Preparation method of nitrogen-doped titanium oxide thin film

A technology of titanium dioxide and thin film, which is applied in the field of preparation of nitrogen-doped titanium dioxide thin film, which can solve the problems of low photon quantum efficiency, impossibility of doping state, precise control of component distribution, etc., and achieve the effect of improved utilization rate, remarkable performance and complete film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of nitrogen-doped titanium dioxide film provided by the present invention comprises:

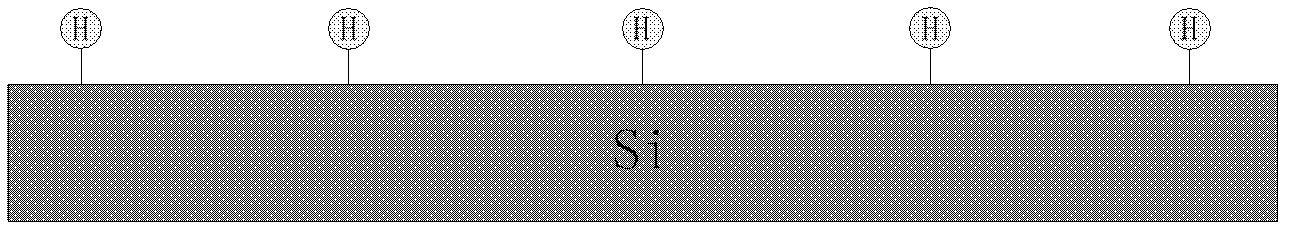

[0030] Step S1: if figure 1 As shown, the silicon-hydrogen bond is formed on the surface of the silicon wafer substrate by treating the surface of the silicon wafer substrate with standard solution and hydrofluoric acid. The standard solution used in this example is prepared by boiling sulfuric acid and hydrogen peroxide at a ratio of 5:100 for 5 minutes.

[0031] Step S2: placing the hydrogenated silicon wafer substrate in the reaction chamber of the atomic layer deposition equipment.

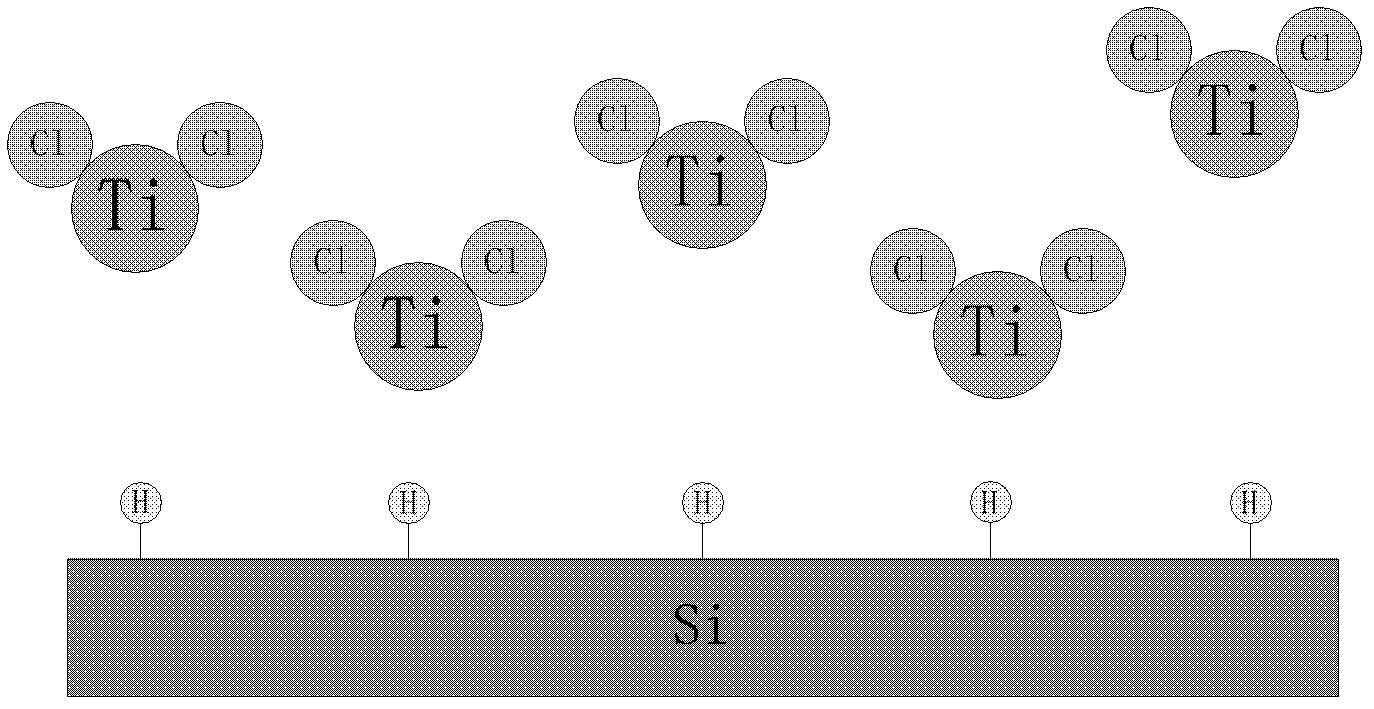

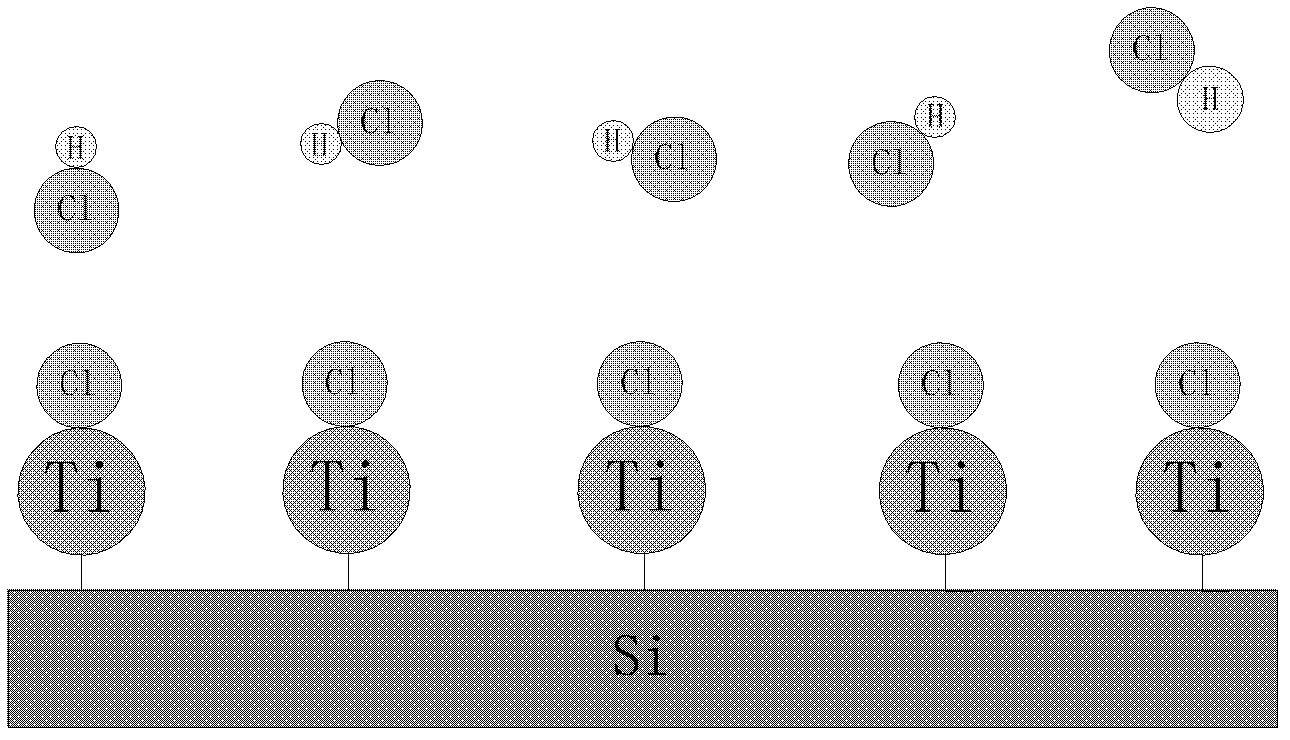

[0032] Step S3: Turn on the device, adjust the working parameters, and achieve the required working conditions for the experiment. combine figure 2 , image 3 As shown, the titanium-containing source gas is introduced into the reaction chamber of the plasma atomic layer deposition equipment, and the titanium atoms in the titanium-containing source gas are adsorbed on ...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that when nitrogen is used as the carrier gas to transport hydrogen gas into the reaction chamber of the atomic layer deposition equipment, the flow rate of nitrogen gas is 1 sccm, the intake time is 0.1s, the reaction time is 1s, and the cleaning time is 1sccm. for 5s, and the substrate temperature is 100°C. The hydrogen flow rate is 1sccm, the plasma discharge power is 1W, and the discharge time is 1s. Other places are completely consistent with Embodiment 1.

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that when nitrogen is used as the carrier gas to transport hydrogen gas into the reaction chamber of the atomic layer deposition equipment, the flow rate of nitrogen gas is 100 sccm, the intake time is 10 s, the reaction time is 10 s, and the cleaning time is 60s, the substrate temperature is 500°C. The hydrogen flow rate is 100sccm, the plasma discharge power is 300W, and the discharge time is 10s. Other places are completely consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com