Silver end electrode slurry for low temperature sintering MLCC

A low-temperature sintering and terminal electrode technology, which is applied in the field of MLCC, can solve the problems of poor compactness, capacitor failure, and easy erosion of plating solution, and achieve excellent performance and improve product performance and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] According to the formula of 1~5 serial numbers of table 1, add surfactant by the amount of silver powder 0.5~1.0wt.% and be dispersed in the alcoholic solution in advance; In the alcohol solution, the ultrasonic vibration is dispersed for pretreatment; the solvent is dried, and the pretreated silver powder is obtained by vibrating and sieving.

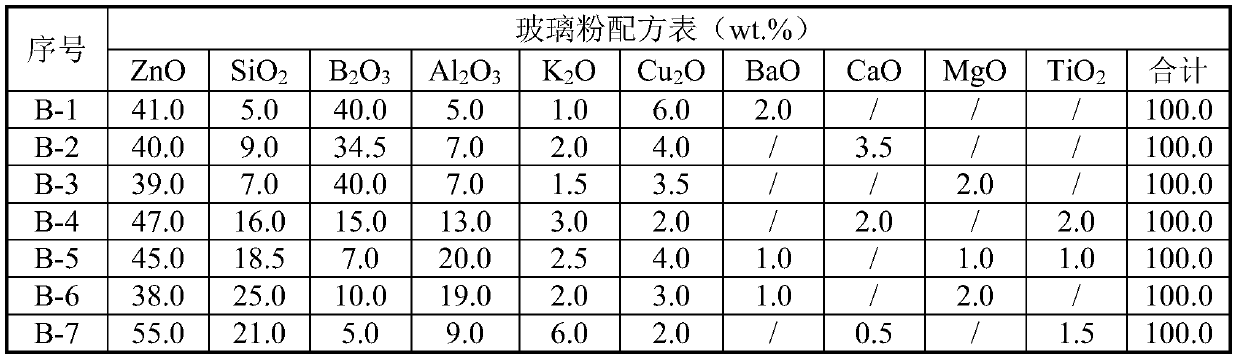

[0043] According to the formula of serial numbers 1 to 7 in Table 2, the inorganic powder of glass powder (components of glass powder) is mixed by a mixer, sintered at high temperature and water quenched, and ball milled to a glass with an average particle size of 1.5 to 3.0 μm. pink.

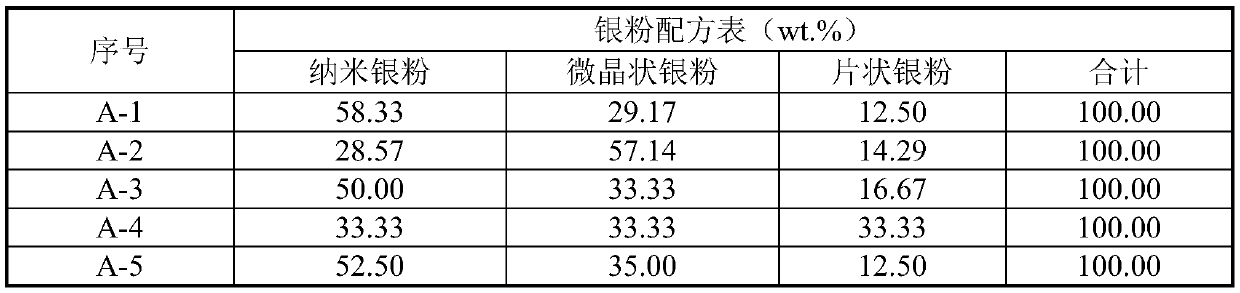

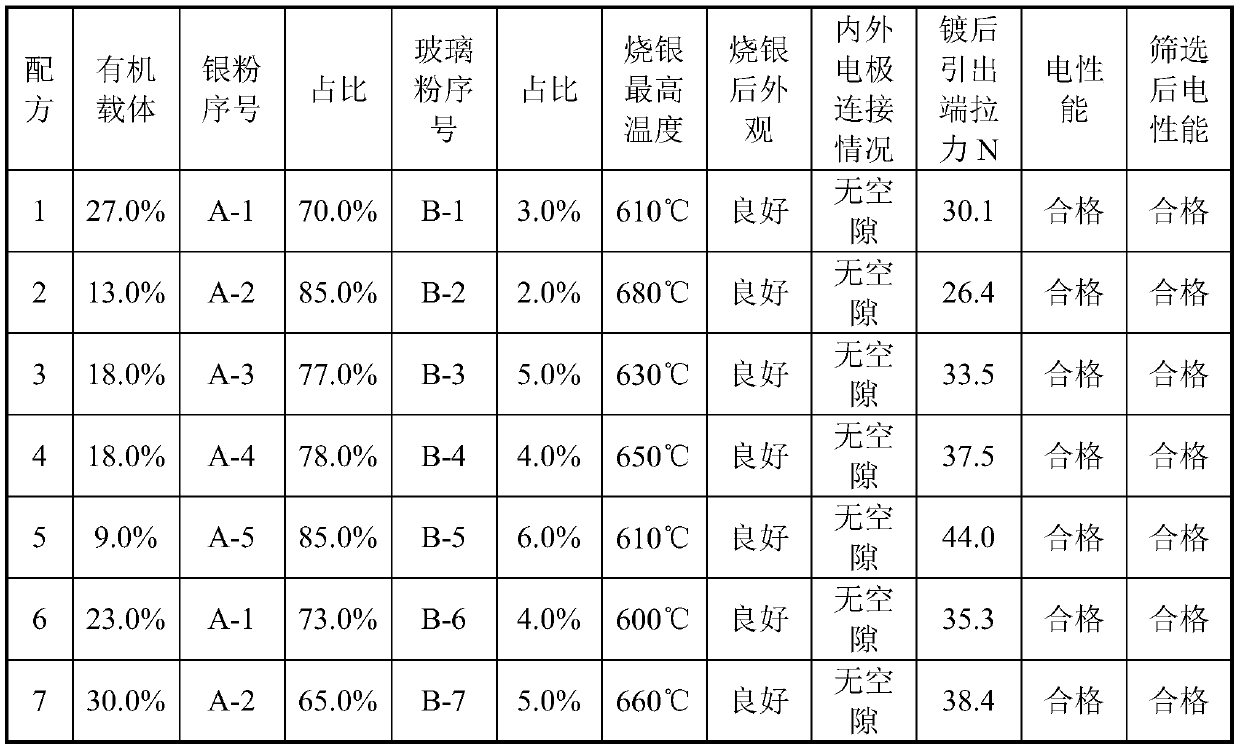

[0044]According to the composition of silver powder and glass powder in Table 1 and Table 2, prepare the 7 groups of formulas shown in Table 3; and process the chip with the number 1 to 7 in Table 3 to verify the electrical and mechanical properties of the product to evaluate the performance of the paste .

[0045] Table 1 silver powder formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com