Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Kirkendall effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Kirkendall effect is the motion of the interface between two metals that occurs as a consequence of the difference in diffusion rates of the metal atoms. The effect can be observed for example by placing insoluble markers at the interface between a pure metal and an alloy containing that metal, and heating to a temperature where atomic diffusion is possible; the boundary will move relative to the markers.

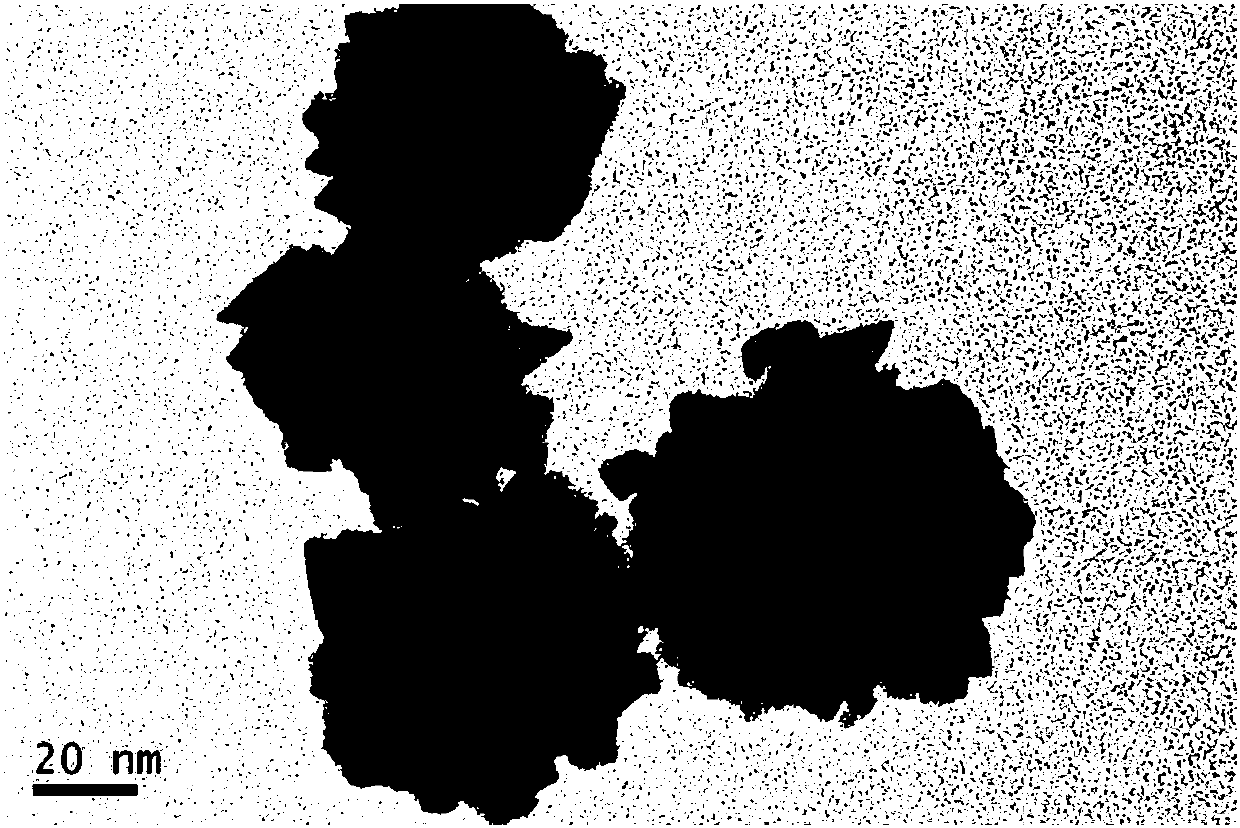

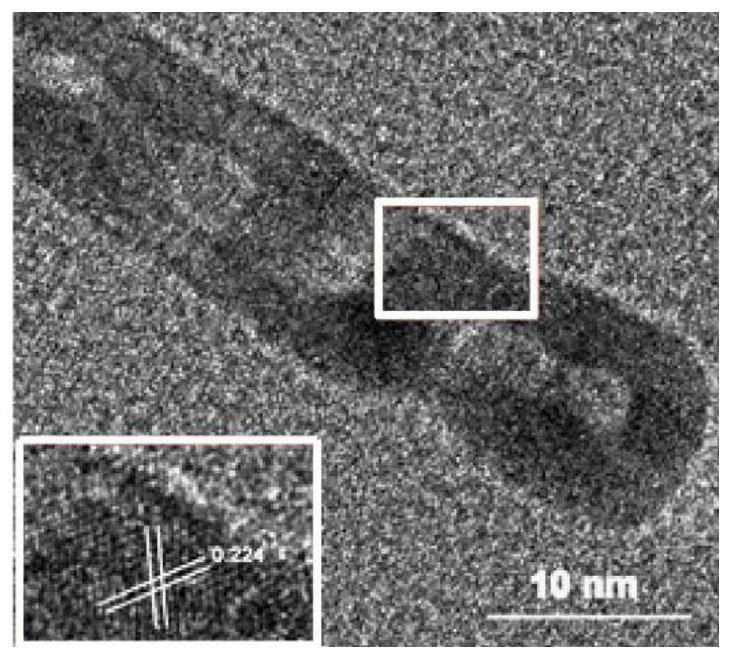

Preparation method of carbon-coated transition metal nano hollow particle

InactiveCN102208616AAchieving controllable synthesisRich sourcesCell electrodesNanoparticlePhysical chemistry

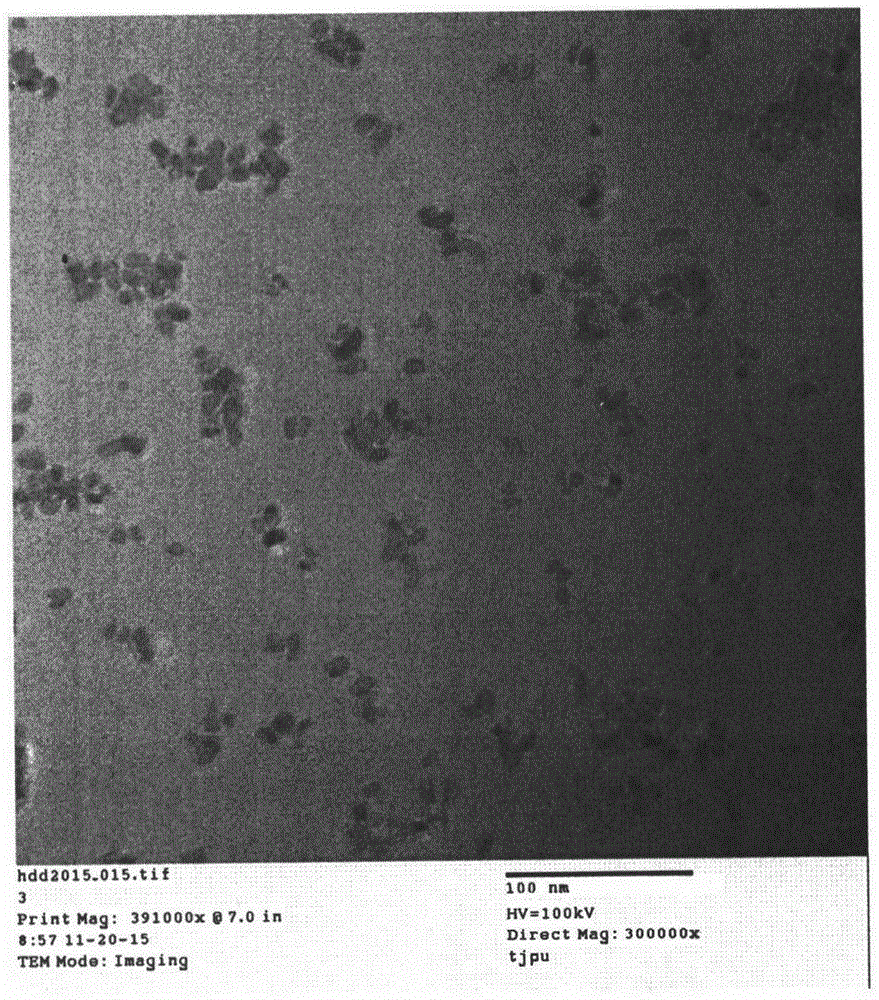

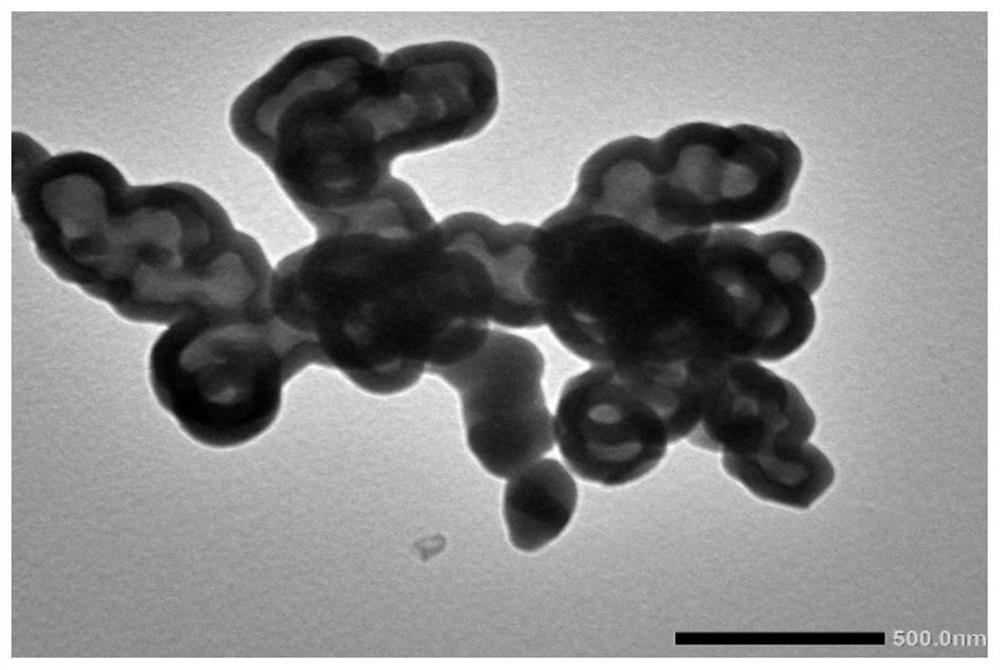

The invention provides a preparation method of a carbon-coated transition metal nano hollow particle. The method comprises the following steps: based on a Kirkendall effect, carrying out dissolving and mixing, high temperature co-pyrolysis and insulation in-situ reduction on an aromatic hydrocarbon compound with oxygen-containing groups and a transition metal compound so as to obtain the carbon coated metal nano hollow particle. The hollow structure shell layer prepared by the method consists of carbon and a nano metal composite material; and the nano particles are evenly distributed, the diameter range of the nano particle is 20nm-80nm, and the thickness of the carbon-coated layer is 2.2nm-4.3nm.

Owner:BEIJING UNIV OF CHEM TECH

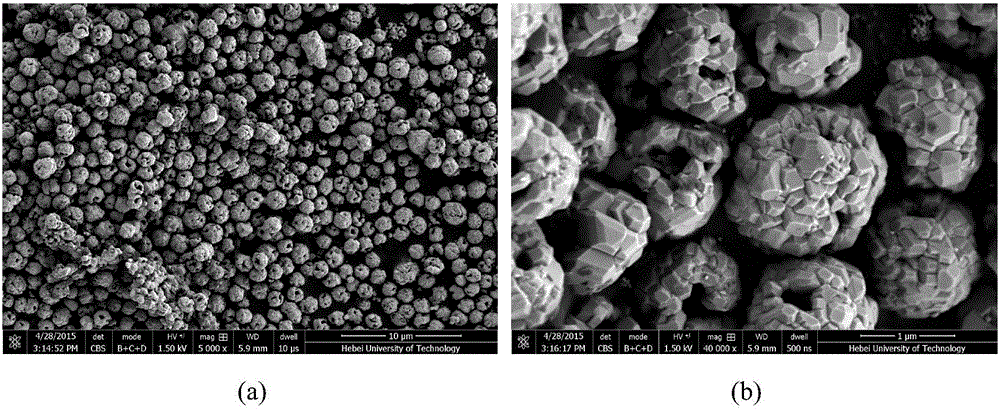

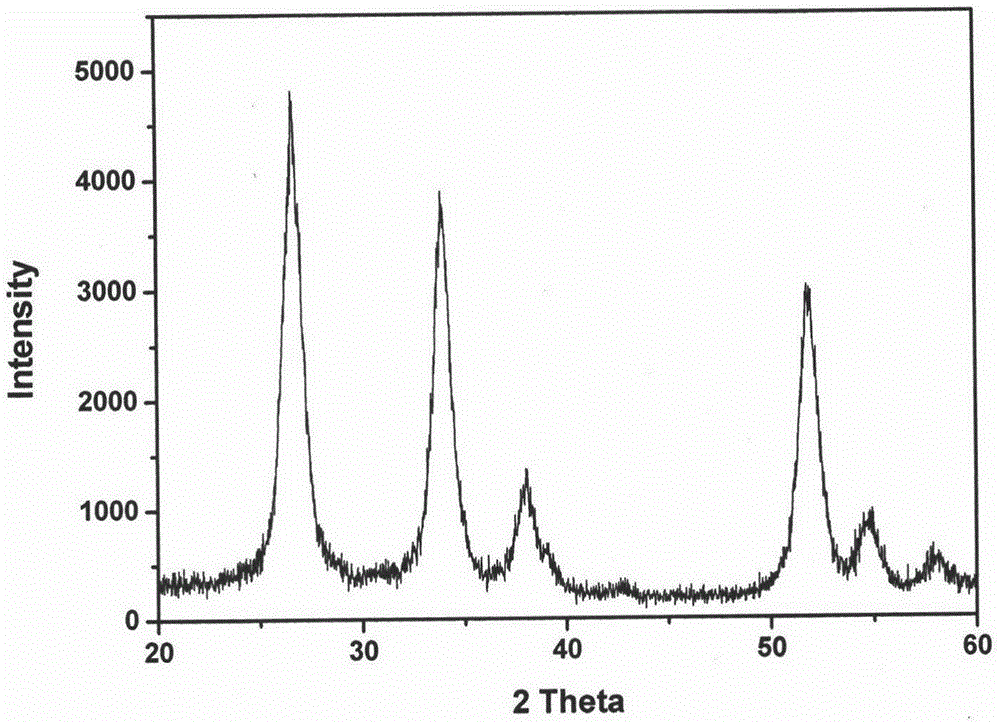

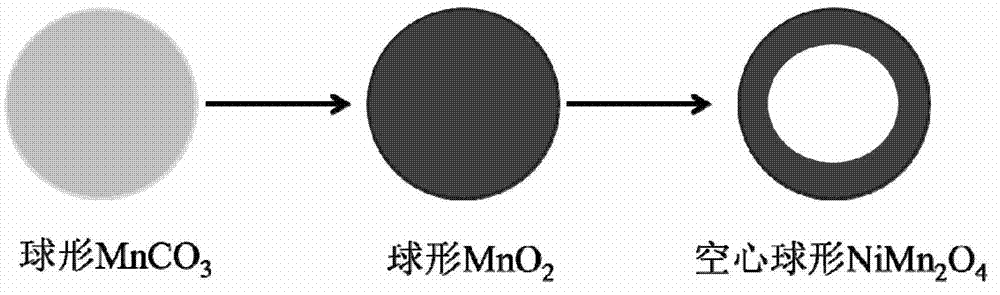

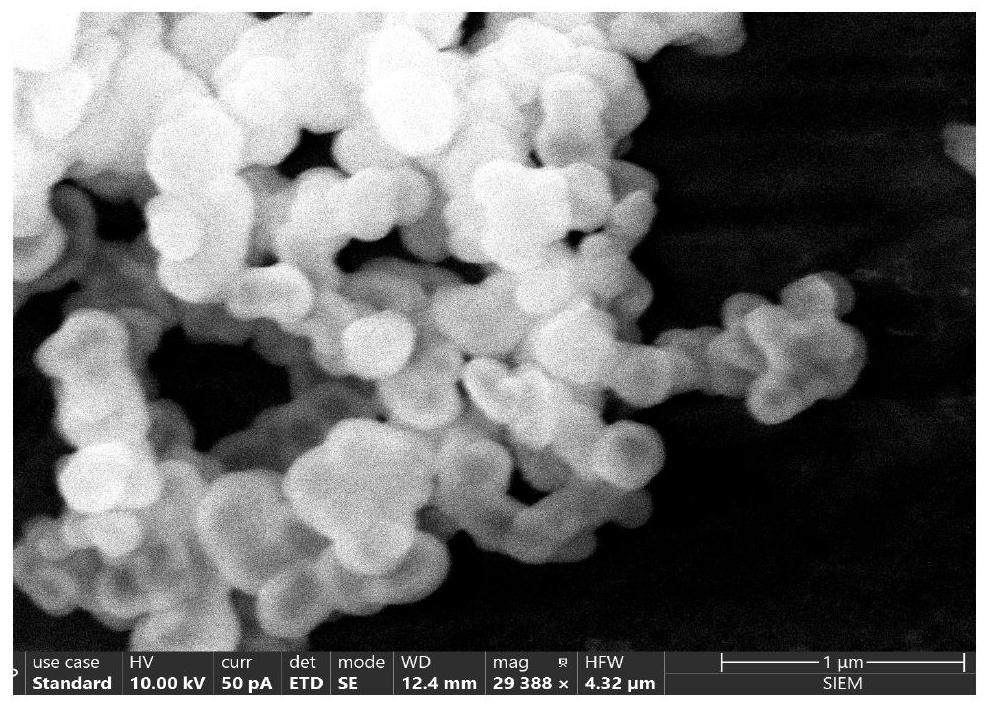

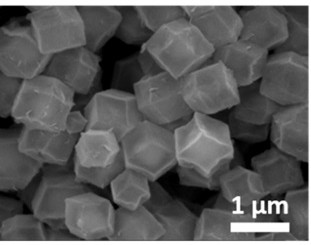

Hollow spherical NiMn2O4 lithium ion battery cathode material and preparation method thereof

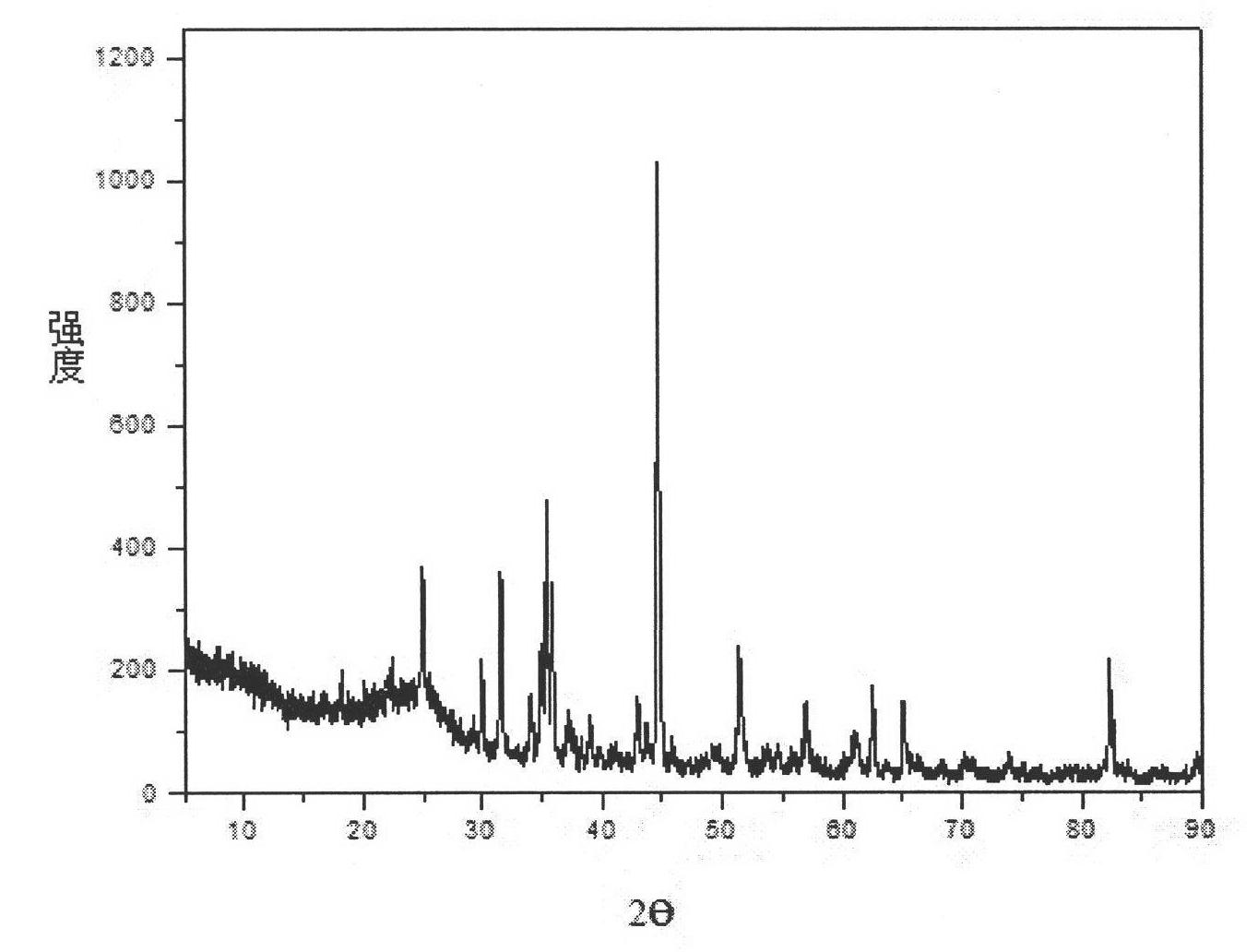

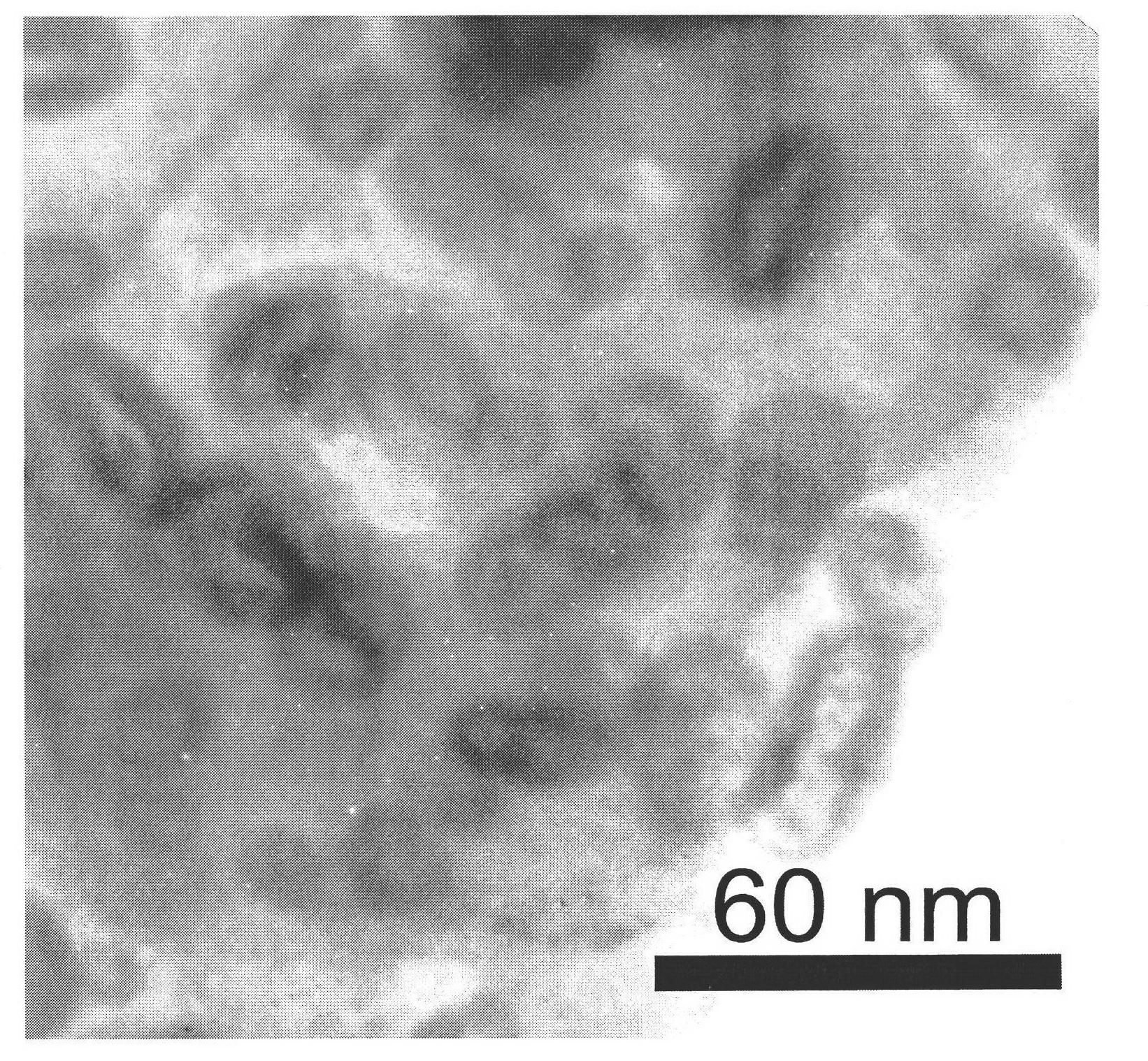

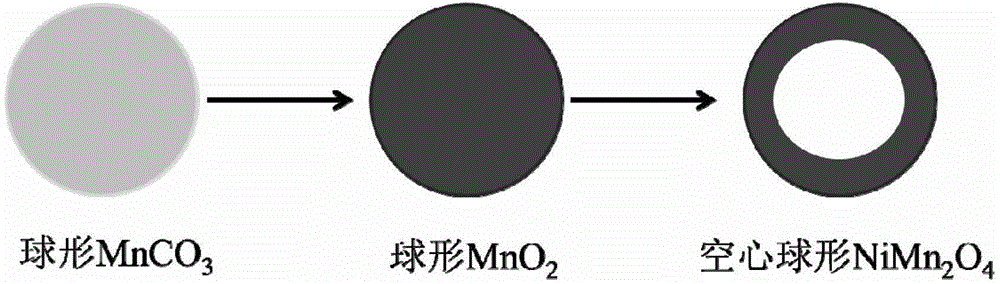

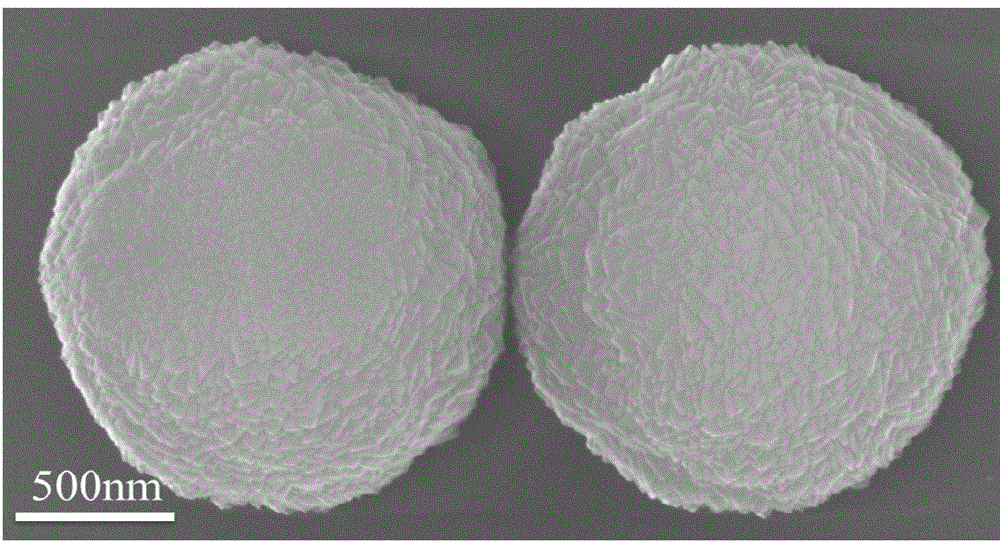

ActiveCN103337604ASimple processEasy to operateCell electrodesNanotechnologyNickel saltSpherical shaped

The invention discloses a hollow spherical NiMn2O4 lithium ion battery cathode material and a preparation method thereof, and belongs to the field of lithium ion battery electrode material technology. Particle size of the hollow spherical material is 1 to 3 micrometers; the spherical shell is made of NiMn2O4 nanometer crystals, and has a porous structure. The porous spherical shell is in favor of penetration of electrolyte, is capable of shortening diffusion distance of lithium ions, and possesses excellent electrochemistry cycling stability and rate capability. The preparation method is based on ''Kirkendall effect'', and the hollow spherical NiMn2O4 can be obtained directly by performing high temperature solid phase reaction. The preparation method comprises following steps: taking solid spherical MnCO3 as a precursor; roasting at a low temperature to obtain porous solid spherical manganese dioxide; and then roasting the porous solid spherical manganese dioxide with a nickel salt to obtain the hollow spherical spinel-type NiMn2O4 cathode material. The preparation method is simple in technologies, do not need a template, and is suitable for large-scaled production.

Owner:BEIJING UNIV OF CHEM TECH

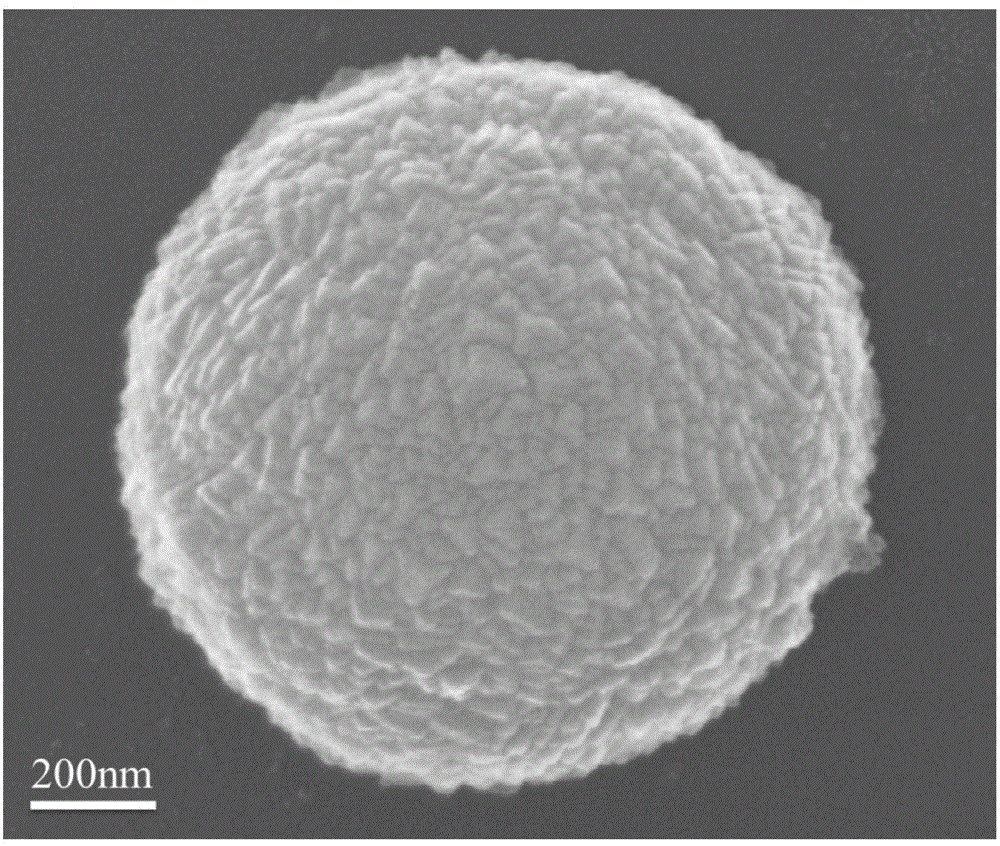

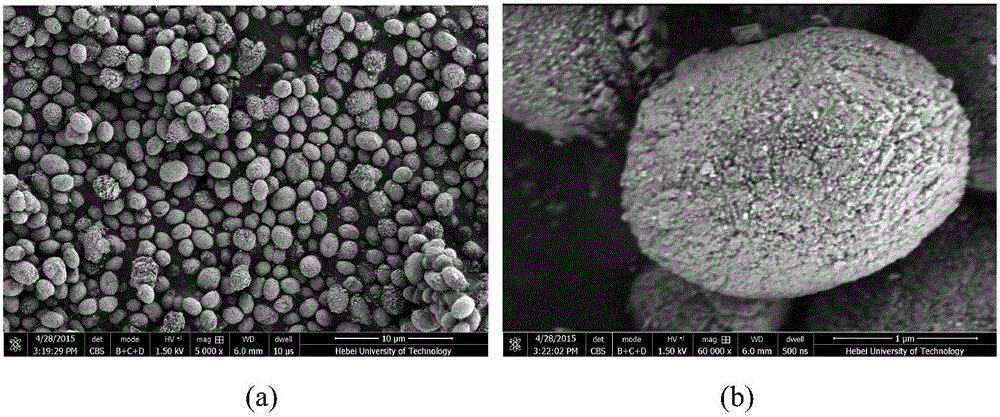

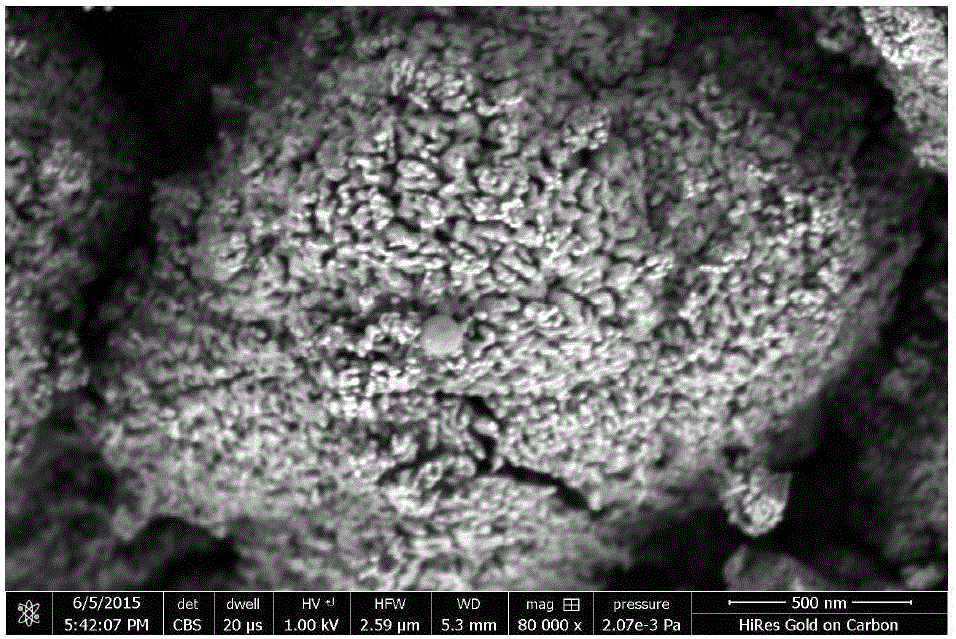

Preparation method of spherical lithium nickel manganese oxide material with hollow porous micro-nano level structure

InactiveCN105742624AUniform supersaturationGuaranteed uniformityCell electrodesMicro nanoLevel structure

The invention provides a preparation method of a spherical lithium nickel manganese oxide material with a hollow porous micro-nano level structure. The method comprises the following steps: (1) dissolving a soluble nickel salt, a manganese salt and urea into a mixed solvent and stirring the mixture to obtain a mixed solution; (2) carrying out hydrothermal reaction at 150-190 DEG C for 4-12 hours and carrying out cooling, washing, filtering and drying to obtain an Ni0.25Mn0.75CO3 precursor; and (3) presintering the precursor in air at 450-550 DEG C, putting the product into absolute ethyl alcohol, adding a lithium source compound, heating and stirring until ethanol volatilization, calcining the product in air at 700-900 DEG C, and carrying out cooling to obtain the LiNi0.5Mn1.5O4 material. Any template agent does not need to be used; the spherical lithium nickel manganese oxide material with the hollow porous micro-nano level structure prepared through a simple kirkendall effect combines the advantages of nano primary particles, the porous structure and the hollow structure, and the rate capability and the cycle performance of the material can be significantly improved.

Owner:HEBEI UNIV OF TECH

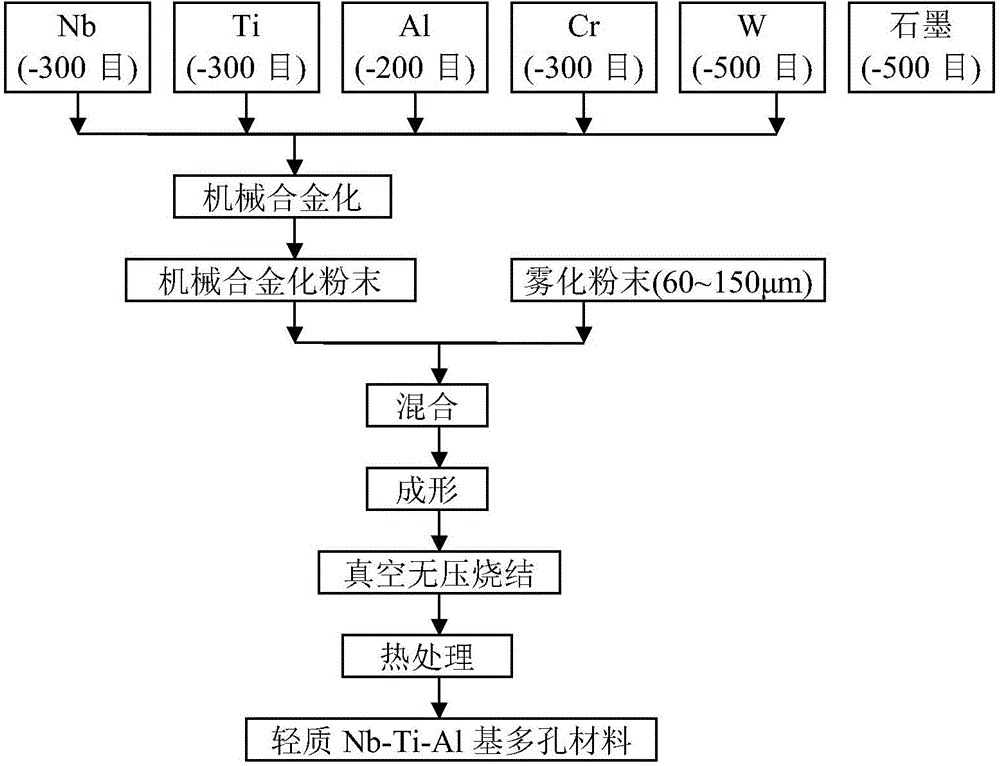

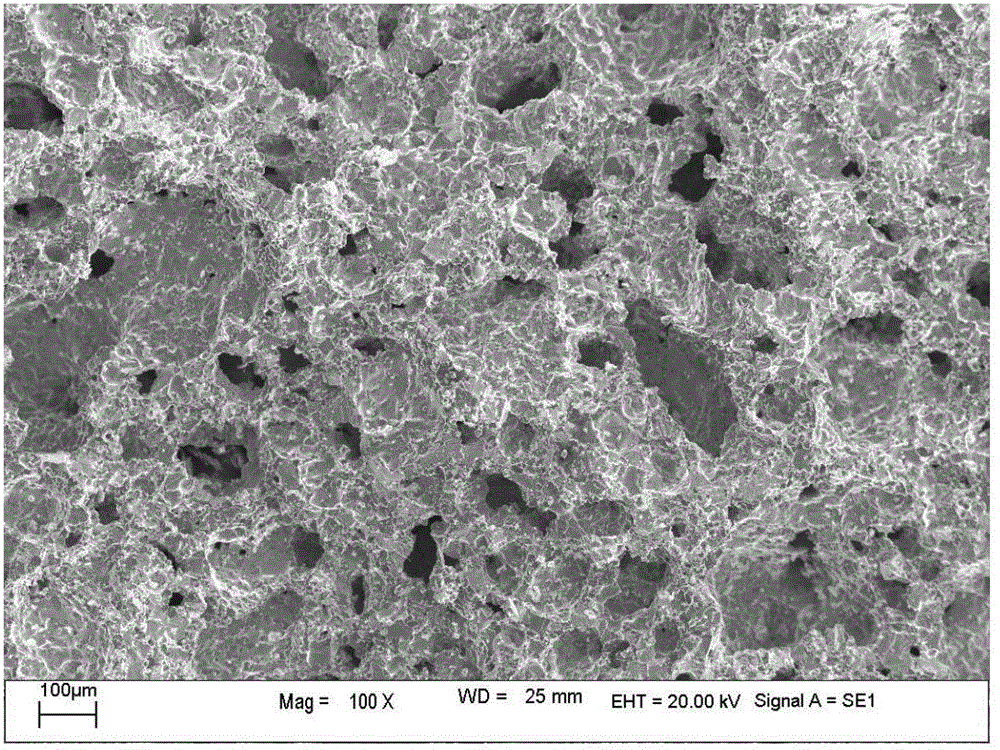

Method for preparing light Nb-Ti-Al based porous material

The invention provides a method for preparing a light Nb-Ti-Al based porous material, and belongs to the technical field of powder metallurgy porous materials. The method comprises the following process procedures: firstly, performing high energy ball milling on niobium powder, titanium powder, aluminum powder and element powder of other alloy elements to obtain mechanical alloyed powder; uniformly mixing Nb-Ti-Al based alloy powder with rotating electrode atomized niobium alloy powder through ball milling and forming at the pressure of 200-700 MPa to obtain a formed blank; performing vacuum pressure-free sintering and thermal treatment on the formed blank to obtain the Nb-Ti-Al based porous material. Pores are formed by virtue of the Kirkendall effect that pores are formed in a substrate because of partial diffusion of the Al element, and the strength of a porous body is improved with the combination of a sintered neck formed by the atomized alloy powder. The light Nb-Ti-Al based porous material is simple in preparation process, and the porous structure is easy to control.

Owner:UNIV OF SCI & TECH BEIJING

AlCrFeNiSiTi high-entropy alloy porous material and preparation method thereof

ActiveCN110735077ADiffuse fullyInhibition of high temperature self-propagating reactionsTransportation and packagingMetal-working apparatusHigh entropy alloysEnergy consumption

The invention belongs to the field of high-entropy alloy materials and discloses an AlCrFeNiSiTi high-entropy alloy porous material and a preparation method thereof. The AlCrFeNiSiTi high-entropy alloy porous material provided by the invention comprises, by atomic percent, 10%-20% of Al, 10%-20% of Cr, 10%-20% of Fe, 10%-20% of Ni, 10%-20% of Si and 10%-20% of Ti. The AlCrFeNiSiTi high-entropy alloy porous material is prepared through an element powder reactive synthesis method. The principal element powder is adopted as a raw material, only a little lubricating agent needs to be added in thepreparation process, energy consumption is low, and the cost is low. Pores are generated through the Kirkendall effect caused by partial diffusion between elements. The controllability of the pore structure is good. There is no need to add a pore forming agent. No follow-up pore forming agent removal problem exists. The AlCrFeNiSiTi high-entropy alloy porous material and the preparation method thereof have the characteristics of short process and high performance.

Owner:CENT SOUTH UNIV

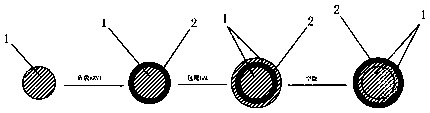

Connecting method of stephanoporate inner core and compact outer shell

The invention discloses a connection method of porous belly core and compact shell, the method is that: choose metal A and B powder in the range of negative 80 to positive 500 items, blend according to atom ratio 1 / 1, then put into a mixer to mix evenly, then package the A,B metal mixing powder into a compact tube made of metal A directly, after 2.5 to 5.0 MPa mould pressing and forming, weld in vacuum at 350 to 1200 DEG C. for 1 to 2 hours; wherein, the spreading speed of metal B in the metal A is large than that of the metal A in the metal B, the porous material is AB alloy, the compact material is metal A. With the method of powder metallurgy, the invention uses little alloy which can produce Kirkendall effect and welding swelling during welding, to finish welding spreading welding, and makes two parts connected into a whole body without air leakage and has good sealing performance, which can realize the integration forming of the porous material and the compact material, and has simple technics and lowers the production cost greatly.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

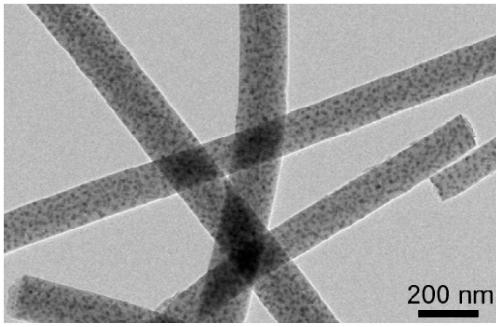

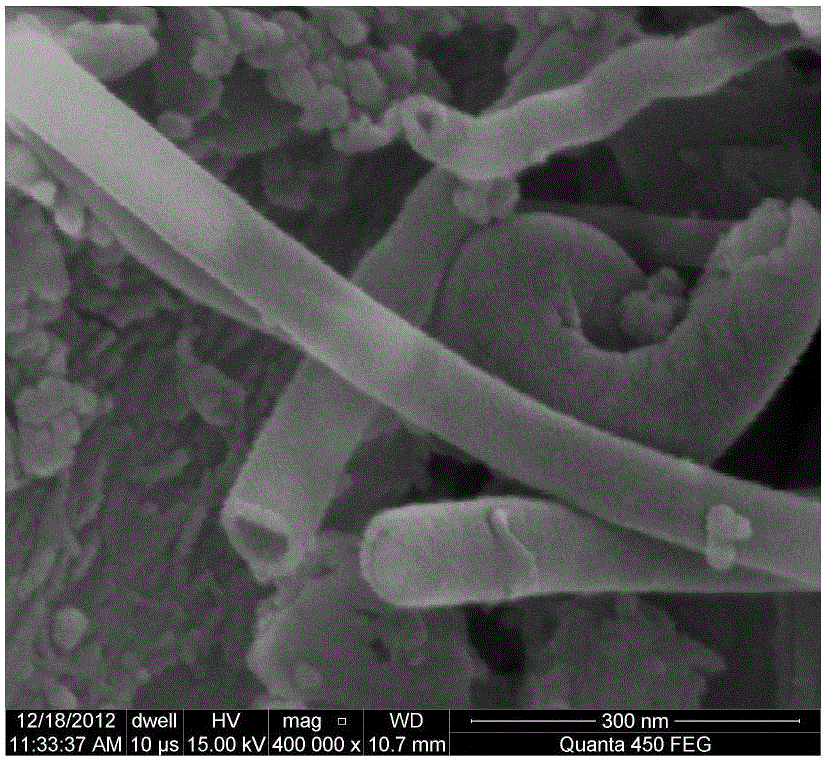

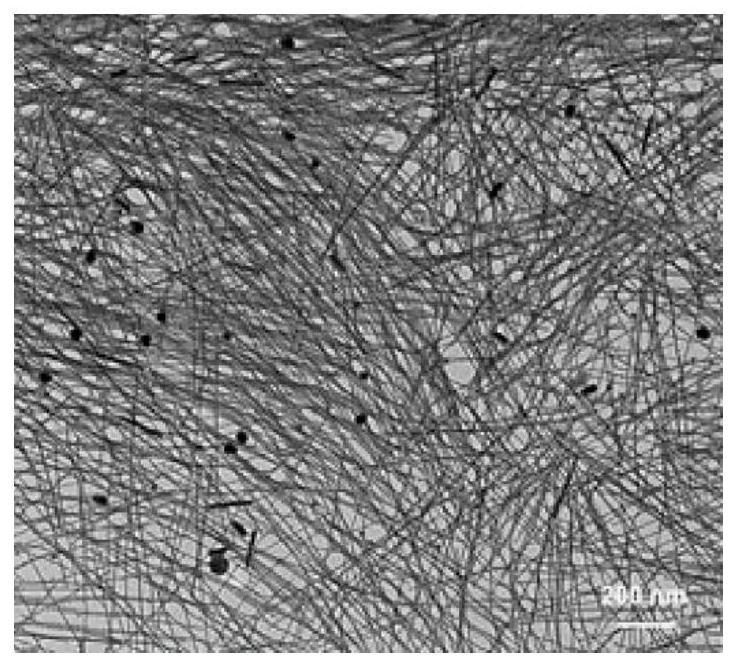

Preparation method and application of hollow structure Co3O4/CeO2 nanoparticle loaded nitrogen doped carbon nanofiber material

ActiveCN110124713AFast transferFast outputPhysical/chemical process catalystsElectrodesFiberSolid carbon

The invention discloses a preparation method of a hollow structure Co3O4 / CeO2 nanoparticle loaded nitrogen doped carbon nanofiber material and application thereof. The preparation method comprises thefollowing steps: 1) preparing a CO<2+> / Ce<3+> / PVP mixed sol; 2) electrospinning the CO2+ / Ce3+ / PVP mixed sol to obtain a solid carbon fiber film; and 3) preoxidizing the solid carbon fiber film in anair atmosphere of 200-300 DEG C, performing heat treatment in an inert atmosphere of 400-1000 DEG C with programmed temperature rise, and obtaining the hollow structure Co3O4 / CeO2 nanoparticle loadednitrogen doped carbon nanofiber composite material by utilizing the Kirkendall effect of nano materials. The preparation method is low in cost, simple and universal. The prepared material is a one-dimensional carbon nanofiber material; hollow Co3O4 / CeO2 composite nanoparticles are uniformly embedded in carbon nanofiber; and the material can be used as an electrolytic water oxygen evolution electrocatalytic material and has higher activity and excellent stability.

Owner:NANJING NORMAL UNIVERSITY

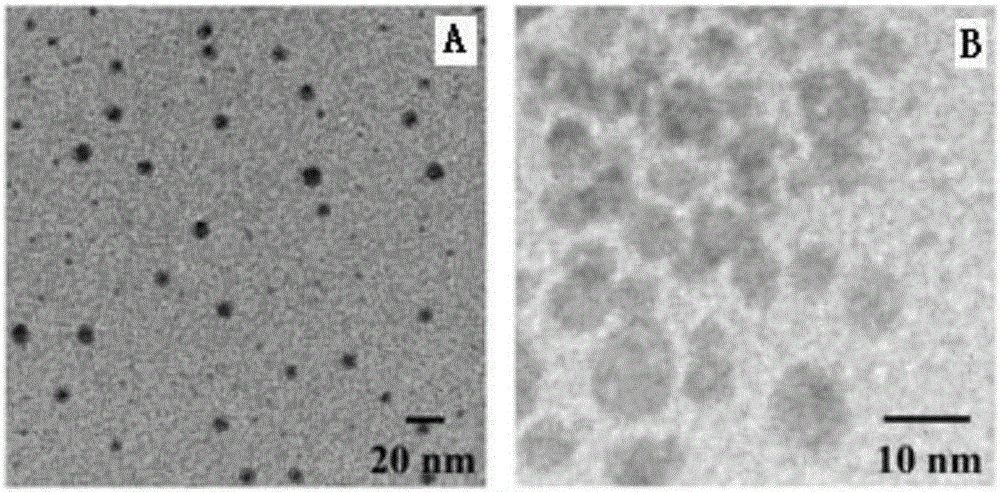

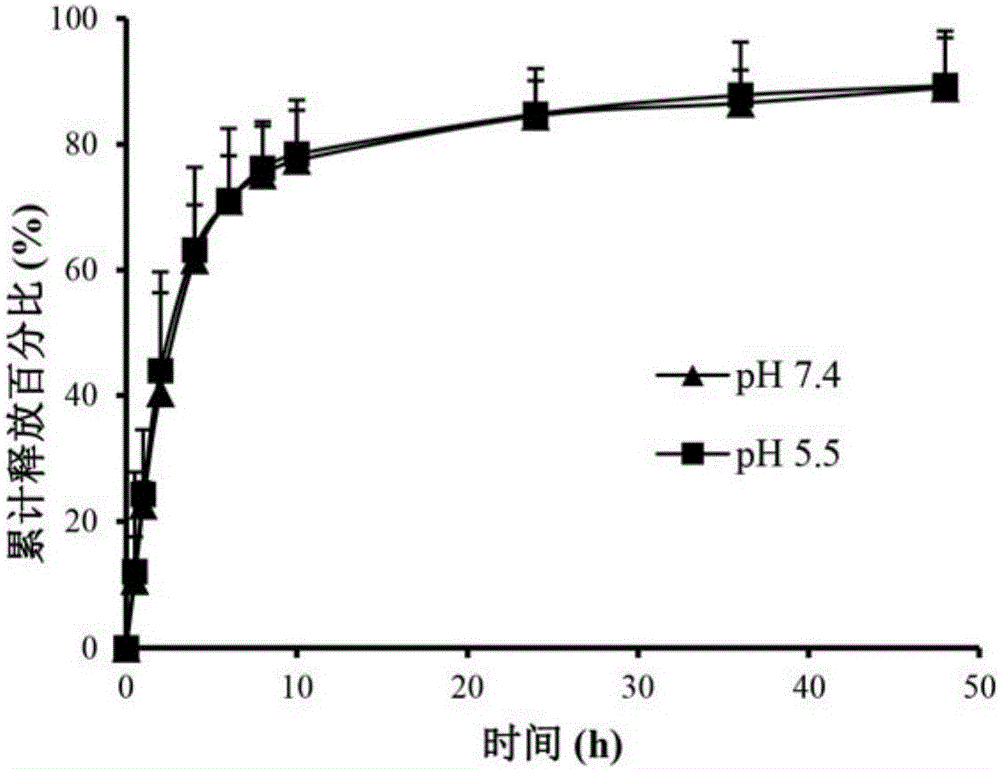

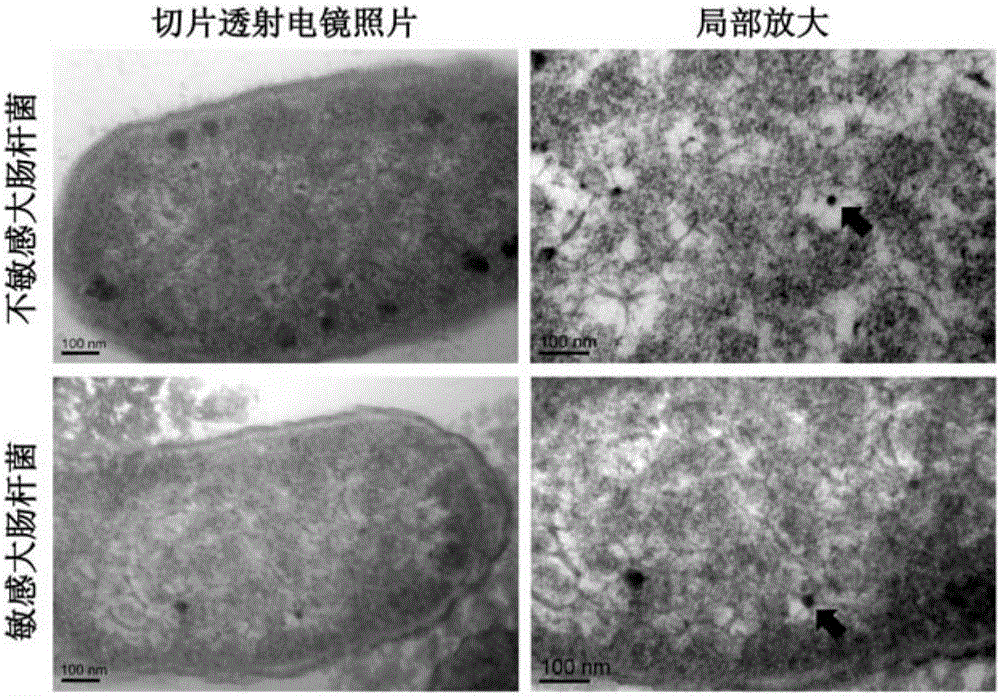

Polyethylene glycol vitamin E succinate modified tigecycline loading silver nanoparticles as well as preparation and application

ActiveCN106727431AStable, safe and synergistic antibacterial effectReduce concentrationAntibacterial agentsInorganic active ingredientsEscherichia coliMinimum inhibitory concentration

The invention provides polyethylene glycol vitamin E succinate modified tigecycline loading silver nanoparticles. First, under the stabilizing effect of polyethylene glycol vitamin E succinate, hollow silver nanoparticles are formed through kirkendall effect, and polyethylene glycol vitamin E succinate modified silver nanoparticles are synthesized, thus the stability of the hollow silver nanoparticles is improved, and toxicity caused by oxidation of the silver nanoparticles is reduced. An antibacterial drug tigecycline is effectively loaded by the hollow structure of polyethylene glycol vitamin E succinate modified tigecycline loading silver nanoparticles. With relatively small particle size, the nanoparticles can penetrate through the cell wall of bacteria, destroy cell membrane and enter cytoplasm; and through the synergistic antibacterial effect of silver nanoparticles and tigecycline, the minimal inhibitory concentration and minimal bactericidal concentration of a drug are remarkably reduced, and the drug resistance of escherichia coli against tigecycline is overcome. The silver nanoparticles can serve as a novel antibacterial nano material for preparing antibacterial drug-resistant drugs and is applied to the field of life science and pharmacy.

Owner:ZHEJIANG UNIV

Silver end electrode slurry for low temperature sintering MLCC

ActiveCN109841405AImprove performanceStrong adhesionFixed capacitor dielectricStacked capacitorsSlurryKirkendall effect

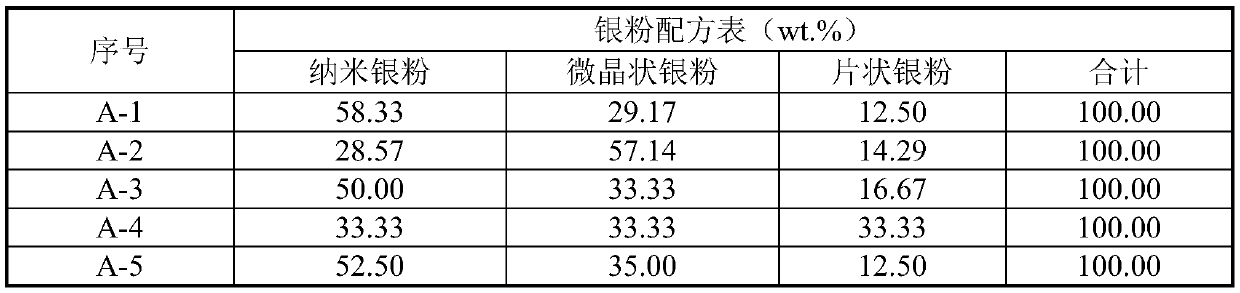

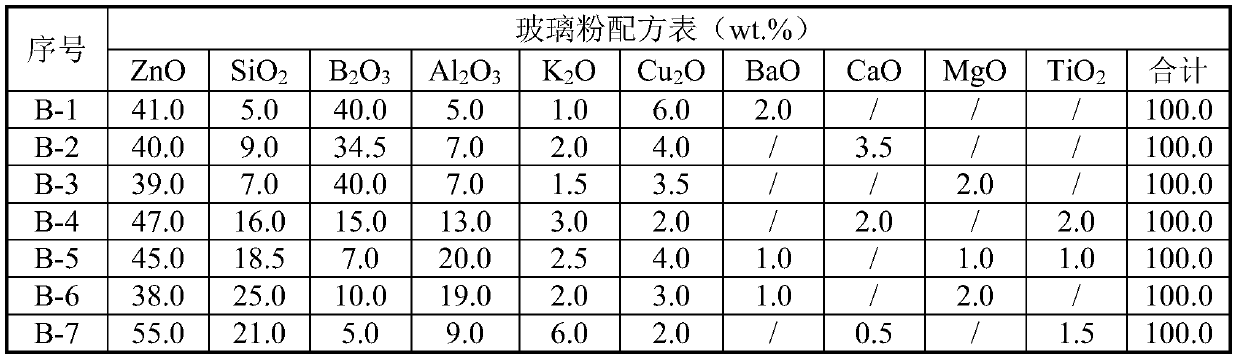

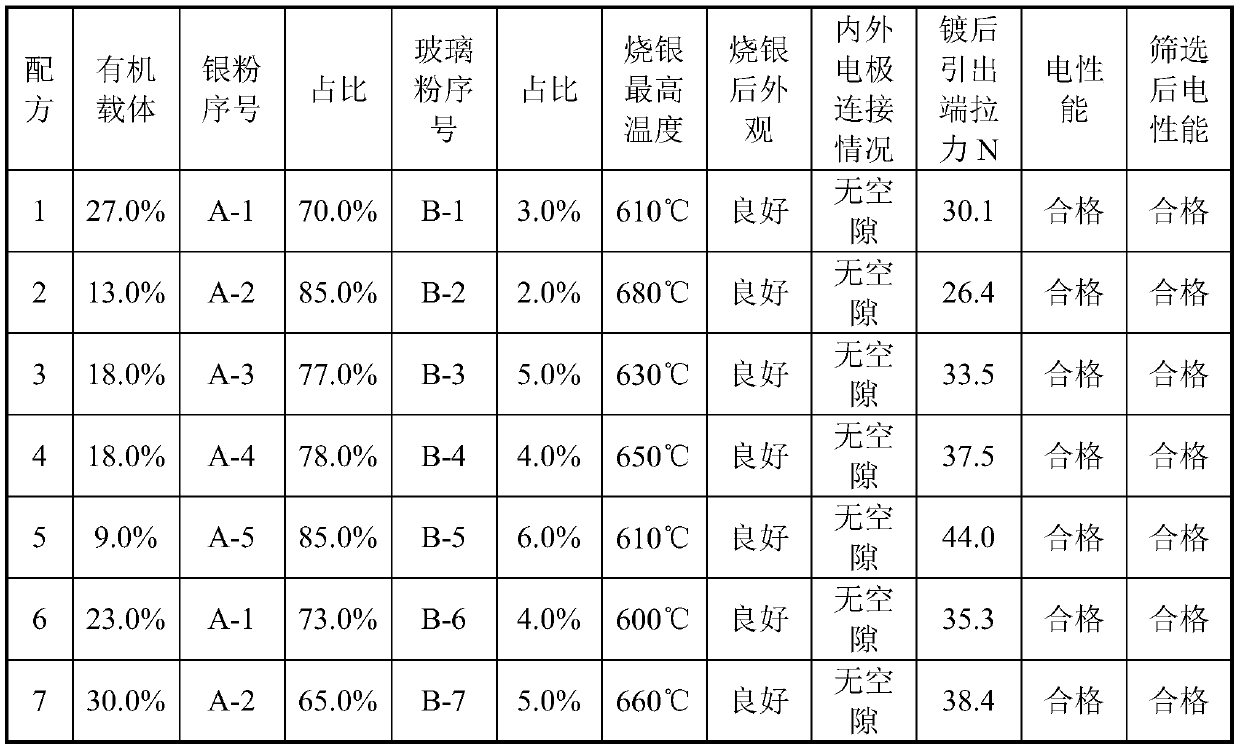

The invention discloses a silver-end electrode slurry for low-temperature sintering MLCC, which comprises 65.0 to 85.0 wt.% of silver powder, 2.0 to 6.0 wt.% of glass powder and 9.0 to 33.0 wt.% of anorganic carrier, wherein the weight ratio of nano silver powder to microcrystalline silver powder in the silver powder is (0.5 to 2.0) to 1; the ratio of the weight sum of the nano silver powder andthe microcrystalline silver powder to the weight of flake silver powder is (2.0 to 7.0) to 1; the glass powder comprises 38.0 to 55.0 wt.% of ZnO, 5.0 to 25.0 wt.% of SiO2, 5.0 to 40.0wt.% of B2O3, 5.0 to 20.0 wt.% of Al2O3, 1.0 to 6.0 wt.% of K2O and 2.0 to 6.0 wt.% of Cu2O. While the slurry ensures good compactness of the silver layer and can also solve the problem of a void generated at a connection place by Kirkendall effects in the case of high-temperature sintering of internal and external electrodes.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

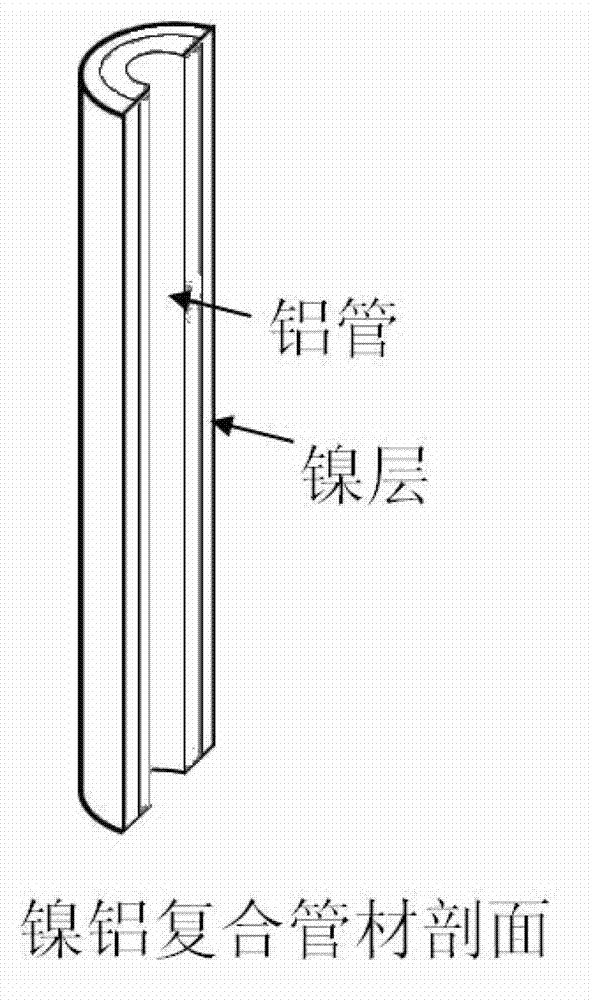

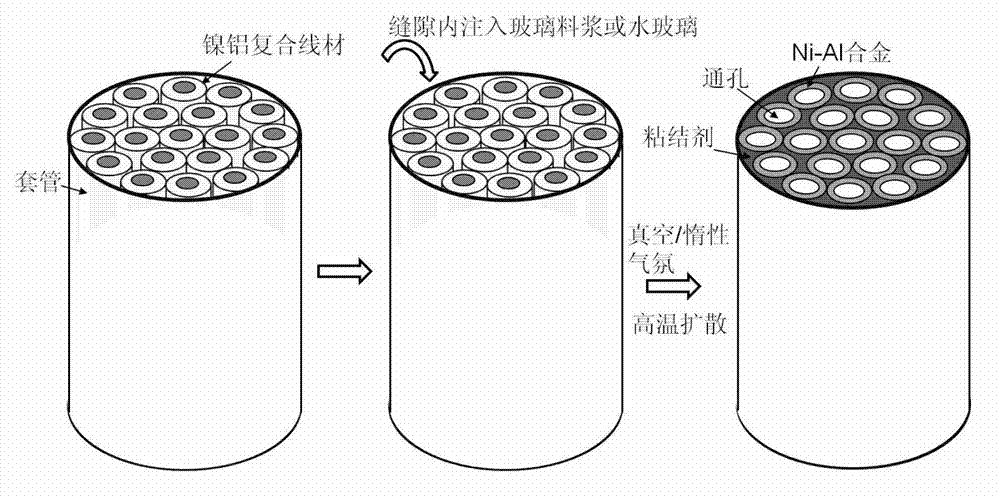

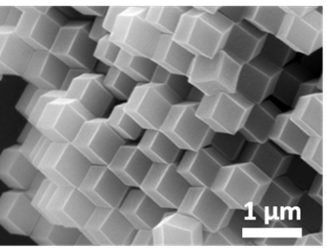

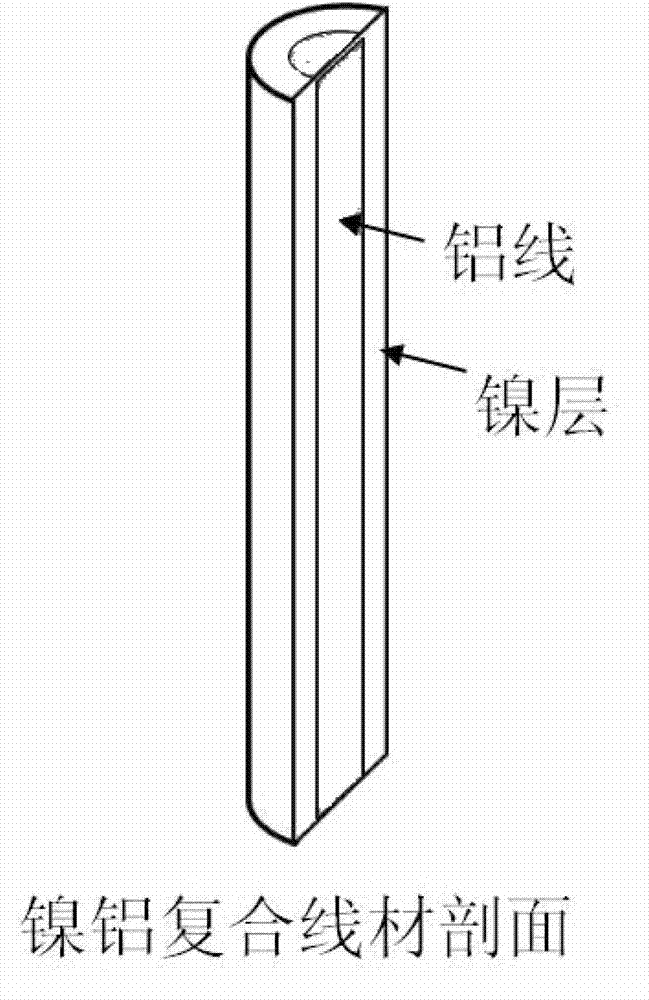

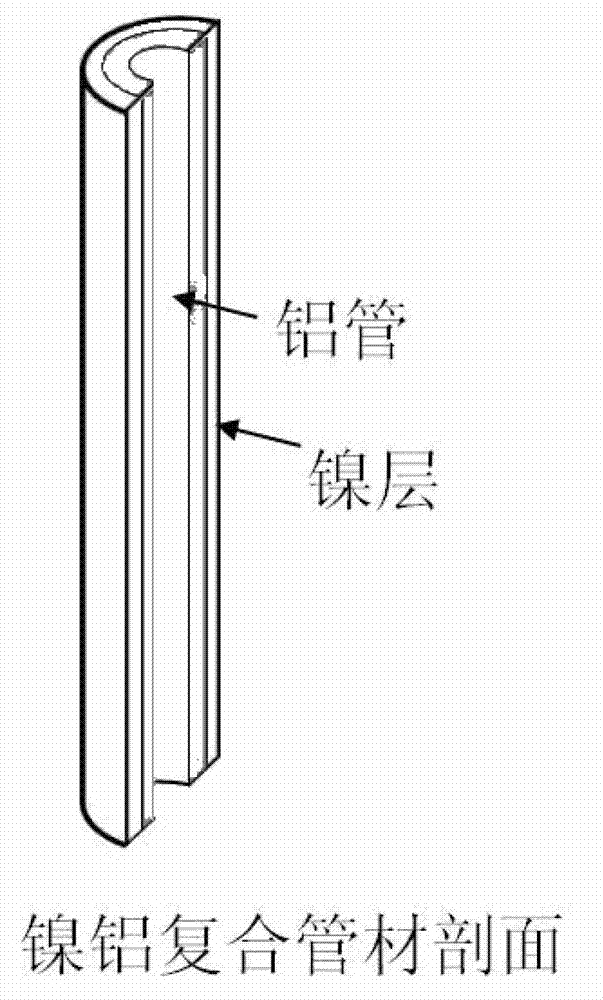

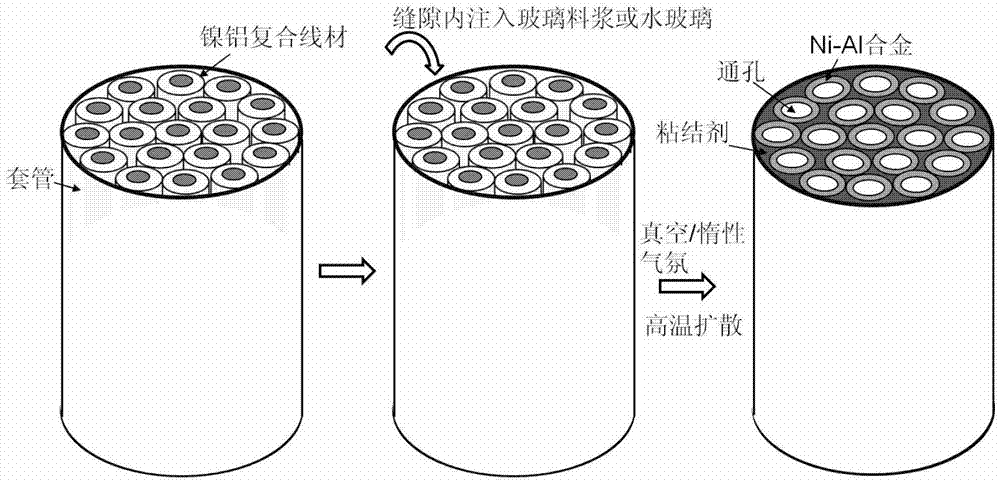

Ni-Al alloy honeycomb material and preparation method thereof

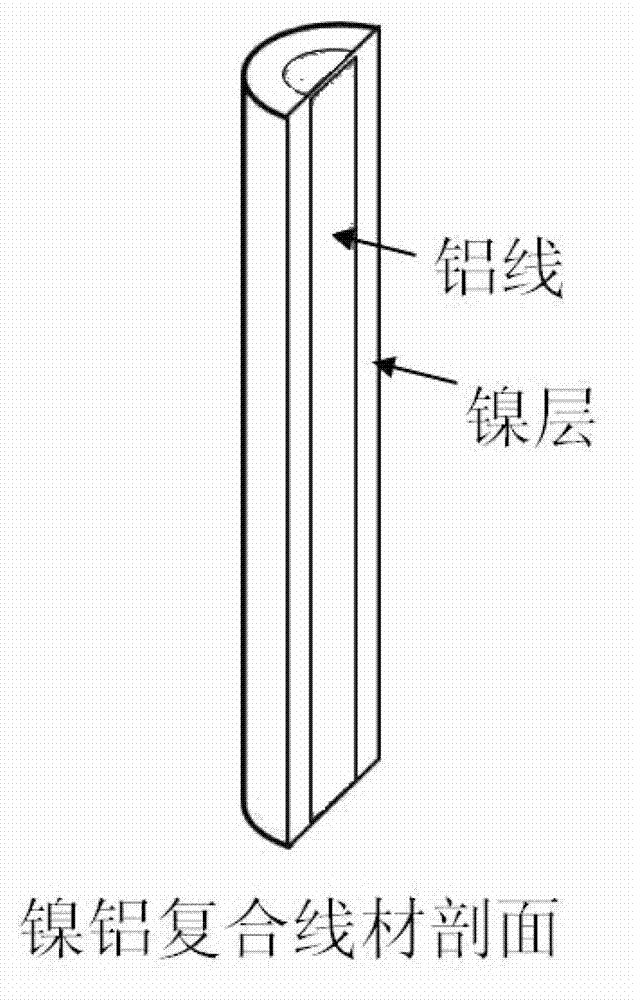

ActiveCN102922791ASolve the mechanical propertiesSolve corrosiveMetal layered productsTemperature resistanceHigh-temperature corrosion

The invention a Ni-Al alloy honeycomb material. The Ni-Al alloy honeycomb material is characterized in that a core is a pure aluminium material or an aluminum alloy material, and is a linear or tube-shaped material specifically, and an outer layer of the Ni-Al alloy honeycomb material is a coating layer made from a pure nickel or nickel base alloy material; and the radial dimension range of a cross-sectional shape is 0.001 mm-10 mm, and the proportion of the diameter of the core linear material or the wall thickness of the core tube-shaped material to the thickness of the coating layer is 0.05 to 1. The invention also relates to a preparation method of the Ni-Al alloy honeycomb material. A hollow structure is formed by utilizing a Kirkendall effect that elements Ni and Al in a nickel-aluminum composite wire or tube are diffused, so that the Ni-Al alloy honeycomb material is obtained, the preparation method solves the problem that the high temperature mechanical properties and high temperature resistance corrosion properties of the conventional metal honeycomb material are universally low, and the preparation method is suitable for large-scale manufacture.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

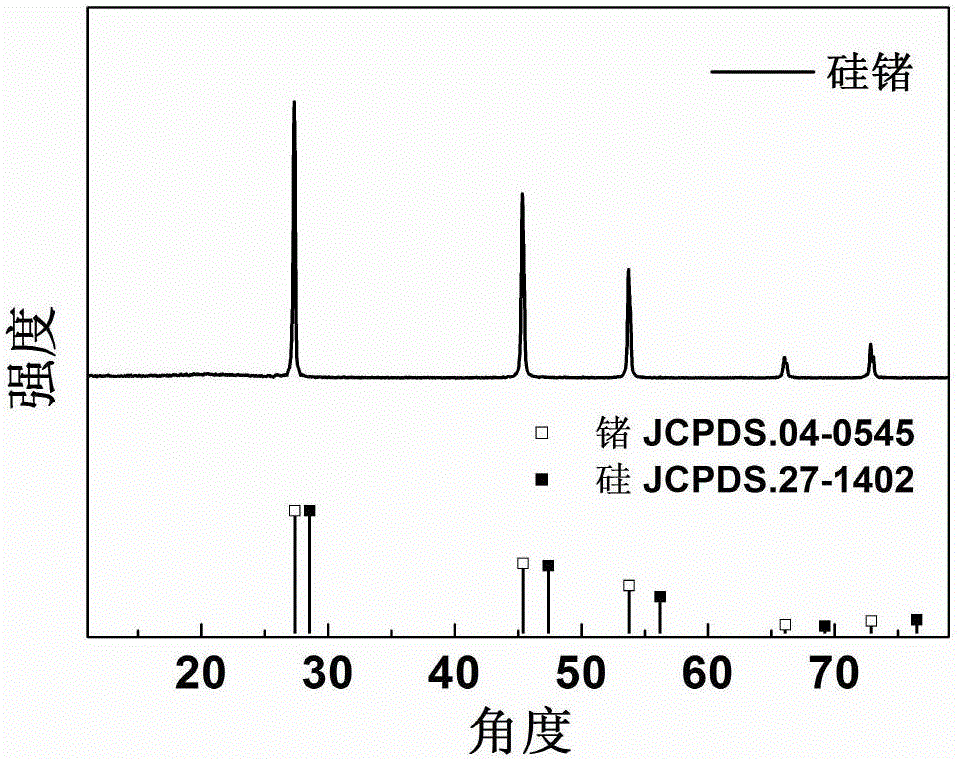

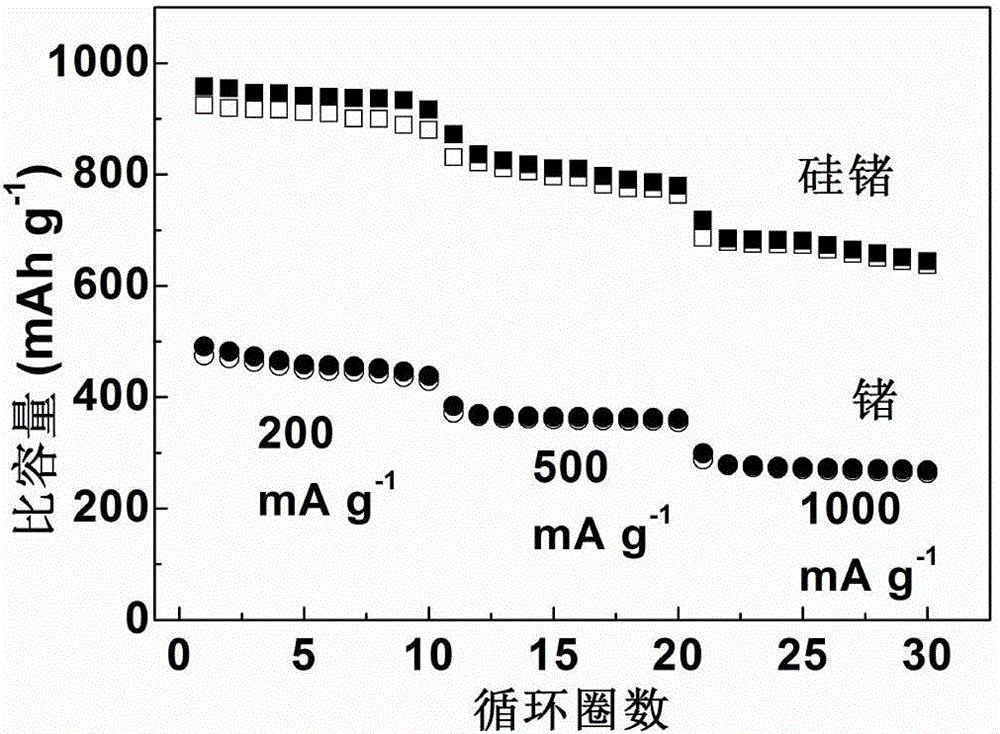

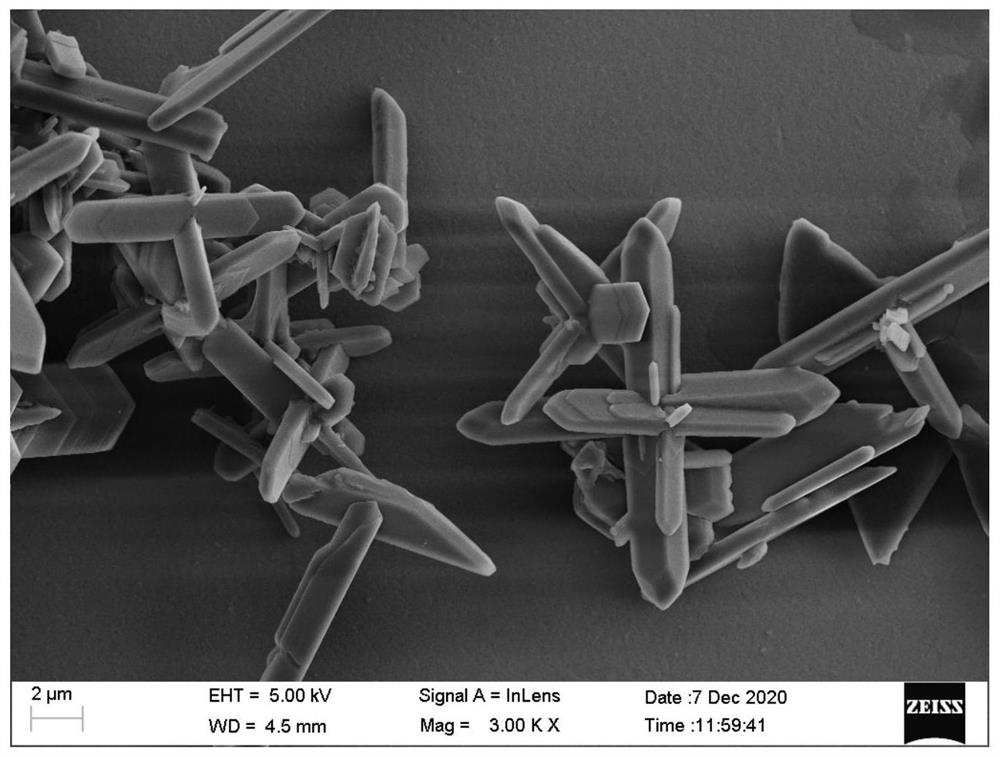

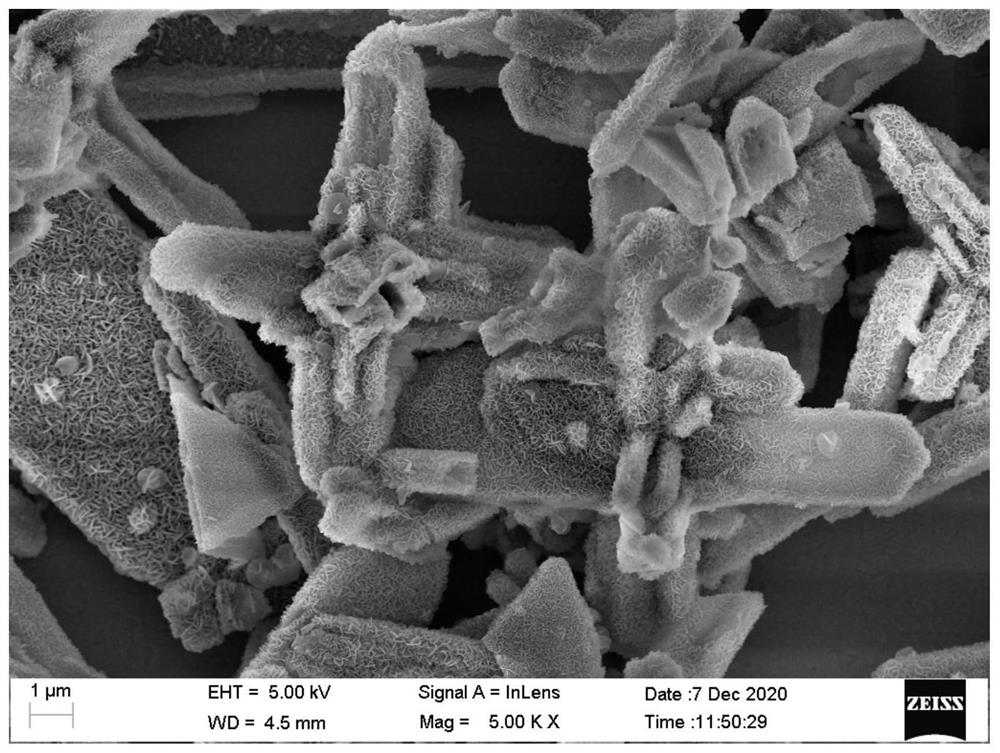

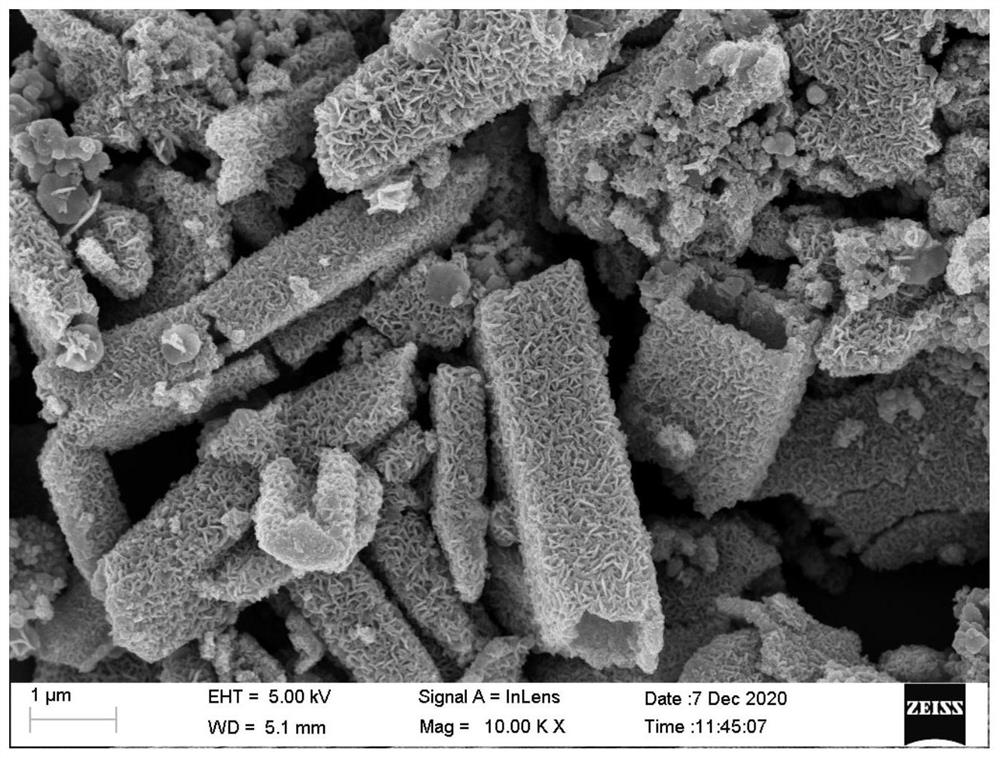

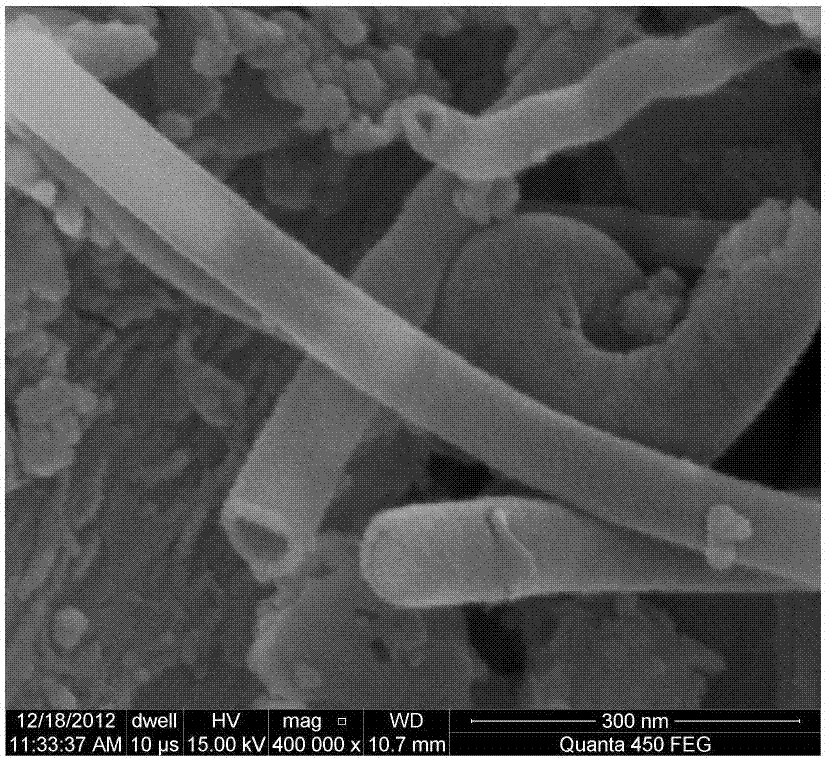

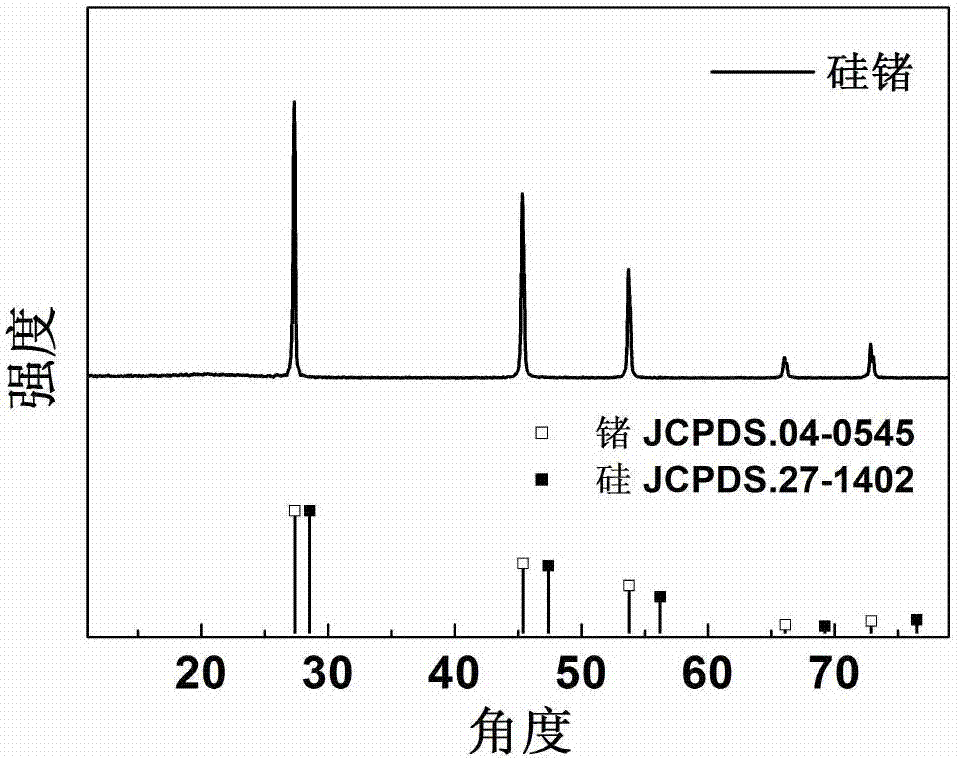

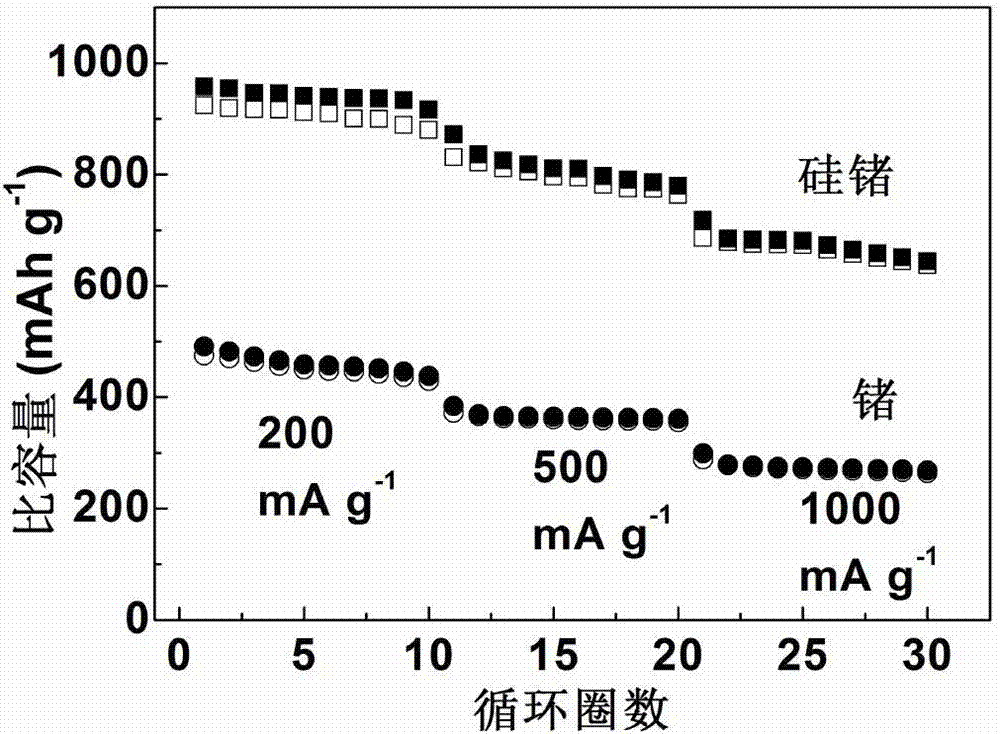

Silicon-germanium solid solution and preparation method and application thereof

ActiveCN105839146AThe electrolysis process is controllableEasy to operateCell electrodesSecondary cellsSolid solutionCharge and discharge

The invention provides a silicon-germanium solid solution and a preparation method and application thereof. According to the silicon-germanium solid solution and the preparation method and application thereof, a composite material containing a silicon precursor and a germanium precursor serves as a cathode, an inert electrode serves as an anode, and a melt containing CaCl2 serves as an electrolyte, so that silicon-germanium solid solution powder is obtained through electrolysis; or, a conductive substrate serves as a cathode, an inert electrode serves as an anode, and a melt containing a silicon precursor, a germanium precursor and CaCl2 serves as an electrolyte, so that a thin film or an array electrode material of the silicon-germanium solid solution on the conductive substrate is obtained through electrolysis. According to the single-step controllable template-free preparation method provided by the invention, the Kirkendall effect is utilized, in the electrolytic process, the diffusion rate of germanium is larger than that of silicon, and a vacancy is formed on one side of the germanium, so that a silicon-germanium solid solution nano hollow structure is obtained; volume change in the charging and discharging processes is effectively relieved, and the cycle performance and rate performance of a battery are significantly improved; and a template is not needed, operation is convenient, and the silicon-germanium solid solution is suitable for large-scale industrial production.

Owner:WUHAN UNIV

Nickel-cobalt-manganese ternary metal sulfide hollow structure material and preparation and application thereof

ActiveCN113436901AGuaranteed stabilityFast transferHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel salt

The invention discloses a nickel-cobalt-manganese ternary metal sulfide hollow structure material and preparation and application thereof, and belongs to the field of supercapacitor electrode materials. The preparation method comprises the following steps: by taking ZIF-67 as a template reactant and a cobalt source, carrying out ion exchange on the ZIF-67, nickel salt and manganese salt under a hydrothermal condition, carrying out an H+ etching effect generated by hydrolysis of metal salt and a Kirkendall effect to prepare a NiCoMn-OH hollow structure material; and the hollow structure material and thioacetamide are subjected to solvothermal reaction to prepare the nickel-cobalt-manganese ternary metal sulfide hollow structure material. The nickel-cobalt-manganese ternary metal sulfide hollow structure material prepared by the method has very high specific surface area and specific capacitance, and the specific capacitance can reach 2098.2 F / g when the nickel-cobalt-manganese ternary metal sulfide hollow structure material is used as an electrode material of a supercapacitor.

Owner:多助科技(武汉)有限公司

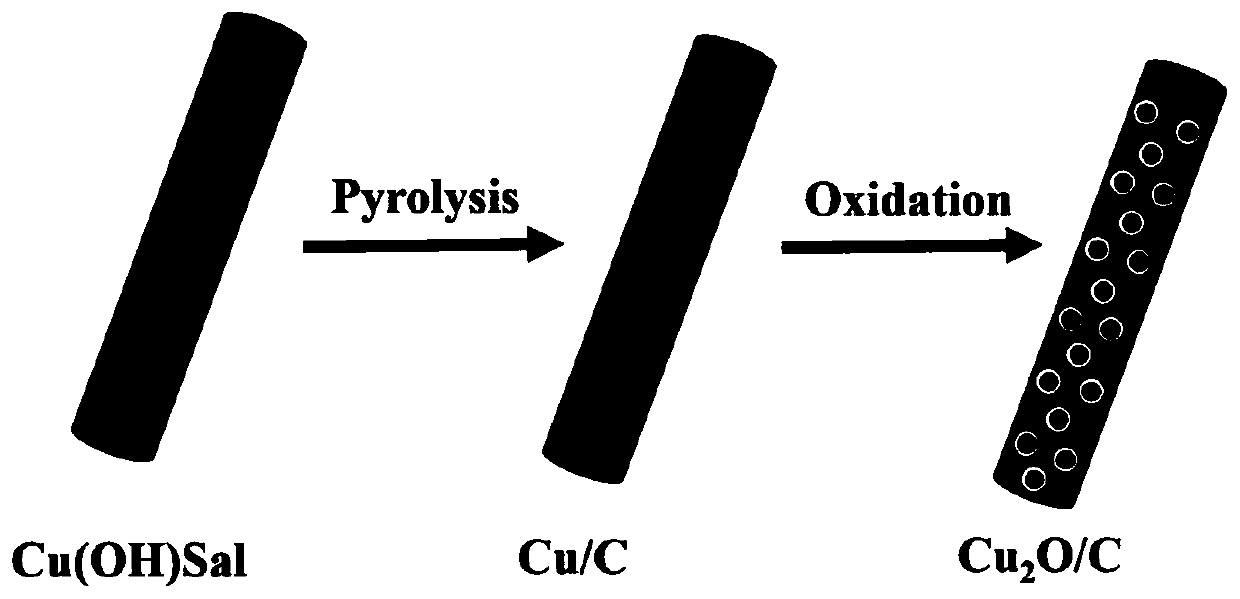

Method for preparing one-dimensional cuprous oxide/carbon nanocomposite catalyst and application

ActiveCN110152664AHigh crystallinityImprove catalytic performanceMaterial nanotechnologyOrganic compound preparationCarbon nanocompositeCrystallinity

The invention discloses a method for preparing a one-dimensional cuprous oxide / carbon nanocomposite catalyst and application. The method disclosed by the invention comprises the following steps: by utilizing an intercalation assembly of salicylate and metal ions, preparing salicylate intercalation layered copper hydroxide having one-dimensional morphology; carrying out solid-state pyrolysis and low-temperature oxidation two-step solid-phase reactions, thereby obtaining the one-dimensional cuprous oxide / carbon nanocomposite catalyst. According to the method disclosed by the invention, cheap water soluble salts serve as reactants, any organic solvent, surfactant, extra carrier, template agent or reducing agent is not needed in the preparation process, the prepared catalyst particle is uniform in distribution, high in purity and high in crystallinity, and the Cu nanoparticles form Cu2O having a hollow structure by utilizing a Kirkendall effect. The catalyst synthesized in the invention has excellent catalytic performance and excellent cycling stability in a liquid phase hydrogenation reaction of p-nitrophenol.

Owner:BEIJING UNIV OF CHEM TECH

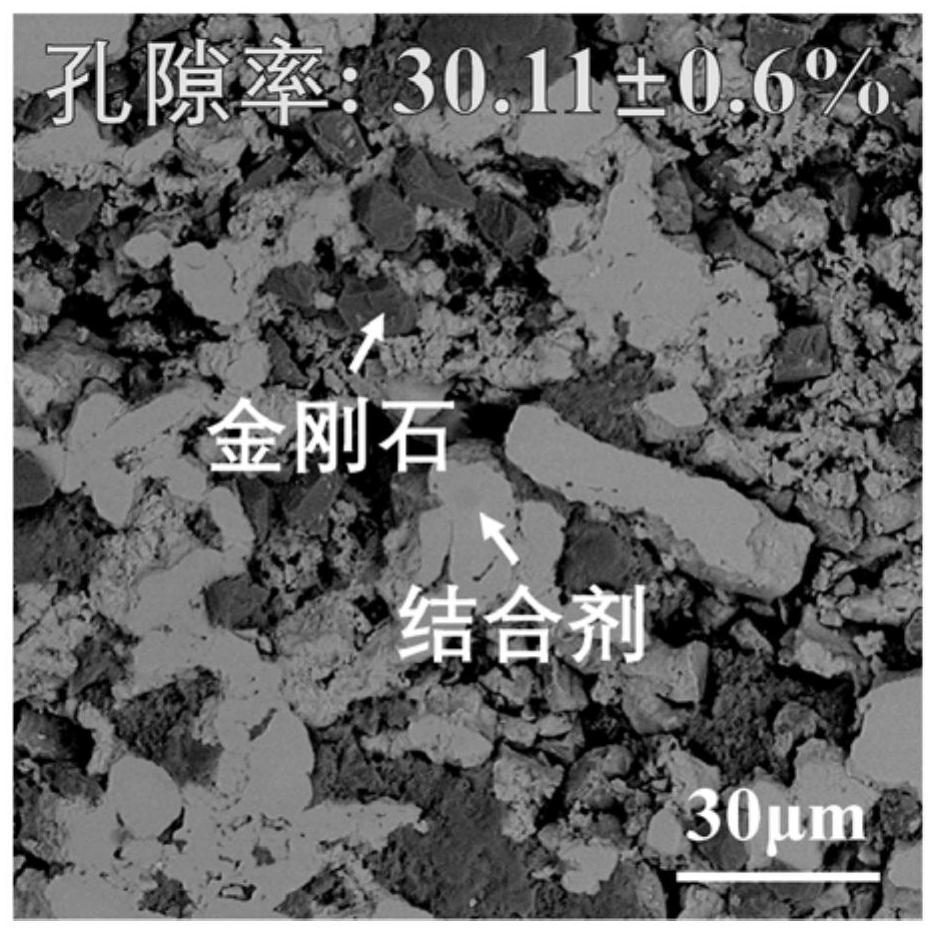

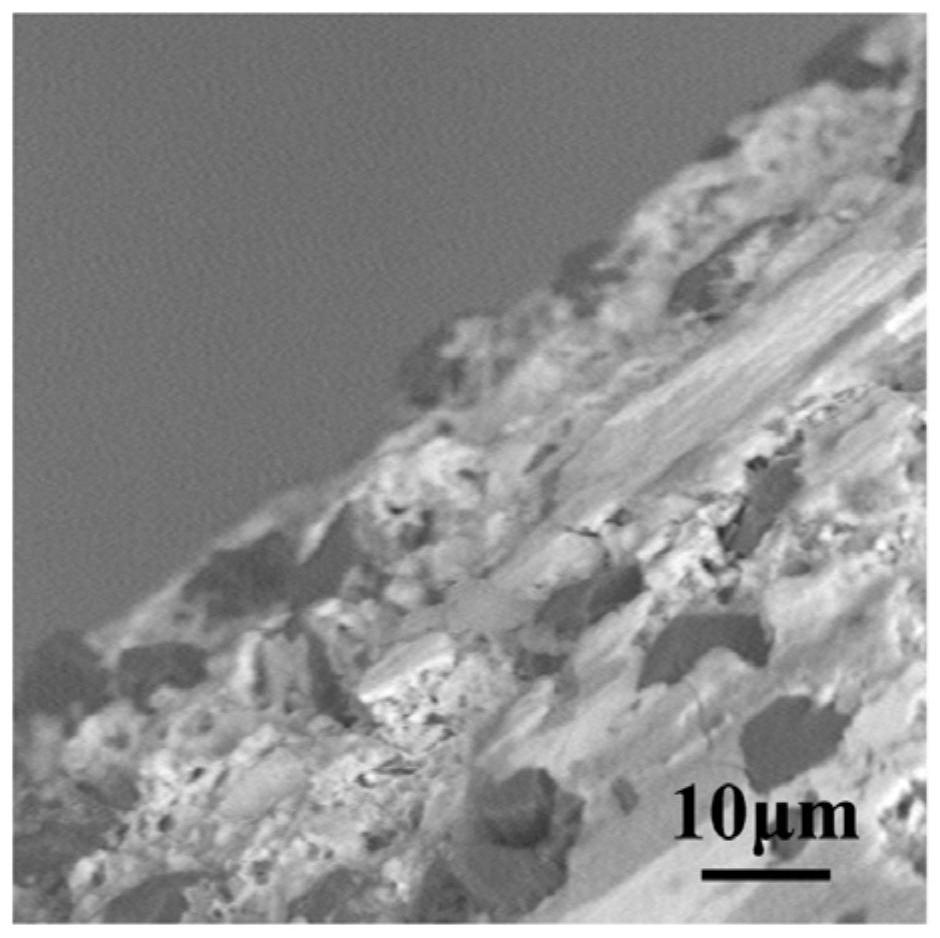

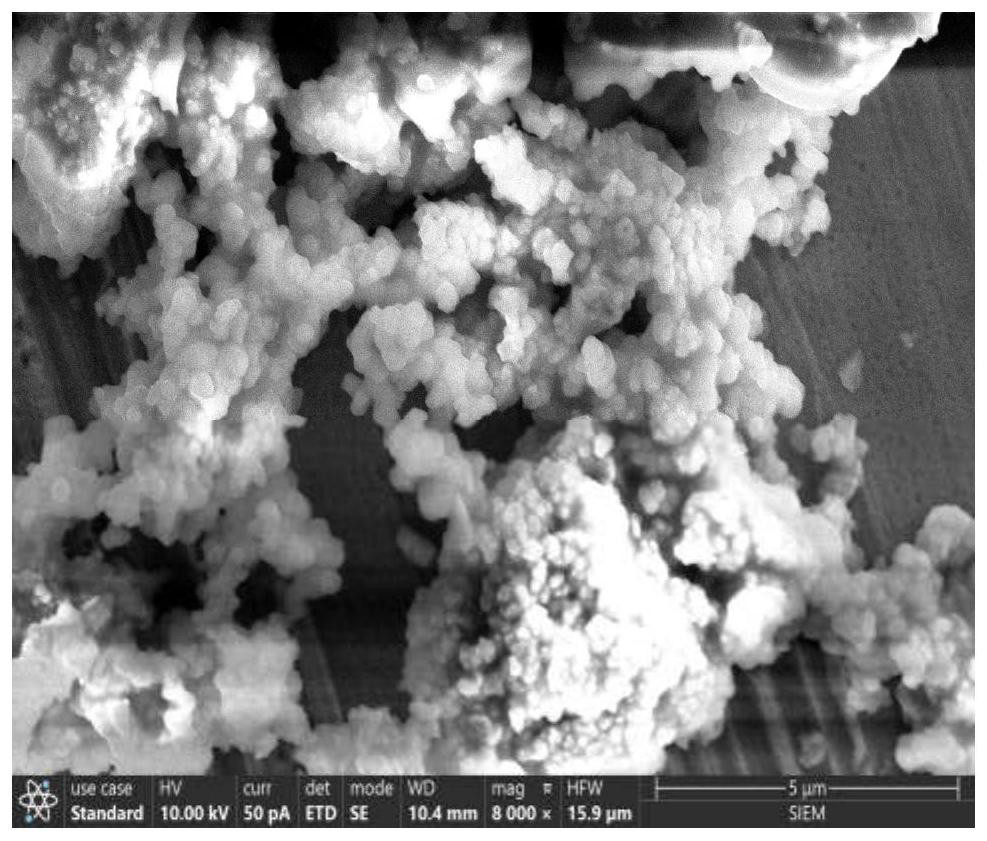

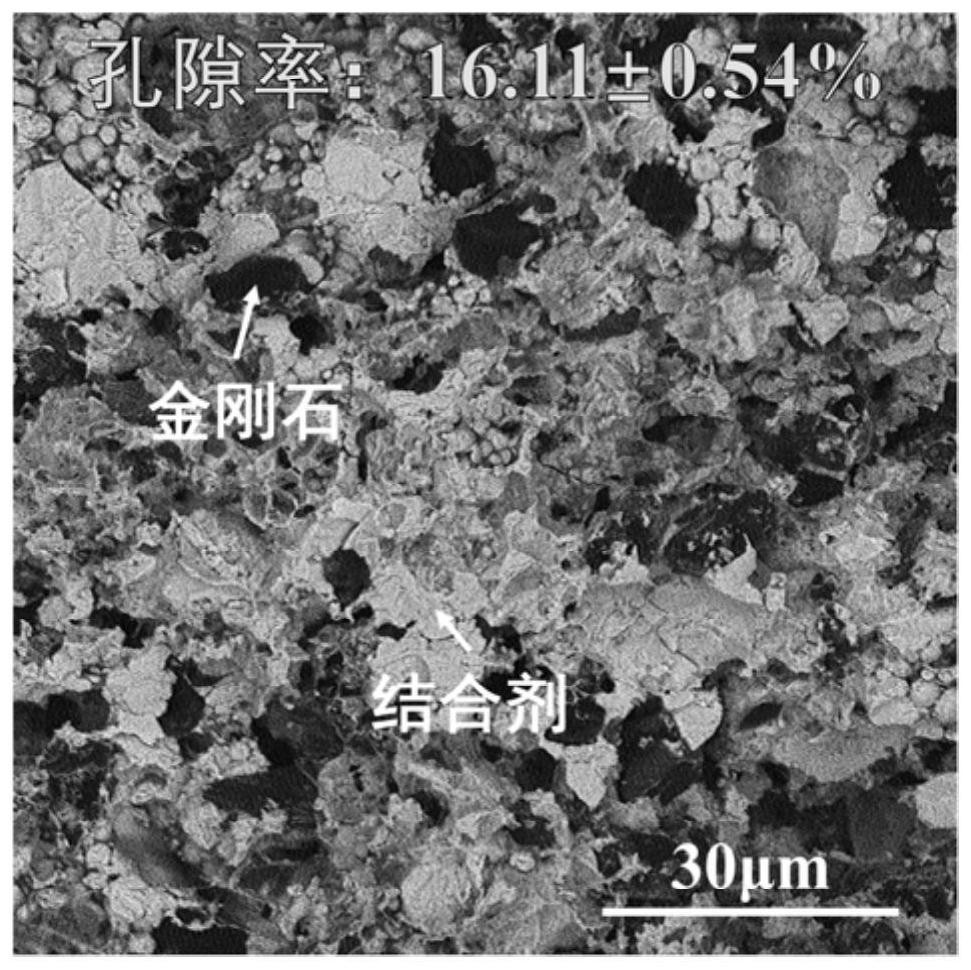

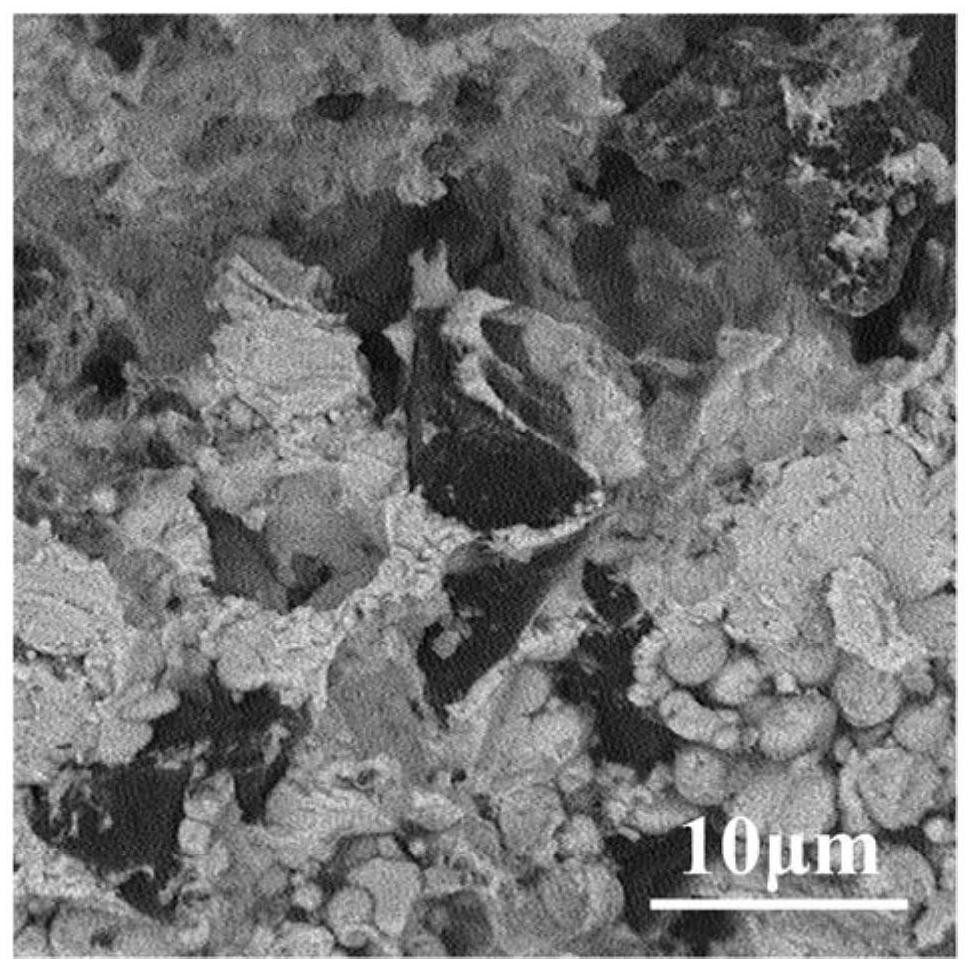

Porous ultrathin grinding wheel for chip cutting and preparation method thereof

ActiveCN113021204ASolve bottlenecks that cannot be thinned furtherGood self-sharpeningAbrasion apparatusGrinding devicesBoron nitrideGrinding wheel

The invention provides a porous ultrathin grinding wheel for chip cutting and a preparation method thereof. The ultrathin grinding wheel is composed of a super-hard abrasive and a metal-based matrix, the super-hard abrasive comprises diamond and cubic boron nitride, the metal-based matrix is a Ti-Al-based alloy, and a porous structure on the ultrathin grinding wheel is generated by utilizing a Kirkendall effect reaction caused by a diffusion rate difference between Ti / Al elements. The preparation method comprises the steps of carrying out material preparation, carrying out cold press molding, carrying out sintering molding and carrying out machining, wherein the sintering molding is composed of two sintering procedures of pore forming and performance adjusting, the sintering conditions of the pore forming procedure are 600-700 DEG C and 10-240 min, and the sintering conditions of the performance adjusting procedure are 750-1100 DEG C and 5-120 min. According to the porous ultrathin grinding wheel for chip cutting and the preparation method thereof, chemical bonding is achieved through mutual diffusion of Ti elements and the super-hard abrasive, so that the holding force of abrasive particles is improved, and the ultrathin grinding wheel can be further thinned; and the self-sharpening capacity of the ultrathin grinding wheel is improved by introducing the porous structure through the Kirkendall effect between the Ti / Al elements, so that the cutting quality of a chip is improved, and materials such as a pore forming agent do not need to be added, so that the production cost is reduced.

Owner:HUAQIAO UNIVERSITY

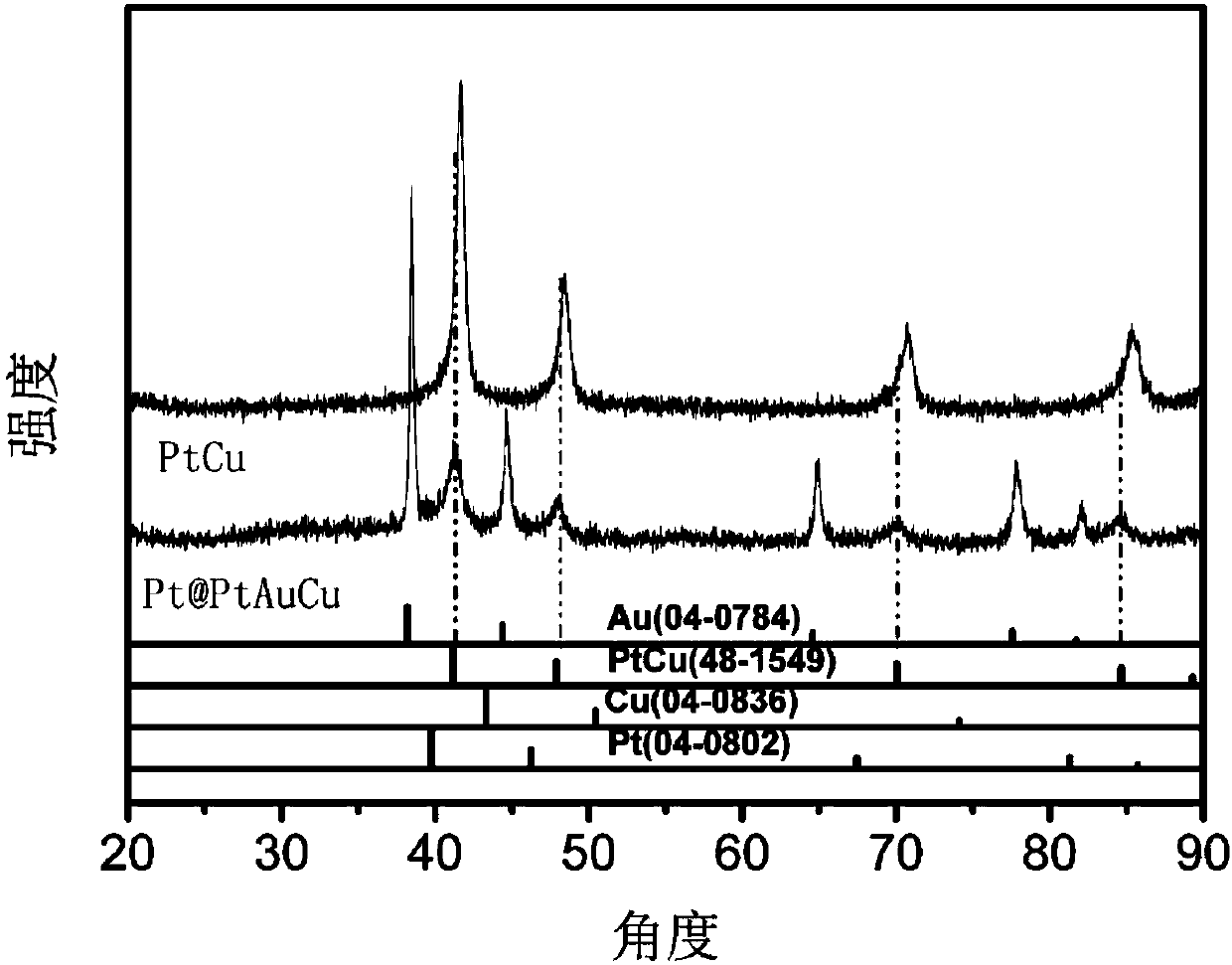

Ternary core-shell structure nanometer electrocatalyst and preparation method thereof

ActiveCN107910566ASimple processEasy to operateMaterial nanotechnologyCell electrodesRoom temperatureDissolution

A ternary core-shell structure nanometer electrocatalyst and a preparation method thereof belong to the technical field of chemical energy. The preparation method comprises the steps of (1) adding a certain amount of metal precursor into deionized water, adding octadecylamine again, and performing stirring for 12 hours to obtain a uniform mixed liquid; (2) placing the obtained uniform mixed liquidinto a polytetrafluoroethylene reaction kettle to obtain a black mixture solution; and (3) centrifugally washing the mixture solution, and performing drying under a room temperature to obtain mixturepowder. The core-shell structure nanometer electrocatalyst with different metal in the interior and the exterior can be formed according to different reduction sequences of different metal, so that the quality activity and the area activity of the ternary core-shell structure electrocatalyst can be improved by dissolution of non-previous metal and a Kirkendall effect, and the stability and the oxidization-reduction performance of the ternary core-shell structure electrocatalyst are improved. The invention can provide the ternary core-shell structure nanometer electrocatalyst with excellent oxidization-reduction performance and having high industrial and commercial values.

Owner:BEIJING UNIV OF TECH

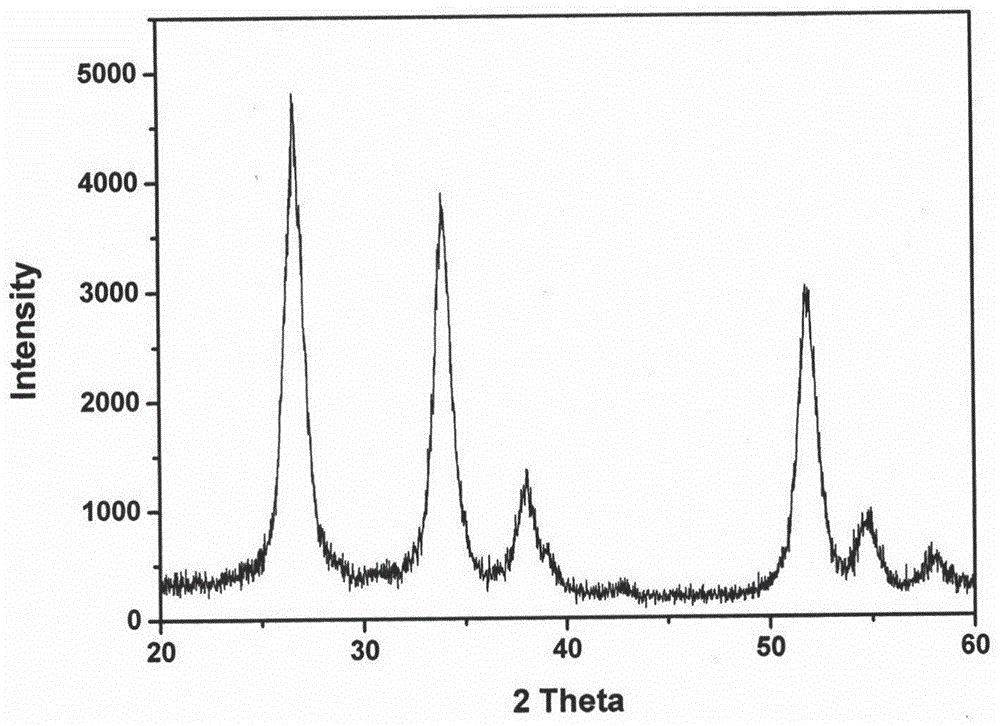

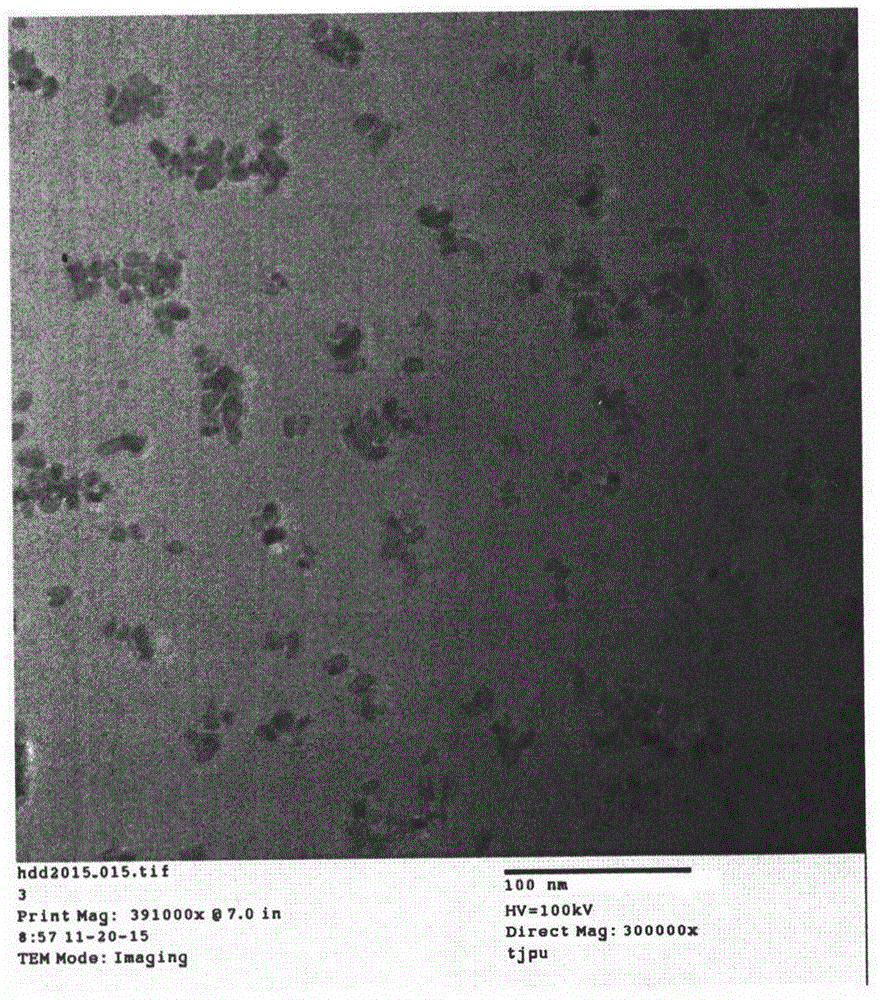

Method for directly preparing stannic oxide nano-particles by using metallic tin

The invention belongs to the field of nano material preparation, and particularly relates to a method for directly preparing stannic oxide nano-particles by using metallic tin. The method specifically comprises the steps of placing metallic tin in a mixed solution of iodine / ethyl alcohol and sodium carbonate, and obtaining a nano stannic oxide material through a high-temperature water / solvent thermal reaction. The stannic oxide nano-particles with a nanoscale size are formed by unequal diffusion of different matters between the interfaces of two phases on the basis of a Kirkendall effect. Through the method, elementary substance tin can be directly used as a raw material, the stannic oxide nano-particles are prepared under the condition of mild pH closed to be neutral, the obtained product is high in purity, an organic template reagent is not needed, energy consumption and pollution caused by high-temperature roasting can be avoided, and the agglomeration of the nano-particles at the high temperature can be avoided.

Owner:TIANJIN POLYTECHNIC UNIV

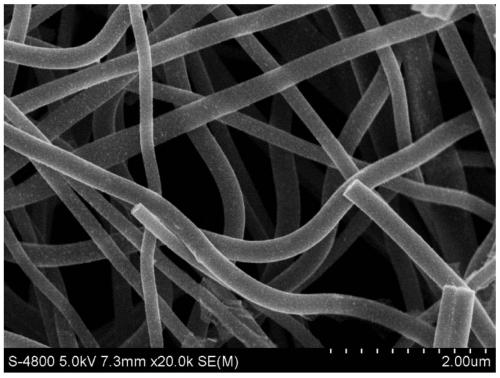

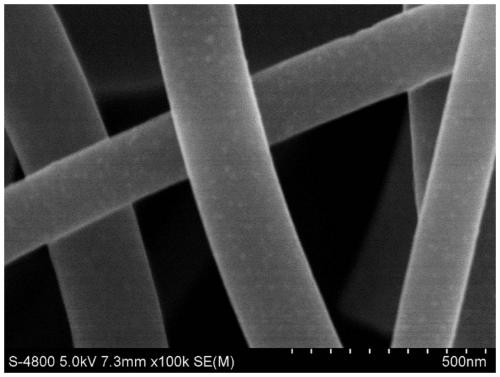

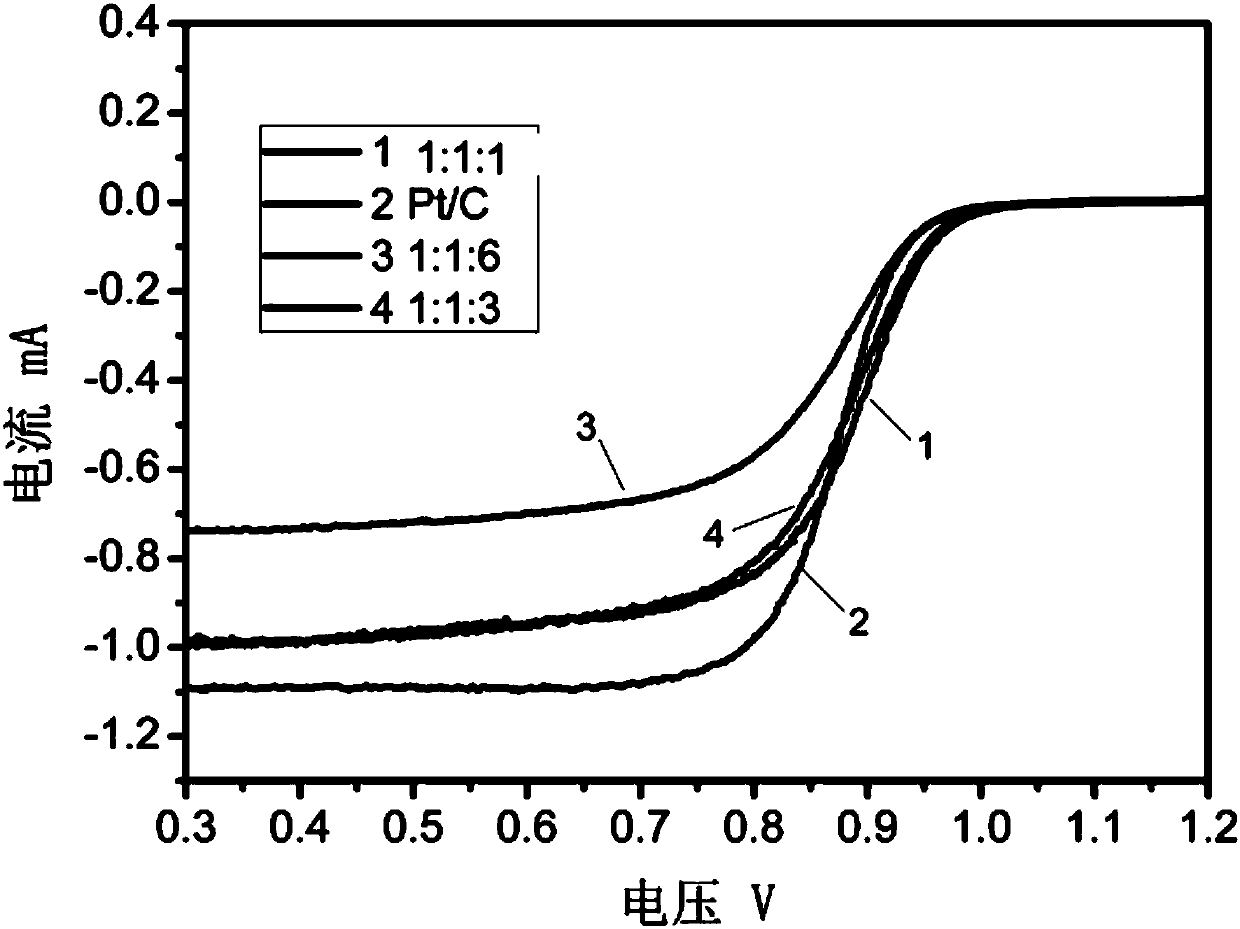

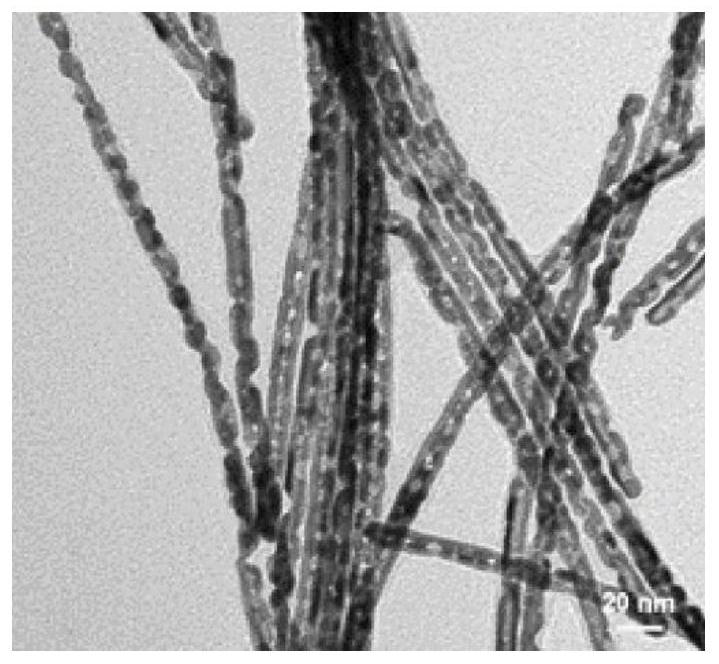

Preparation method of dual-element Pt/PdPt/Pt sandwich tube wall porous nanotube and porous nanotube

The invention provides a porous nanotube with a rough surface and a dual-element Pt / PdPt / Pt interlayer tube wall and a preparation method of the porous nanotube. The Kirkendall effect is used for enabling platinum ions to generate a nucleation phenomenon on the surface of a palladium nanowire, internal palladium is gradually removed through gaps of a deposition layer, and then the hollow PdPt nanotube with the outer diameter being 8.6 nm and the wall thickness being about 2.2 nm is formed; the nanotube is further processed to form an interlayer structure with a tube wall element of Pt / PdPt / Pt. According to the product PdPt nanotube, the platinum element can be fully exposed on the inner side and the outer side of the nanotube wall, the utilization rate of platinum in the material is greatly increased, the tube wall interlayer contains the PdPt double elements, and the catalytic reaction activity is greatly improved through the stress and strain effect between the double metals. When the catalyst is used as a fuel cell cathode reaction catalyst, the reaction activity of the catalyst is greatly improved in an oxygen reduction reaction, the active specific surface area ECSA of the catalyst is 1.46 times that of commercial Pt / C sold in the market, the mass activity (MA) of the catalyst is 14.3 times that of the commercial Pt / C, and the actual specific activity (SA) of the catalyst is 9.64 times that of the commercial Pt / C.

Owner:YANSHAN UNIV

Hollow spherical NiMn2O4 lithium ion battery cathode material and preparation method thereof

ActiveCN103337604BSimple processEasy to operateCell electrodesNanotechnologyNickel saltLithium-ion battery

The invention discloses a hollow spherical NiMn2O4 lithium ion battery cathode material and a preparation method thereof, and belongs to the field of lithium ion battery electrode material technology. Particle size of the hollow spherical material is 1 to 3 micrometers; the spherical shell is made of NiMn2O4 nanometer crystals, and has a porous structure. The porous spherical shell is in favor of penetration of electrolyte, is capable of shortening diffusion distance of lithium ions, and possesses excellent electrochemistry cycling stability and rate capability. The preparation method is based on ''Kirkendall effect'', and the hollow spherical NiMn2O4 can be obtained directly by performing high temperature solid phase reaction. The preparation method comprises following steps: taking solid spherical MnCO3 as a precursor; roasting at a low temperature to obtain porous solid spherical manganese dioxide; and then roasting the porous solid spherical manganese dioxide with a nickel salt to obtain the hollow spherical spinel-type NiMn2O4 cathode material. The preparation method is simple in technologies, do not need a template, and is suitable for large-scaled production.

Owner:BEIJING UNIV OF CHEM TECH

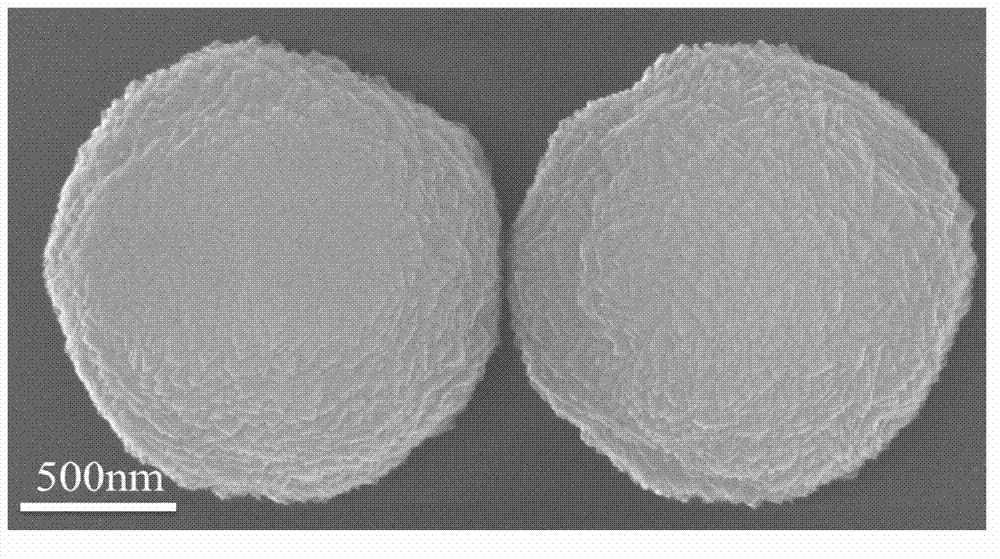

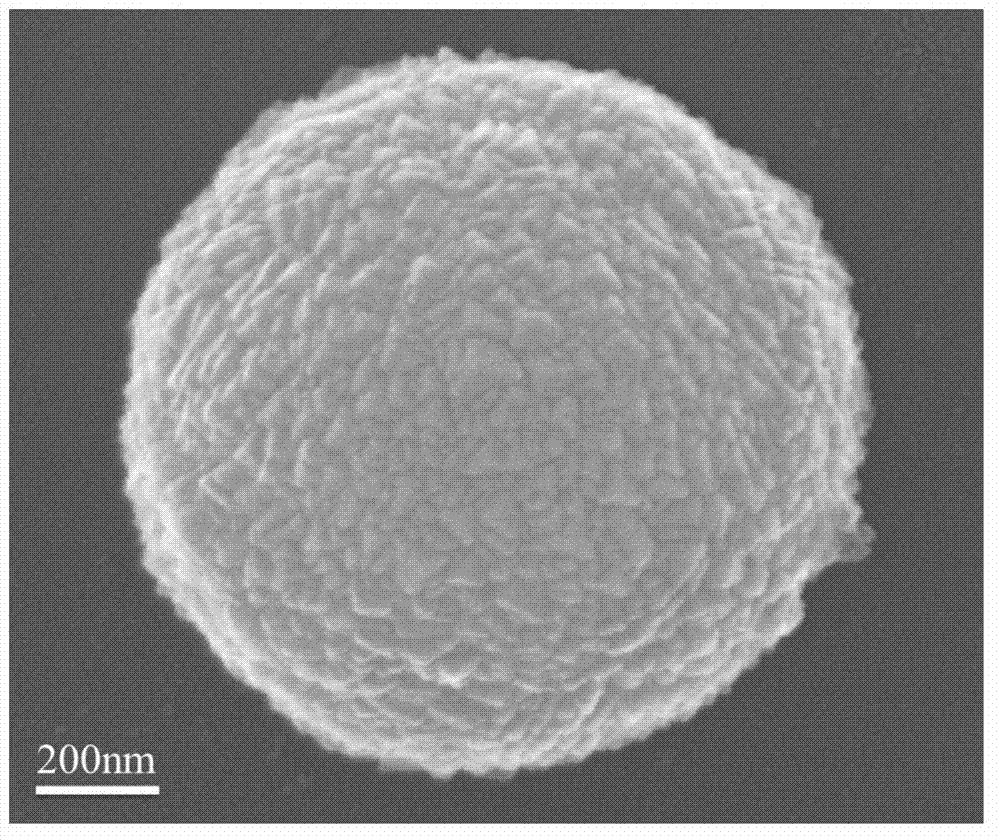

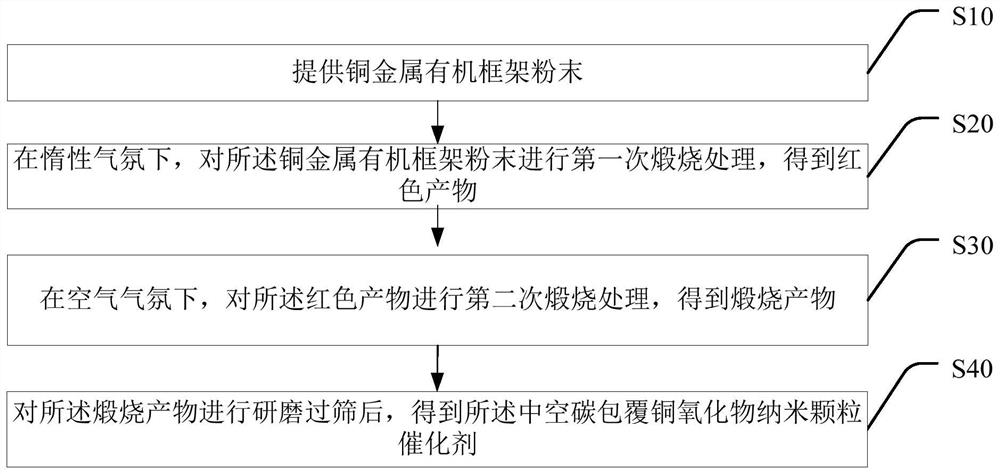

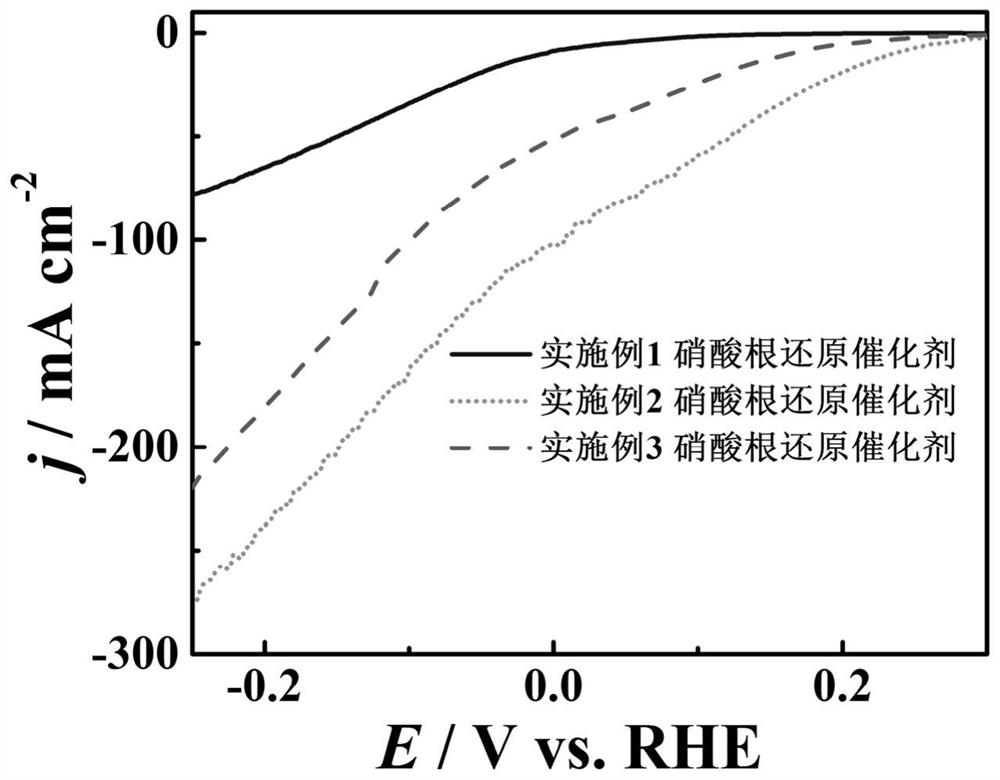

Hollow carbon-coated copper oxide nanoparticle catalyst as well as preparation method and application thereof

ActiveCN113235113AIncrease spawn rateThe synthesis method is simpleElectrodesAir atmospherePtru catalyst

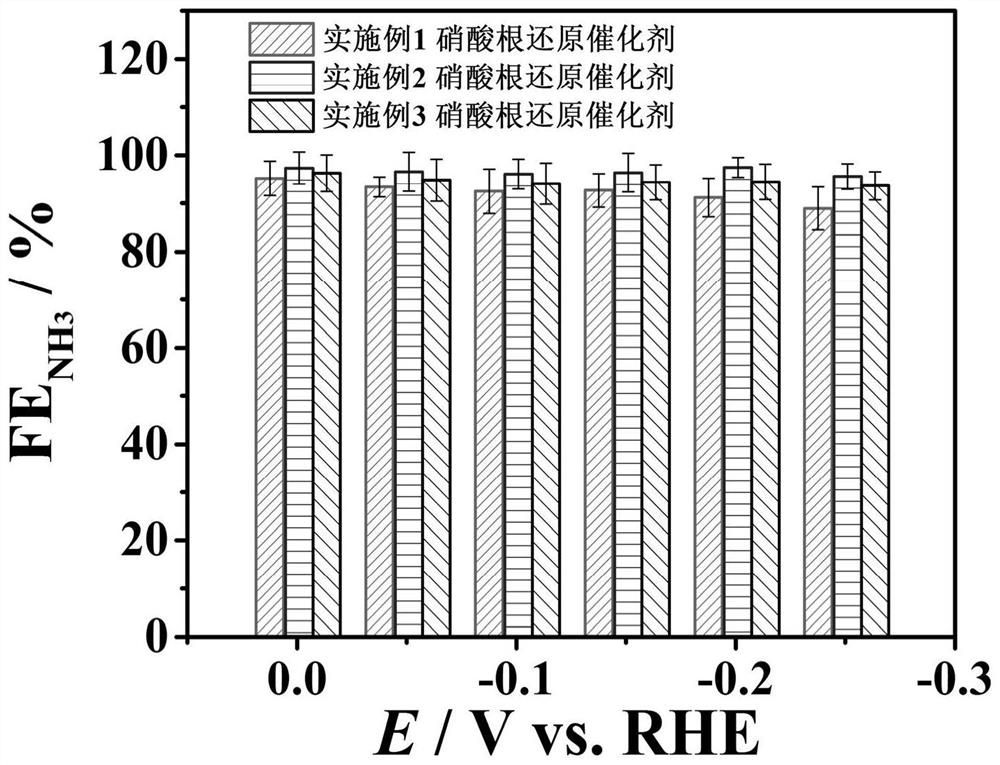

The invention discloses a hollow carbon-coated copper oxide nanoparticle catalyst and a preparation method and application thereof. The preparation method comprises the steps: in an inert atmosphere, calcining copper metal organic framework powder for the first time, and obtaining a red product; carrying out secondary calcination treatment on the red product in an air atmosphere to obtain a calcined product; and grinding and sieving the calcined product to obtain the hollow carbon-coated copper oxide nanoparticle catalyst. The hollow carbon-coated copper oxide nano-particle catalyst with rich oxygen vacancies is effectively synthesized by utilizing the Kirkendall effect, due to the unique hollow structure and the rich oxygen vacancies, the maximum Faraday efficiency of ammonia of the catalyst is 94.2% under the potential of -0.2 V Vs RHE, the generation rate of ammonia reaches 487.8 mmol g<cat><-1> h<-1>, and the maximum Faraday efficiency of the catalyst is 94.2% under the potential of-0.2 V Vs RHE, and is about 2.4 times of the conversion rate of ammonia in the Haber-Bosch reaction.

Owner:SHENZHEN UNIV

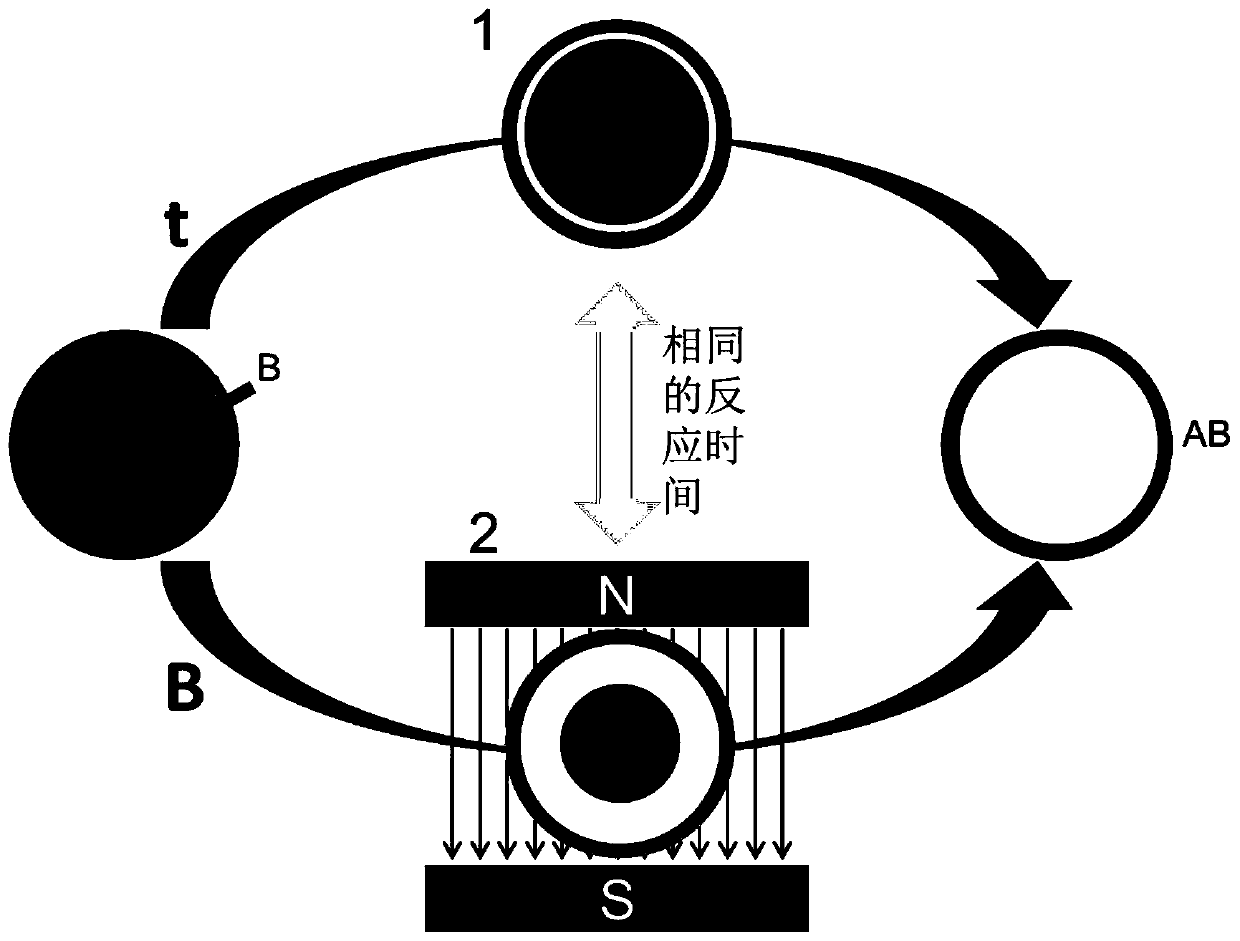

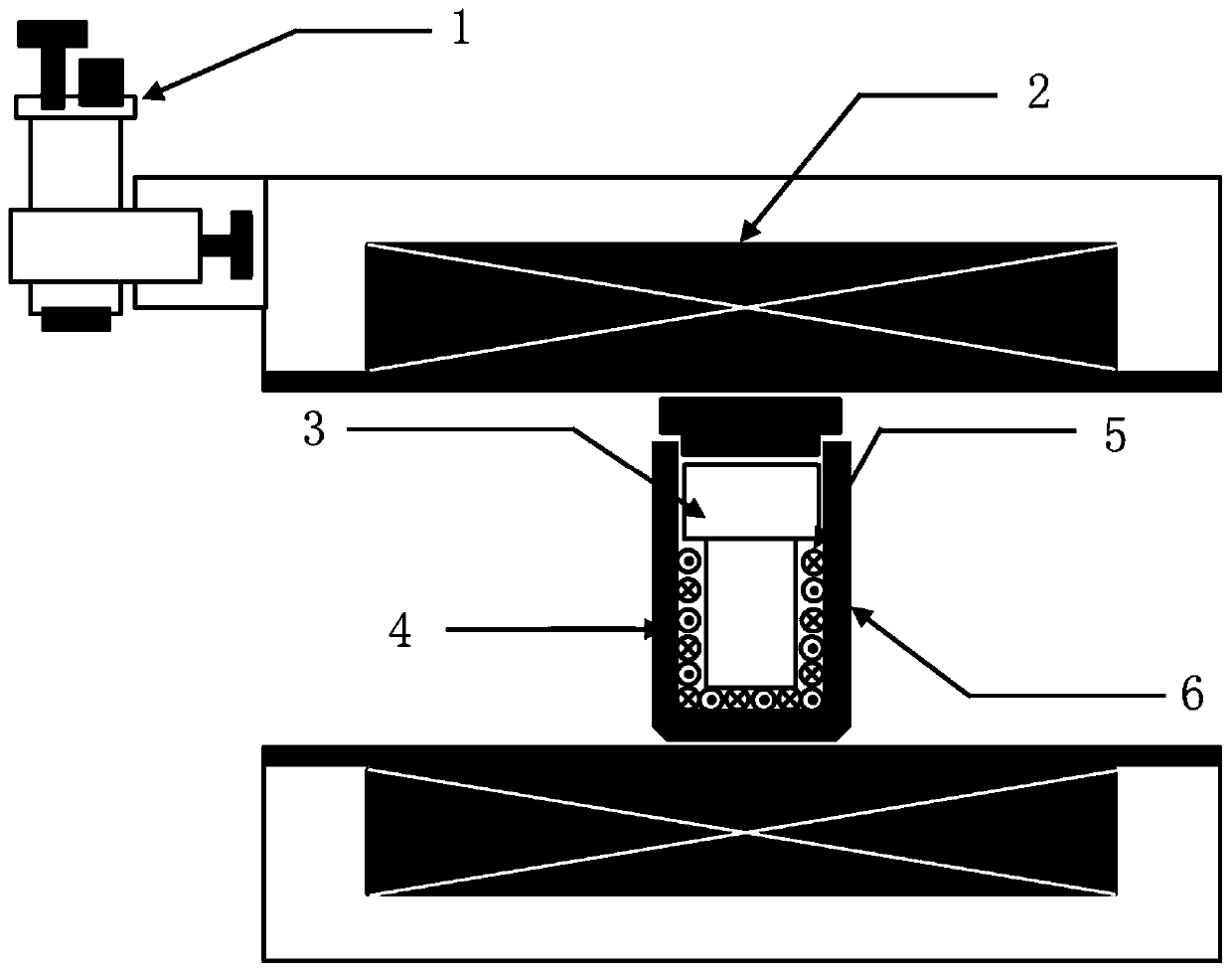

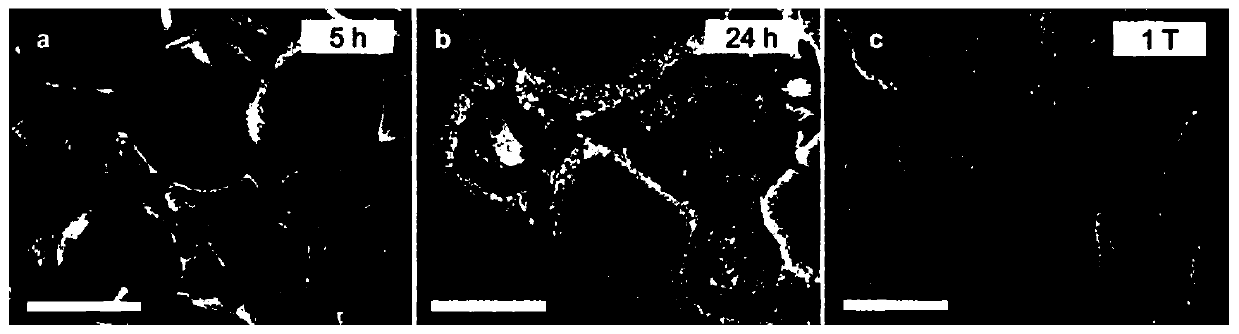

Method for preparing hollow/mesoporous nano structure material by adjusting Kirkendall effect through magnetic field

ActiveCN107399738APromote interdiffusionPromote formationSiliconNanotechnologyNano structuringNanostructured materials

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Iron carbon composite material with novel structure, and preparation method thereof

InactiveCN110193367AAvoid reunion inactivationEvenly dispersedCarbon compoundsOther chemical processesCarbon compositesMicrosphere

The invention discloses an iron carbon composite material with a novel structure, and a preparation method thereof. According to the preparation method, micrometer grade carbon microsphere (GAC) is taken as a composite material carrier, based on Kirkendall effect, under air combustion driving force, dispersion of nanometer grade zero-valent iron onto carbon microsphere surfaces is promoted, wherein the carbon microspheres are prepared through suspension polymerization method, prepared of GAC-GAC-nZVI is realized through reduction of ferrous sulphate with a reducing agent and cladding of phenolic resin-carbonization-air combustion based on Kirkendall effect. The GAC-GAC-nZVI preparation method is capable of realizing optimization on active carbon pore structure, ensuring uniform dispersionof nanometer grade zero-valent ion, and GAC-GAC-nZVI adsorption degradation performance is improved greatly.

Owner:东北大学秦皇岛分校

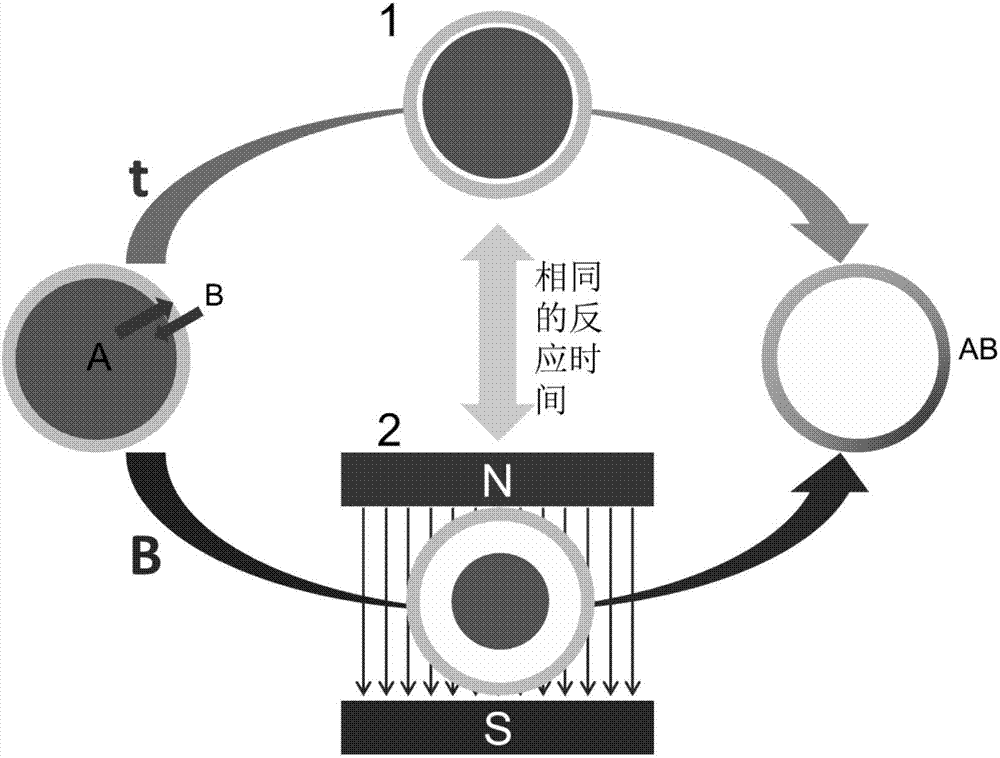

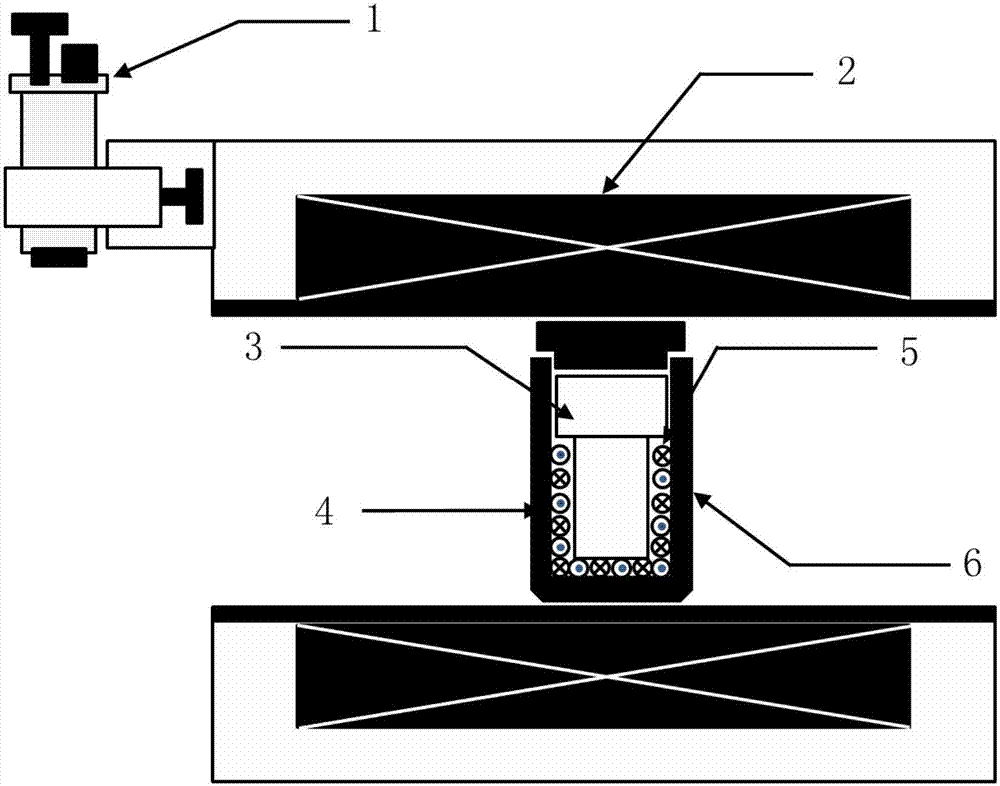

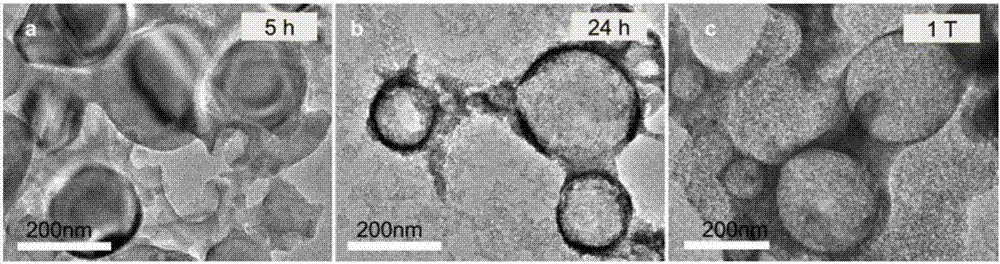

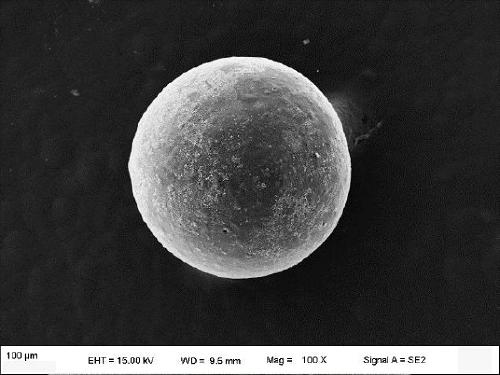

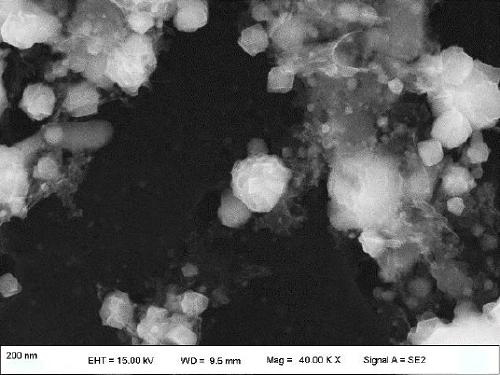

A method for preparing hollow/mesoporous nanostructured materials by modulating the Kirkendall effect with a magnetic field

ActiveCN107399738BPromote interdiffusionPromote formationSiliconNanotechnologyNanostructured materialsNanostructure

The invention discloses a method for preparing a hollow / mesoporous nano structure material by adjusting the Kirkendall effect through a magnetic field. In the process that a hollow / mesoporous nano structure material is prepared through the Kirkendall effect, a hydrothermal reaction step is implemented under an external magnetic field condition. Due to an external magnetic field, the time that a solid nano structure material is transformed into the hollow / mesoporous nano structure material is greatly shortened at a relatively low temperature by virtue of the Kirkendall effect, so that great benefit values are made since the reaction preparation cost is reduced, and current development themes of energy conservation and environment protection are met.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A method for directly preparing tin dioxide nanoparticles by utilizing metallic tin

The invention belongs to the field of nano material preparation, and particularly relates to a method for directly preparing stannic oxide nano-particles by using metallic tin. The method specifically comprises the steps of placing metallic tin in a mixed solution of iodine / ethyl alcohol and sodium carbonate, and obtaining a nano stannic oxide material through a high-temperature water / solvent thermal reaction. The stannic oxide nano-particles with a nanoscale size are formed by unequal diffusion of different matters between the interfaces of two phases on the basis of a Kirkendall effect. Through the method, elementary substance tin can be directly used as a raw material, the stannic oxide nano-particles are prepared under the condition of mild pH closed to be neutral, the obtained product is high in purity, an organic template reagent is not needed, energy consumption and pollution caused by high-temperature roasting can be avoided, and the agglomeration of the nano-particles at the high temperature can be avoided.

Owner:TIANJIN POLYTECHNIC UNIV

A kind of silicon germanium solid solution and its preparation method and application

ActiveCN105839146BThe electrolysis process is controllableEasy to operateCell electrodesSecondary cellsSolid solutionCharge and discharge

The invention provides a silicon-germanium solid solution and a preparation method and application thereof. According to the silicon-germanium solid solution and the preparation method and application thereof, a composite material containing a silicon precursor and a germanium precursor serves as a cathode, an inert electrode serves as an anode, and a melt containing CaCl2 serves as an electrolyte, so that silicon-germanium solid solution powder is obtained through electrolysis; or, a conductive substrate serves as a cathode, an inert electrode serves as an anode, and a melt containing a silicon precursor, a germanium precursor and CaCl2 serves as an electrolyte, so that a thin film or an array electrode material of the silicon-germanium solid solution on the conductive substrate is obtained through electrolysis. According to the single-step controllable template-free preparation method provided by the invention, the Kirkendall effect is utilized, in the electrolytic process, the diffusion rate of germanium is larger than that of silicon, and a vacancy is formed on one side of the germanium, so that a silicon-germanium solid solution nano hollow structure is obtained; volume change in the charging and discharging processes is effectively relieved, and the cycle performance and rate performance of a battery are significantly improved; and a template is not needed, operation is convenient, and the silicon-germanium solid solution is suitable for large-scale industrial production.

Owner:WUHAN UNIV

Connecting method of stephanoporate inner core and compact outer shell

The invention discloses a method for connecting porous inner cores with compact casings, which comprises the following steps: -80-+500 meshes of metal powder A and B are selected and blended in atom ratio 1:1, then are put into a mixer to mix evenly; the mixed powder A, B is directly packaged into a compact tube made of metal A, after 2.5 to 5.0 MPa mould pressing and forming, the mixed powder A, B is sintered in vacuum at 350 to 1200 DEG C for 1 to 2 hours; wherein, the diffusion velocity of metal B in the metal A is quicker than the diffusion velocity of the metal A in the metal B, the porous material is AB alloy, the compact material is metal A. By adopting the powder metallurgy method, the invention takes use of the Kirkendall effect and the sintering grow phenomenon when some alloys is sintered to achieve sintering and diffusion welding of porous material and compact material, so that the porous material and the compact material are connected into an integral part without any air leakage and good air tightness. The invention can realize the integrated molding of the porous material and the compact material, and the process is simple and the production cost is greatly reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Hollow silicon dioxide as well as preparation method and application thereof

PendingCN114620737AReduce stressHigh mechanical strengthSilicaSemiconductor/solid-state device detailsSilicon oxideMoisture absorption

The invention discloses hollow silicon dioxide as well as a preparation method and application thereof. The preparation method comprises the following steps: 1) dispersing monatomic silicon powder in a liquid-phase reaction system to obtain a silicon powder dispersion liquid; and 2) slowly dropwise adding ammonia water into the silicon powder dispersion liquid obtained in the step 1) until the pH value of the reaction system is 10-10.4, and then carrying out hydrothermal reaction. The hollow silicon dioxide is prepared from monatomic silicon powder through interface diffusion, preliminary oxidation and hollowing of silicon atoms and hydroxyl groups in a hydrothermal reaction. The hollow silicon dioxide prepared by utilizing the Kirkendall effect at the interface is compact in surface, has the characteristics of low stress, high mechanical strength and low moisture absorption, and can improve the reliability and reduce the dielectric constant and dielectric loss when being used as a filler of an electronic packaging material; the hollow silicon dioxide provided by the invention has the advantages of simple preparation method, no need of multi-step reaction, low cost and higher application value.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Porous Cu-Sn-based ultra-thin grinding wheel for chip dicing and preparation method thereof

ActiveCN113084717ASolve bottlenecks that cannot be thinned furtherGood self-sharpeningAbrasion apparatusGrinding devicesGrinding wheelMachining

The invention provides a porous Cu-Sn-based ultra-thin grinding wheel for chip dicing and a preparation method thereof. According to the porous Cu-Sn-based ultra-thin grinding wheel, a metal matrix tire of the ultra-thin grinding wheel is Cu-Sn-Ti alloy, and a porous structure of the ultra-thin grinding wheel is generated by utilizing a Kirkendall effect caused by a diffusion rate difference between Cu / Sn elements. The preparation method comprises the steps of material preparation, cold press molding, brazing molding and machining, wherein the brazing molding process comprises two heating procedures of pore forming and active brazing, the parameters of the pore forming procedure are 200-250 DEG C and 30-240 minutes, and the parameters of the active brazing process are 650-950 DEG C and 5-100 minutes. According to the porous Cu-Sn-based ultra-thin grinding wheel and the preparation method thereof, a metal bonding agent and a super-hard abrasive material undergo chemical metallurgical reaction by utilizing an active brazing technology, so that the holding force of abrasive particles is improved, and the ultra-thin grinding wheel can be further thinned; and the self-sharpening capacity of the ultra-thin grinding wheel is improved by introducing the porous structure through the Kirkendall effect between the Cu / Sn elements, so that the chip dicing quality is improved, and in addition, materials such as a pore forming agent do not need to be added, so that the production cost is lowered.

Owner:HUAQIAO UNIVERSITY

Manganese oxide-fesimnti intermetallic compound-based composite porous electrode material and preparation method thereof

The invention belongs to the field of composite materials, and discloses a manganese oxide-FeSiMnTi intermetallic compound-based composite porous electrode material and a preparation method thereof. The manganese oxide-FeSiMnTi intermetallic compound-based composite porous electrode material comprises 5%-15% of MnOx, 40%-50% of Fe, 15%-35% of Si, 5%-15% of Mn and 5%-15% of Ti, wherein x is equal to 1,3 / 4 or 2. According to the manganese oxide-FeSiMnTi intermetallic compound-based composite porous electrode material and the preparation method thereof, a mode of mixing oxide powder and element powder is adopted, a substrate is synthesized and prepared by using reaction between the element powder, and an oxide / intermetallic compound-based composite material is prepared by combining an initially added oxide component; and the mixing mode forms a large number of pores by fully utilizing a Kirkendall effect caused by partial diffusion of a rapid diffusion component in a substrate material component under a high-temperature condition through design of the substrate material component and design of a sintering process, and finally the oxide / intermetallic compound-based composite porous material is prepared. The controllability of a pore structure is relatively good, a pore forming agent does not need to be added, and the manganese oxide-FeSiMnTi intermetallic compound-based composite porous electrode material has the characteristic of short process.

Owner:CENT SOUTH UNIV

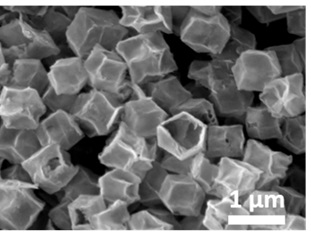

High-efficiency water decomposition catalyst hollow cobalt phosphide and preparation method thereof

ActiveCN113832477AHas a hollow structureParticle surface flatNanotechnologyPhosphidesPtru catalystAqueous solution

The invention discloses a high-efficiency water decomposition catalyst hollow cobalt phosphide and a preparation method thereof, and relates to the technical field of water decomposition catalyst preparation. The microstructure of the cobalt phosphide is a single-shell nanocage, and the cobalt phosphide takes CoP as a shell, is a hollow rhombic dodecahedron and is shaped like a cage. The preparation method comprises the preparation steps: by taking a Na2MoO4 aqueous solution as a reaction medium, constructing a Co(OH)2 hollow structure through a Kirkendall effect, then annealing the prepared Co(OH)2 hollow structure in air at the temperature of 500 DEG C to prepare a Co3O4 single-shell nanocage, and then annealing a Co3O4 single-shell nanocage precursor and NaH2PO2 at the temperature of 700 DEG C in an N2 atmosphere to form CoP with the CoP hollow structure. The hollow cobalt phosphide prepared by the method disclosed by the invention has the advantages of mesoporous property, larger specific surface area and higher water decomposition efficiency.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

Ni-al alloy honeycomb material and preparation method thereof

ActiveCN102922791BSuitable for large-scale productionMetal layered productsHoneycombTemperature resistance

The invention a Ni-Al alloy honeycomb material. The Ni-Al alloy honeycomb material is characterized in that a core is a pure aluminium material or an aluminum alloy material, and is a linear or tube-shaped material specifically, and an outer layer of the Ni-Al alloy honeycomb material is a coating layer made from a pure nickel or nickel base alloy material; and the radial dimension range of a cross-sectional shape is 0.001 mm-10 mm, and the proportion of the diameter of the core linear material or the wall thickness of the core tube-shaped material to the thickness of the coating layer is 0.05 to 1. The invention also relates to a preparation method of the Ni-Al alloy honeycomb material. A hollow structure is formed by utilizing a Kirkendall effect that elements Ni and Al in a nickel-aluminum composite wire or tube are diffused, so that the Ni-Al alloy honeycomb material is obtained, the preparation method solves the problem that the high temperature mechanical properties and high temperature resistance corrosion properties of the conventional metal honeycomb material are universally low, and the preparation method is suitable for large-scale manufacture.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com