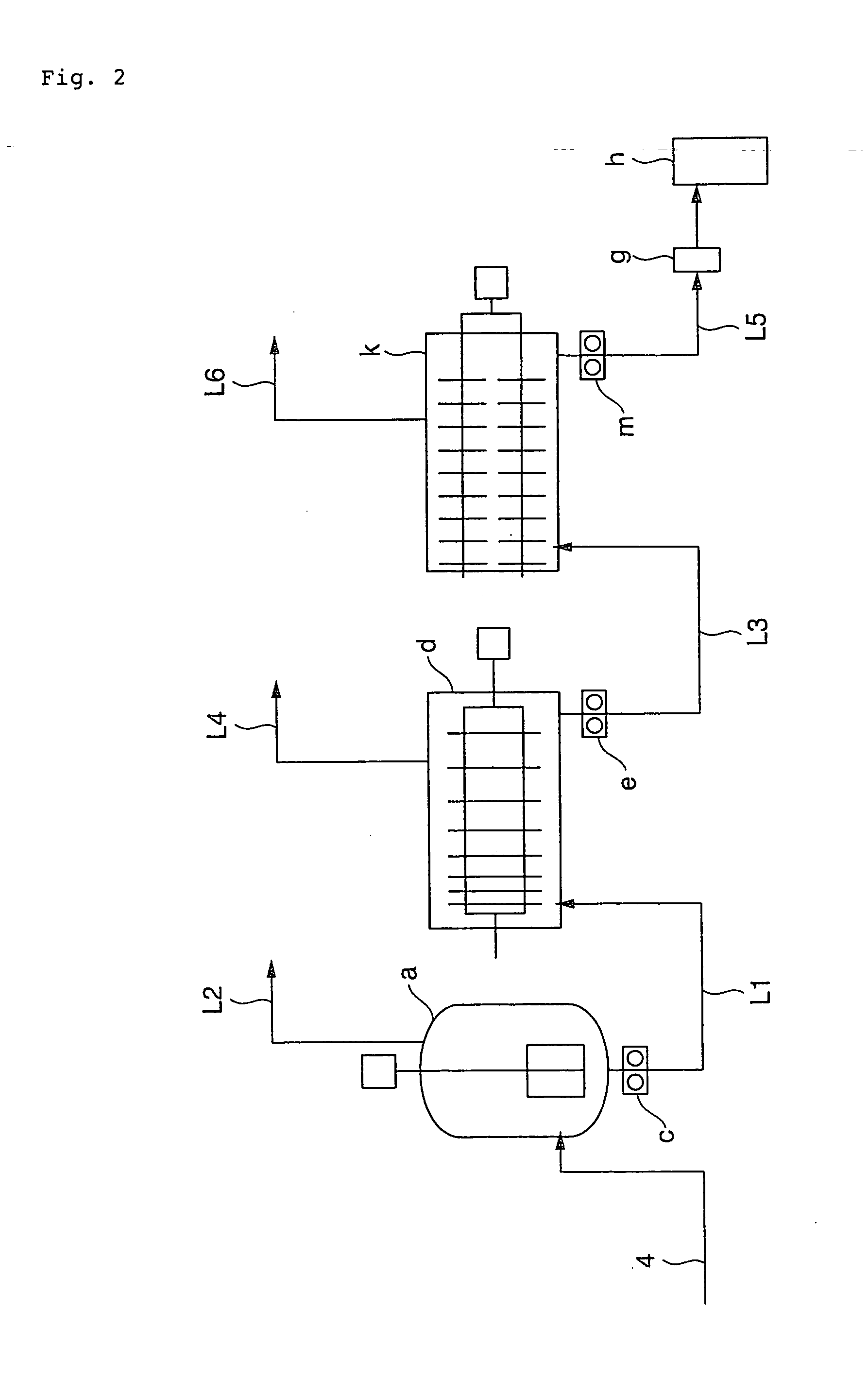

Polybutylene terephthalate and process for production thereof

ActiveCN101253217AExcellent toneImprove hydrolysis resistancePolytetramethylene terephthalatePolyethylene terephthalate

Disclosed is a process for producing a polybutylene terephthalate continuously from terephthalic acid and 1,4-butanediol using a titanium compound and a compound of at least one metal selected from the metals belonging to Groups I and II on the periodic table as catalysts, the process satisfying the following conditions (a) to (c): (a) terephthalic acid and 1,4-butanediol are subjected to continuous esterification in the presence of a titanium catalyst in an amount of 460 [mu]mol or less in terms of a titanium atom per mol of a terephthalic acid unit, thereby producing an oligomer; (b) the oligomer is subjected to continuous polycondensation in the presence of a compound of at least one metal selected from the metals belonging to Groups I and II on the periodic table in an amount of 450 [mu]mol or less in terms of the metal atom per mol of a terephthalic acid unit; and (c) until the esterification rate of the oligomer reaches 90% or higher, the compound of the metal may be added in an amount of 300 [mu]mol or less in terms of the metal atom per mol of a terephthalic acid unit, and after the esterification rate of the oligomer reaches 90% or higher, the compound of the metal may be added in an amount of 10 [mu]mol or more in terms of the metal atom per mol of a terephthalic acid unit.

Owner:MITSUBISHI RAYON CO LTD

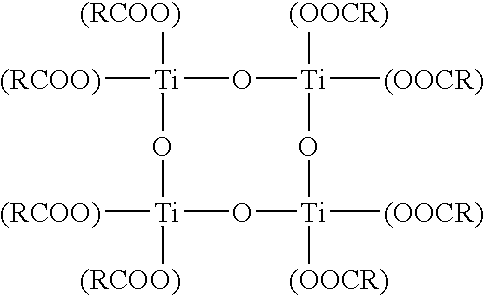

Coating formulation and process for the production of titanate-based ceramic film with the coating formulation

InactiveUS20080090006A1Improve solubilityReduce film thicknessElectrolytic capacitorsFinal product manufactureOrganic acidOrganic solvent

A coating formulation contains the following components (A), (B) and (C): (A) an organic acid-titanium compound having at least one titanium atom and at least one C2-12 aliphatic organic acid residual group as essential constituents and having no constituent other than the essential constituents, (B) fine particles of a titanate-based compound, said fine particles having an average particle size of from 10 to 100 nm, and (C) an organic solvent. A content of the components (A) is from 0.1 to 1.5 mol / kg in terms of titanium atoms, and a content of the component (B) is from 0.1 to 1.5 mol / kg in terms of titanium atoms. A production process for a titanate-based ceramic film, which makes use of the coating formulation, is also disclosed.

Owner:ADEKA CORP

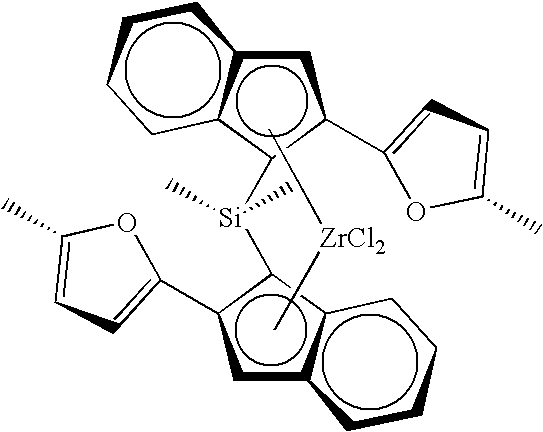

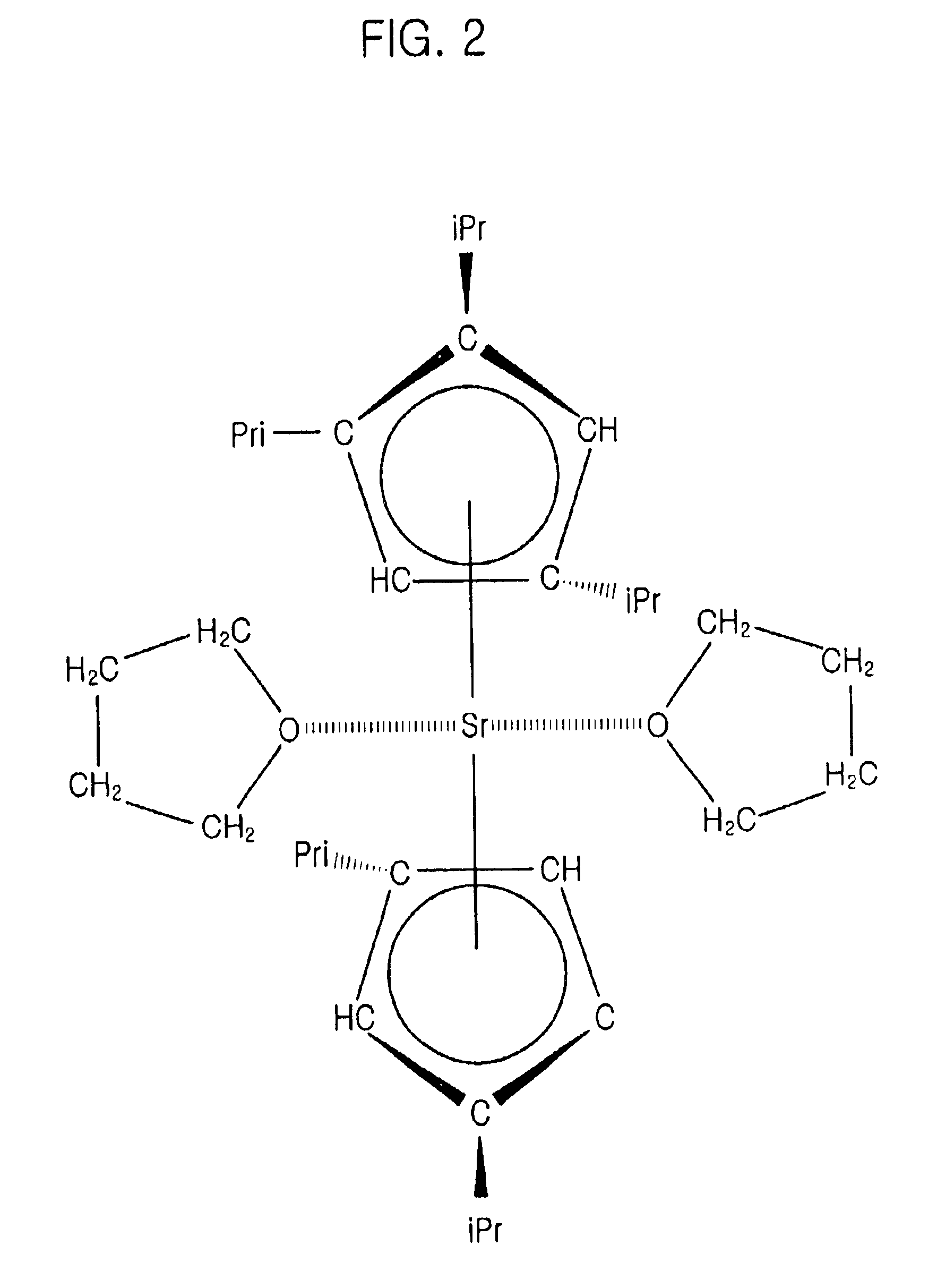

Metallocene compound, olefin polymerization catalyst containing the compound, and method for producing an olefin polymer by use of the catalyst

InactiveUS6846943B2High molecular weightEasy to synthesizeSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceHafnium

The present invention provides a metallocene compound which produces an olefin polymer having a high molecular weight with a high stereoregularity. The metallocene compound has the following formula (1):Q(C5H4-mR1m)(C5H4-nR2n)MXY (1)wherein (C5H4-mR1m) and (C5H4-nR2n) each independently represent a cyclopentadienyl group;C5H4-m and C5H4-n each independently represent a cyclopentadienyl ring;m represents an integer of 1-3;n represents an integer of 2 or 3;R1 and R2 are each independently a substituent bonded respectively to C5H4-m and C5H4-n, and represent a hydrocarbon group of 1-20 carbon atoms, a silicon-containing hydrocarbon group of 1-20 carbon atoms or a heteroaromatic group;each R1m and each R2n may be the same or different;one pair of R2's in the R2n are bonded to each other to form at least one ring;Q represents a divalent group for cross-linking (C5H4-mR1m) and (C5H4-nR2n);M represents a titanium atom, a zirconium atom or a hafnium atom; andX and Y are the same or different and each a hydrogen atom, a halogen atom or a hydrocarbon group.

Owner:JNC CORP

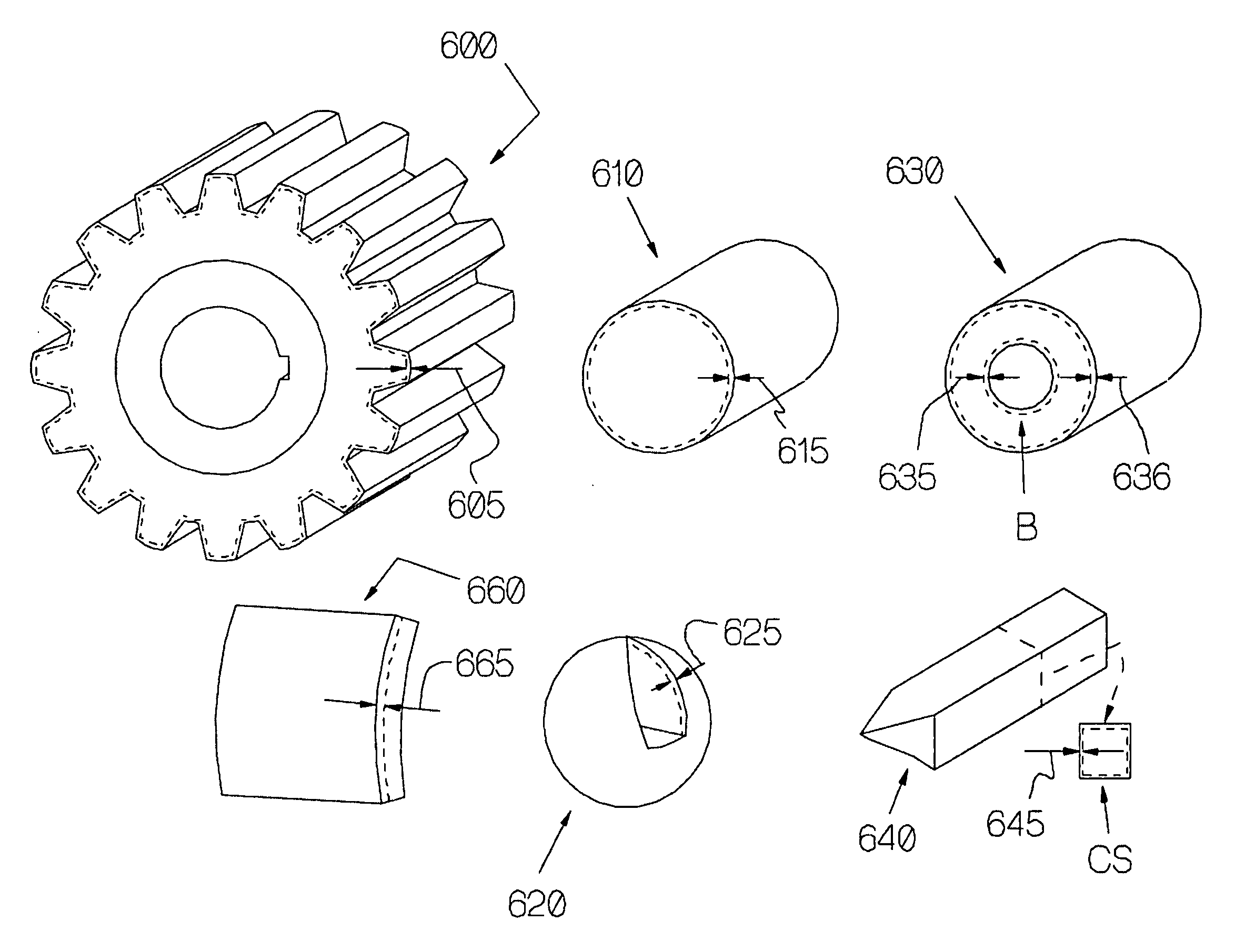

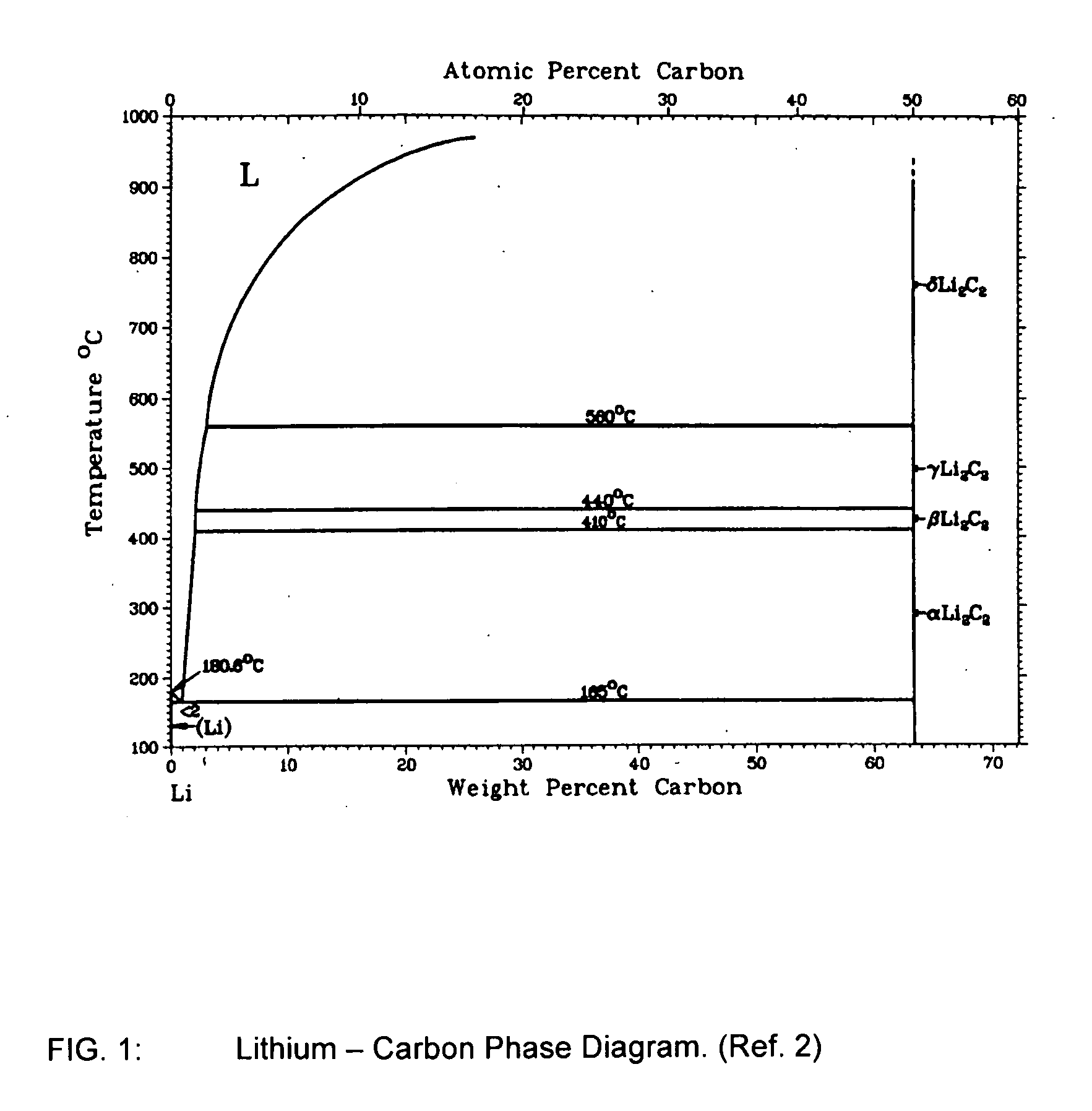

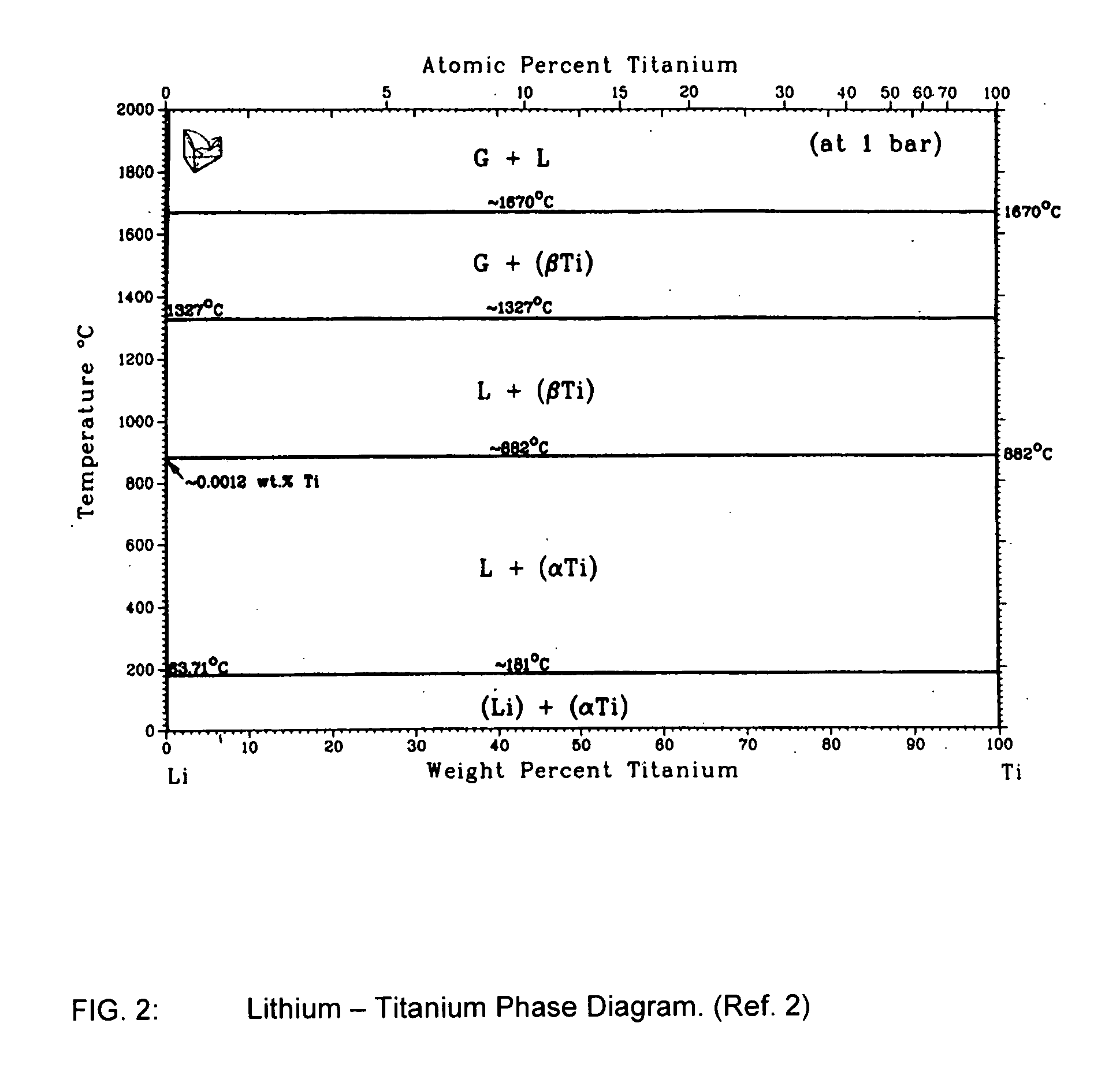

System and method for surface hardening of refractory metals

A process of converting an outer layer of an object made of a refractory metal, such as titanium, into a carbide of the refractory metal. A molten metal, such as molten lithium, is placed adjacent the outer surface of the object. The lithium does not react with the titanium, nor is it soluble within the titanium to any significant extent at the temperatures involved. The molten lithium contains elemental carbon, that is, free carbon atoms. At high temperature, the carbon diffuses into the titanium, and reacts with titanium atoms to form titanium carbide in an outer layer. Significantly, no other atoms are present, such as hydrogen or oxygen, which can cause problems, because they are blocked by the molten lithium.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

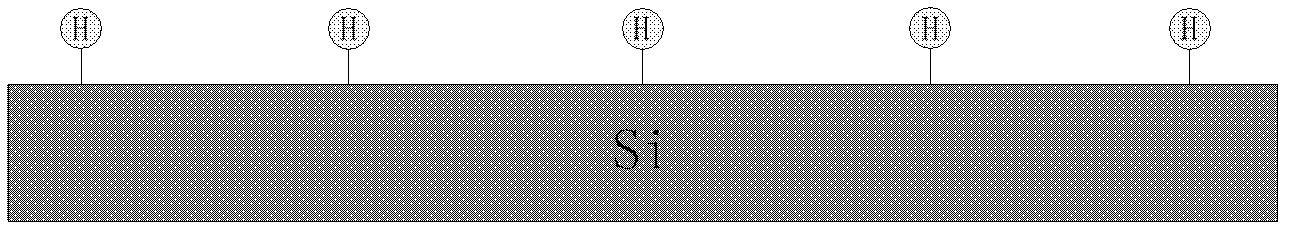

Method for forming high dielectric layers using atomic layer deposition

InactiveUS6849300B2Improve responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOxygenAtomic layer deposition

A method for manufacturing semiconductor device is disclosed which forms a high dielectric layer using atomic layer deposition (ALD). The method for forming a high dielectric layer having a first metal element, a titanium atom and an oxygen atom includes: on a surface of a substrate, adsorbing a first organic source combining a ligand, wherein the ligand includes at least oxygen and C—H combination in the first metal element; forming an atomic layer of the first metal element and the oxygen by inducing reduction reaction of the first organism source and a NH3 gas, which are adsorbed on the surface of the substrate; adsorbing a second organism source combining a ligand, wherein the ligand includes at least oxygen and C—H combination on the titanium; and forming an atomic layer of the titanium and the oxygen by inducing reduction reaction of the second organism source and the NH3 gas, which are adsorbed on the surface of the substrate.

Owner:SK HYNIX INC

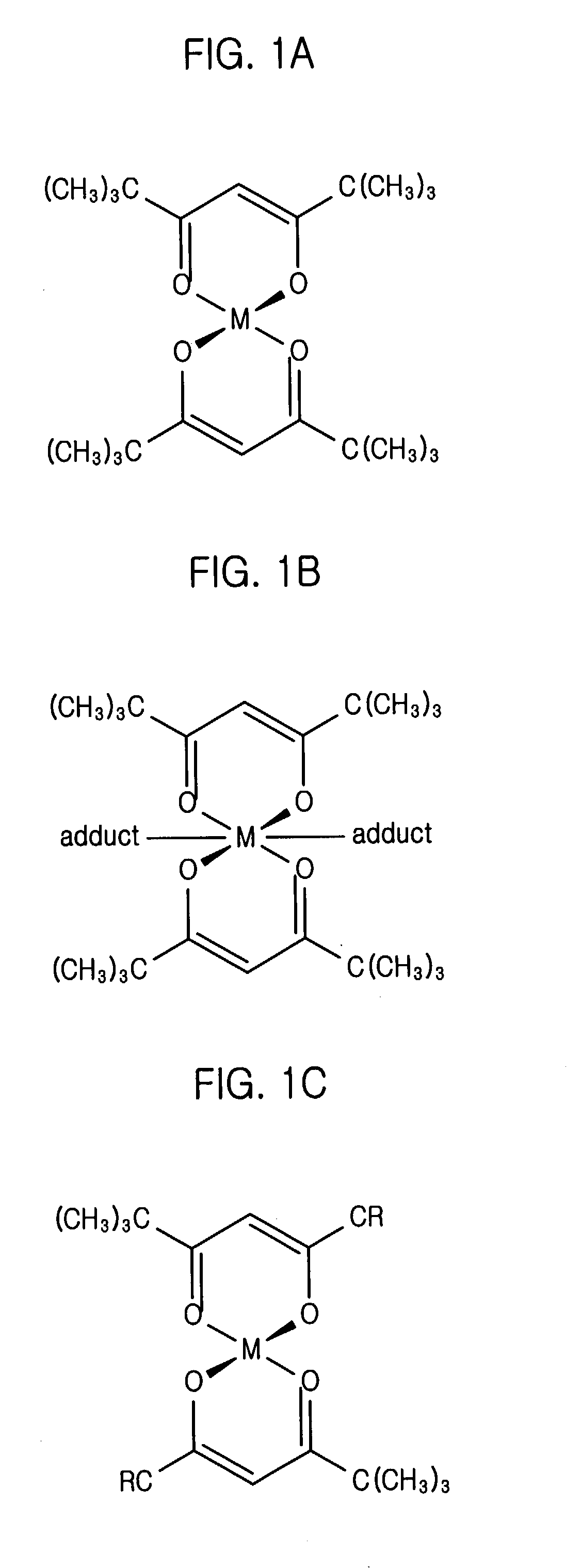

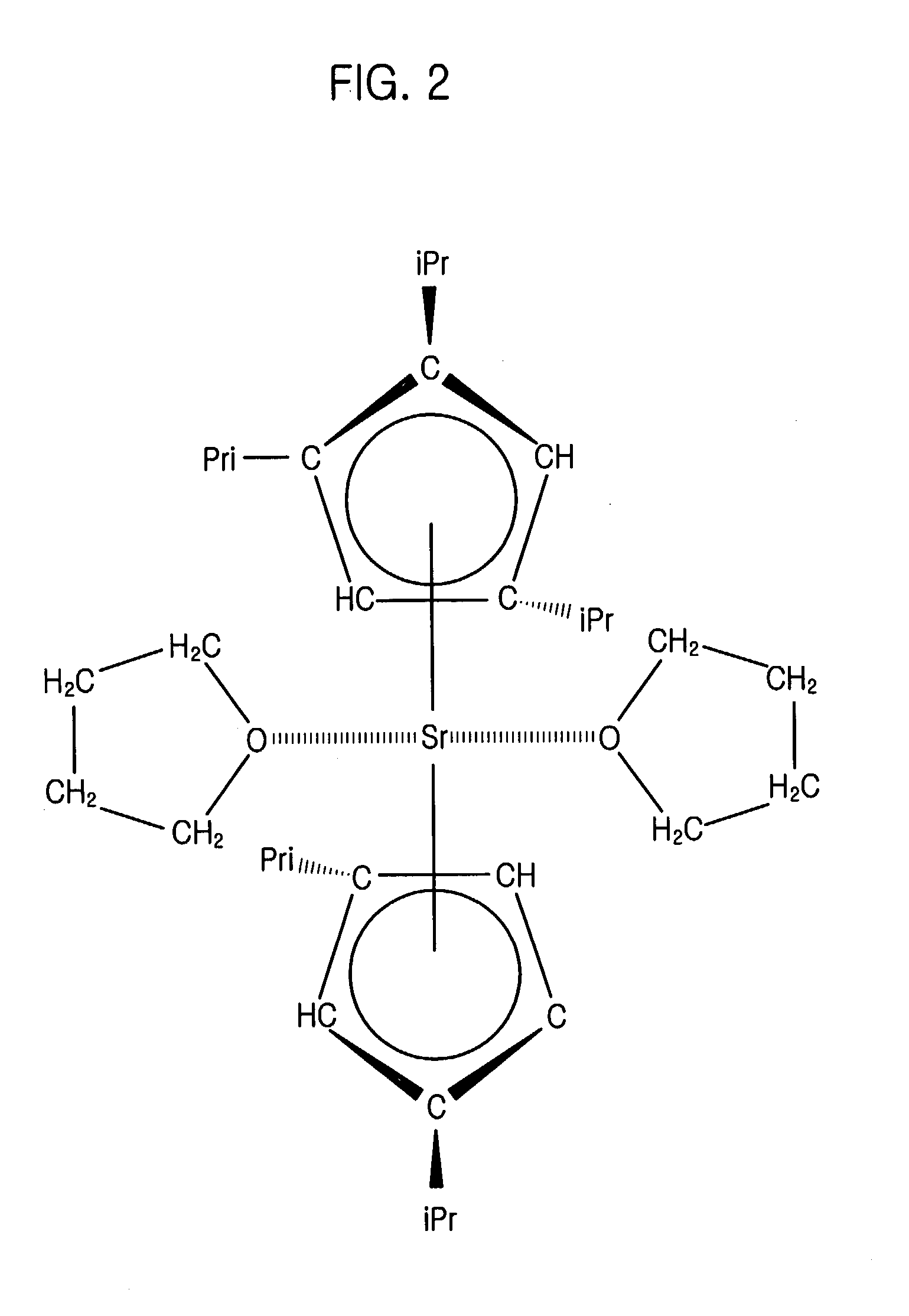

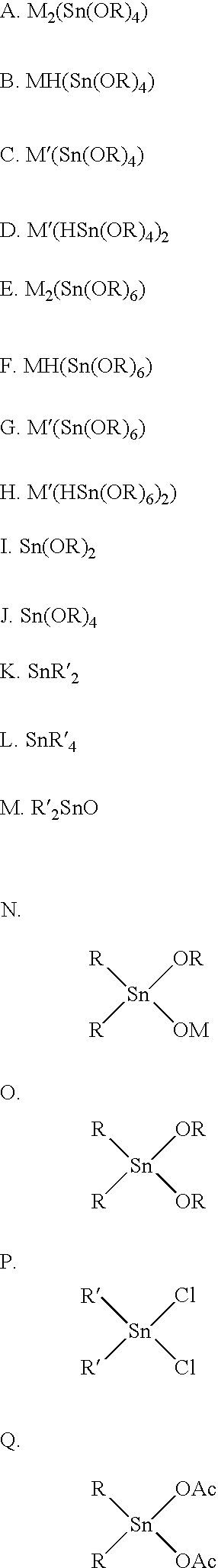

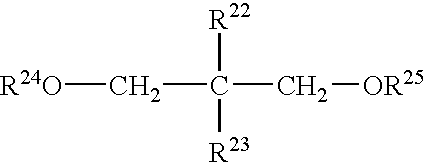

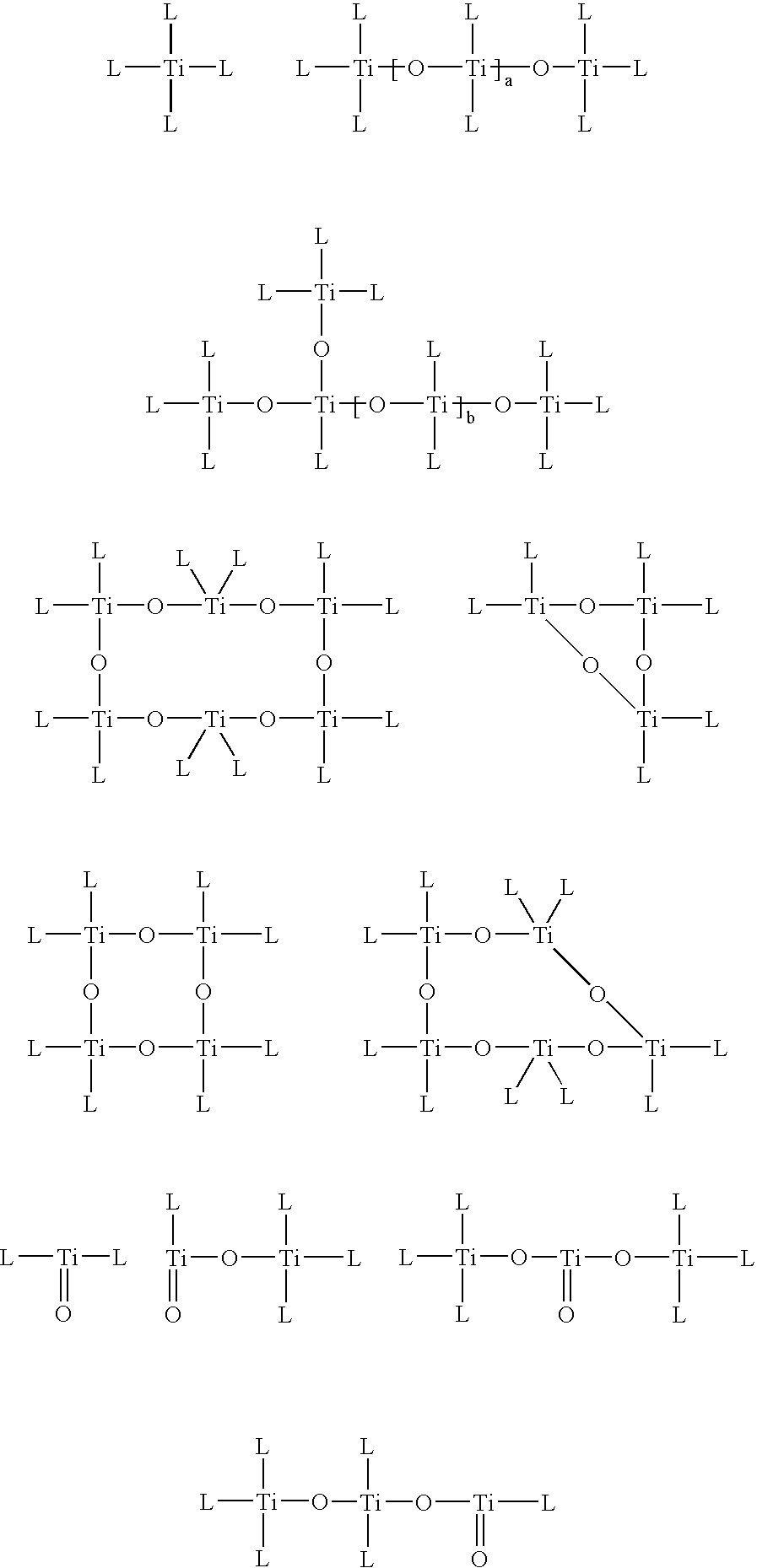

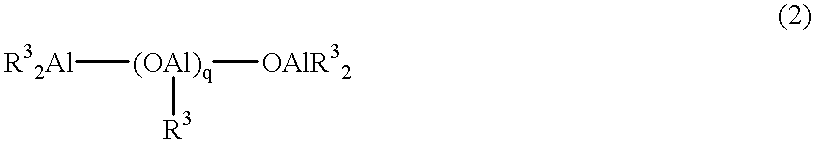

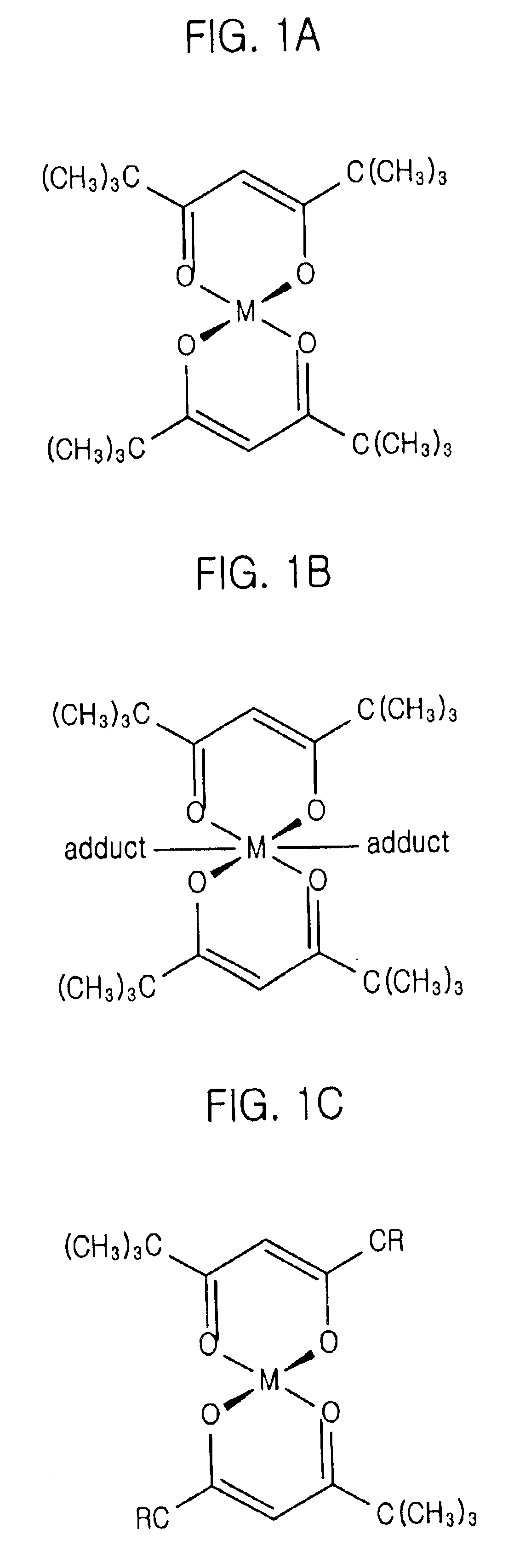

Catalysts and methods for polymerizing macrocyclic oligomers

Cyclic oligomers containing ester linkages are polymerized in the presence of a catalyst having at least one oxygen atom bonded to two metal atoms. At least one of the metal atoms is a tin atom, which is preferably tetravalent, i.e., bonded to three other groups in addition to the oxygen atom. The other metal atom may also be another tin atom, which is again preferably tetravalent, or a zinc, aluminum or titanium atom. The catalyst may contain multiple oxygen atoms that are bonded to two such metal atoms as described. These catalysts are active, efficient polymerization catalysts. They are often liquids at polymerization temperatures. The catalysts can be formed in situ in the polymerization process, which provides additional flexibility in the process and increased storage stability of starting materials.

Owner:DOW GLOBAL TECH LLC

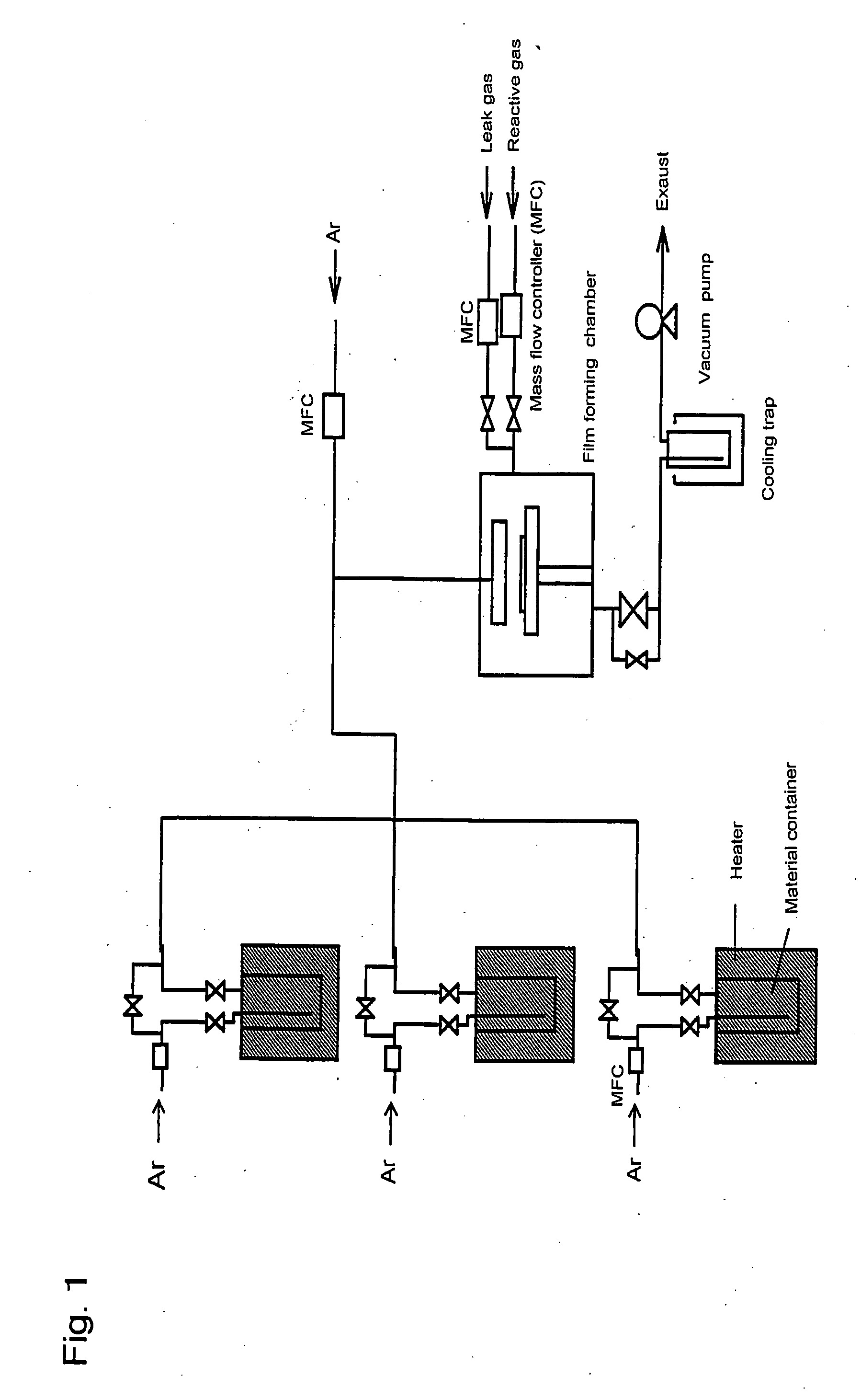

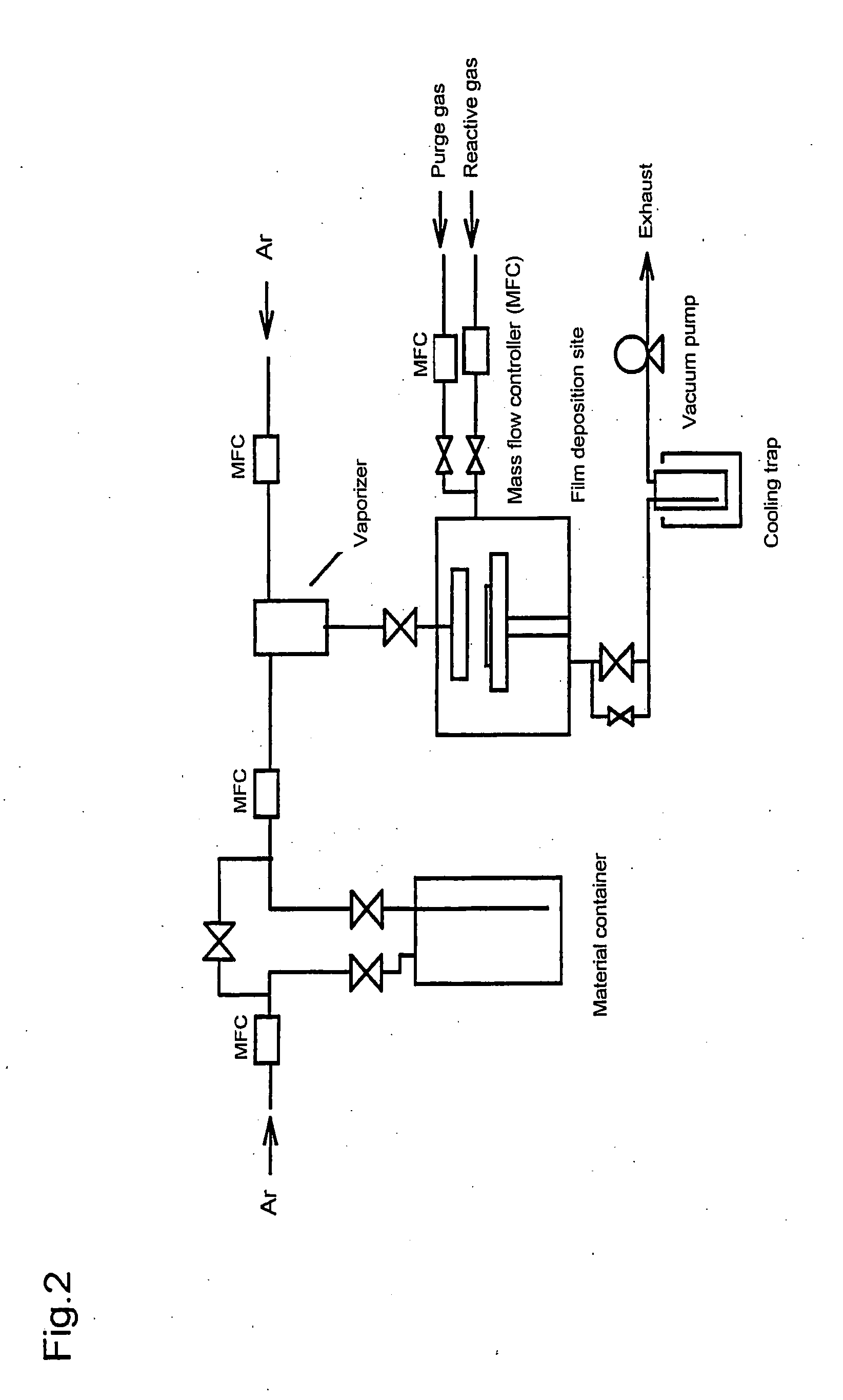

Preparation method of nitrogen-doped titanium oxide thin film

ActiveCN103160802AComplete structureImprove performanceChemical vapor deposition coatingChemical reactionNitrogen gas

The invention discloses a preparation method of nitrogen-doped titanium oxide thin film. The method comprises successively introducing titanium-containing gas into a reaction cavity to form silicon-titanium bonds; introducing nitrogen and hydrogen into an atomic layer deposition reaction chamber for plasma discharge, wherein part of nitrogen atoms generated by ionizing the nitrogen form covalent bonds with part of titanium atoms, and non-bonded electrons of the nitrogen atoms bond with ionized hydrogen atoms; introducing an oxygen-containing source into the atomic layer deposition reaction chamber to form titanium-oxygen bonds; and growing layer by layer the titanium oxide thin film containing the nitrogen atoms. The preparation method of the nitrogen-doped titanium oxide thin film provided by the invention utilizes a plasma atomic layer deposition device to dope nitrogen for the titanium dioxide thin film. By utilizing characteristics of monolayer cycle growth of atomic layer deposition and high chemical reactivity of the plasma, the titanium dioxide thin film can be uniformly doped with the nitrogen atoms in the whole thin film structure during a growth process, so that the doped thin film structure is complete, and significant in performance, and can effectively improve utilization rate of TiO2 for visible light.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Polyester resin and catalyst for polyester production, process for producing polyester resin with the catalyst, polyester resin obtained with the catalyst, and hollow molded container comprising the polyester resins

InactiveUS7300998B2Increase chanceProduced in advanceSynthetic resin layered productsDomestic footwearSolubilityProduction rate

The object of the present invention is to provide a high quality polyester resin having high productivity, stability and safety, a catalyst for polyester production with high catalytic activity, a method for producing the polyester resin with the catalyst, a polyester resin obtained with the catalyst, and a hollow molded container having the polyester resin. The polyester resin of the present invention satisfies specific parameters regarding polymerizability, stability, and metal content. The catalyst for polyester production satisfies specific parameters. The catalyst particularly preferably has: (a) a solid titanium-containing compound which has a maximum solubility in ethylene glycol of 1,000 ppm or more in terms of converted titanium amount when dissolved in ethylene glycol with heating at 150° C., and which has titanium, oxygen, carbon, and hydrogen, and optionally an alkali metal, and has a Ti—O—C bond; and (b) an alkali metal compound, the molar ratio of the alkali metal atoms to the titanium atom in the catalyst being in the range of 20 / 1 to 0.1 / 1.

Owner:MITSUI CHEM INC

Polyester polymerization catalyst and method for producing polyester using the same

ActiveUS20110178265A1Improve catalytic stabilityHigh activityTitanium organic compoundsMonocomponent polyesters artificial filamentPolyesterMannitol

Provided are a polyester polymerization catalyst with which the generation of foreign materials caused by the catalyst or mold pollution at the time of molding are reduced and polyesters having remarkably superior thermal stability and color tone can be obtained.Provided is a polyester polymerization catalyst produced by the reaction of a titanium compound and a mannitol in a molar ratio of titanium atom to mannitol of from 1:1 to 1:3. A method for producing a polyester employs the polyester polymerization catalyst.

Owner:TORAY IND INC

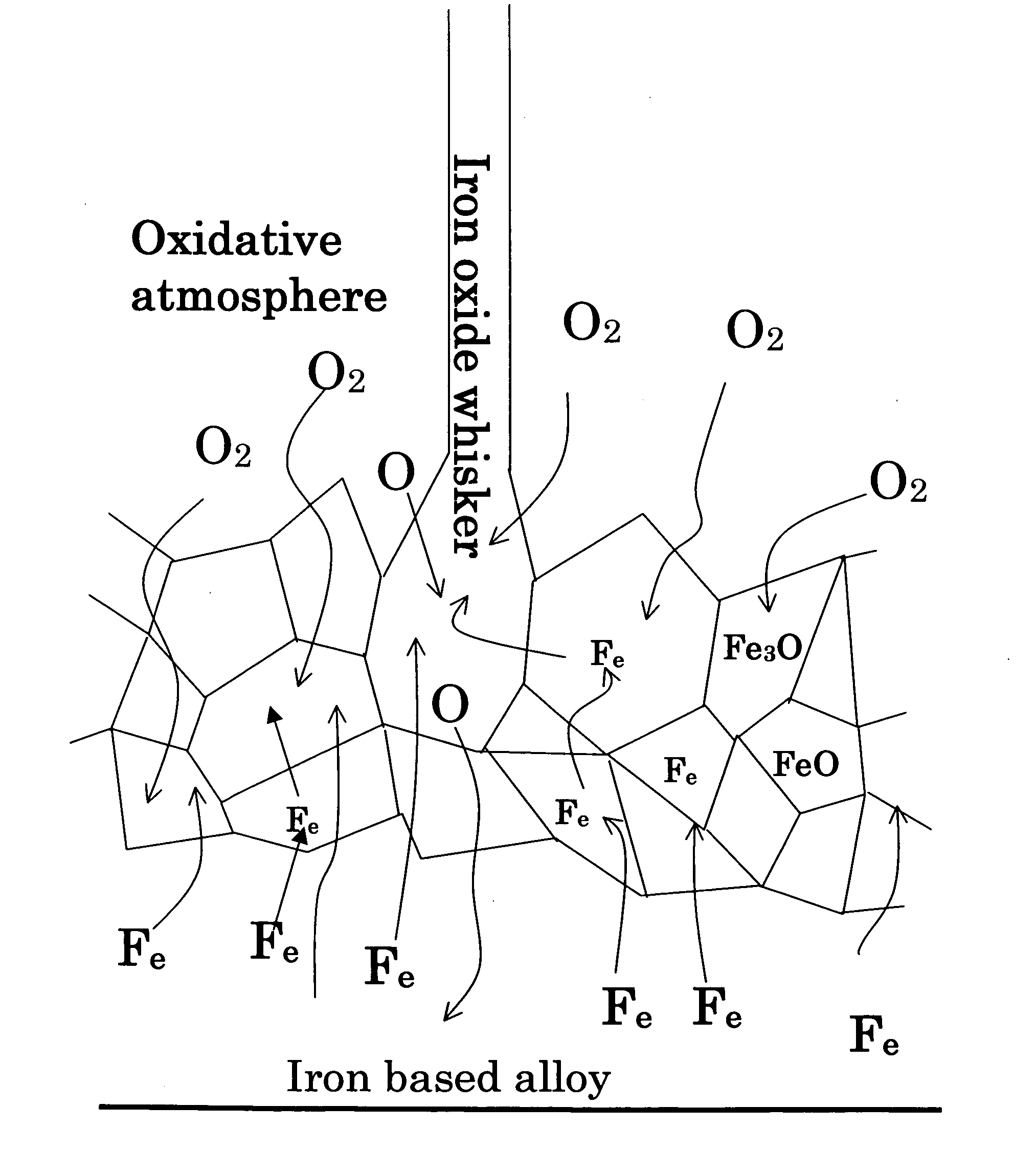

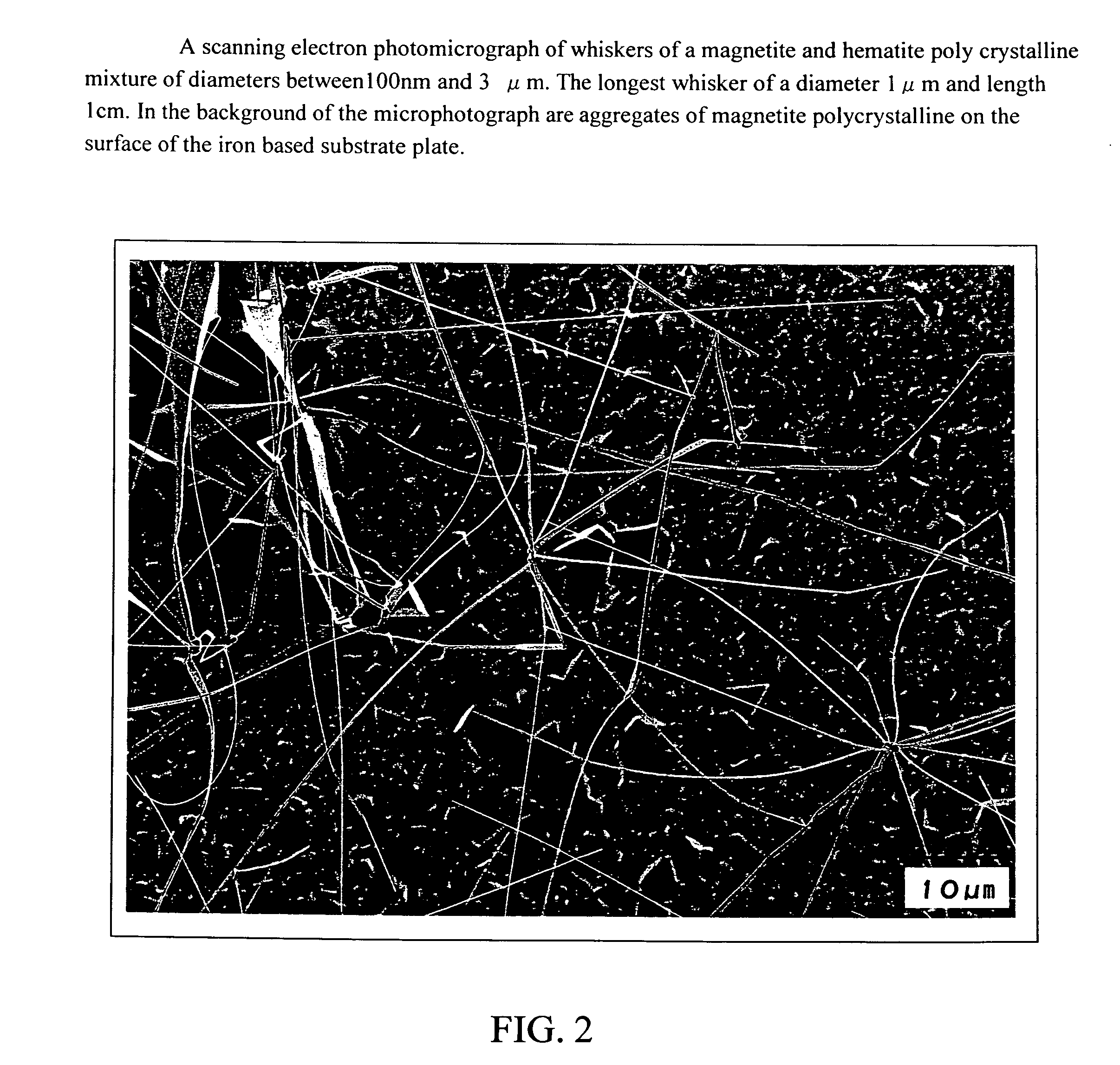

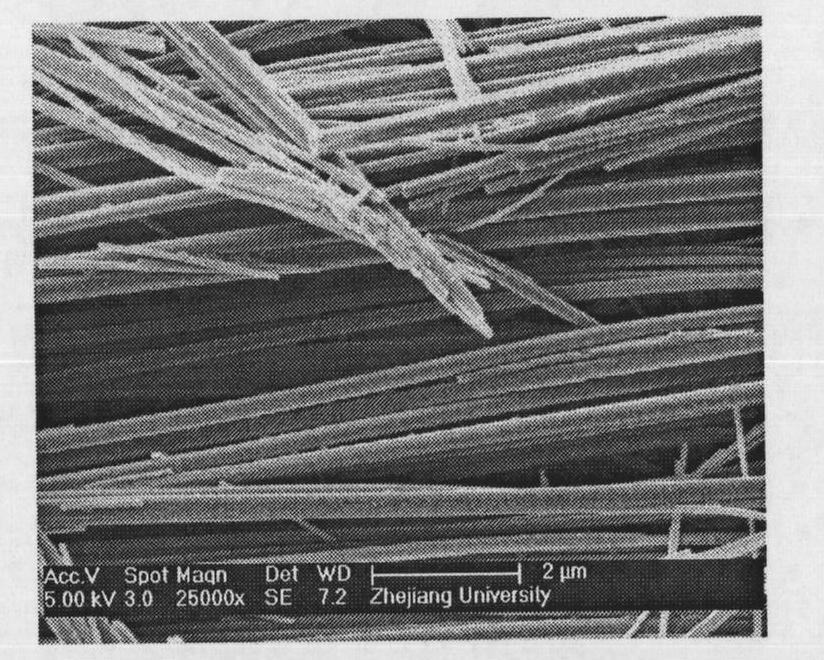

Iron Oxide Whisker of High Aspect Ratio, Titanium Oxide Whisker of High Aspect Ratio, Structure Containing These and Process for Producing Them

InactiveUS20070292339A1High aspect ratioImprove magnetic propertiesMaterial nanotechnologyPolycrystalline material growthTitanium metalWhiskers

An iron oxide whisker of high aspect ratio or titanium oxide whisker of high aspect ratio that is useful as a magnetic material for magnetic recording, a part of micromachine, etc.; and a structure having such a whisker erected on a basal plate that is useful as a catalyst, etc. There is provided an iron oxide whisker of 5 nm to 2 μm diameter and ≧20 aspect ratio wherein the content of non-iron metal atoms is ≦10 at %, and provided a titanium oxide whisker of 5 nm to 20 μm diameter and ≧5 aspect ratio wherein the content of non-titanium metal atoms is ≦10 at %. Further, there is provided a structure, such as a basal plate having these whiskers densely erected thereon. These whiskers excel in magnetic properties, etc., and the structures having these erected exert excellent characteristics, such as large contact area as a catalyst and freedom from clogging, and hence are useful. In the production of these oxide whiskers, an iron or titanium material is brought into contact with an oxidative atmosphere so as to react the surface iron or titanium atoms with oxygen brought into contact therewith at high temperature, thereby attaining growth as oxide whiskers.

Owner:KANAZAWA R & D

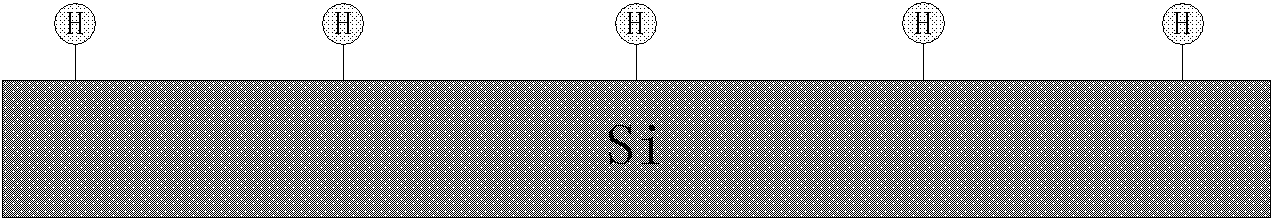

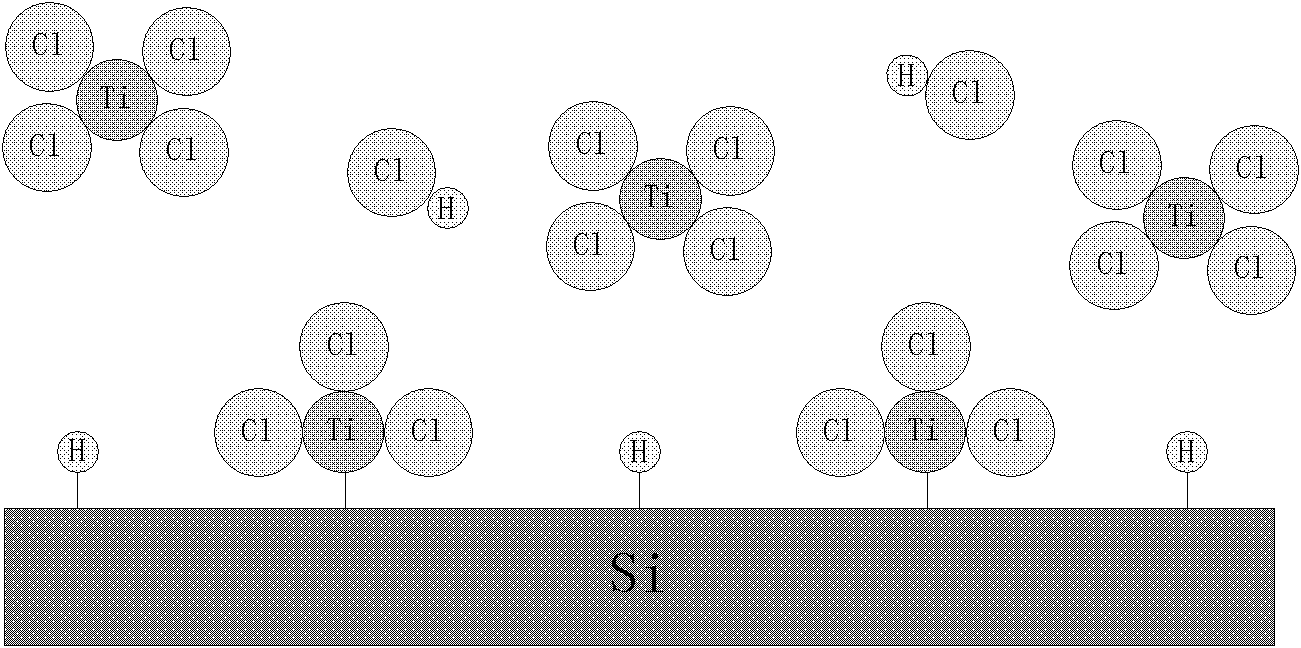

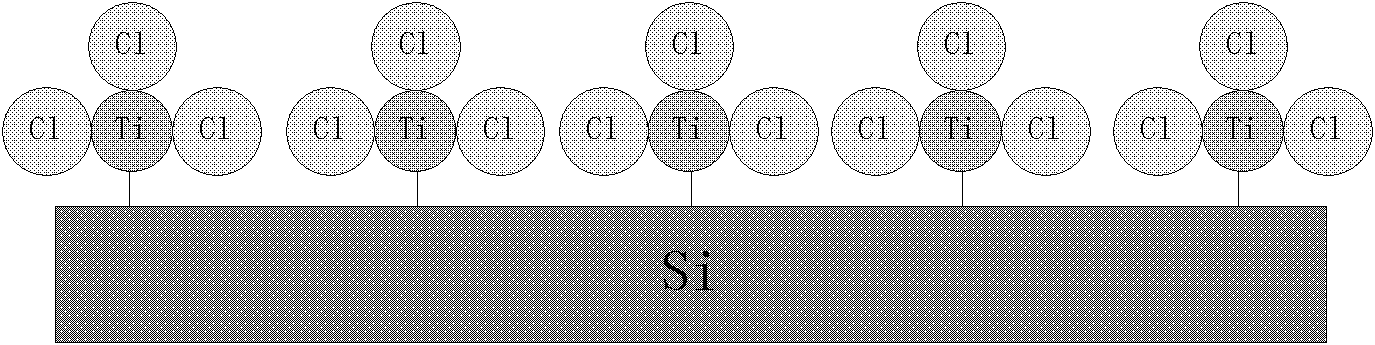

Nitrogen doped titanium dioxide film preparation method

The invention relates to the technical field of titanium dioxide preparation, and concretely relates to a nitrogen doped titanium dioxide film preparation method. The preparation method comprises the following steps: disposing a silicon substrate in the reaction chamber of an atomic layer deposition apparatus; letting a titanium source gas in the reaction chamber of the atomic layer deposition (ALD) apparatus by treating nitrogen as a carrying gas to make titanium atoms in the titanium source gas be adsorbed on the silicon substrate; letting nitrogen in the reaction chamber of the ALD apparatus, and carrying out plasma discharge for making parts of nitrogen atoms and parts of the titanium atoms form covalent bonds after nitrogen ionization; letting an oxygen-containing source in the reaction chamber of the ALD apparatus for making the titanium atoms unreacted with the nitrogen atoms and oxygen atoms in the oxygen-containing source form titanium-oxygen bonds; and repeating the above steps to grow the nitrogen atom-containing titanium dioxide film layer by layer. The preparation method which utilizes the ALD apparatus to carry out nitrogen doping of the titanium dioxide film has the advantages of realization of the uniform nitrogen doping in a whole structure, high nitrogen element content after nitrogen doping, and substantially increased film performances.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

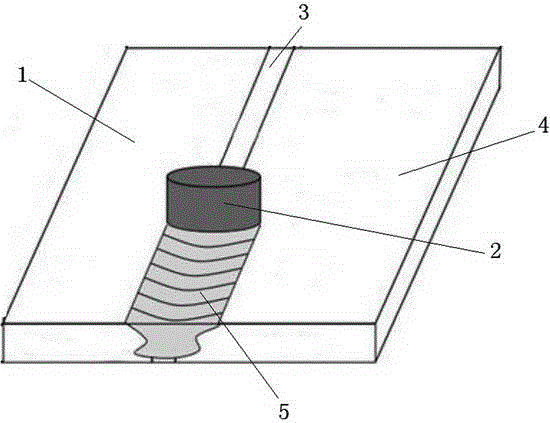

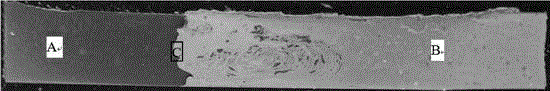

Method for adjusting and controlling brittle phase in titanium/aluminum dissimilar metal friction stir welding joint

ActiveCN104801848AImprove joint performanceImprove performanceWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingMetallic materials

The invention discloses a method for adjusting and controlling the brittle phase in a titanium / aluminum dissimilar metal friction stir welding joint. The method adopts the principle of introducing a third alloy element by adding a zinc-based intermediate layer to block the direct contact between titanium atom and aluminum atom, so as to disturb the generation of brittle phase in a Ti-Al system. The method comprises the following specific steps: mounting a self-made stirring head; clamping a workpiece to be welded and a zinc-based intermediate layer material, and laying the zinc-based intermediate layer material in a position butted with the workpiece to be welded; adjusting the position of the stirring head, so as to enable the stirring head to be in an initial position; setting welding technical parameters including the rotate speed of the stirring head, a welding speed, a welding dip angle and press amount; ensuring that a stirring pin is pressed into the workpiece under the technical parameters and moves in the direction parallel with the joint of the workpiece to be welded at the welding speed, and accomplishing the friction stir welding of the workpiece to be welded. The method realizes the adjustment and control of the brittle phase in the titanium / aluminum dissimilar metal friction stir welding joint, and effectively improves the performance of the welding joint.

Owner:NANCHANG HANGKONG UNIVERSITY

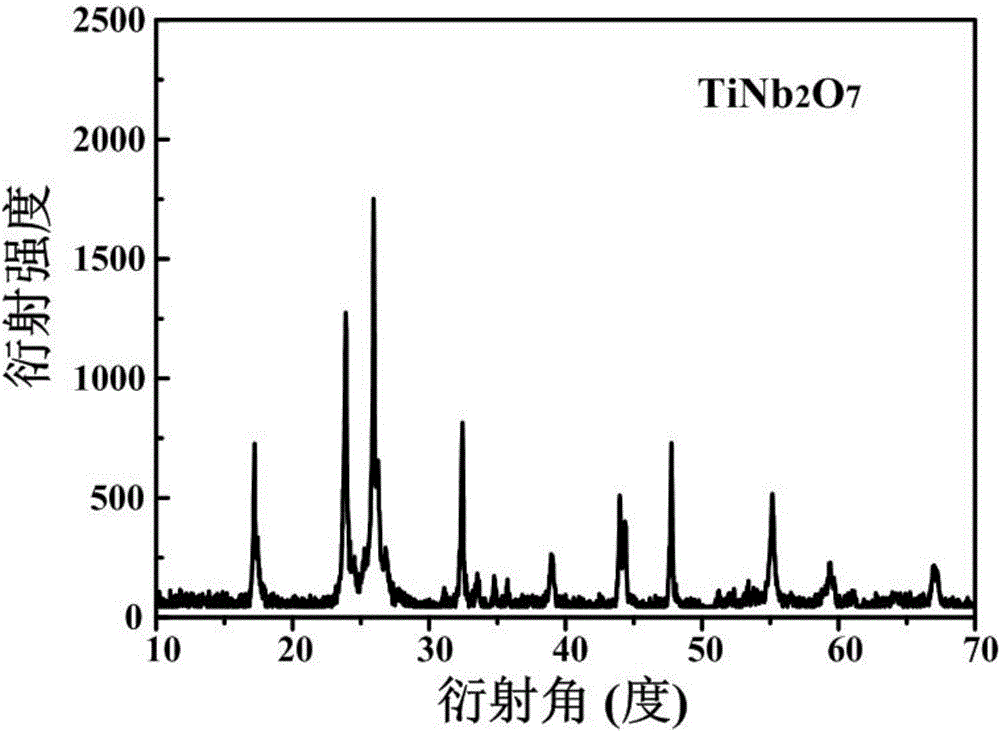

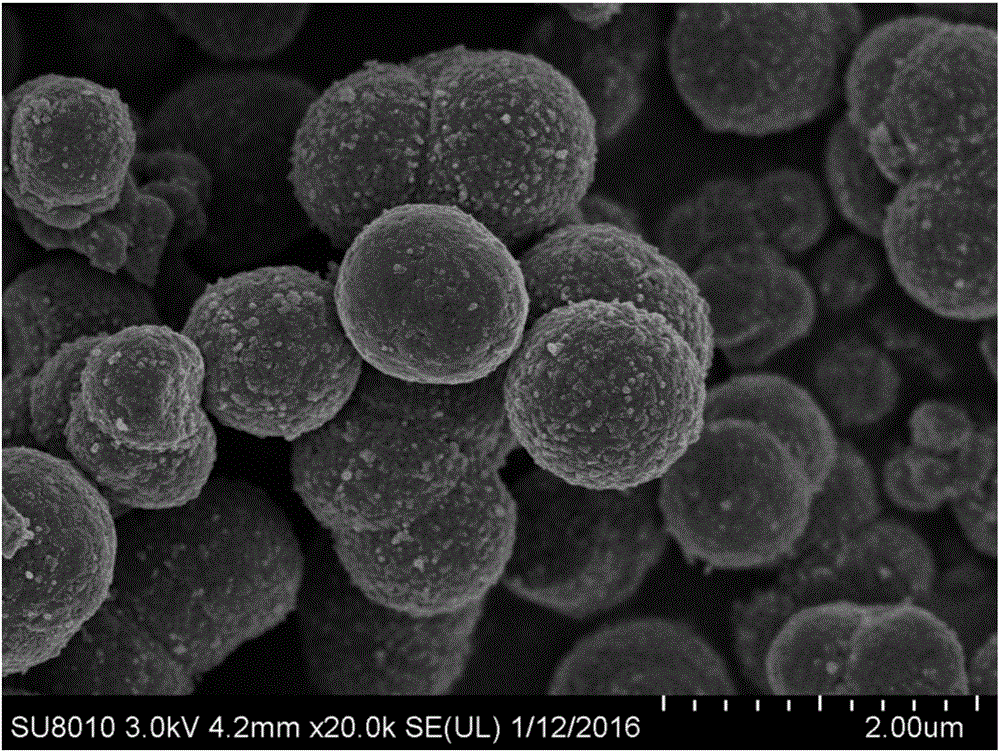

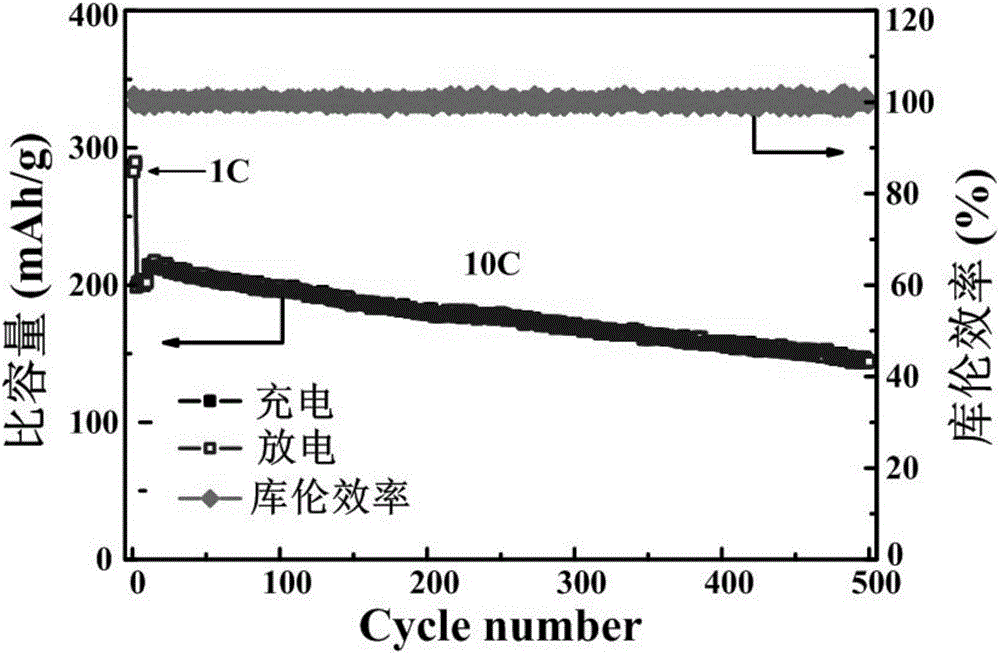

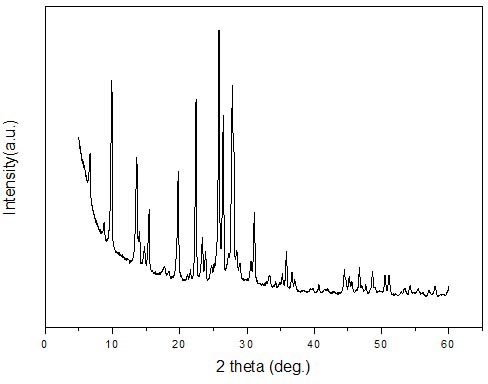

Spherical titanium niobate electrode material and preparation method thereof

The invention discloses a preparation method of a spherical titanium niobate electrode material. The preparation method comprises the following steps that a niobium source and a titanium source are dissolved in a certain amount of organic solvent, and mixing is carried out to obtain a mixed solution, wherein the concentration of niobium in the mixed solution ranges from 0.02 mol / L to 7.8 mol / L, and the ratio of niobium atoms to titanium atoms is 1.6:1 to 2.5:1; the obtained solution is contained in a reaction still, heating and reacting are carried out in a constant-temperature drying box at preset heating temperature, then natural cooling is carried out to reach room temperature, and sediment is obtained; the obtained sediment is washed with deionized water and ethyl alcohol many times, and vacuum drying is carried out at preset drying temperature to obtain powder; the obtained powder is calcined at preset calcining temperature, and the spherical titanium niobate electrode material is obtained. The invention further discloses the spherical titanium niobate electrode material.

Owner:NANYANG NORMAL UNIV

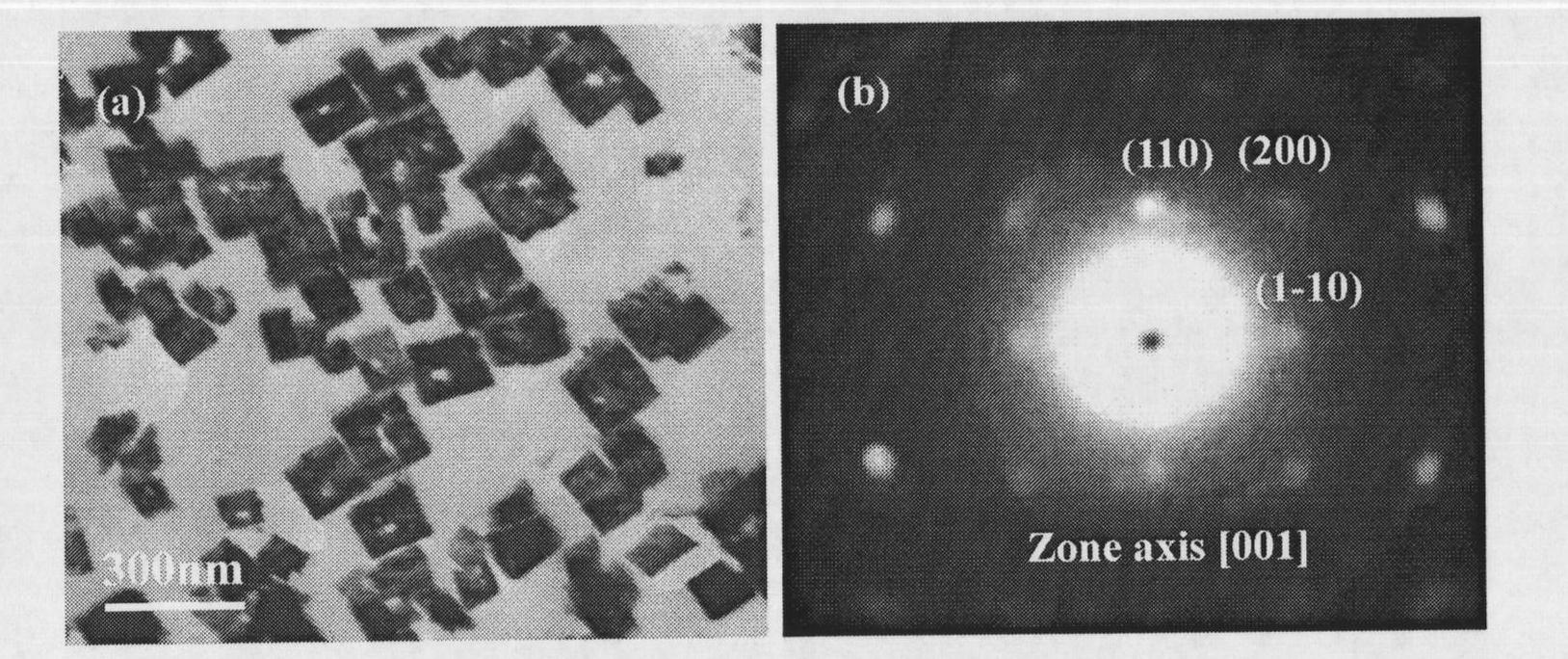

Method for raising efficiency of battery prepared from dye sensitized TiO2 Nano crystal

InactiveCN1540772AChange surface stateIncrease the ratio of chemical bonding adsorptionLight-sensitive devicesFinal product manufactureChemical adsorptionOpto electronic

TiO2 Nano grains with size less than and equal to 2nm are formed on surface of TiO2 Nano grain with size larger than 10 nm through chemical deposition method, thus surface state of TiO2 Nano grain is changed. Number of unsaturated titanium atoms is much more than number of TiO2 Nano grain with large size. The said changed surface state of TiO2 Nano grain possesses better characteristic of chemical adsorption so as to increase proportion of chemical adsorption of dye molecule on surface of Nano crystal. Result is to raise opto-electronic conversion efficiency of battery of TiO2 Nano crystal.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for manufacturing a memory device having a nanocrystal charge storage region

ActiveUS7335594B1NanoinformaticsSemiconductor/solid-state device manufacturingMaterials scienceAbsorption layer

A method for manufacturing a memory device having a metal nanocrystal charge storage structure. A substrate is provided and a first layer of dielectric material is grown on the substrate. An absorption layer is formed on the first layer of dielectric material. The absorption layer includes a plurality of titanium atoms bonded to the first layer of dielectric material, a nitrogen atom bonded to each titanium atom, and at least one ligand bonded to the nitrogen atom. The at least one ligand is removed from the nitrogen atoms to form nucleation centers. A metal such as tungsten is bonded to the nucleation centers to form metallic islands. A dielectric material is formed on the nucleation centers and annealed to form a nanocrystal layer. A control oxide is formed over the nanocrystal layer and a gate electrode is formed on the control oxide.

Owner:SPANSION LLC

Method for preparing two-way memory nickel-titanium alloy for artificial sphincters through rapid solidification

ActiveCN103409663ASimple preparation processImprove performanceLigamentsMusclesTitanium alloyVacuum arc

The invention discloses a method for preparing a two-way memory nickel-titanium alloy for artificial sphincters through rapid solidification. The method comprises the following steps of: weighing high-purity nickel and high-purity titanium which are used as raw materials according to the condition that the atomic ratio of nickel atoms to titanium atoms is 51:49; putting and smelting the raw materials a nonconsumable vacuum arc smelting furnace, absorbing molten metal into a copper die cavity by virtue of a negative-pressure suction casting method carried out by a water-cooled copper die, and carrying out rapid solidification, thereby obtaining a material in the required shape; homogenizing the material; fixing the treated material in a semicircular die with curvature radius, deforming the material under constraint of the die to correspond to the curvature of the die, putting the material together with the die into a resistance furnace to undergo constraint aging at 350-500 DEG C which is maintained for 10-100 hours and quenching the material and the die in water, thus preparing the two-way memory nickel-titanium alloy material for the artificial sphincters. The two-way memory nickel-titanium alloy material has narrow temperature zone response, has a straight shape at normal temperatures of human bodies and has bigger deformation curvature after temperature raising, thus being suitable for serving as the function material of the artificial sphincters.

Owner:SOUTH CHINA UNIV OF TECH

Biaxially oriented polyester film for backsheet of solar batteries

ActiveUS20130012665A1Improve hydrolysis resistanceLow hazeThin material handlingPhotovoltaic energy generationPolyesterEnd-group

The present invention provides a biaxially oriented polyester film for a backsheet of solar batteries which exhibits a good hydrolysis resistance and a low haze. The present invention relates to a biaxially oriented polyester film for a backsheet of solar batteries, comprising titanium in an amount of not more than 20 ppm in terms of a titanium atom, phosphorus in an amount of not more than 70 ppm in terms of a phosphorus atom, and antimony in an amount of not more than 10 ppm in terms of an antimony atom; and having a carboxyl end group content of not more than 26 equivalents / t and an intrinsic viscosity of 0.65 to 0.90.

Owner:MITSUBISHI CHEM CORP

Preparation method of titanium-containing nano-mordenite molecular sieve

InactiveCN102674389AHigh titanium contentEasy to synthesizeNanotechnologyMordenite aluminosilicate zeoliteSynthesis methodsMordenite

The invention discloses a synthesis method of a titanium-containing nano-mordenite molecular sieve, comprising the following steps of: firstly, dissolving an aluminum source in sodium hydroxide solution, adding a silicon source, stirring by strong magnetic force at room temperature for evenly dispersing, mixing the evenly-dispersed silicon source and aluminum source solution to prepare glue at room temperature, adding the mordenite molecular sieve serving as a seed crystal, quickly adding Ti-containing micromolecule organic amine solution into the mixed solution, stirring by strong magnetic force at room temperature for evenly dispersing, transferring into a reaction crystallization kettle, carrying out crystallization reaction at 150-170DEG C for 0.5-3d, and carrying out conventional leaching, washing and drying operations to obtain a solid product. The synthesis method has the characteristic that the titanium atom is led into a micropore skeleton in the manner of quadridentate and high dispersion by using hydro-thermal synthesis, the micromolecule organic amine serving as the chelant of impurity metal titanium atom, and the one-step method is used, so that the obtained titanium-containing nano-mordenite molecular sieve is high in crystallinity and purity, controllable in particle size and shape and low in cost, and causes little environment pollution, thereby being convenient for the large-scale industrial production.

Owner:EAST CHINA NORMAL UNIV

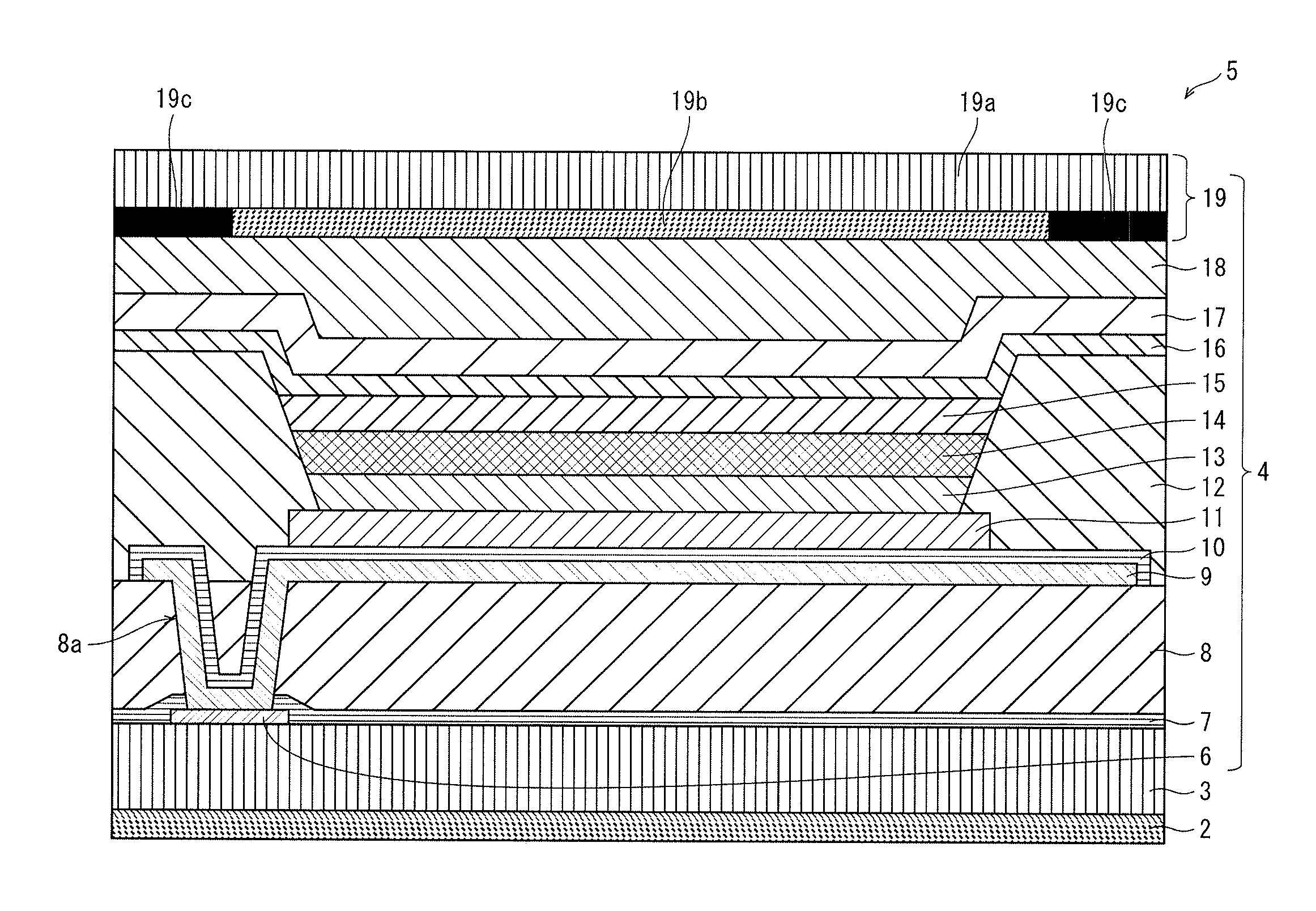

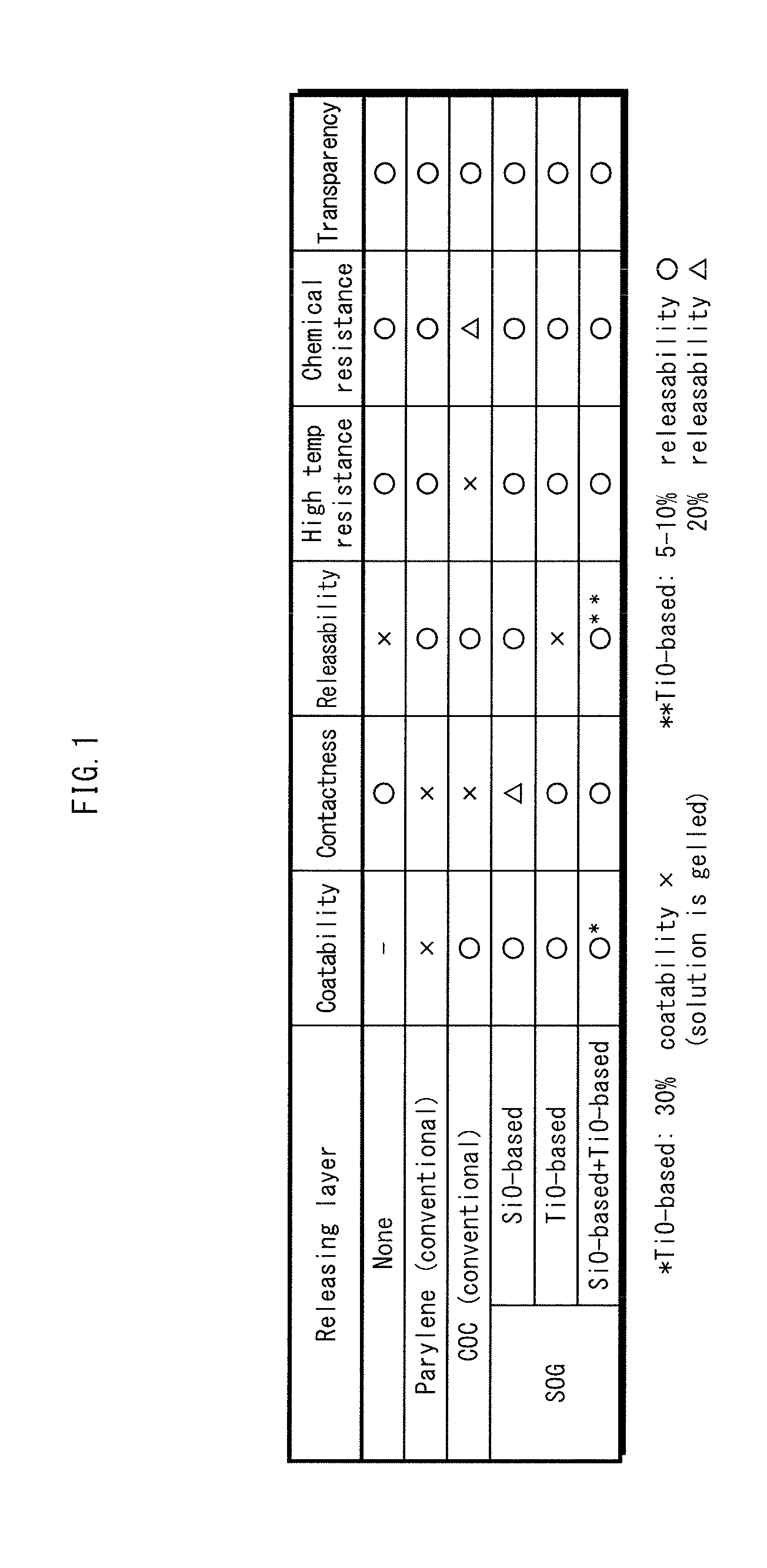

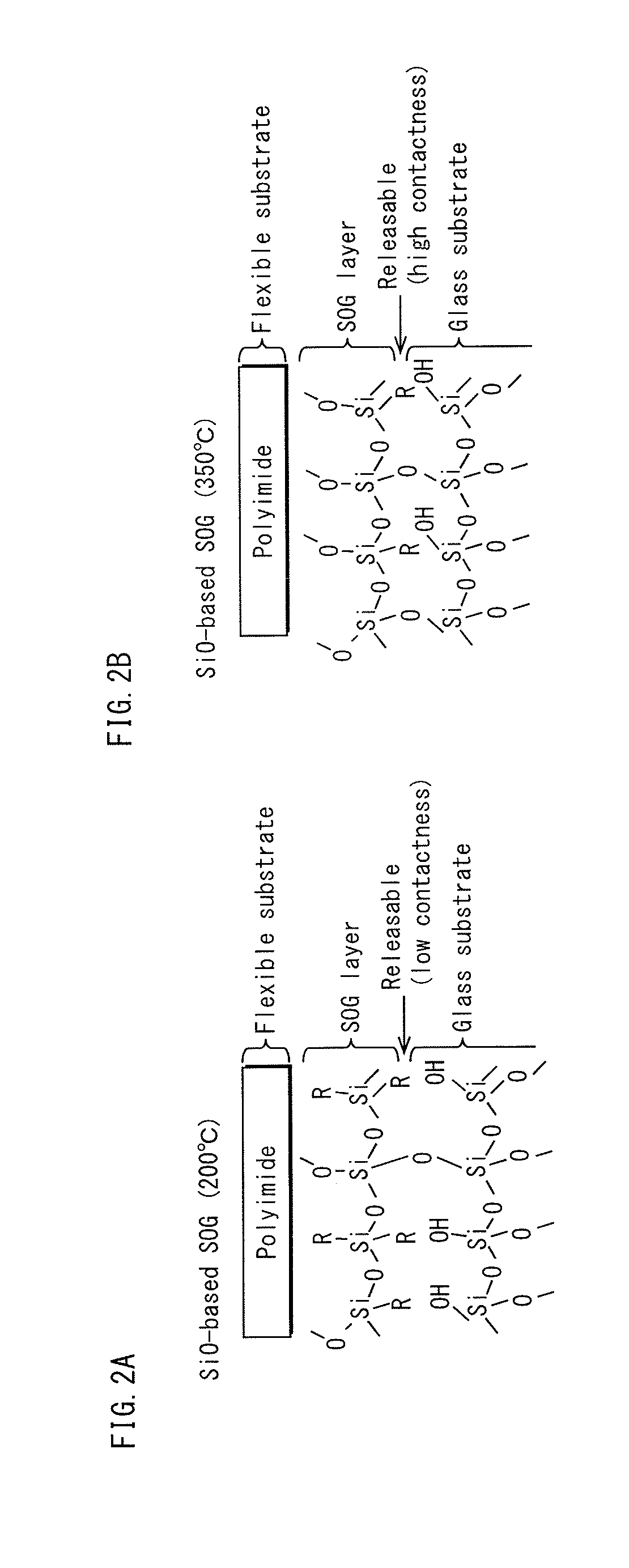

Flexible device manufacturing method and flexible device

ActiveUS20140070203A1Improve balanceFinal product manufactureElectroluminescent light sourcesEngineeringSilicon

Flexible device manufacturing method including: forming thin film by coating surface of support with predetermined solution in state where hydroxyl groups are present on surface; forming releasing layer by baking thin film; forming flexible substrate on releasing layer; forming device on flexible substrate; and releasing releasing layer, flexible substrate and device from support at interface between support and releasing layer. Predetermined solution contains alkylsilane alkoxide derivative and titanium alkoxide derivative. Baking temperature for baking thin film is at least 200° C. and at most 350° C. Ratio of number of silicon atoms in alkylsilane alkoxide derivative to number of titanium atoms in titanium alkoxide derivative is 3.3:1 to 4.1:1 when baking temperature is at least 200° C. and less than 270° C., 3.3:1 to 23:1 when baking temperature is at least 270° C. and at most 330° C., and 19:1 to 23:1 when baking temperature is more than 330° C. and at most 350° C.

Owner:SAMSUNG DISPLAY CO LTD

Lead titanate nanotube with one-dimensional crystal structure and preparation method thereof

InactiveCN101830499AHigh purityGood crystal stabilityNanostructure manufactureTitanium compoundsSpace groupOxygen

The invention discloses a lead titanate nanotube with a one-dimensional crystal structure, which has the characteristics as follows: (a) a space group is I4 / m; (b) cell parameters show that each PbTiO3 unit cell is composed of forty atoms, wherein, Pb:Ti:O=1:1:3; and (c) x, y, and z space positions of a lead atom, a titanium atom and an oxygen atom in each unit cell are respectively as follows: Pb (0.165, 0.151 and 0.5), Ti (0.471, 0.142 and 0.5), O1 (0.605, 0.028 and 0.5), O2 (0.169, 0.289 and 0.0) and O3 (0.543, 0.260 and 0.5). The lead titanate nanotube prepared by a hydrothermal method has the one-dimensional crystal structure, high purity, good crystallization stability and good dispersibility, and has wide application prospect in the fields such as microelectronic devices, drivers, sensors and the like. The preparation method of the invention has simple equipment, easy control of process conditions, low cost and easy industrialized production.

Owner:ZHEJIANG UNIV

Polybutylene Terephthalate Pellet, Compound Product and Molded Product Using the Same, and Processes for Producing the Compound Product and Molded Product

InactiveUS20070265382A1Excellent in color toneImprove hydrolysis resistanceConductive materialNon-conductive material with dispersed conductive materialPolytetramethylene terephthalateTetrachloroethane

An object of the present invention is to provide a polybutylene terephthalate pellet capable of producing a molded product which is excellent in color tone, hydrolysis resistance, transparency and molding stability, and has a less content of impurities. A polybutylene terephthalate pellet comprises polybutylene terephthalate containing titanium in an amount of not more than 90 ppm by weight, as calculated as titanium atom, and having an end methoxycarbonyl group concentration of not more than 0.5 μeq / g, wherein said pellet has an average intrinsic viscosity of 0.90 to 2.00 dL / g and a difference in intrinsic viscosity between a central portion and a surface layer portion of the pellet is not more than 0.10 dL / g. As preferred embodiments, there is exemplified a polybutylene terephthalate pellet having an end carboxyl concentration of 10 to 25 μeq / g, an end vinyl concentration of 0.1 to 10 μeq / g, and an solution haze of not more than 5%, when measured as a turbidity value of a solution prepared by dissolving 2.7 g of polybutylene terephthalate in 20 mL of a mixed solution containing phenol and tetrachloroethane at a weight ratio of 3:2.

Owner:MITSUBISHI CHEM CORP

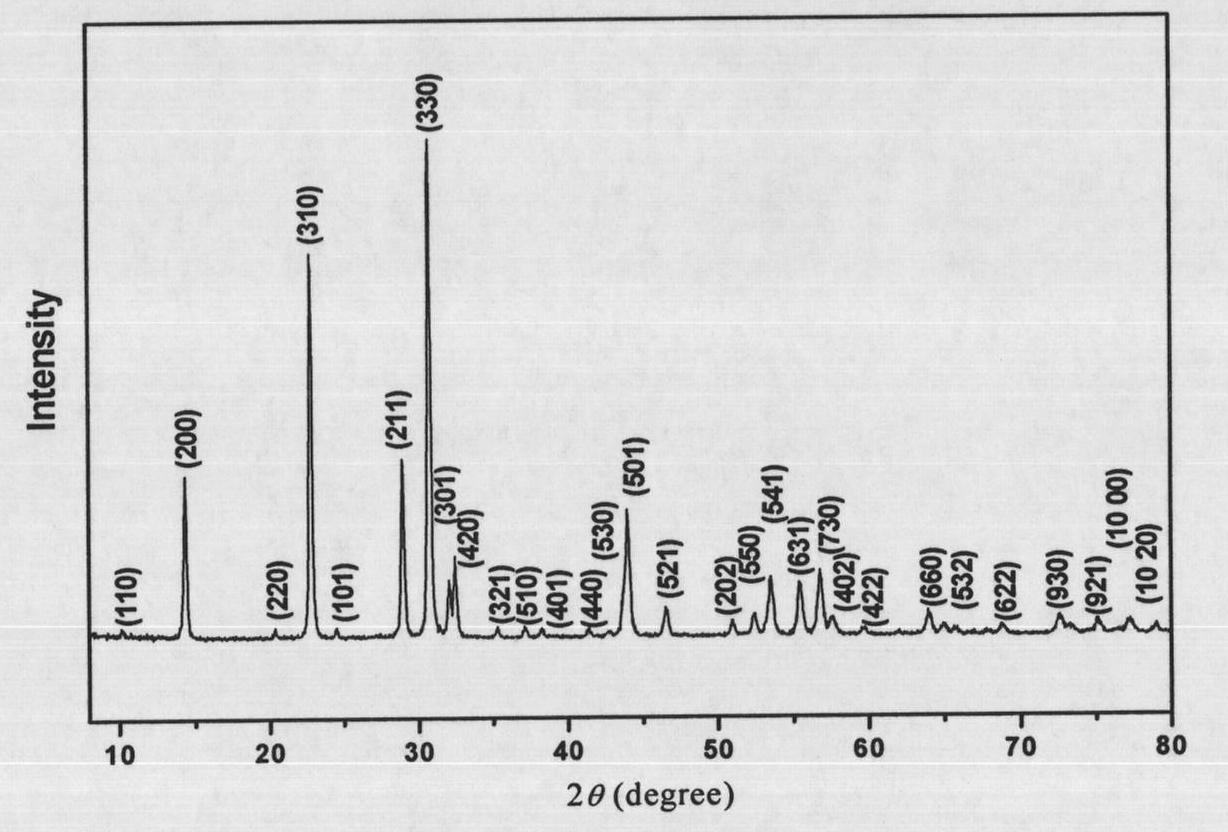

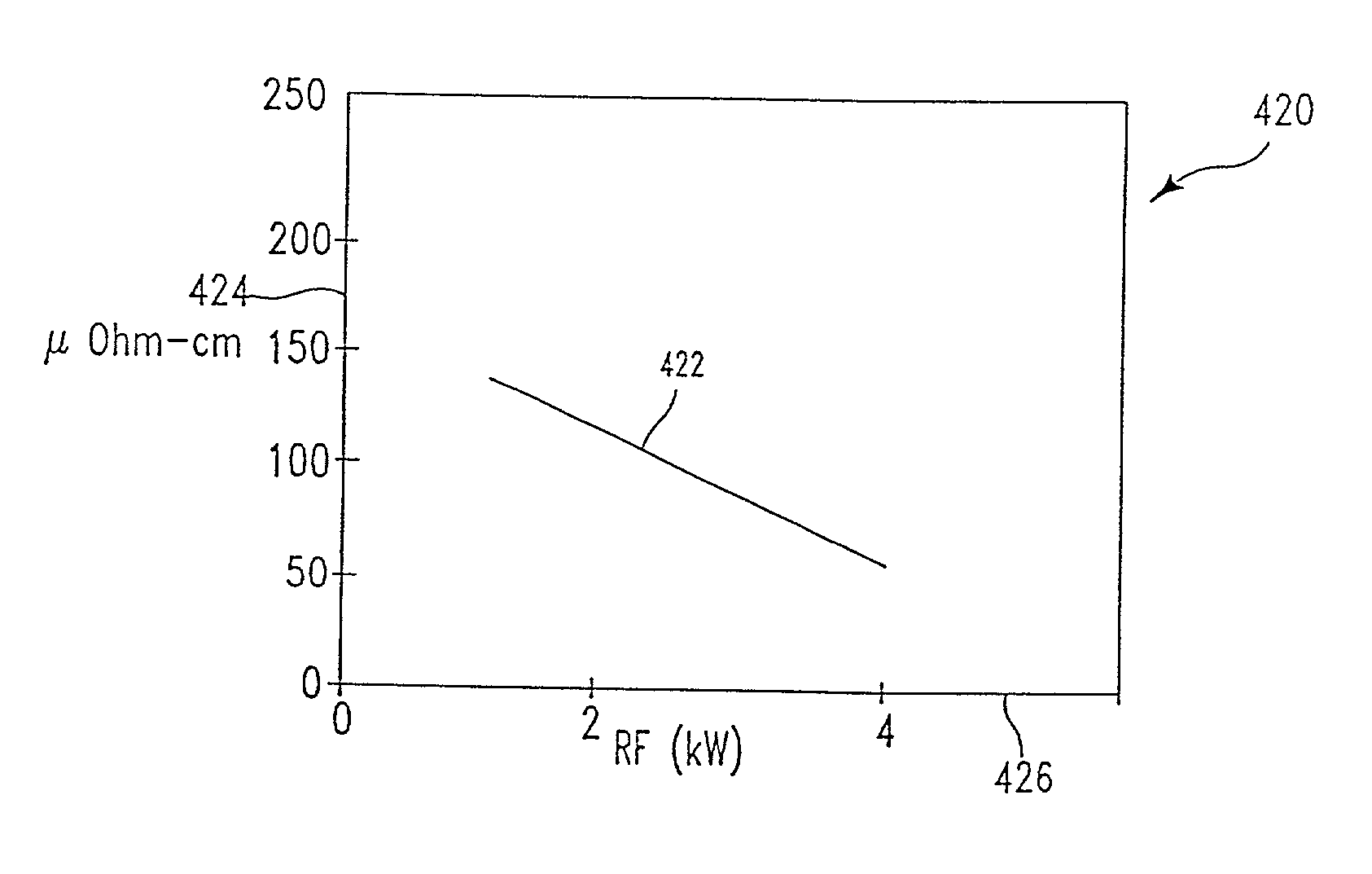

Method of producing smooth titanium nitride films having low resistivity

InactiveUS20020125123A1Layered productsSemiconductor/solid-state device detailsTitanium nitrideCrystal orientation

The resistivity of titanium nitride films is reduced, by about 40% (to less than about 60 muOhm-cm), for example; and, the film surface roughness is reduced, by about 45% (to less than 6 Å) by using a combination of particular process conditions during deposition of the film. In particular, titanium atoms produced by impact of inert gas ions upon a titanium target travel through a high density, inductively coupled rf plasma, an ion metal plasma (IMP), in which the titanium atoms are at least partially ionized. The ionized titanium ions are contacted with ionized nitrogen atoms also present in the processing chamber. The resultant gas phase composition is contacted with the surface of a semiconductor substrate on which a titanium nitride barrier layer is to be deposited. By controlling the gas phase deposition mixture composition, the quantity of the deposition mixture contacting the substrate surface over a given time period, and the pressure in the process vessel, the resistivity and surface roughness of the titanium nitride layer is adjusted. The resistivity of the titanium nitride barrier layer is principally determined by the crystal orientation of the titanium nitride. The more nearly the crystal orientation approaches 100% of the {200} orientation (the lower the percentage of {111} orientation), the lower the film resistivity. Crystal orientation is obtained by increasing the ionized content of the deposition mixture and by slowing the rate of deposition of the titanium nitride film (barrier layer). The surface roughness of the titanium nitride layer is reduced principally by reducing the pressure in the process vessel, which affects the film formation dynamics. An increase in ionized content of the deposition mixture helps reduce surface roughness until an inflection point is reached, after which surface roughness increases with increased ionized content.

Owner:NGAN KENNY KING TAI +1

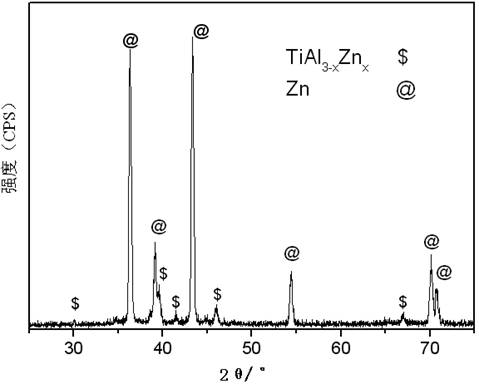

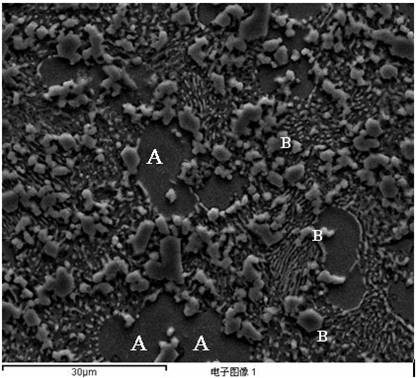

Zinc-aluminum-titanium master alloy and preparation method thereof

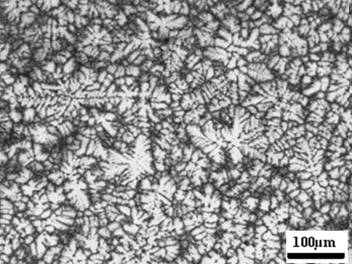

The invention discloses a Zn-Al-Ti intermediate alloy comprising the following ingredients in percentage by weight: 2.94-40wt% of Al, 4-16wt% of Ti and the balance of Zn. The invention also discloses a preparation method of the intermediate alloy. After the prepared Zn-Al-Ti intermediate alloy is added into Zn-Al alloy to be refined, TiAl3-xZnx particles can directly serve as a nucleation core inthe primary alpha-Al crystal grain crystallization process in the Zn-Al alloy so as to achieve the purpose of refining the crystal grain. In addition, parts of TiAl3-xZnx particles are melted to release titanium atoms; and the primary alpha-Al crystal grain is refined by composition undercooling action. The preparation method disclosed by the invention is simple, the obtained intermediate alloy has efficient crystal grain refining action, and the alpha-Al crystal grain after Zn-Al alloy is solidified can be obviously refined.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com