Method for thinning sapphire wafer

A sapphire wafer and sapphire technology, applied in stone processing equipment, fine working devices, electrical components, etc., can solve problems such as heat dissipation and grounding problems of high-power devices, complex precision processing technology, and difficult machining, and achieve small deformation , fill the technical gap, and achieve the effect of complete chip structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

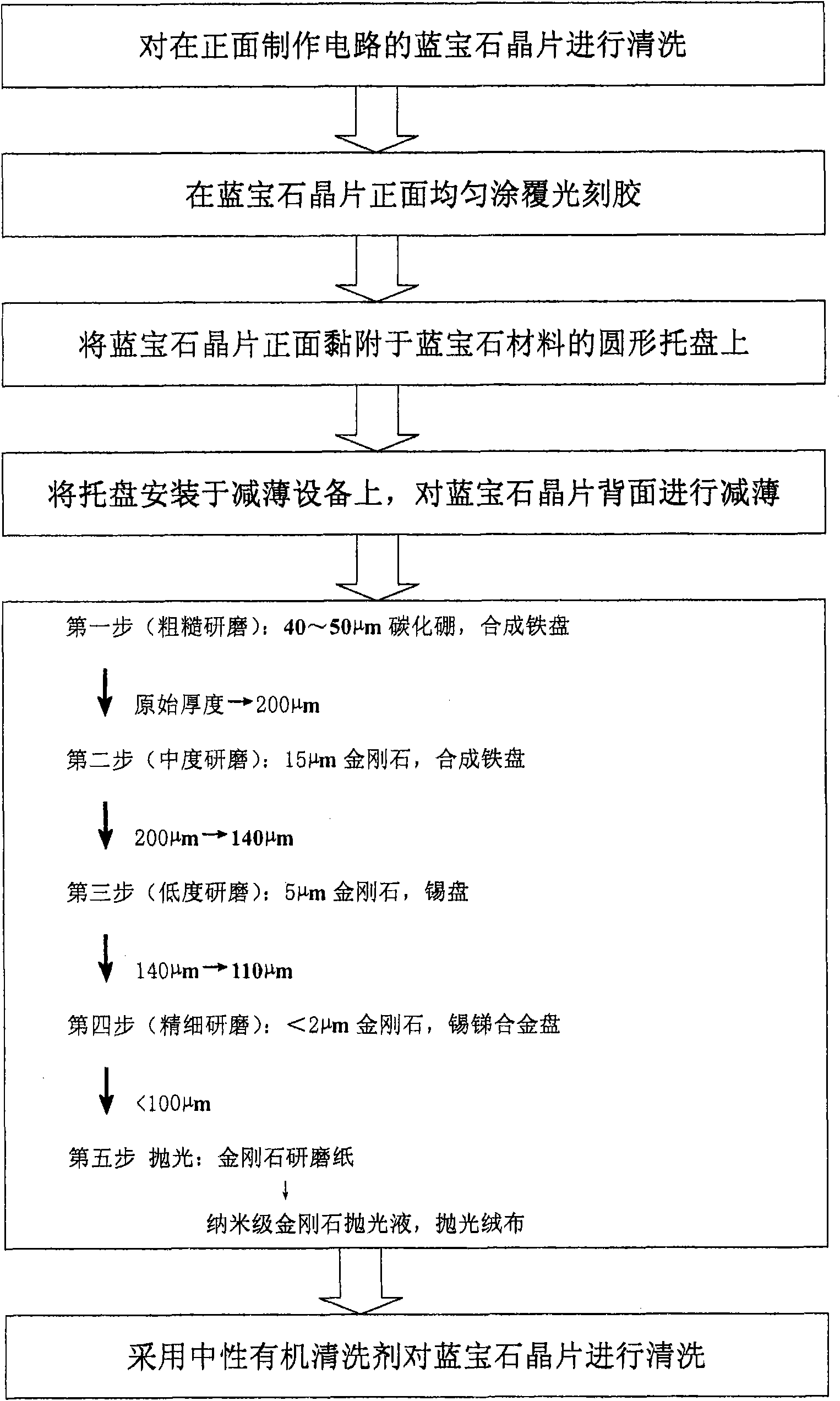

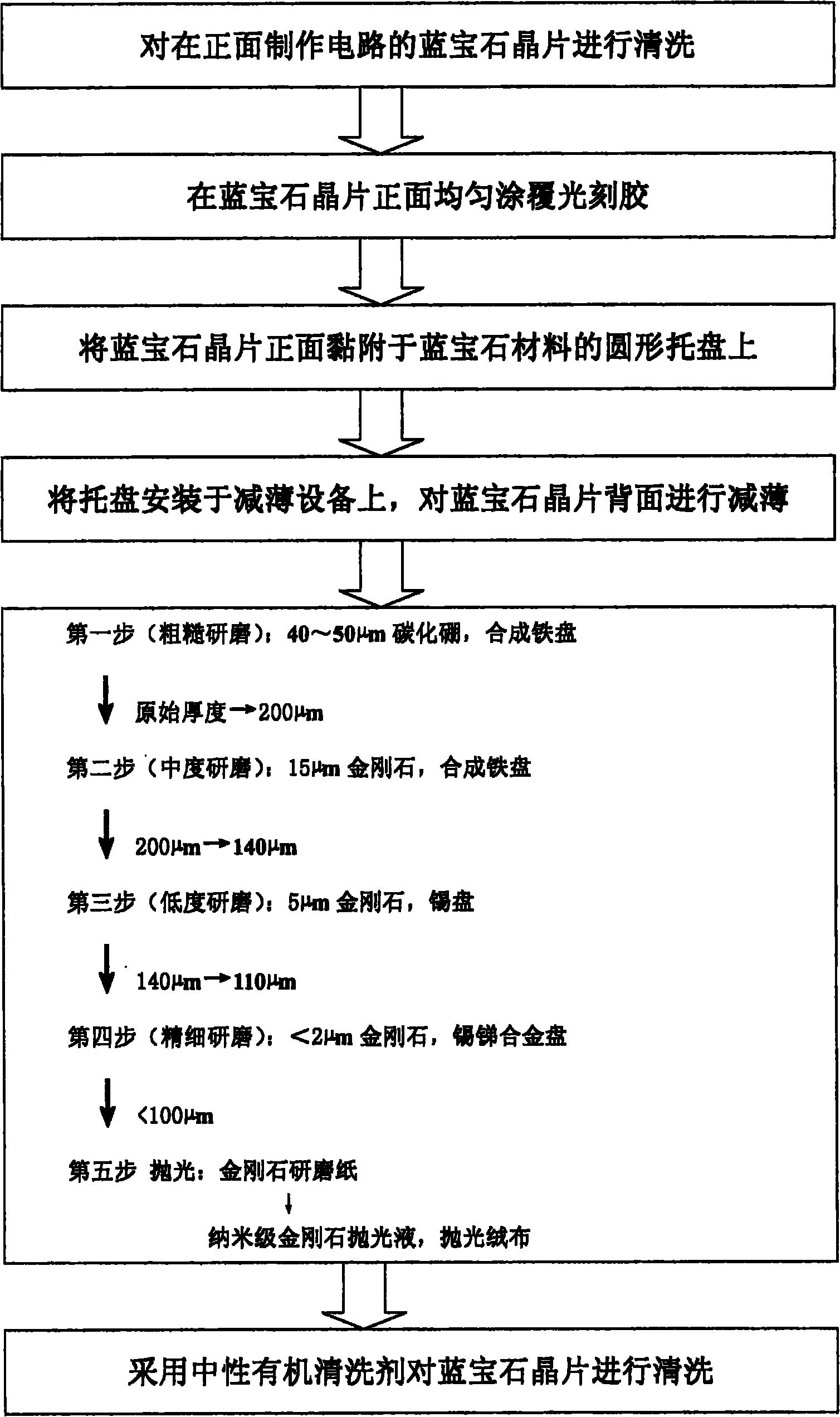

[0032] Such as figure 1 as shown, figure 1 It is a flow chart of a method for thinning a sapphire wafer provided by the present invention, the method comprising the following steps:

[0033] Step 1: Clean the sapphire wafer on which the circuit is made on the front side;

[0034] Step 2: Coating photoresist evenly on the front of the sapphire wafer, the thickness of the photoresist is 3-5 μm;

[0035] Step 3: Attach the front side of the sapphire wafer to the sapphire round tray;

[0036] Step 4: Install the sapphire round tray on the thinning equipment to thin the back of the sapphire wafer;

[0037] Step 5: Roughly grind the back of the sapphire wafer, including: using boron carbide grinding slurry, combined with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com