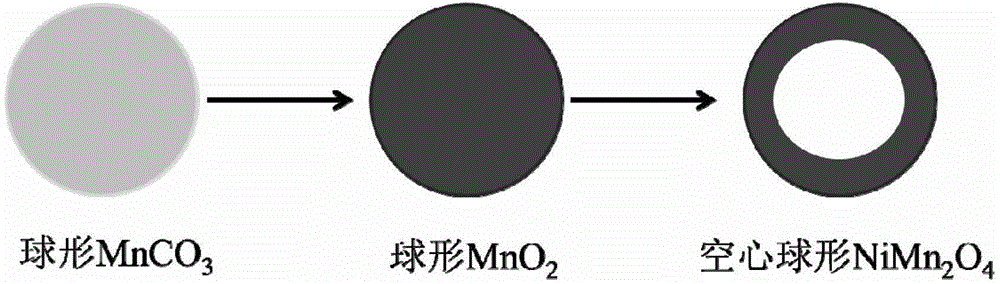

Hollow spherical NiMn2O4 lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., to achieve the effects of simple process, excellent electrochemical cycle stability and rate performance, and shortened diffusion distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

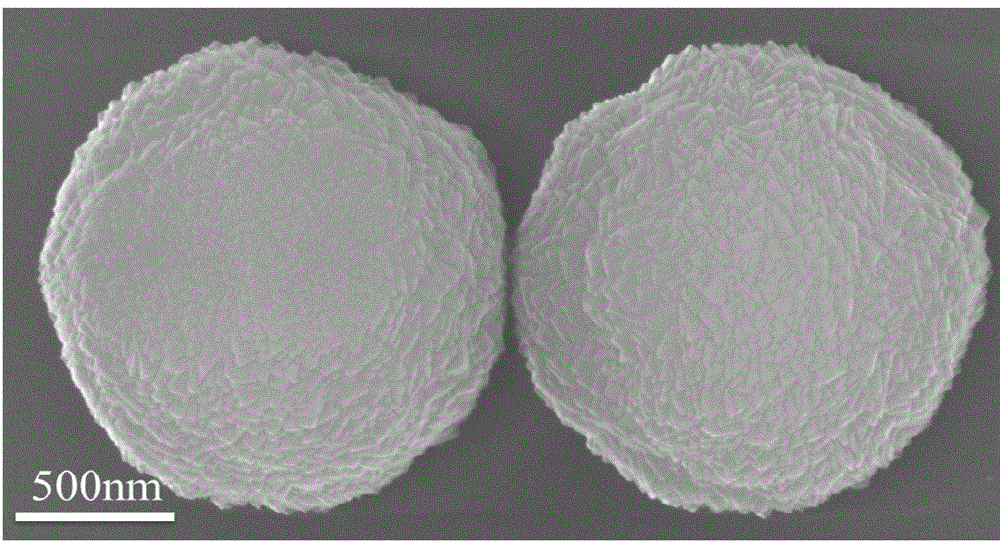

[0021] 1.69 g MnSO 4 ·H 2 O and 7.9 g NH 4 HCO 3 were dissolved in 200 mL deionized water to obtain their respective solutions; to the stirring MnSO 4 Add 20 mL of absolute ethanol to the solution, and add the prepared NH 4 HCO 3solution, and reacted for 1 hour to obtain a white precipitate, which was washed with absolute ethanol and deionized water and centrifuged 3 times each to remove SO 4 2- ; place the resulting sample at 50 o Dry in C oven for 20 hours to obtain figure 2 The spherical MnCO shown 3 powder.

[0022] The above MnCO 3 The powder is placed in a muffle furnace, with 3 o C min -1 The rate of heating up to 400 o C and constant temperature for 5 hours, then naturally cooled to room temperature to obtain image 3 The black spherical MnO shown 2 powder.

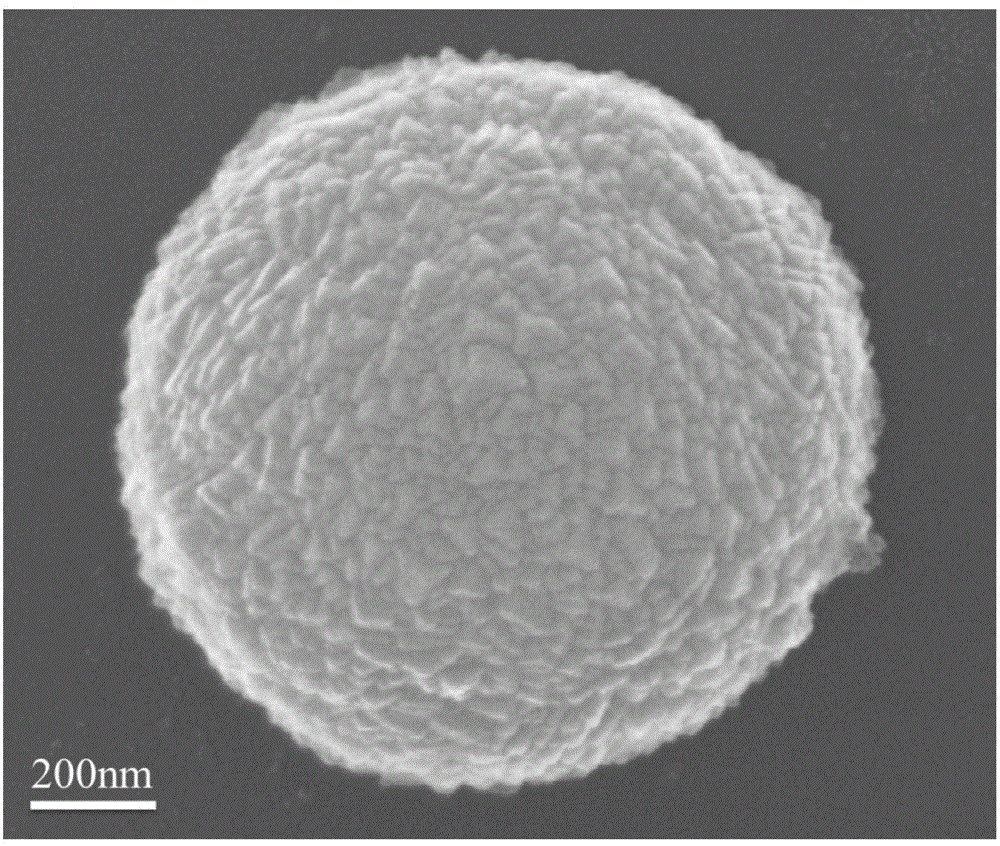

[0023] Weigh 1 g of the above MnO 2 and 1.431 g Ni(Ac) 2 4H 2 O into a beaker, add 80 mL of absolute ethanol, at 50 o Heating, stirring and dispersing to dryness under C; Pour the obtained mix...

Embodiment 2

[0026] 1.69 g MnSO 4 ·H 2 O and 15.8 g NH 4 HCO 3 were dissolved in 500 mL deionized water to obtain their respective solutions; to the stirring MnSO 4 Add 50 mL of absolute ethanol to the solution, and add the prepared NH 4 HCO 3 solution, reacted for 2 hours to obtain a white precipitate, washed with absolute ethanol and deionized water and centrifuged 3 times each to remove SO 4 2- ; Place the resulting sample at 60 o Dry in a C oven for 15 hours to obtain spherical MnCO 3 powder.

[0027] The above MnCO 3 The powder is placed in a muffle furnace, with 5 o C min -1 The rate of heating up to 400 o C and constant temperature for 8 hours, then naturally cooled to room temperature to obtain black spherical MnO 2 powder.

[0028] Weigh 1 g of the above MnO 2 and 1.431 g Ni(Ac) 2 4H 2 O into a beaker, add 80 mL of absolute ethanol, at 50 o Heating, stirring and dispersing to dryness under C; Pour the obtained mixture into an agate mortar and grind for 30 minutes...

Embodiment example 3

[0030] 1.69 g MnSO 4 ·H 2 O and 11.85 g NH 4 HCO 3 were dissolved in 300 mL deionized water to obtain their respective solutions; to the stirring MnSO 4 Add 60 mL of absolute ethanol to the solution, and at the same time add the prepared NH 4 HCO 3 solution, reacted for 3 hours to obtain a white precipitate, washed with absolute ethanol and deionized water and centrifuged 3 times each to remove SO 4 2- ; place the resulting sample at 80 o Dry in a C oven for 10 hours to obtain spherical MnCO 3 powder.

[0031] The above MnCO 3 The powder is placed in a muffle furnace, with 1 o C min -1 The rate of heating up to 450 o C and constant temperature for 10 hours, then naturally cooled to room temperature to obtain black spherical MnO 2 powder.

[0032] Weigh 1 g of the above MnO 2 and 1.672 g Ni(NO 3 ) 2 ·6H 2 O into a beaker, add 80 mL of absolute ethanol, at 50 o Heating, stirring and dispersing to dryness under C; pour the obtained mixture into an agate mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com