Hollow silicon dioxide as well as preparation method and application thereof

A hollow silicon dioxide and silicon powder technology, applied in the chemical industry, can solve the problems of complex preparation route, low mechanical strength, and many surface voids, and achieve the effects of simple preparation method, high mechanical strength and high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1) Mix 0.5g 50nm spherical elemental silicon powder with 40mL deionized water and ultrasonic water bath for 2h to form a highly dispersed silicon powder dispersion solution;

[0061] 2) The above dispersion is placed in a 100mL PTFE hydrothermal reactor lining, under 600r / min magnetic stirring conditions, slowly add admixonia aqueous solution with a pipette gun with a concentration of 15%, stop the dropwise addition when the pH meter reading is stable at 10, and the added ammonia is about 1mL;

[0062] 3) After mixing evenly, quickly lining the PTFE in the matching stainless steel jacket, and react in the 180 °C blast drying box for 48h;

[0063] 4) The prepared solution was washed 3 times with absolute ethanol and deionized water, and the resulting product was dried in a blast at 140 °C for 4 h and calcined at 1000 °C in a muffle furnace for 8 h.

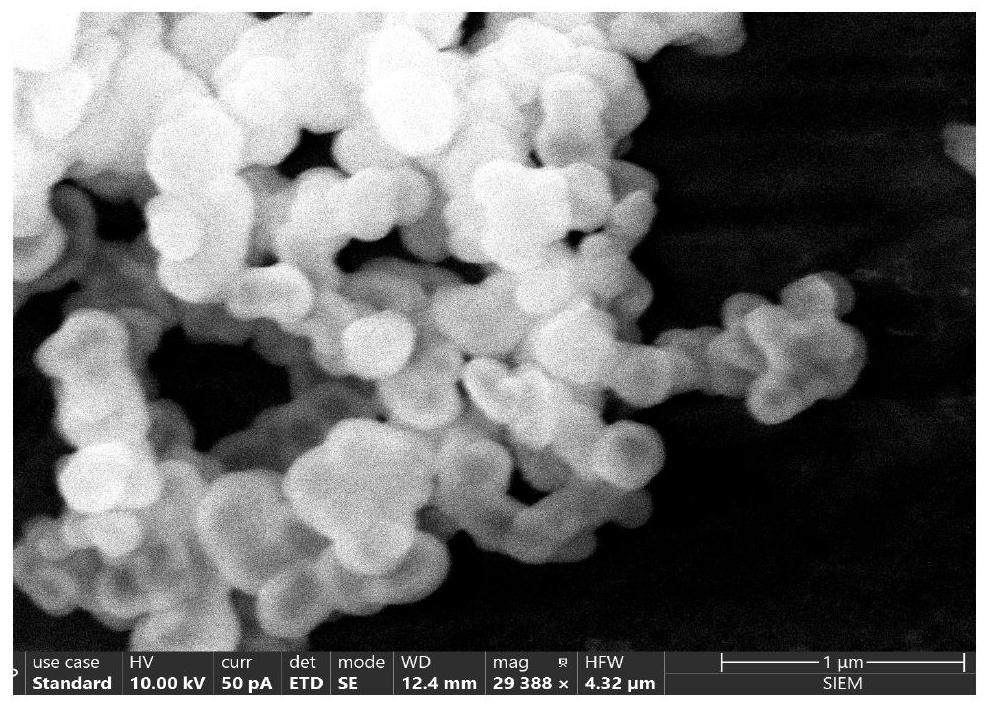

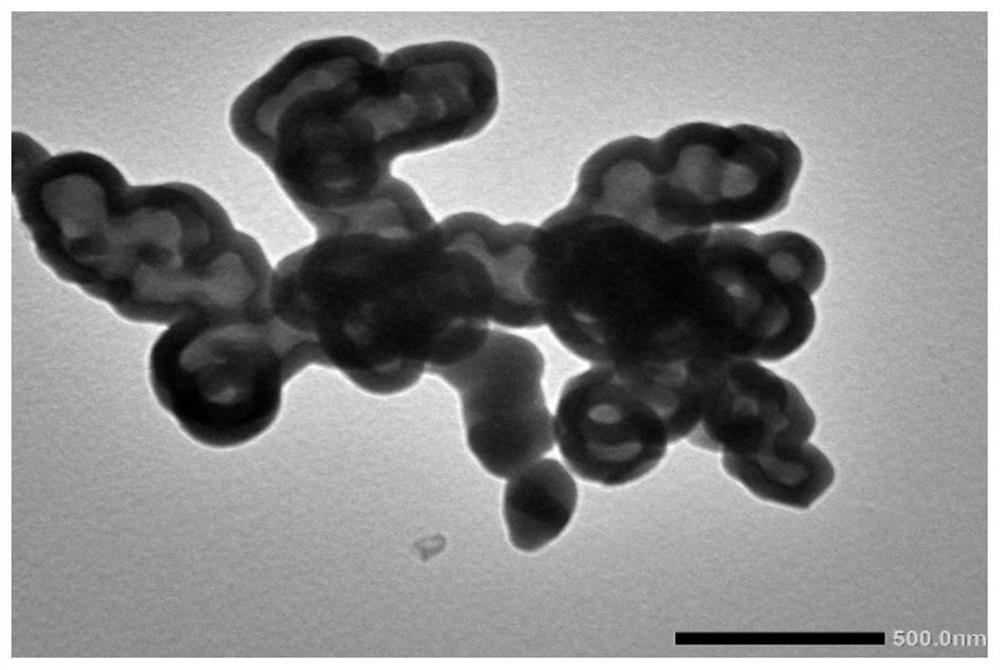

[0064] Test the resulting sample of the SEM ( Figure 1 ) and TEM ( Figure 2 It was found to be a hollow structure with a parti...

Embodiment 2

[0066] 1) Mix 0.5g 50nm spherical elemental silicon powder with 40mL deionized water and ultrasonic water bath for 2h to form a highly dispersed silicon powder dispersion solution;

[0067]2) The above dispersion is placed in a 100mL PTFE hydrothermal reactor lining, under 600r / min magnetic stirring conditions, slowly add admixonia aqueous solution with a pipette gun with a concentration of 15%, stop the dropwise addition when the pH meter reading is stable at 10, and the added ammonia is about 1mL;

[0068] 3) After mixing evenly, quickly lining the PTFE in the matching stainless steel jacket, and react in the 180 °C blast drying box for 48h;

[0069] 4) The prepared solution was washed 3 times with absolute ethanol and deionized water, and the resulting product was dried at 140 °C blast for 4 h, and placed in a muffle furnace at 800 °C for calcination for 8 h.

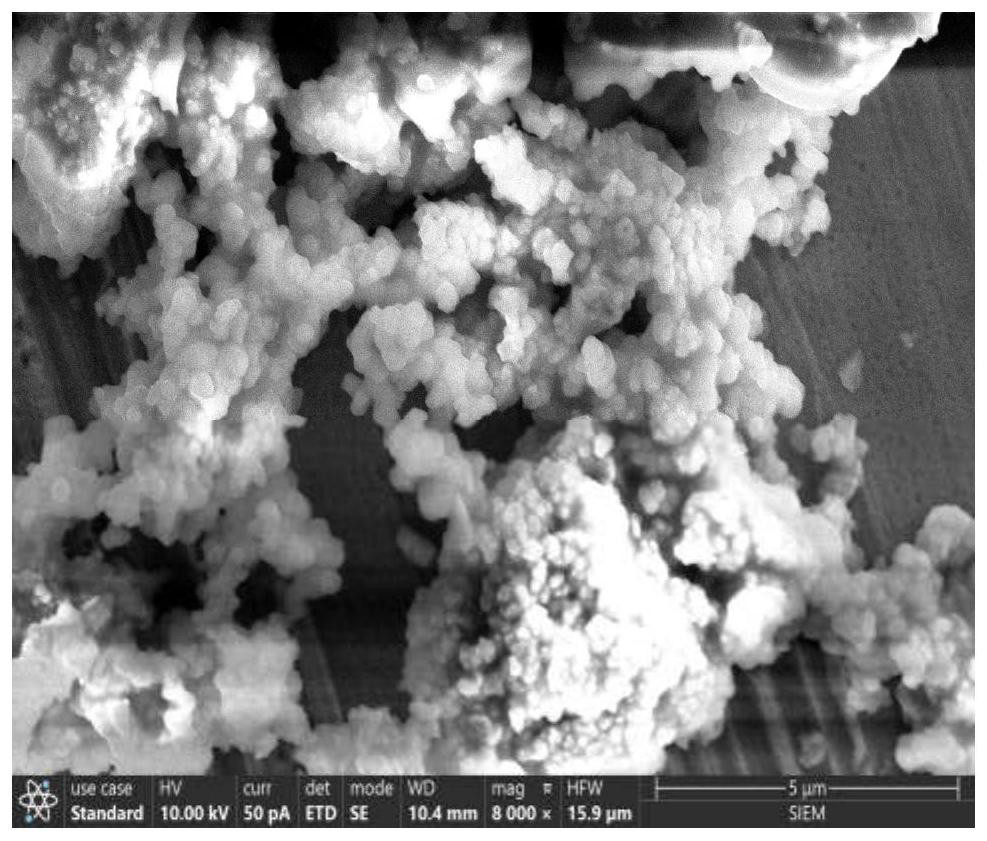

[0070] The SEM and TEM of the obtained samples were tested and found to be hollow structures with a particle size of a...

Embodiment 3

[0072] 1) Mix 0.5g 50nm spherical elemental silicon powder with 40mL deionized water and ultrasonic water bath for 2h to form a highly dispersed silicon powder dispersion solution;

[0073] 2) The above dispersion is placed in a 100mL polytetrafluoroethylene hydrothermal reactor lining, under the condition of magnetic stirring of 600r / min, the aqueous ammonia solution of 15% of the concentration prepared by slowly adding ammonia is slowly added with a pipette, and the drop-dosing is stopped when the pH meter reading is stable at 10.4, and the ammonia added is about 1.05mL;

[0074] 3) After mixing evenly, quickly lining the PTFE in the matching stainless steel jacket, and react in the 180 °C blast drying box for 48h;

[0075] 4) The prepared solution was washed 3 times with absolute ethanol and deionized water, and the resulting product was dried in a blast at 140 °C for 4 h and calcined at 1000 °C in a muffle furnace for 8 h.

[0076] The SEM and TEM of the obtained samples were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com