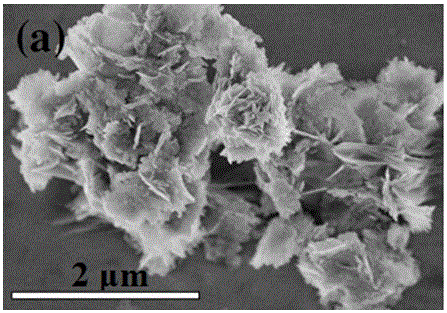

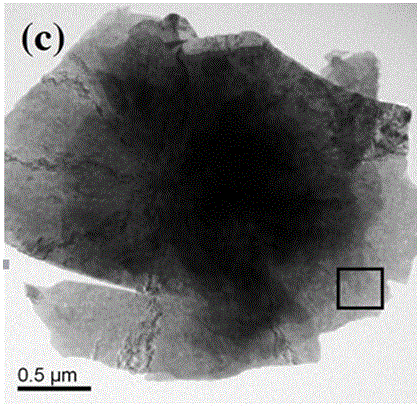

Preparation method for flower-like titanium nitride/carbon nitride/graphene composite nanomaterial

A composite nanomaterial and graphene composite technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problem of few multi-component nanocomposites of titanium nitride, and achieve short cycle, low cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of petal-shaped titanium nitride / carbon nitride / graphene composite nanomaterial, comprising the steps of:

[0024] (1) Preparation of titanium nitride: Add 0.1mL, 36% concentrated hydrochloric acid and 15g of titanium citrate to 50mL of anhydrous ethanol / water mixed solvent in sequence under constant stirring, and then continue to stir at 35°C for 5h , to obtain a sol-like substance, and place the sol at 90°C for 12 hours to dry and then grind it into a powder; Pure ammonia gas, then raise the temperature at a constant speed under the condition of flowing ammonia gas at this flow rate, raise the temperature of the furnace to 1000°C, keep this temperature for 6 hours, and then lower the temperature to room temperature under the condition of flowing ammonia gas to obtain dark blue Titanium nitride;

[0025] (2) Preparation of titanium nitride / carbon nitride / graphene ternary composite nanomaterials: Dissolve 6g of cyanamide and 0.8g of templating agen...

Embodiment 2

[0027] A preparation method of petal-shaped titanium nitride / carbon nitride / graphene composite nanomaterial, comprising the steps of:

[0028] (1) Preparation of titanium nitride: Add 0.12mL, 36% concentrated hydrochloric acid and 20g of titanium citrate to 60mL of anhydrous ethanol / water mixed solvent in sequence under constant stirring, and then continue to stir at 30°C for 8 hours , to obtain a sol-like substance, and the sol was dried at 100°C for 12 hours and then ground into a powder; Pure ammonia gas, then raise the temperature at a constant speed under the condition of flowing ammonia gas at this flow rate, raise the temperature of the furnace to 1100°C, keep this temperature for 6 hours, and then lower the temperature to room temperature under the condition of flowing ammonia gas to obtain dark blue Titanium nitride;

[0029] (2) Preparation of titanium nitride / carbon nitride / graphene ternary composite nanomaterials: Dissolve 10 g of melamine and 1 g of templating ag...

Embodiment 3

[0031] A preparation method of petal-shaped titanium nitride / carbon nitride / graphene composite nanomaterial, comprising the steps of:

[0032] (1) Preparation of titanium nitride: Add 0.11mL, 36% concentrated hydrochloric acid and 16g of titanium citrate to 70mL of anhydrous ethanol / water mixed solvent in sequence under constant stirring, and then continue to stir at 36°C for 6h , to obtain a sol-like substance, and dry the sol at 90°C for 12 hours and then grind it into a powder; Pure ammonia gas, then raise the temperature at a constant speed under the condition of flowing ammonia gas at this flow rate, raise the temperature of the furnace to 1050°C, keep this temperature for 7 hours, and then lower the temperature to room temperature under the condition of flowing ammonia gas to obtain dark blue Titanium nitride;

[0033] (2) Preparation of titanium nitride / carbon nitride / graphene ternary composite nanomaterials: Dissolve 8g of cyanamide and 0.9g of template agent lysine i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com