Method for preparing hollow/mesoporous nano structure material by adjusting Kirkendall effect through magnetic field

A nanostructure and magnetic field modulation technology, applied in the nano field, can solve problems such as increasing the cost of commercial preparation, and achieve the effect of reducing the cost of reaction preparation, huge benefit value and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

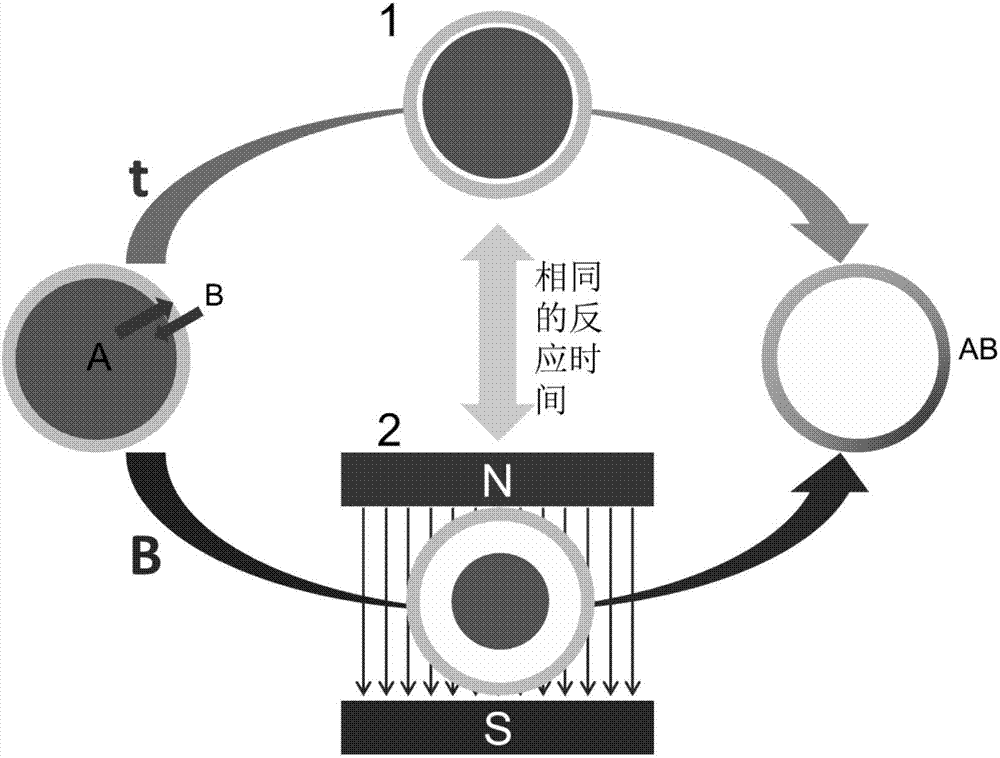

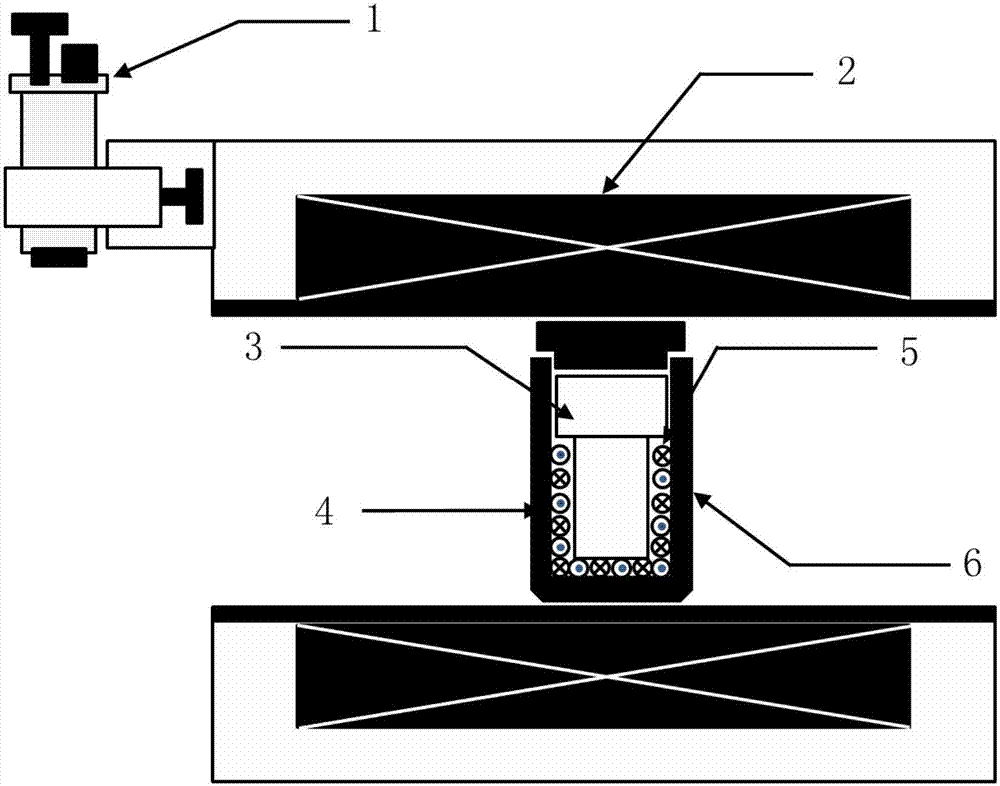

Method used

Image

Examples

Embodiment

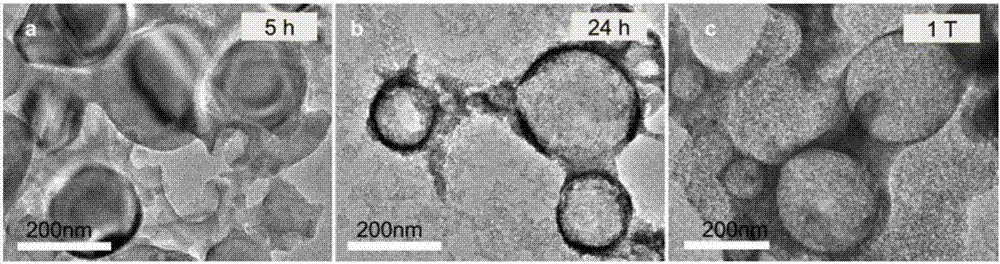

[0024] First, silicon nanoparticles are partially oxidized in a tube furnace at 800°C under an air atmosphere to form a thin oxide layer on the surface of silicon nanoparticles, and the partially oxidized silicon nanoparticles are obtained as precursors for hydrothermal reactions. Then, the partially oxidized silicon nanoparticles are uniformly dispersed in deionized water by ultrasonic treatment, added into a stainless steel autoclave with a polytetrafluoroethylene substrate, sealed after packaging, and then the stainless steel autoclave is put into a heater Finally, the heater equipped with a stainless steel autoclave was placed in a steady-state magnetic field at 1T for a hydrothermal reaction at 180°C for 5 hours, and the same precursor solution was prepared and reacted for 5 hours and 24 hours respectively without a magnetic field. TEM test was carried out, and the results were as follows image 3 shown.

[0025] image 3 is a transmission electron microscope (TEM) pict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com