Preparation method of carbon-coated transition metal nano hollow particle

A transition metal, carbon coating technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of being easily oxidized and not stable, and achieve good commercial application prospects, rich raw material sources, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 10g of resorcinol and 20g of ferrocene in a weight ratio of 1:2 and dissolve them in acetone, mechanically stir until the acetone is completely volatilized, then place the resulting solid in a high-pressure reactor, and add 60ml of high-temperature silicone oil as a reaction medium , under continuous uniform mechanical stirring and nitrogen protection, the temperature was gradually raised to 420 ° C and slowly lowered, and kept at 400 ° C for 6 hours to obtain co-pyrolysis products.

[0024] The reaction product was subjected to repeated thermal extraction with petroleum ether and pyridine as solvents until the filtrate was colorless and clear. After suction filtration and drying, the carbon-coated iron nanometer hollow particle material is obtained.

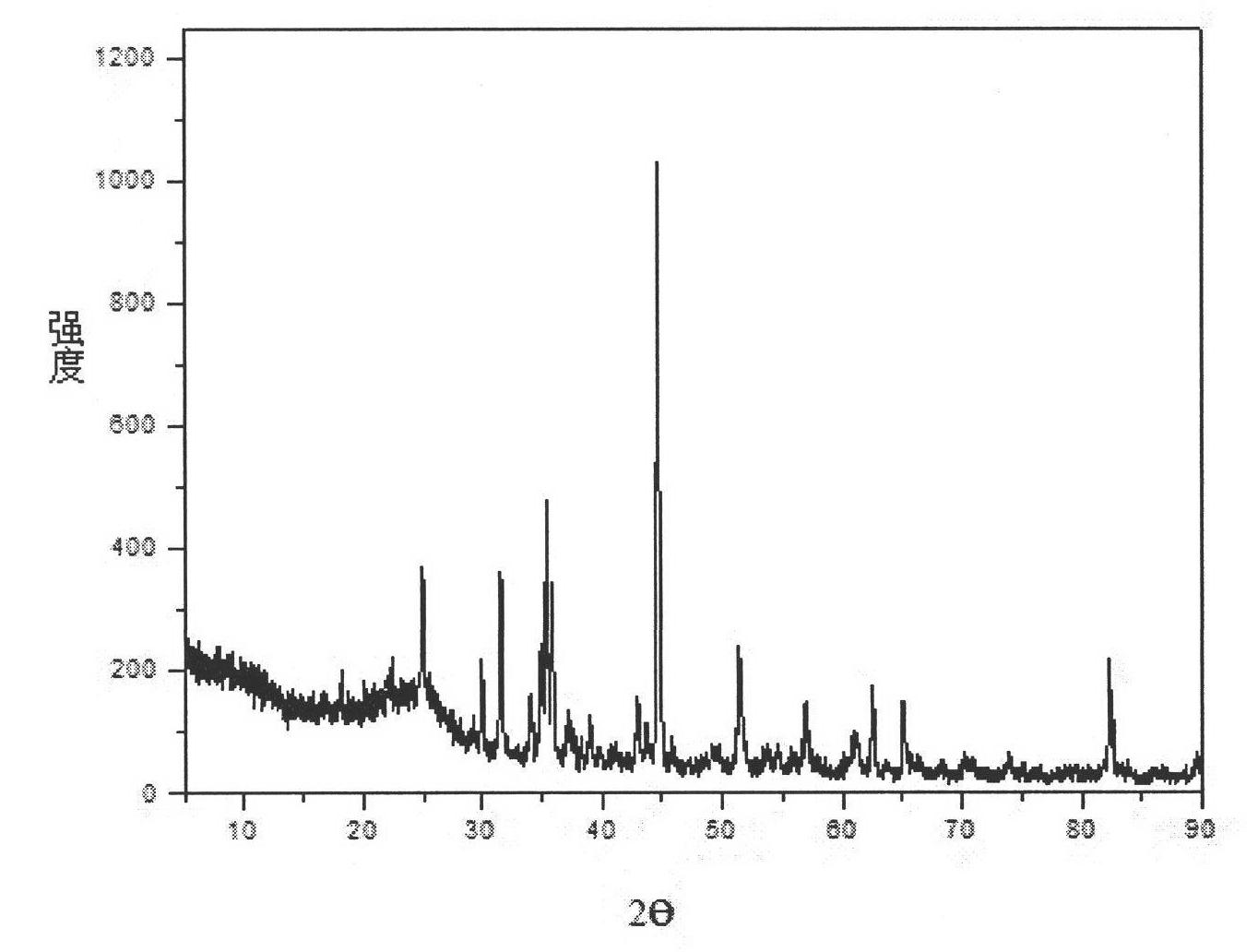

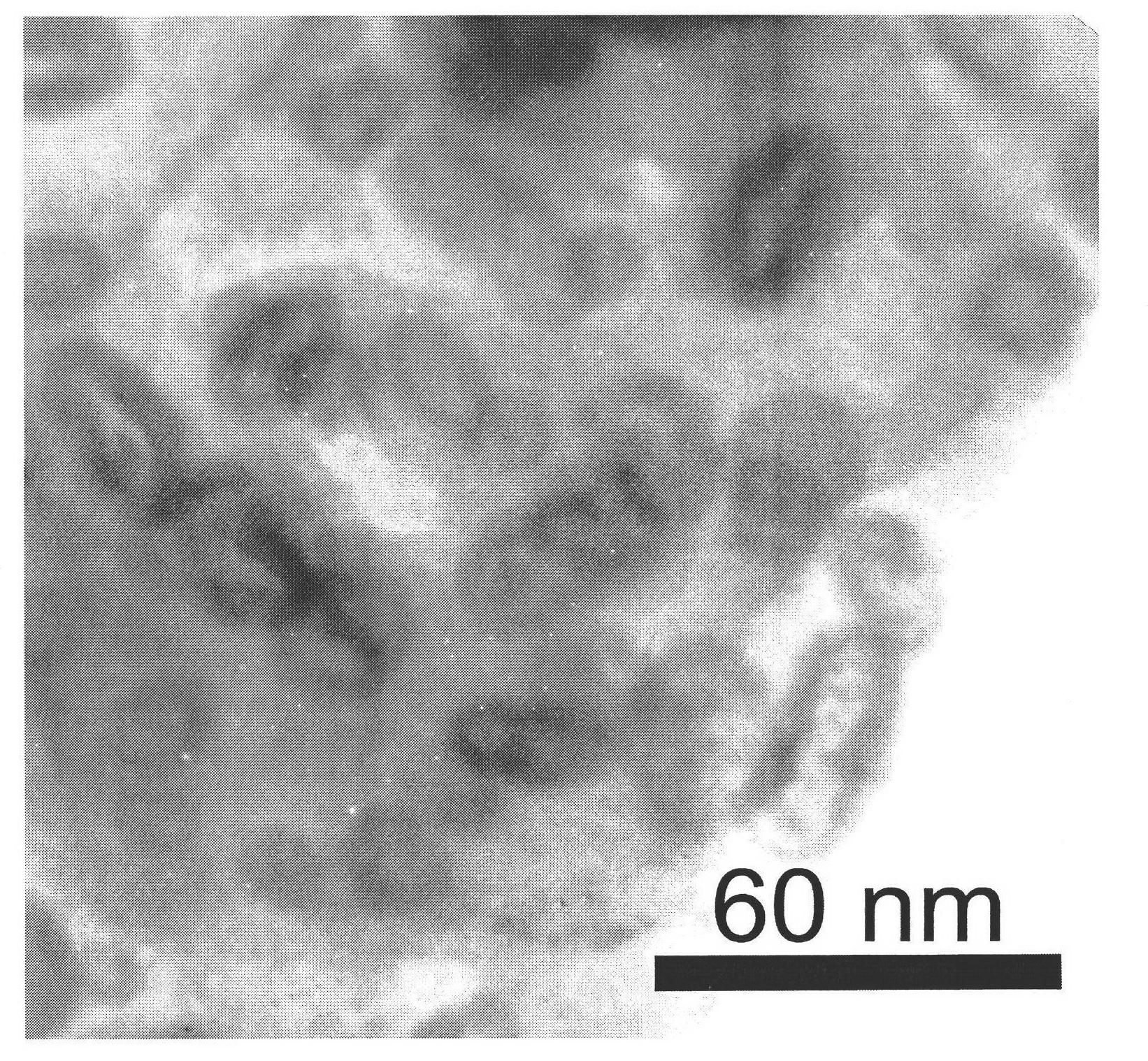

[0025] as attached figure 1 X-ray diffraction (XRD) analysis shows that the metal shell of the obtained product is composed of iron (α-Fe), and the carbon shell has a high density and orderly arrangement; as shown ...

Embodiment 2

[0027] The operation method is the same as in Example 1, except that 10g of phloroglucinol and 30g of cobaltocene are weighed in a weight ratio of 1:3 and dissolved in acetone, and 100ml of high-temperature-resistant simethicone oil is added as a reaction medium. Under protection, the temperature was gradually raised from room temperature to 540°C for pyrolysis reaction, and then the temperature was lowered to 400°C for 8 hours. Finally, carbon-coated cobalt nano hollow particle materials were obtained, and there were metal element particles with smaller particle sizes in some shell nanoparticles. According to X-ray diffraction and transmission electron microscope (TEM) photos, the average thickness of the carbon-coated metal shell is about 2.2nm, the metal component is mainly cobalt, and the smaller particle size distribution of the core part is 35-50nm.

Embodiment 3

[0029] The operation method is the same as in Example 1, except that 20 g of phenol and 10 g of palladium acetylacetonate are weighed and dissolved in acetone at a weight ratio of 1:0.5, and 80 ml of high-temperature-resistant simethicone oil is added. The temperature is raised to 500° C. for pyrolysis reaction, and then the temperature is lowered to 400° C. for 4 hours to obtain a carbon-coated palladium nano hollow particle material with significantly increased amorphous carbon content. According to X-ray diffraction and transmission electron microscope (TEM) photos, the average thickness of the carbon-coated metal shell is about 4.3nm, the diameter of the nanoparticles ranges from 25nm to 40nm, and the metal component is mainly elemental palladium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com