Ternary core-shell structure nanometer electrocatalyst and preparation method thereof

An electrocatalyst, core-shell structure technology, applied in nanotechnology, nanotechnology, structural parts, etc., to achieve the effect of improving utilization, mild conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh out 40mgHAuCl 4 , 50 mg H 2 PtCl 4 and 17 mg CuCl 2 2H 2 O, add 26ml of water to dissolve. Then add 0.194g of reducing agent octadecylamine, and stir at room temperature for 12h. The obtained mixture solution was put into a polytetrafluoroethylene reaction kettle, and reacted for 63 hours at 160° C. in a blast drying oven to obtain a black mixture solution. The black mixture solution was centrifuged and washed with a mixture of n-hexane and ethanol. Finally dry at room temperature.

Embodiment 2

[0029] Weigh out 40mgHAuCl 4 , 50 mg H 2 PtCl 4 and 49.7 mg CuCl 2 2H 2 O, add 26ml of water to dissolve. Then add 0.194g of reducing agent octadecylamine, and stir at room temperature for 12h. The obtained mixture solution was put into a polytetrafluoroethylene reaction kettle, and reacted for 63 hours at 160° C. in a blast drying oven to obtain a black mixture solution. The black mixture solution was centrifuged and washed with a mixture of n-hexane and ethanol. Finally dry at room temperature.

Embodiment 3

[0031] Weigh out 40mgHAuCl 4 , 50 mg H 2 PtCl 4 and 98.3 mg CuCl 2 2H 2 O, add 26ml of water to dissolve. Then add 0.194g of reducing agent octadecylamine, and stir at room temperature for 12h. The obtained mixture solution was put into a polytetrafluoroethylene reaction kettle, and reacted for 63 hours at 160° C. in a blast drying oven to obtain a black mixture solution. The black mixture solution was centrifuged and washed with a mixture of n-hexane and ethanol. Finally dry at room temperature.

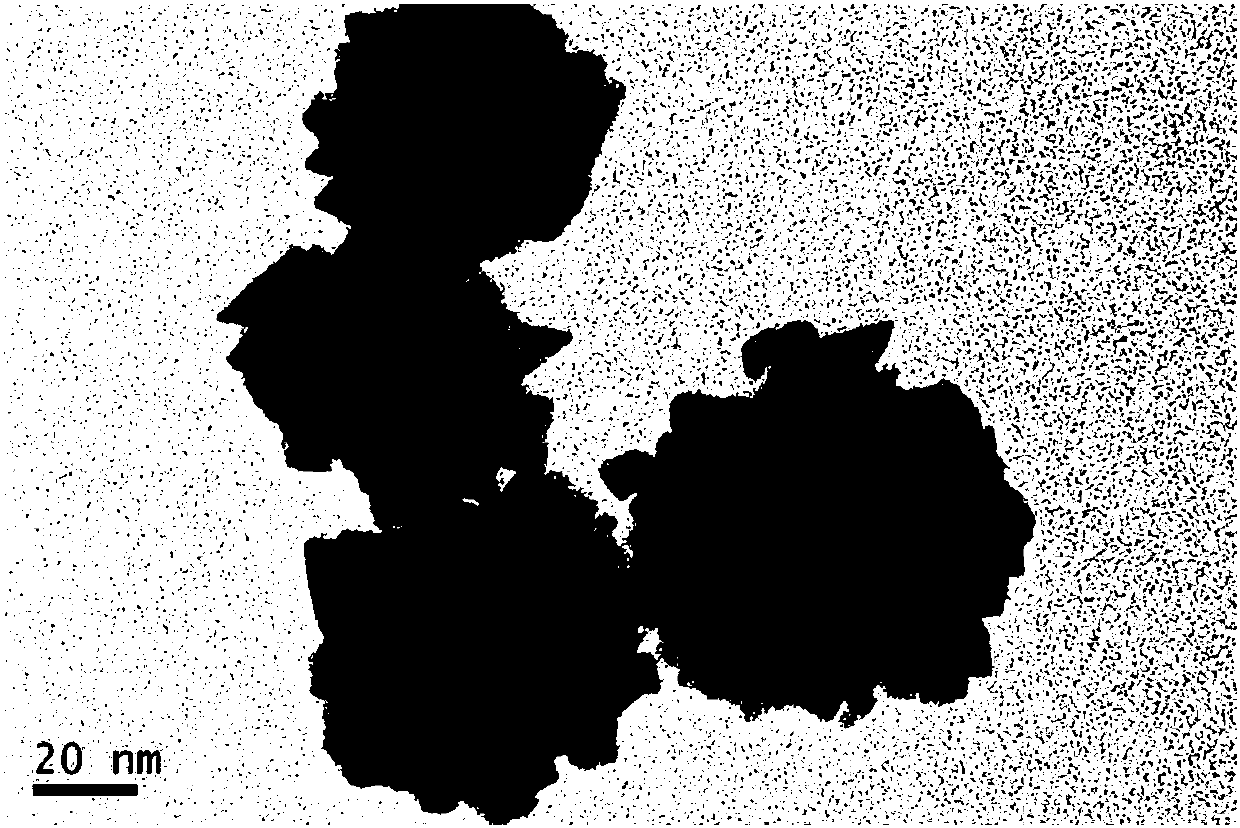

[0032] figure 1 It is the transmission electron microscope image of the Pt@PtAuCu ternary core-shell structure. Depend on figure 1 It can be seen that the ternary core-shell nanocatalysts prepared in Example 1 are uniformly dispersed.

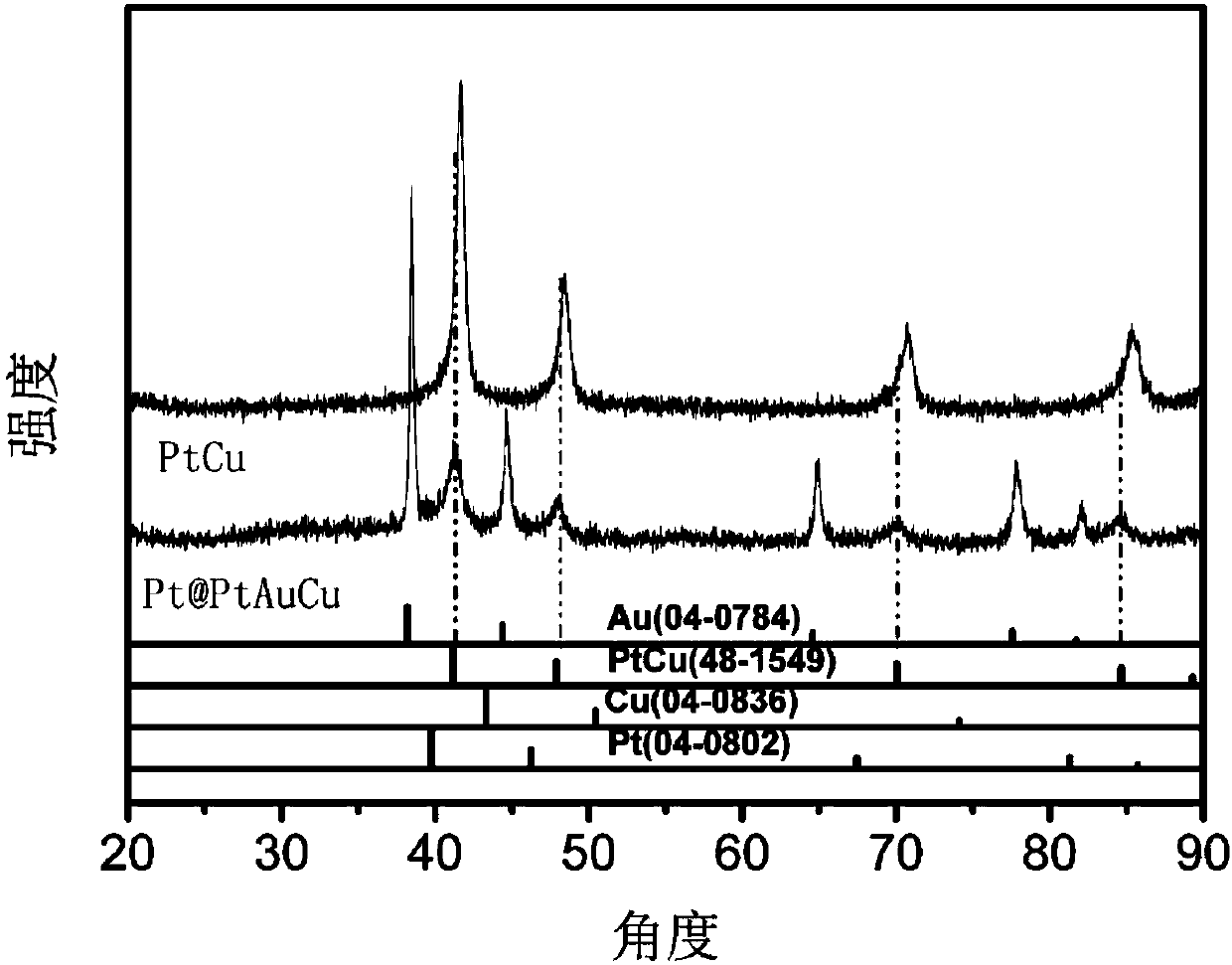

[0033] figure 2 It is the XRD pattern of Example 1Pt@PtAuCu ternary core-shell structure and Comparative Example 1PtCu. It can be seen from the figure that the PtCu peak of the catalyst in Example 1 moves at a low angle relative to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com