Method for quickly preparing high-quality graphene

A graphene, high-quality technology, applied in the field of rapid preparation of high-quality graphene, can solve the problems of intrinsic property damage, many graphene defects, unfavorable environmental protection, etc., and achieve convenient operation, good sheet effect, and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

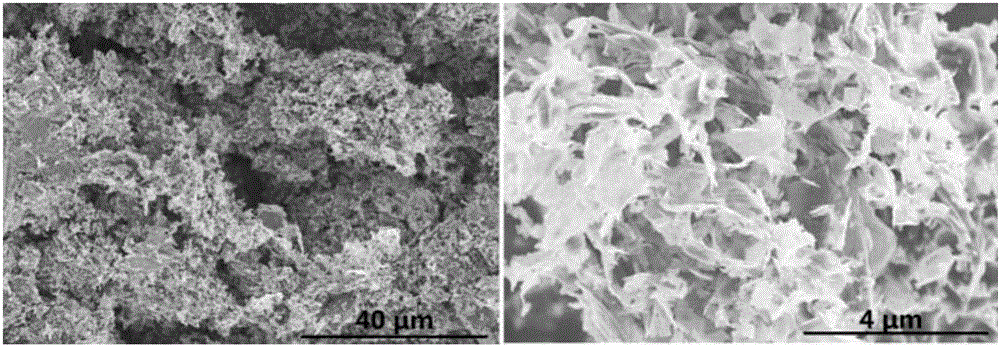

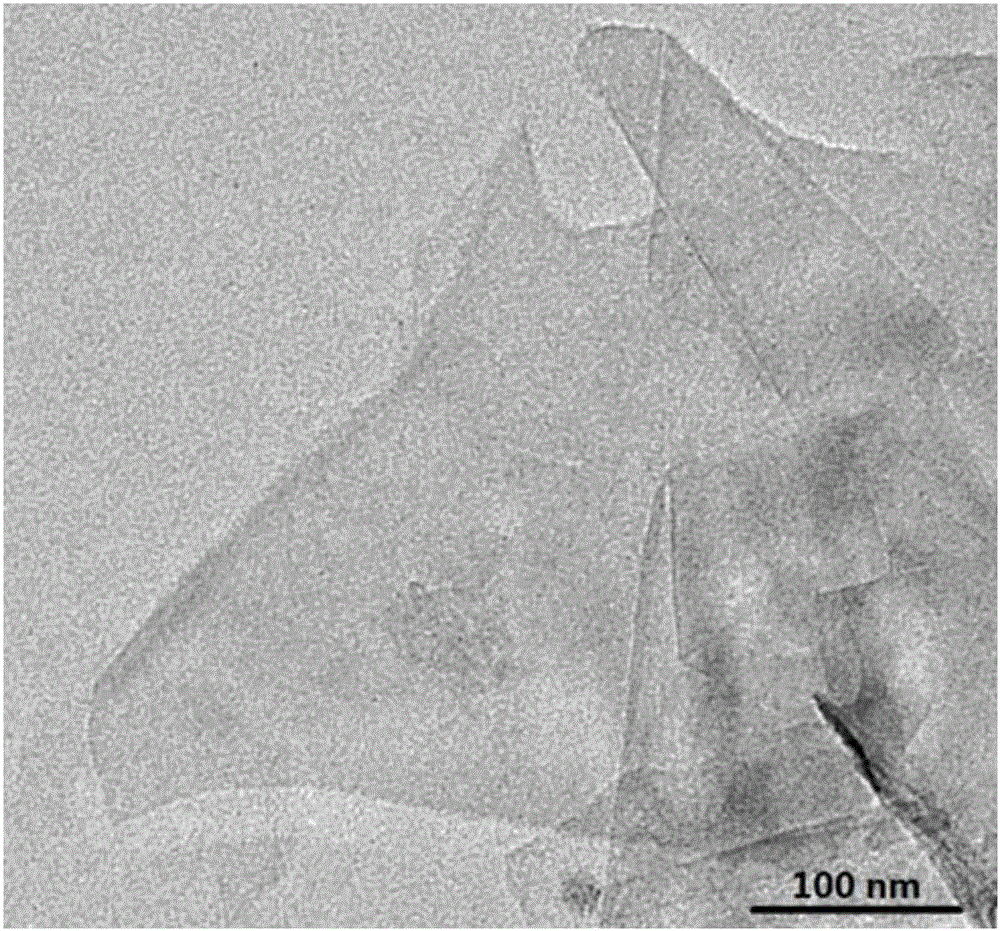

Image

Examples

Embodiment 1

[0035] 1) Using 80-mesh flake graphite powder as raw material, using ammonium bicarbonate solid as intercalation agent, according to the ratio of graphite powder and intercalation agent mass ratio of 1:4, after pre-mixing graphite powder and intercalation agent evenly, spare;

[0036] 2) Put the pre-mixed mixture in step 1) into a stainless steel ball mill tank, add 400g of zirconia grinding balls of different sizes according to the ball-to-material ratio of 6-20:1, and control the total charge to 1 / 2 of the ball mill tank volume 1 / 3 to 2 / 3 of the mixture was stirred and milled in a ball mill at a speed of 90r / min for 1 hour to obtain a uniform black solid mixture;

[0037] 3) Put the black solid mixture obtained in step 2) into a polytetrafluoroethylene-lined stainless steel hydrothermally sealed reaction kettle, heat it in a vacuum oven at a temperature of 60°C for 2 hours, take it out, cool it to room temperature, and then transfer Put it into a ceramic crucible, put it in...

Embodiment 2

[0041] 1) Using 80-mesh flake graphite powder as raw material, using ammonium bicarbonate solid as intercalation agent, according to the mass ratio of graphite powder and intercalation agent as 1:20, after pre-mixing graphite powder and intercalation agent evenly, spare;

[0042] 2) Put the pre-mixed mixture in step 1) into a stainless steel ball mill tank, add 400g of zirconia grinding balls of different sizes according to the ball-to-material ratio of 6-20:1, and control the total charge to 1 / 2 of the ball mill tank volume 1 / 3 to 2 / 3 of the mixture was stirred and milled in a ball mill for 1 hour at a speed of 100r / min to obtain a uniform black solid mixture;

[0043] 3) Put the black solid mixture obtained in step 2) into a polytetrafluoroethylene-lined stainless steel hydrothermally sealed reaction kettle, heat it in a vacuum oven at a temperature of 80°C for 2 hours, take it out, cool it to room temperature, and then transfer Put it into a ceramic crucible, put it into a...

Embodiment 3

[0045] 1) Using 8000-mesh flake graphite powder as raw material, using ammonium bicarbonate solid as intercalation agent, according to the ratio of graphite powder and intercalation agent mass ratio of 1:20, after pre-mixing graphite powder and intercalation agent evenly, spare;

[0046] 2) Put the pre-mixed mixture in step 1) into a stainless steel ball mill tank, add 400g of zirconia grinding balls of different sizes according to the ball-to-material ratio of 6-20:1, and control the total charge to 1 / 2 of the ball mill tank volume 1 / 3 to 2 / 3 of the mixture was stirred and milled in a ball mill at a speed of 90r / min for 1 hour to obtain a uniform black solid mixture;

[0047] 3) Put the black solid mixture obtained in step 2) into a polytetrafluoroethylene-lined stainless steel hydrothermally sealed reaction kettle, heat it in a vacuum oven at a temperature of 70°C for 2 hours, take it out, cool it to room temperature, and then transfer Put it into a ceramic crucible, put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com