Preparation method of CsPbBr3 perovskite three-dimensional cube microcavity sample

A technology of cube and perovskite, applied in the field of preparation of nano/micron materials, can solve the problem of unsatisfactory optical field limitation, and achieve the effects of highly controllable morphology and size, high crystal quality, and excellent control performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The deposition sheet (10 mm × 15 mm) and the quartz boat (20 mm × 20 mm × 60 mm) were ultrasonically cleaned with deionized water and absolute ethanol for 5 min, and dried in a drying oven for 24 h.

[0025] (2) Weigh CsBr and PbBr according to the molar ratio of 2:1 2 Powder (raw material purity>99.999%), put into the above-mentioned dried quartz boat, both ends as evaporation source.

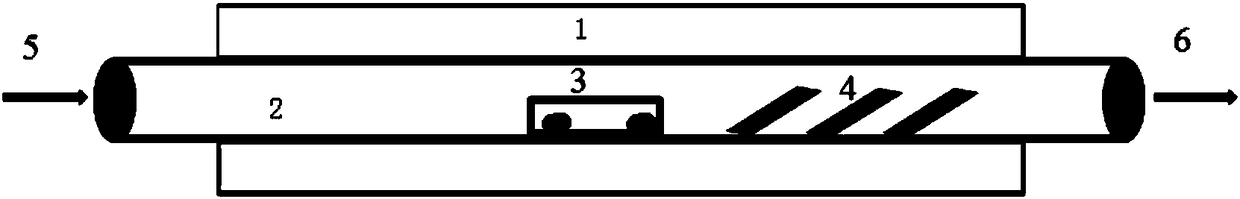

[0026] (3) One end of the quartz boat filled with CsBr powder is located near the thermocouple in the center of the quartz tube, and one end of the quartz boat filled with PbBr powder 2 One end of the powder faces the air outlet. 3 deposition sheets are placed at the downwind outlet, about 56cm away from the center of the quartz boat, and the distance between each sheet is about 3cm;

[0027] (4) After the evaporation source is placed, close the quartz tube; close the quartz tube, vacuumize for 5 minutes, and pass high-purity nitrogen into the quartz tube to discharge the air in t...

Embodiment 2

[0030] This embodiment mainly examines CsPbBr 3 CsBr and PbBr during the fabrication of perovskite three-dimensional cubic microcavities 2 The effect of evaporation source ratio, deposition sheet type, placement position, reaction temperature, reaction time and carrier gas rate on the morphology and size of the obtained sample. Please refer to Example 1 for specific experimental procedures. The difference is that the proportion of raw materials, type of deposition sheet, placement position, reaction temperature, reaction time and carrier gas rate were changed respectively. The specific experimental parameters are shown in Table 1.

[0031] Table 1 Preparation of the above CsPbBr 3 Experimental conditions of perovskite three-dimensional cube microcavity:

[0032]

[0033] From the experimental results, it can be seen that appropriate changes in the proportion of raw materials, the type of deposition sheet and the reaction time have almost no effect on the morphology of the...

Embodiment 3

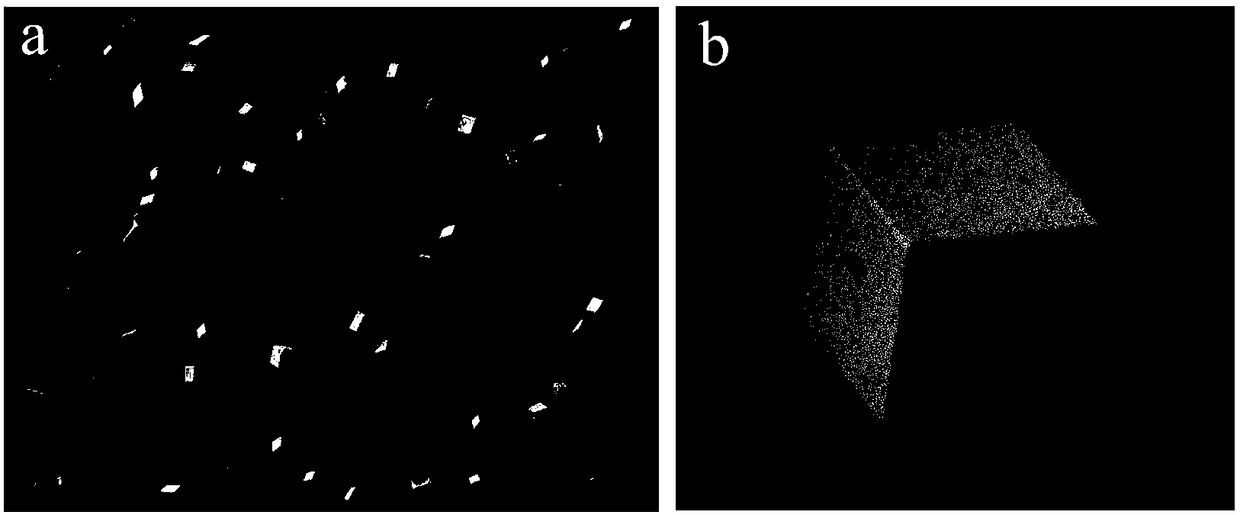

[0035] This example investigates the CsPbBr gained in embodiment 1 3 Whether the perovskite three-dimensional cubic microcavity sample can be used as an optical microcavity and gain medium, and further used as a micro laser.

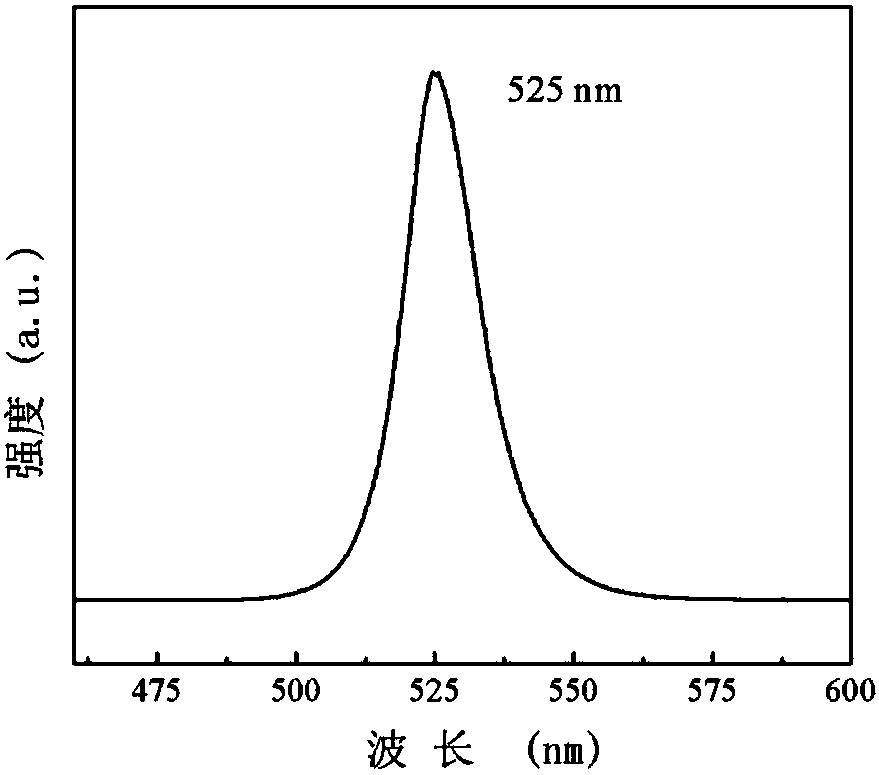

[0036] The experimental equipment is an ultrafast transient spectrometer (model HR Evolution&FLS980). The specific experimental steps are: place the substrate containing the sample horizontally on the sample stage of the microfluorescence spectrometer, adjust the sample stage, and select a single CsPbBr under the microscope 3 Three-dimensional cubic microcavities. The 400 nm femtosecond laser (model Libra-USP-10k-HE) was turned on and the laser light was introduced into the spectrometer. Adjust the microscope lens, focus the light spot to the minimum and ensure that the entire sample is covered, and then perform spectrum detection immediately. The fluorescence spectrum of the sample can be obtained at low power, such as image 3 shown. The single-mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com