Method for preparing high-purity iron through high-temperature fused salt electrodeposition

A high-temperature molten salt and electrodeposition technology, applied in the new field of metallurgy, can solve the problems of limited electrochemical window, long production cycle, low reaction rate, etc., and achieve the effect of controllable electrolysis process, short process and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

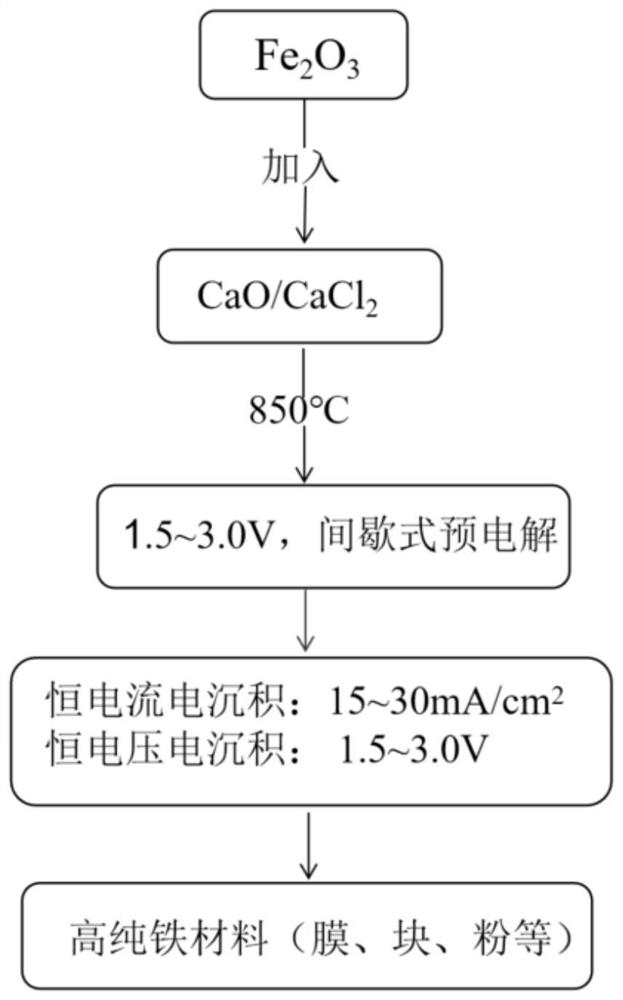

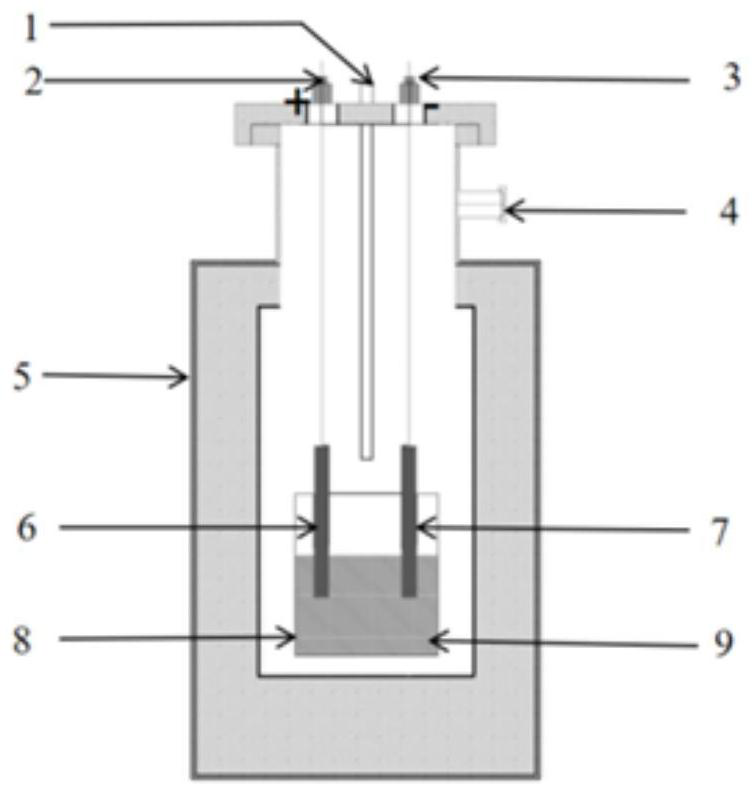

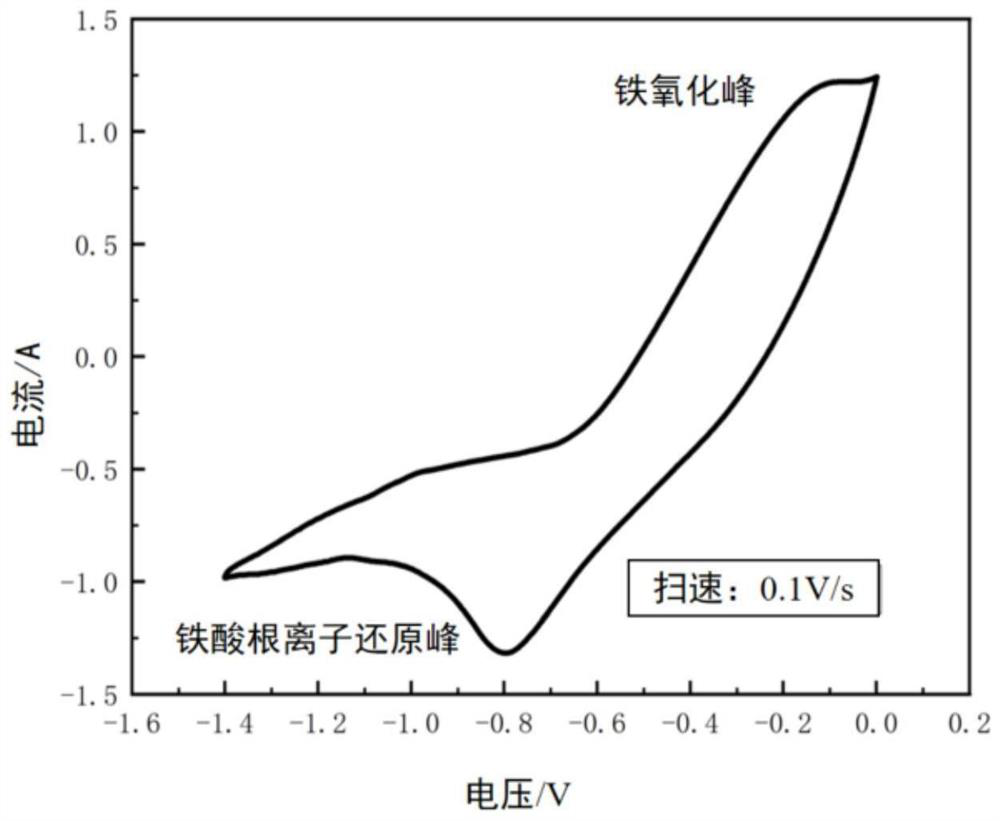

[0033] The flow chart of the present invention prepares high-purity iron material sees figure 1 , 100g CaCl 2 , 4.0gFe 2 o 3 , 4.0g CaO was added to the high-purity corundum crucible, the temperature was raised to 400°C under the high-purity argon atmosphere, and the temperature was kept for 5 hours. The structure of the electrolytic cell is as follows figure 2 Shown, then heated to 850 ℃, insulation 12h. figure 2 Mark 1-gas inlet, 2-anode lead, 3-cathode lead, 4-gas outlet, 5-high temperature resistance furnace, 6-anode, 7-cathode, 8-crucible, 9-CaCl 2 -Fe 2 o 3 -CaO molten salt system. Put two high-purity carbon rods as the anode and cathode into the crucible for pre-electrolysis. The pre-electrolysis voltage is 2.0V and the time is 12h. After standing for 12h, repeat the pre-electrolysis process 3 times. Then, cyclic voltammetry test was carried out, and the test results were as follows: image 3 As shown, it can be seen that ferrite ion oxidation peak and iron re...

Embodiment 2

[0035] The implementation of this case is roughly the same as in Example 1, but a constant voltage of 2.0V is used for deposition, and the microscopic morphology and EDS energy spectrum of the obtained high-purity iron product are as follows Figure 6 As shown, it can be seen that the constant voltage electrodeposition mode is more likely to form iron grains and less likely to form iron films.

Embodiment 3

[0037] 100gCaCl 2 , 4.0gFe 2 o 3 1. Add 4.0g CaO into the high-purity corundum crucible, raise the temperature to 400°C under high-purity argon atmosphere, and keep it warm for 5h. Then it was heated to 850°C under high-purity argon atmosphere and kept for 12 hours. Two high-purity carbon rods were used as anode and cathode, and put into a crucible for pre-electrolysis. The pre-electrolysis voltage was 2.5V and the time was 12h. After the pre-electrolysis finishes, then re-put into a high-purity carbon rod as the anode of the electrolytic cell, use the high-purity carbon rod in the pre-electrolysis process as the substrate of the electrolytic cell cathode, that is, the product, carry out electrodeposition, and apply 0.08A (current The density is 15mA / cm 2 ) continuous constant current deposition for 5 hours, the obtained surface morphology is as follows Figure 7 As shown, it can be seen that the grown iron film is dense and has no holes. The cross-sectional topography a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com