A kind of silicon germanium solid solution and its preparation method and application

A technology of silicon-germanium solid solution and solution, applied in the field of electrochemical materials, can solve the problems of large-scale production of silicon-germanium solid solution materials and complex processes, etc., and achieve the effects of controllable electrolysis process, ease of volume change, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a silicon germanium solid solution, including scheme one or scheme two;

[0026] The first scheme is specifically: using a composite material including a silicon precursor and a germanium precursor as a cathode, using an inert electrode as an anode, and using a CaCl 2 The melt is the electrolyte, and the silicon germanium solid solution powder is obtained by electrolysis;

[0027] The second scheme is specifically: using the conductive substrate as the cathode and the inert electrode as the anode to contain silicon precursors, germanium precursors and CaCl 2 The melt of the silicon germanium is an electrolyte solution, and a thin film or an array electrode of a silicon germanium solid solution on a conductive substrate is obtained by electrolysis.

[0028] In the present invention, the composite material including silicon precursor and germanium precursor is used as the cathode. In the present invention, the preparation me...

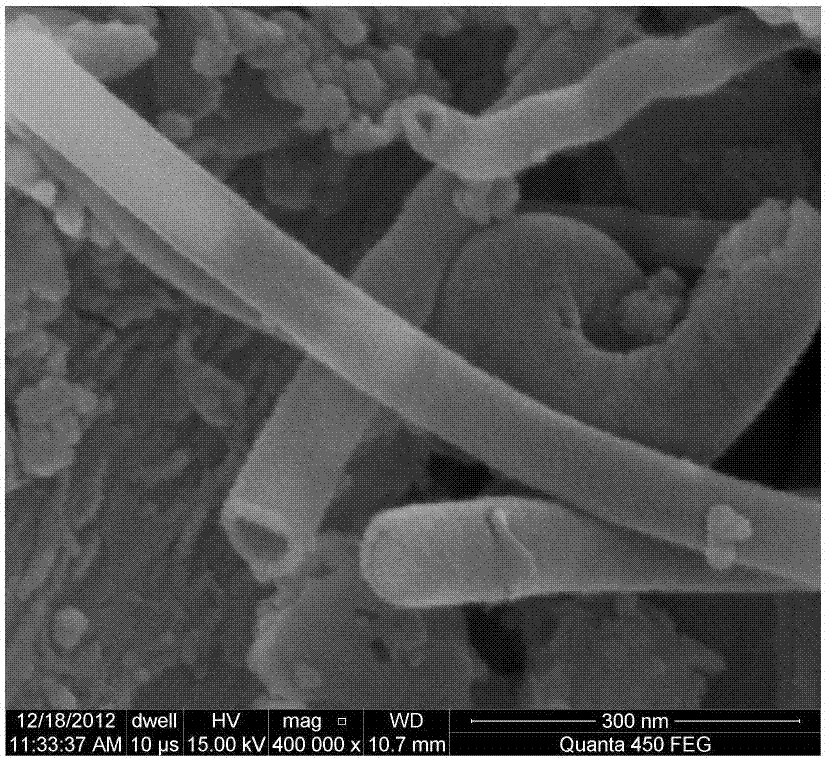

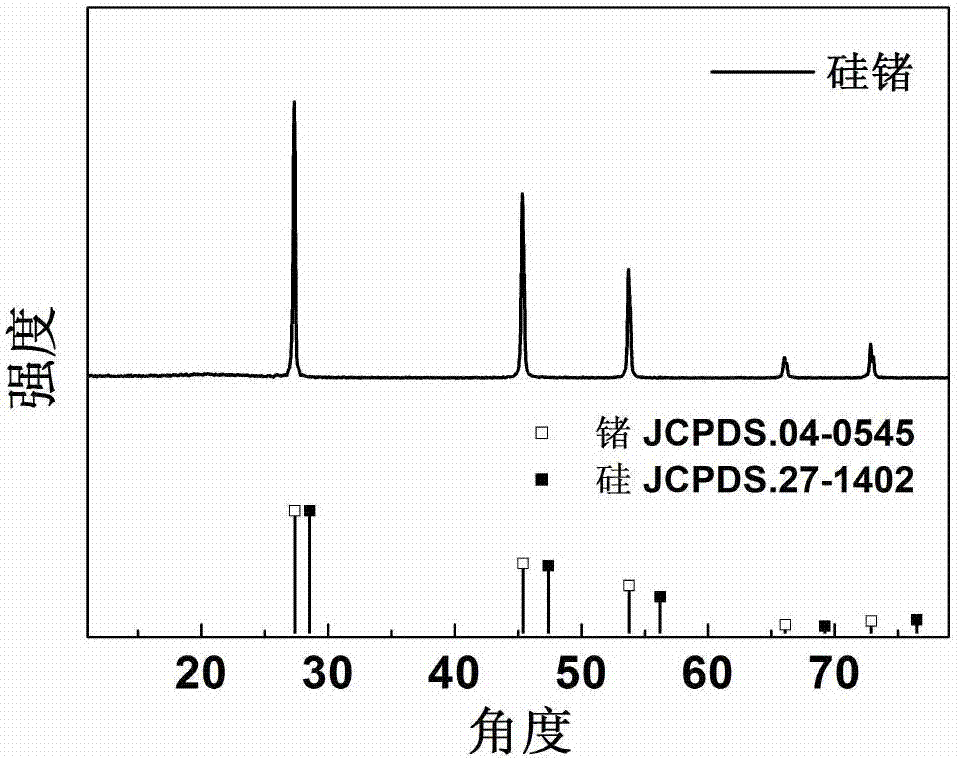

Embodiment 1

[0067] Weigh 500g anhydrous CaCl 2 Mixed salt with NaCl (CaCl 2and NaCl molar ratio of 1:1) in an alumina crucible, put the crucible into a well-sealed stainless steel container in a high-temperature furnace; heat the chloride salt at 250°C for 48h to remove residual moisture, and then continue Into the stainless steel container into the argon, and raise the temperature to 800 ℃. The reference electrode is a high-temperature fully-sealed reference electrode disclosed in the patent CN 200420017446.7, with a nickel sheet as the cathode and graphite as the anode, including CaCl 2 And the melt of NaCl is used as the electrolyte, and the pre-electrolysis is carried out at 2.6V for 8 hours to completely melt the chloride salt and improve the purity of the chloride salt. Weigh 0.5g SiO2 2 and GeO 2 Mixture (SiO 2 and GeO 2 The molar ratio is 1:1), pressed into small discs at 6MPa, and then sintered at 700°C for 2h. The sintered small disc was bound to a molybdenum wire as the ...

Embodiment 2

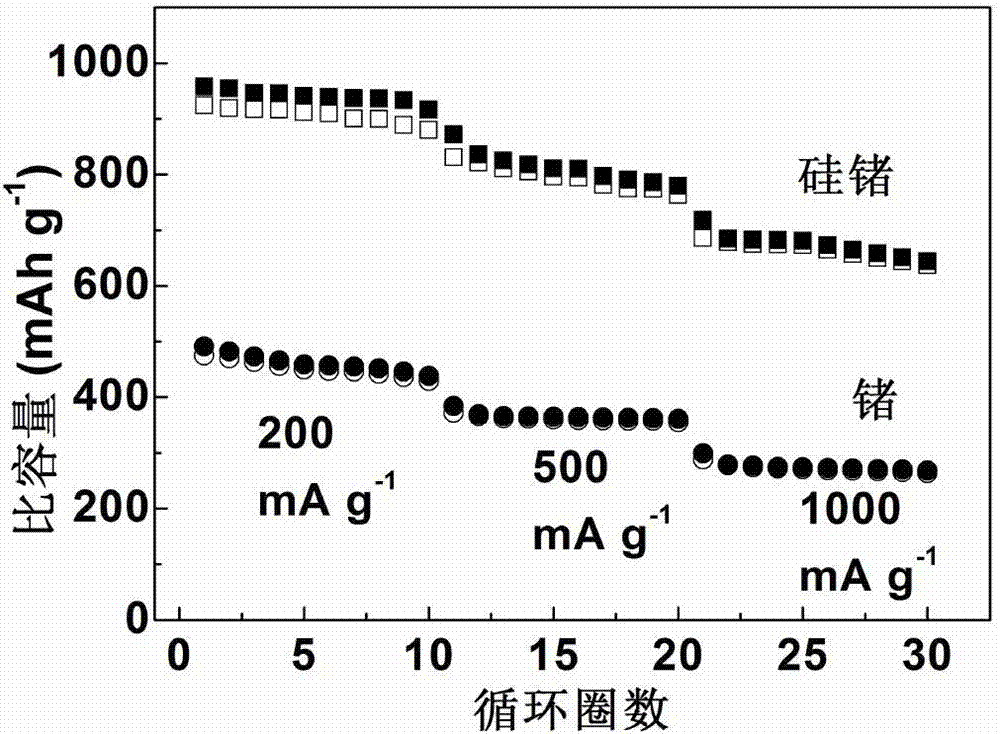

[0072] With deionized water as a solvent, the silicon germanium solid solution prepared in Example 1 was mixed with carboxymethyl cellulose, polyacrylic acid and acetylene black in a mass ratio of 80:5:5:10, and evenly coated on the copper foil, 120 After vacuum drying at ℃ for 10 h, electrode sheets were made. In an argon glove box, the electrode sheet is used as the working electrode, the lithium sheet is used as the counter electrode, the electrolyte is 1M LiPF6 / DEC / EC (the mass ratio of DEC and EC is 1:1), and the separator is polypropylene microporous membrane Celgard 2400 , made of CR2016 lithium-ion batteries. Use Neware battery tester to conduct charge and discharge test on the assembled battery, the voltage range is 0.01-1.5V, and the current density is 200mA·g in turn. -1 , 500mA·g -1 , 1000mA·g -1 10 cycles were carried out under each, and the specific capacity was 634mAh·g after 30 cycles -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com