Iron carbon composite material with novel structure, and preparation method thereof

A composite material and new structure technology, applied in the direction of carbon compounds, chemical instruments and methods, and other chemical processes, can solve the problems of increasing the specific surface area of activated carbon and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

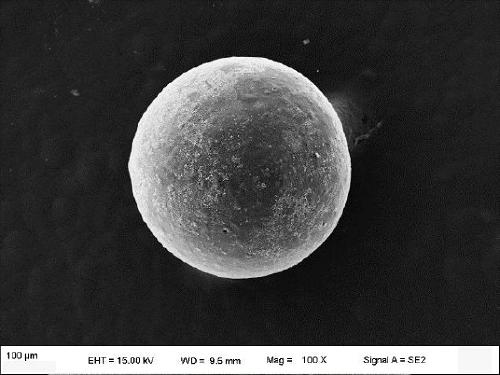

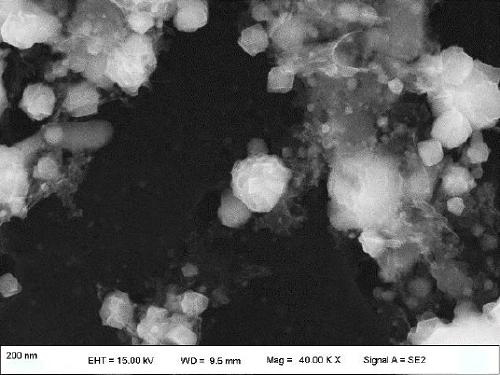

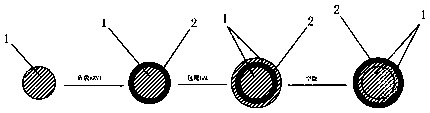

[0039] A preparation method of a novel iron-carbon composite material (GAC-GAC-nZVI), comprising the following steps:

[0040] S1. Preparation of micron-scale activated carbon microspheres: prepare activated carbon microspheres by suspension polymerization; specifically include the following steps:

[0041] S1.1. Dissolve the mixture of phenol and formaldehyde with a molar ratio of 1:2 in 300ml of water, then mix 10g of triethylamine and 1.7g of gum arabic powder;

[0042] S1.2, then the whole system at 95 0 React at a temperature of C for 5 hours, collect the phenolic resin microspheres from the reaction solution by suction filtration, and wash repeatedly with water and ethanol, and finally 0 C dry;

[0043] S1.3. Put the phenolic resin microspheres into a high-temperature atmosphere furnace with a crucible. pass at 800 0 C carbonization in a nitrogen atmosphere for 1 hour to collect carbon microspheres and cooled to room temperature, the heating rate was 3 0 C / min, put ...

Embodiment 2

[0049] A preparation method of a novel iron-carbon composite material (GAC-GAC-nZVI), comprising the following steps:

[0050] S1. Preparation of micron-scale activated carbon microspheres: prepare activated carbon microspheres by suspension polymerization; specifically include the following steps:

[0051] S1.1. Dissolve the mixture of phenol and formaldehyde with a molar ratio of 1:2.5 in 300ml of water, then mix 10g of triethylamine and 1.7g of gum arabic powder;

[0052] S1.2, then the whole system in 96 0 React at a temperature of C for 5 hours, collect the phenolic resin microspheres from the reaction solution by suction filtration, and wash repeatedly with water and ethanol, and finally 0 C dry;

[0053] S1.3. Put the phenolic resin microspheres into a high-temperature atmosphere furnace with a crucible. pass at 800 0 C carbonization in a nitrogen atmosphere for 2 hours to collect carbon microspheres and cooled to room temperature, the heating rate was 3 0 C / min, p...

Embodiment 3

[0059] A preparation method of a novel iron-carbon composite material (GAC-GAC-nZVI), comprising the following steps:

[0060] S1. Preparation of micron-scale activated carbon microspheres: prepare activated carbon microspheres by suspension polymerization; specifically include the following steps:

[0061] S1.1. Dissolve the mixture of phenol and formaldehyde with a molar ratio of 1:2 in 300ml of water, then mix 10g of triethylamine and 1.7g of gum arabic powder;

[0062] S1.2, then the whole system in 97 0 The reaction was carried out at a temperature of C for 5 hours, and the phenolic resin microspheres were collected from the reaction liquid by suction filtration, and washed repeatedly with water and ethanol. Finally at 60 0 C dry;

[0063] S1.3. Put the phenolic resin microspheres into a high-temperature atmosphere furnace with a crucible. pass at 800 0 C carbonization in a nitrogen atmosphere for 2 hours to collect carbon microspheres and cooled to room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com