Magnetic field for plating on inner wall of long pipe and field-enhanced arc ion plating device

An arc ion and coating device technology, which is applied in the field of material surface modification to achieve the effects of easy focusing and restraint, improved coating uniformity, and improved uniformity and deposition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

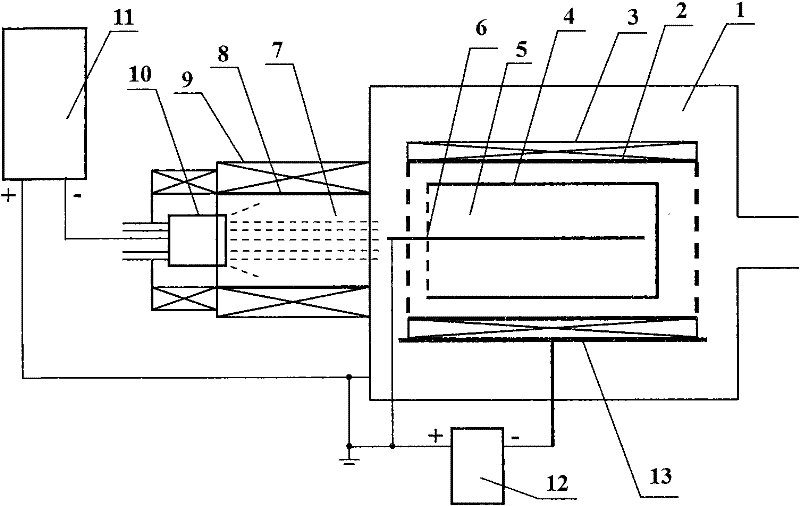

[0046] After cleaning and drying the Φ60×100mm low-alloy steel mold with Φ30×70mm blind holes, fix it on the workpiece table of the arc ion plating device. Such as figure 1 As shown, the arc ion plating device mainly includes: vacuum chamber 1, workpiece magnetic field coil supporting cylinder I2, workpiece magnetic field coil 3, workpiece auxiliary electrode 6, plasma beam I7, plasma focusing magnetic field coil supporting cylinder I8, plasma Focusing magnetic field coil I9, cathode target I10, cathode target power supply 11, pulse bias power supply 12, workpiece table 13, etc., the specific structure is as follows:

[0047] The workpiece 4, the workpiece magnetic field coil supporting cylinder I2, the workpiece magnetic field coil 3, the workpiece auxiliary electrode 6 and the workpiece table 13 are arranged in the vacuum chamber 1, the workpiece magnetic field coil 3 is arranged outside the workpiece magnetic field coil supporting cylinder I2, and the workpiece magnetic fie...

Embodiment 2

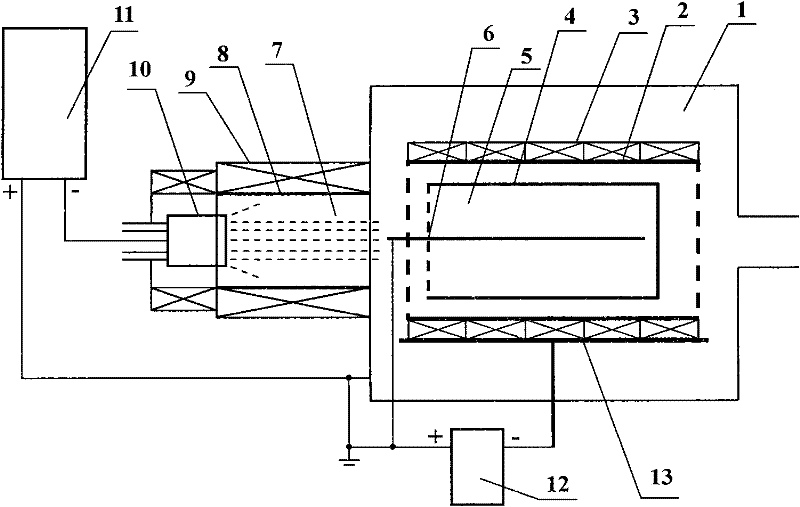

[0053] Clean and dry a Φ50×80mm stainless steel tube with a Φ25×60mm blind hole, and fix it on the workpiece table of the arc ion plating device. Such as figure 2 shown, with figure 1 The difference is that the magnetic field of the workpiece magnetic field coil 3 in this embodiment adopts a gradient magnetic field, and the gradient magnetic field means that the magnetic field generating device placed outside the tubular workpiece in the vacuum chamber is three electromagnetic coils, and parameters such as the wire diameter and winding density of the electromagnetic coil Similarly, the magnetic induction of these electromagnetic coils is realized by adjusting the current of the electromagnetic coils respectively, and the magnetic induction decreases gradually along the direction of the plasma beam, thereby forming a gradient magnetic field. The gradient magnetic field is relative to the uniform magnetic field, and its characteristic is that the magnetic induction intensity g...

Embodiment 3

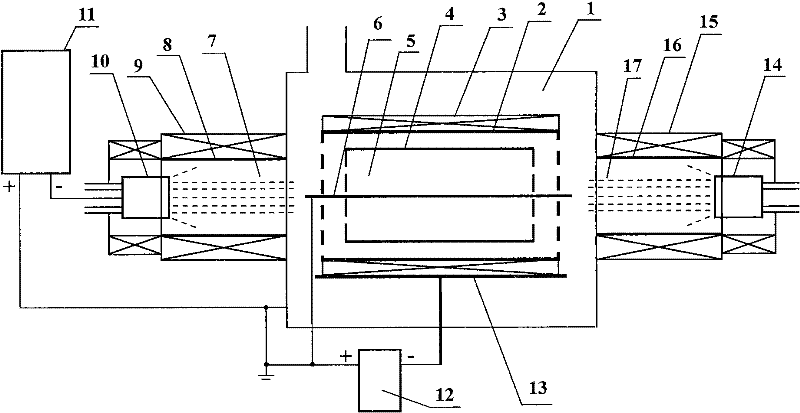

[0057] Clean and dry the Φ50×200mm stainless steel part with a Φ30×140mm through hole, and fix it on the workpiece table of the arc ion plating device. Such as image 3 As shown, the arc ion plating device mainly includes: vacuum chamber 1, workpiece magnetic field coil supporting cylinder I2, workpiece magnetic field coil 3, workpiece auxiliary electrode 6, plasma focusing magnetic field coil supporting cylinder I8, plasma focusing magnetic field coil I9, cathode Target I10, cathode target power supply 11, pulse bias power supply 12, workpiece table 13, cathode target II14, plasma focusing magnetic field coil II15, plasma focusing magnetic field coil support cylinder II16, etc. The specific structure is as follows:

[0058] The workpiece 4, the workpiece magnetic field coil supporting cylinder I2, the workpiece magnetic field coil 3, the workpiece auxiliary electrode 6 and the workpiece table 13 are arranged in the vacuum chamber 1, the workpiece magnetic field coil 3 is arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com