Porous ultrathin grinding wheel for chip cutting and preparation method thereof

A porous and ultra-thin technology, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that the cutting quality cannot be further improved, the thinning of ultra-thin grinding wheels is difficult to carry out, and the self-sharpening of ultra-thin grinding wheels is reduced. ability and other issues, to achieve the effect of improving self-sharpening ability, improving cutting quality, and improving abrasive holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

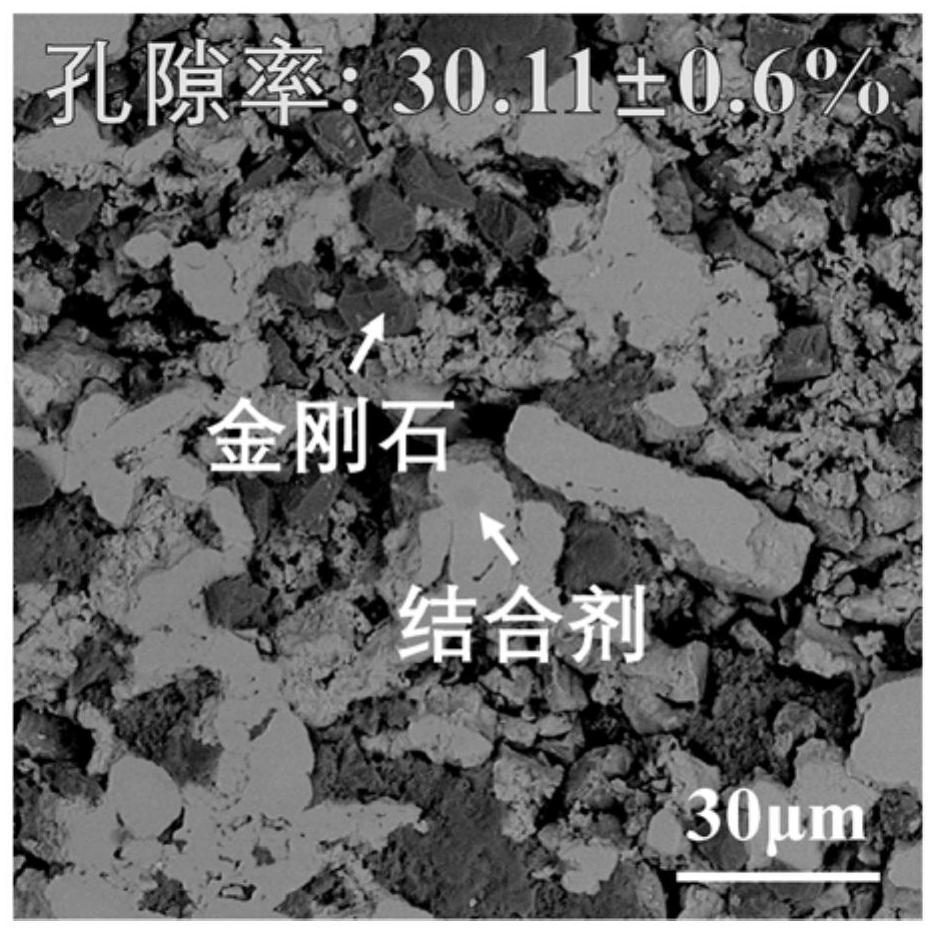

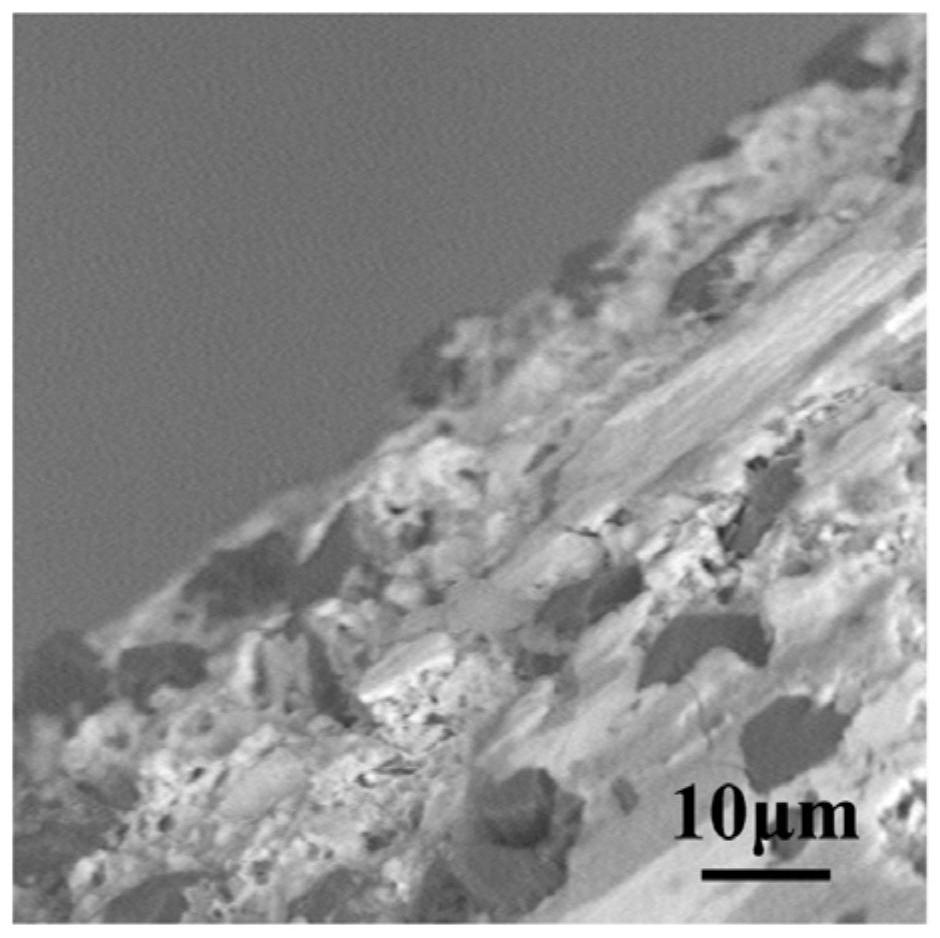

[0023] A method for preparing a porous ultra-thin grinding wheel for chip scribing, the ultra-thin grinding wheel is composed of superabrasives and a metal-based matrix, the ultrathin grinding wheel has a porous structure; the superabrasive is diamond, the The ultra-hard abrasive accounts for 50% of the volume content of the ultra-thin grinding wheel, and the abrasive grain size is 3-5 μm; the metal-based matrix is a Ti-Al-based alloy, and the mass content of metal Al in the Ti-Al-based alloy is The ratio is 10%, the metal Ti content is the balance, and the powder particle size of the metal Al and metal Ti is 3-5 μm;

[0024] Its preparation method concrete steps are as follows:

[0025] (1) Material preparation: first accurately weigh Ti powder, Al powder and diamond powder, put them into a three-dimensional vortex mixer for 4 hours of material mixing, and then pass through a 200-mesh screen; then add phenolic resin glue according to 12% mass ratio , stir and mix until the...

Embodiment 2

[0032] A method for preparing a porous ultra-thin grinding wheel tool for chip scribing, the ultra-thin grinding wheel is composed of a superhard abrasive and a metal-based matrix, the ultra-thin grinding wheel has a porous structure; the superhard abrasive is diamond, and the The volume ratio of the superabrasive to the ultra-thin grinding wheel is 25%, and the particle size of the abrasive is 9-12 μm; the metal-based matrix is a Ti-Al-based alloy, and the mass of metal Al in the Ti-Al-based alloy is The content ratio is 15%, the metal Ti content is the balance, and the powder particle size of the metal Al and metal Ti is 4-6 μm;

[0033] Its preparation method concrete steps are as follows:

[0034] (1) Material preparation: first accurately weigh Ti powder, Al powder and diamond micropowder, put them into a three-dimensional vortex mixer for 4 hours of material mixing, and then pass through a 100-mesh screen; then add phenolic resin glue according to 10% mass ratio , sti...

Embodiment 3

[0041] A method for preparing a porous ultra-thin grinding wheel tool for chip scribing, the ultra-thin grinding wheel is composed of superabrasives and a metal-based matrix, the ultrathin grinding wheel has a porous structure; the superabrasives are cubic nitride Boron, the volume content ratio of the ultra-hard abrasive to the ultra-thin grinding wheel is 25%, and the abrasive particle size is 19-21 μm; the metal-based matrix is a Ti-Al-based alloy, and the Ti-Al-based alloy The mass content ratio of metal Al is 20%, the content of metal Ti is the balance, and the powder particle size of the metal Al and metal Ti is 8-10 μm;

[0042] Its preparation method concrete steps are as follows:

[0043] (1) Material preparation: first accurately weigh Ti powder, Al powder and cubic boron nitride micropowder, put them into a three-dimensional vortex mixer for 3 hours, and then pass through a 100-mesh sieve; then add 13% mass ratio Epoxy resin glue, stir and mix until there is no l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com