Method for adjusting and controlling brittle phase in titanium/aluminum dissimilar metal friction stir welding joint

A technology of friction stirring and dissimilar metals, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of limited application prospects, deterioration of joint mechanical properties, uneven distribution of brittle phases, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

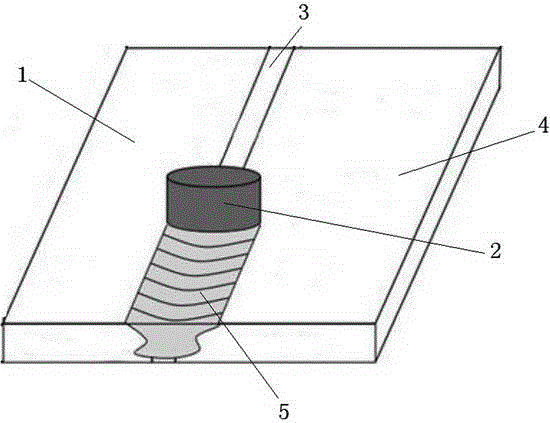

[0031] This embodiment provides a control method for the brittle phase in the friction stir welding joint of dissimilar metals between TC4 titanium alloy and 2A14 aluminum alloy, using a zinc-based intermediate layer material with a thickness of 0.05 mm. Specifically include the following steps:

[0032] The first step is to install the stirring head with a stirring pin diameter of 6mm on the friction stir welding equipment, and place the zinc-based intermediate layer material with a thickness of 0.05mm on the joint between the 3mm thick TC4 titanium alloy and the 3mm thick 2A14 aluminum alloy place, and then fix it on the fixture.

[0033] In the second step, adjust the stirring head so that it is at the starting position of welding, and align the center line of the stirring needle on the stirring head with the joint position between the TC4 titanium alloy and the 2A14 aluminum alloy.

[0034] The third step is to set the process parameters, the rotation speed is set to 600 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com