Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Stable gas source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency copper-iron automatic flame brazing machine and brazing method thereof

InactiveCN102581419AImprove permeabilityImprove wettabilityMetal working apparatusSolder feeding devicesControl systemEngineering

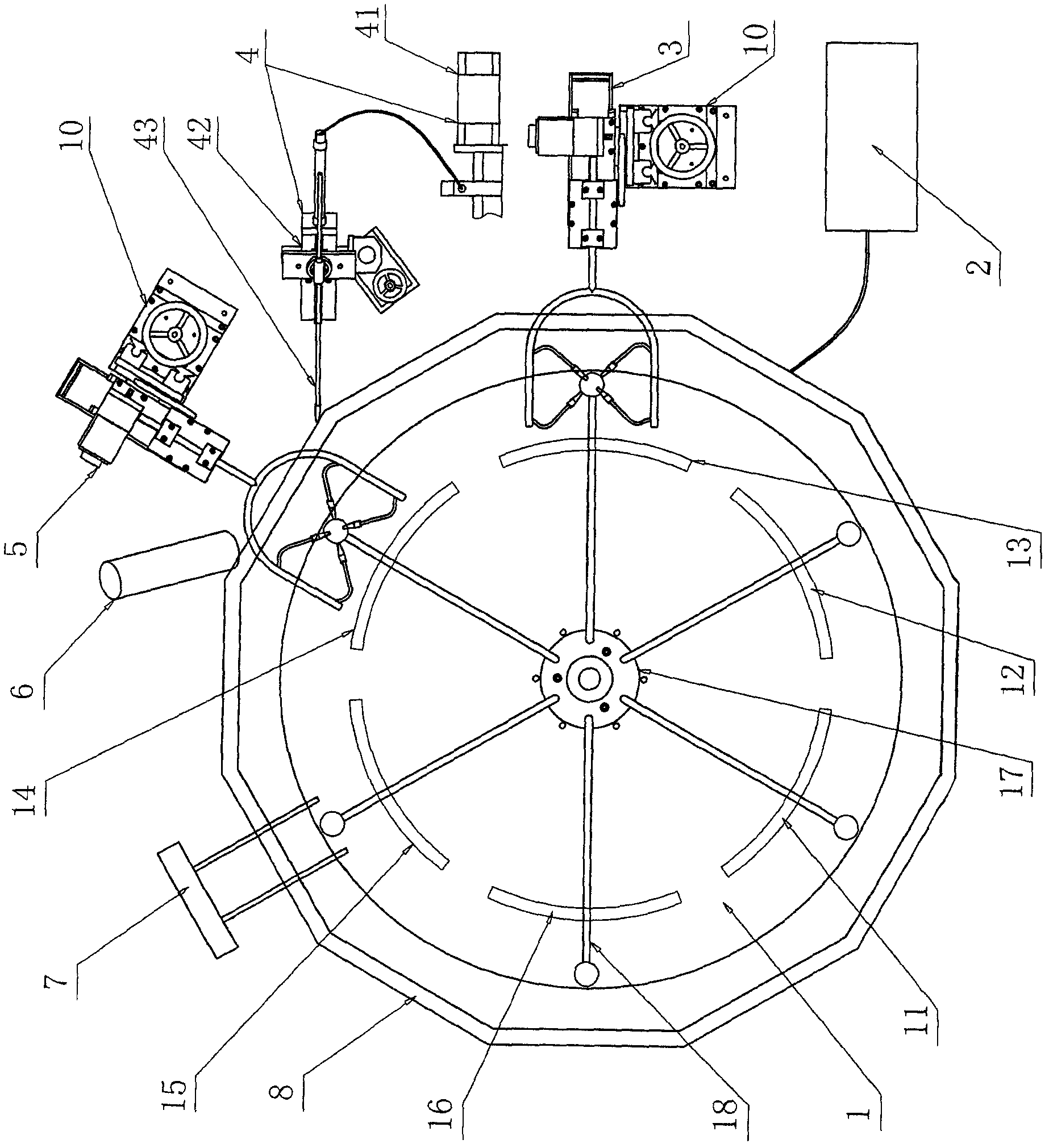

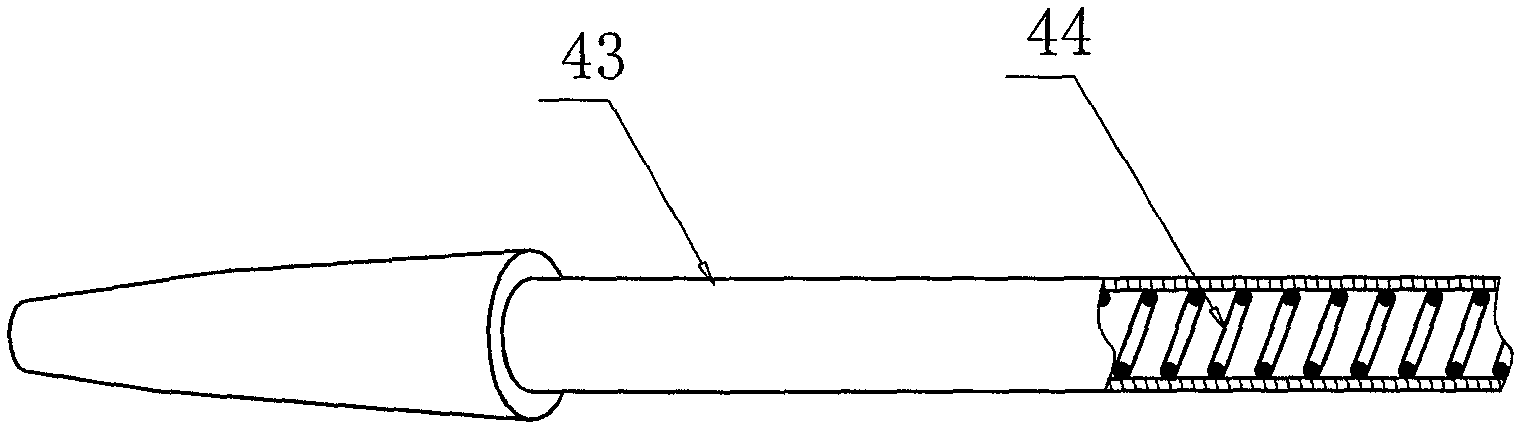

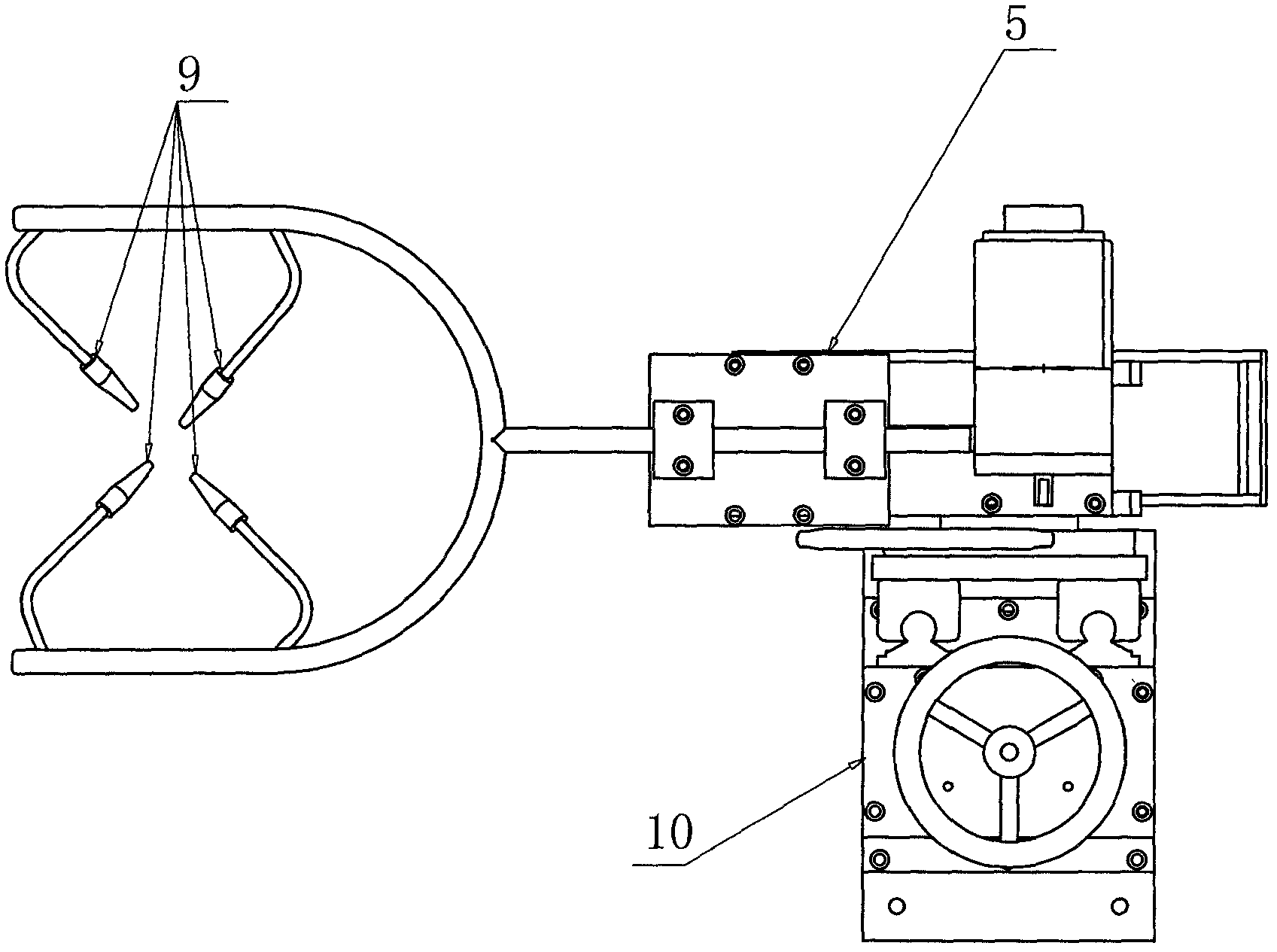

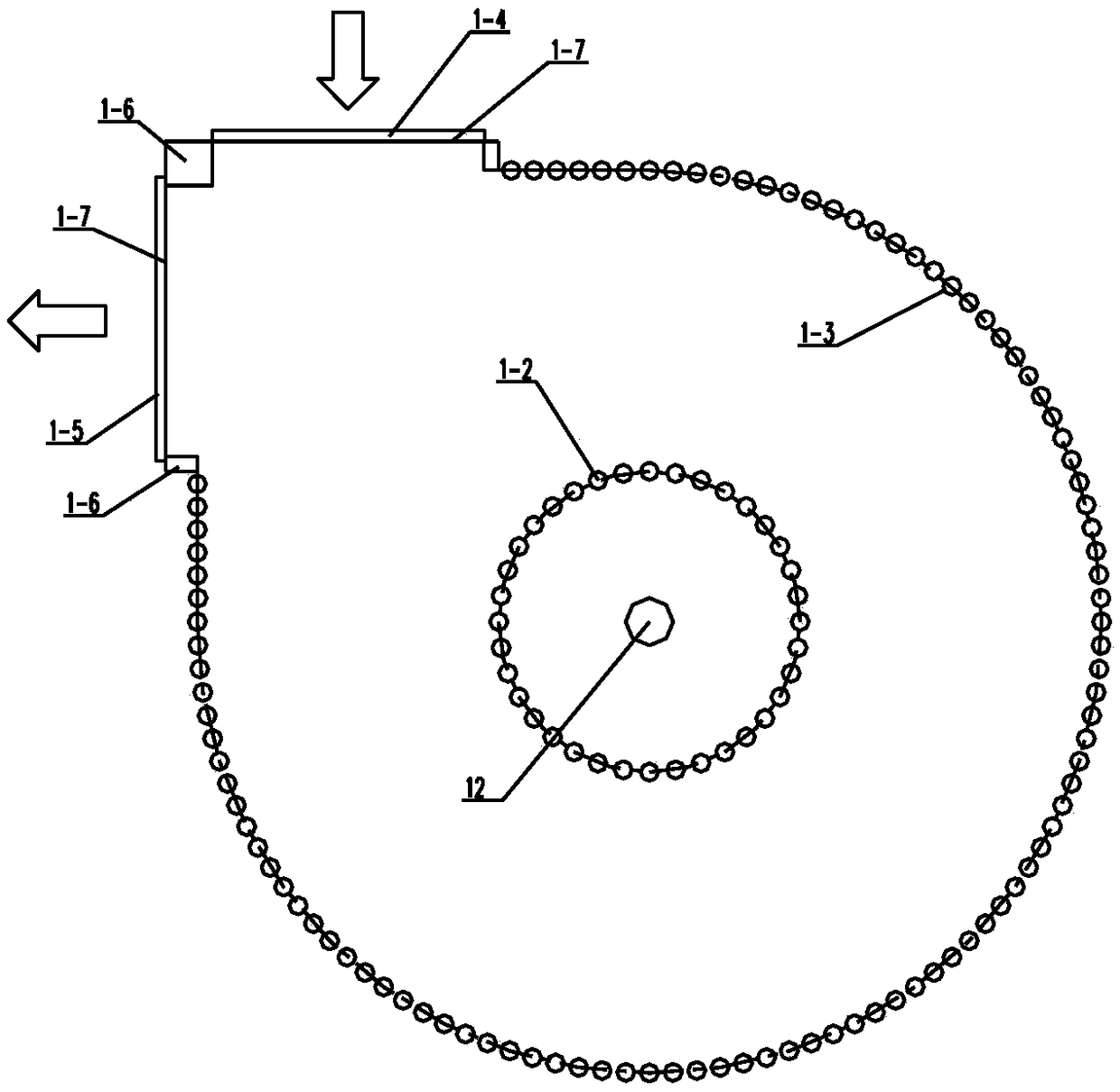

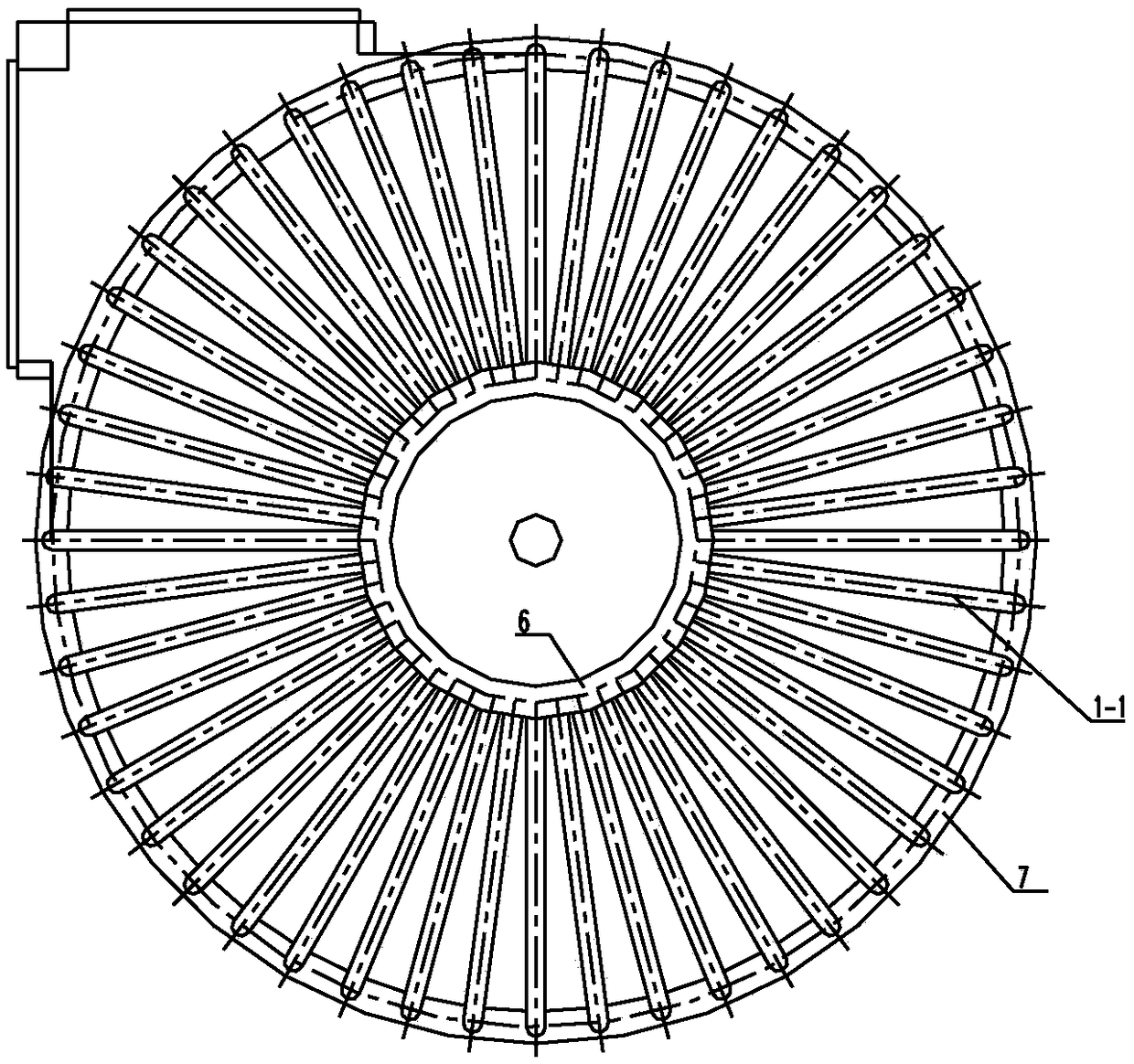

The invention relates to a high-efficiency copper-iron automatic flame brazing machine and a brazing method thereof, in particular to a brazing device for compressor hot rolled plate shell cover and copper pipe girth welding, which comprises a rotary disc, a control system and a flame welding mechanism, wherein the rotary disc comprises a loading station, a sensing station, a preheating station, a welding station, a cooling station and an unloading station; a flame preheating mechanism is installed correspondingly to the preheating station; a temperature sensing device for detecting welding temperature on the welding station is installed correspondingly to the welding station. The automatic flame brazing machine disclosed by the invention overcomes the shortages of the prior art, breaks through the core technology of the flame welding (controlling temperature of the flame), and reduces the dependency of the existing compressor hot rolled plate shell cover and the copper pipe girth welding on the high-silver solder, thereby reducing the brazing cost remarkably.

Owner:佛山市泓实机械制造有限公司

Leadless bone porcelain and method for preparing same

The invention discloses leadless bone china and a preparation method thereof. The leadless bone china consists of cattle bone coal, pig bone coal, sandstone in Datong, quartz, feldspar, kaolin, calcined kaolin, and bentonite. The preparation method is as follows: leadless bone china is sorted manually, pulverized and processed; b. calcining, ball milling and alkaline cleaning process equipment and process are adopted for the bone coal; c. wet process is adopted for preparing semi-finished china and glaze; d. roll forming process and chain-type dryness are adopted for flat products and products in regular shape; e. high temperature biscuit firing with natural gas and medium and low temperature glaze firing are adopted; f. machine and manual spraying glazing are adopted for glazing; g. a roller hearth furnace is adopted for enamel firing in the environment of natural gases. The leadless bone china is primarily prepared with sandstone in Datong; the molding ratio of the product is as high as 96 percent; the product is transparent, light, fine and hard; the china is harder, whiter and more transparent than the ordinary china.

Owner:SHANXI MINGHE CERAMIC

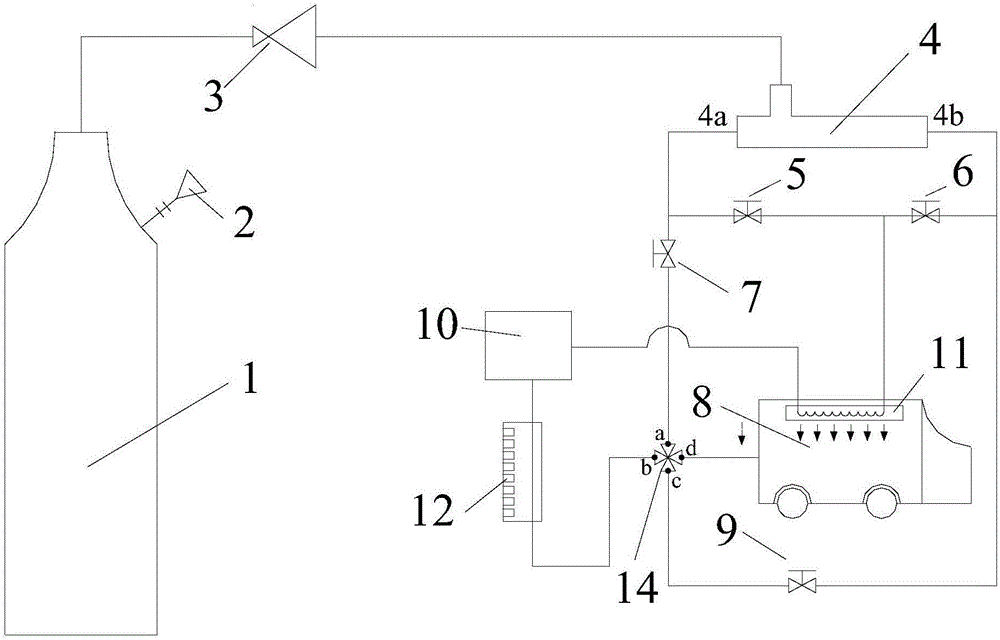

Air conditioning system for automobile based on vortex pipe

InactiveCN106183707AReduce energy consumptionStable gas sourceAir-treating devicesCompression machinesEngineeringMechanics

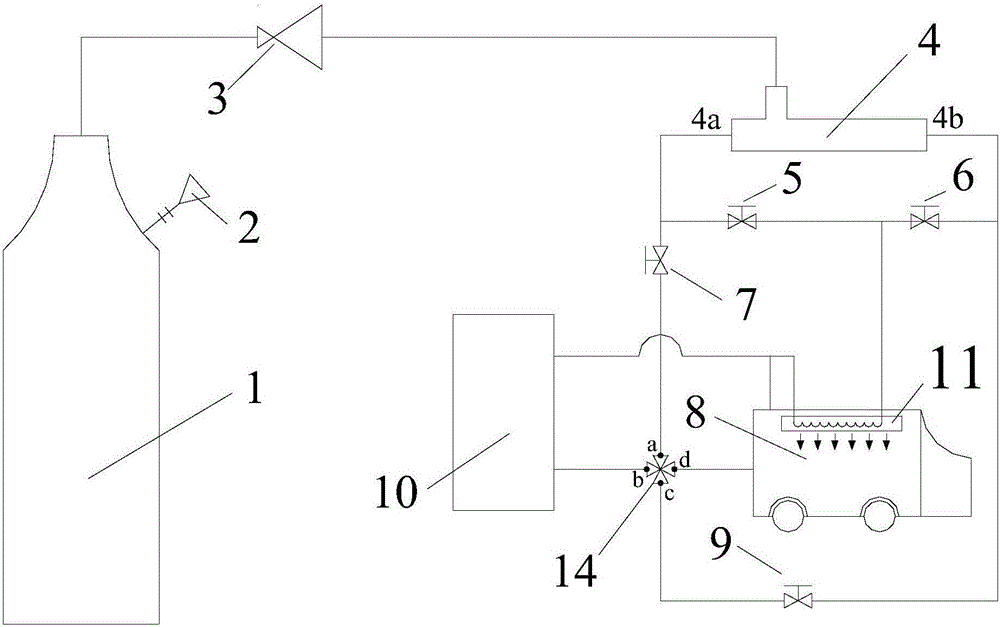

The invention discloses an air conditioning system for an automobile based on a vortex pipe. The air conditioning system comprises an air supply unit, a heat exchanger, and the vortex pipe, wherein the heat exchanger is arranged in the automobile; an inlet of the vortex pipe is connected with the air supply unit; and one outlet of a hot end outlet and a cold end outlet of the vortex pipe is connected with an inlet of a heat exchanging medium pipeline of the heat exchanger, and the other outlet of the hot end outlet and the cold end outlet of the vortex pipe communicates with the surrounding environment. In summer, cold fluid is cooled by the heat exchanger in the automobile or directly introduced in a compartment for cooling, and in winter, hot fluid can also be heated by the heat exchanger in the automobile or directly introduced in the compartment for heating. The air conditioning system disclosed by the invention has the outstanding advantages of being simple in device, high in reliability, small in occupied space, high in energy utilization efficiency and the like, and has good application prospects in the field of air conditioning in automobiles.

Owner:ZHEJIANG UNIV

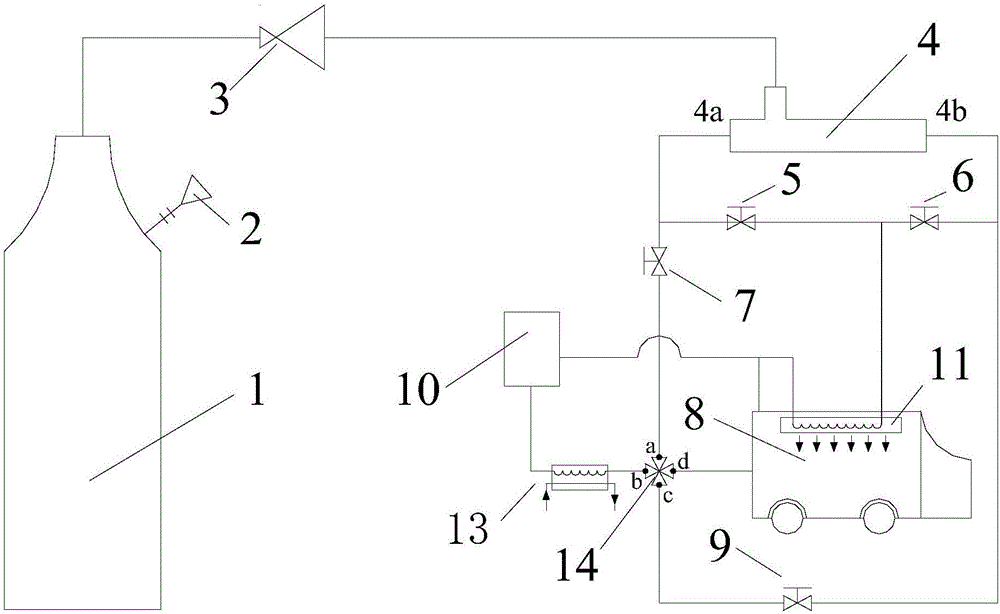

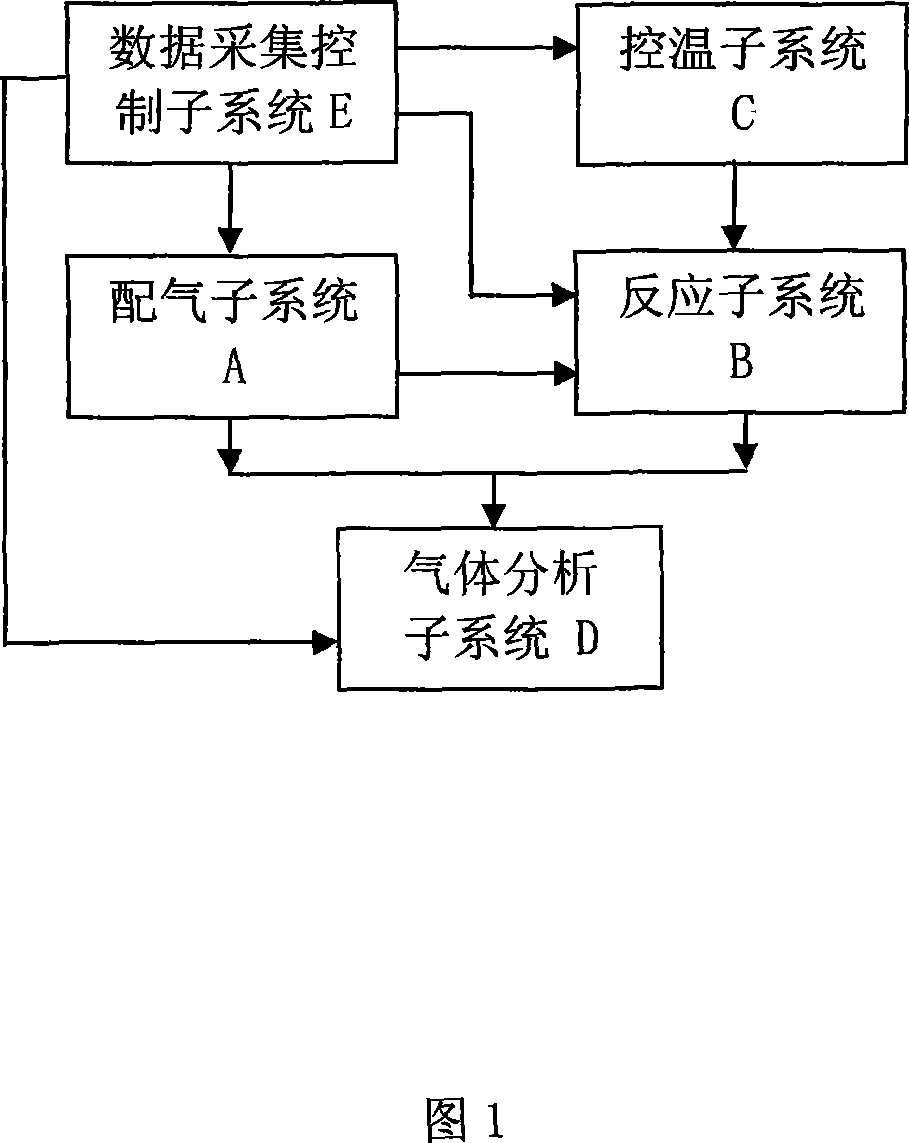

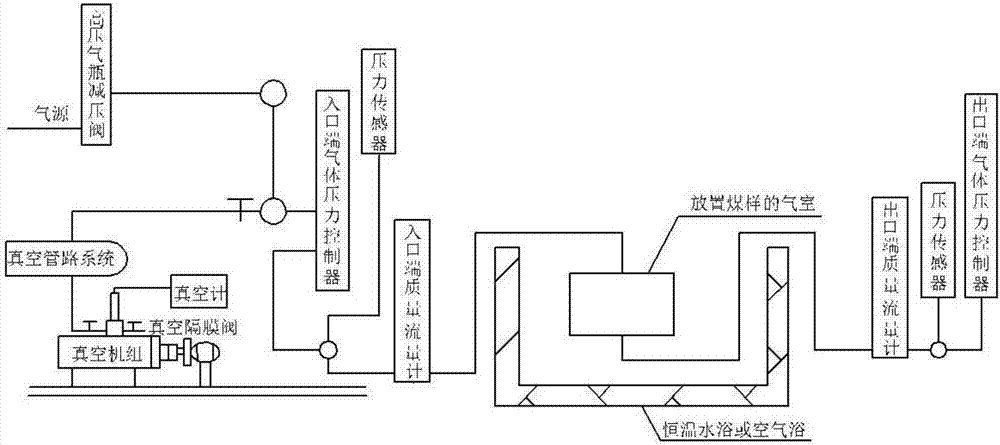

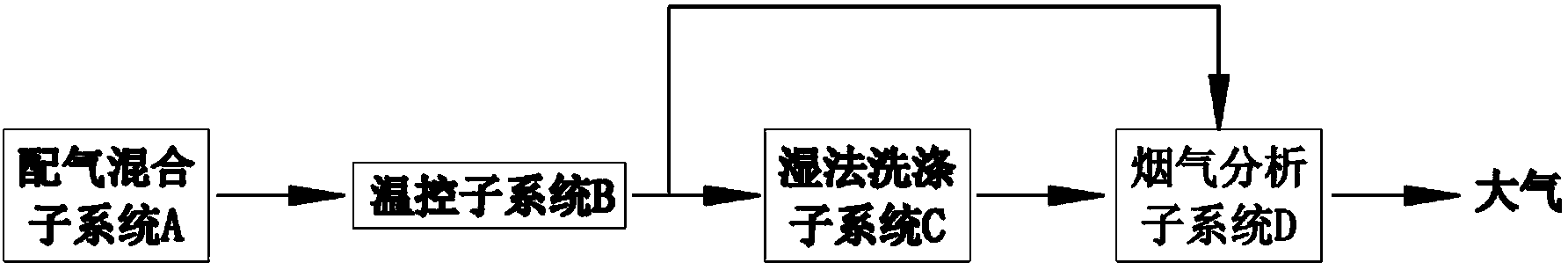

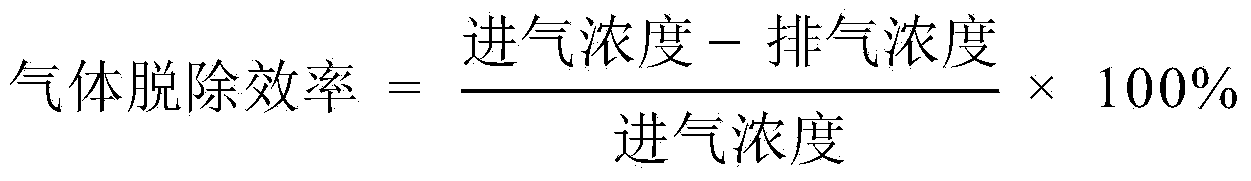

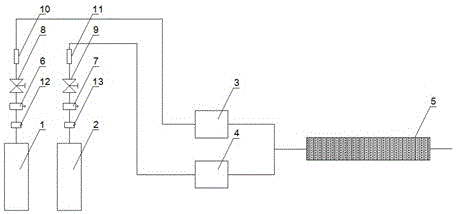

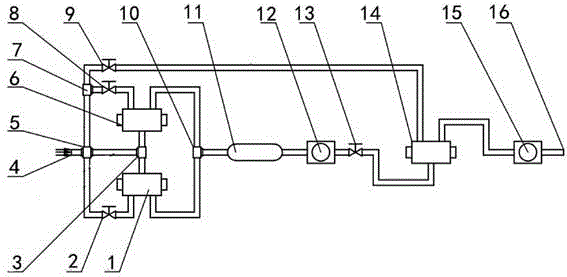

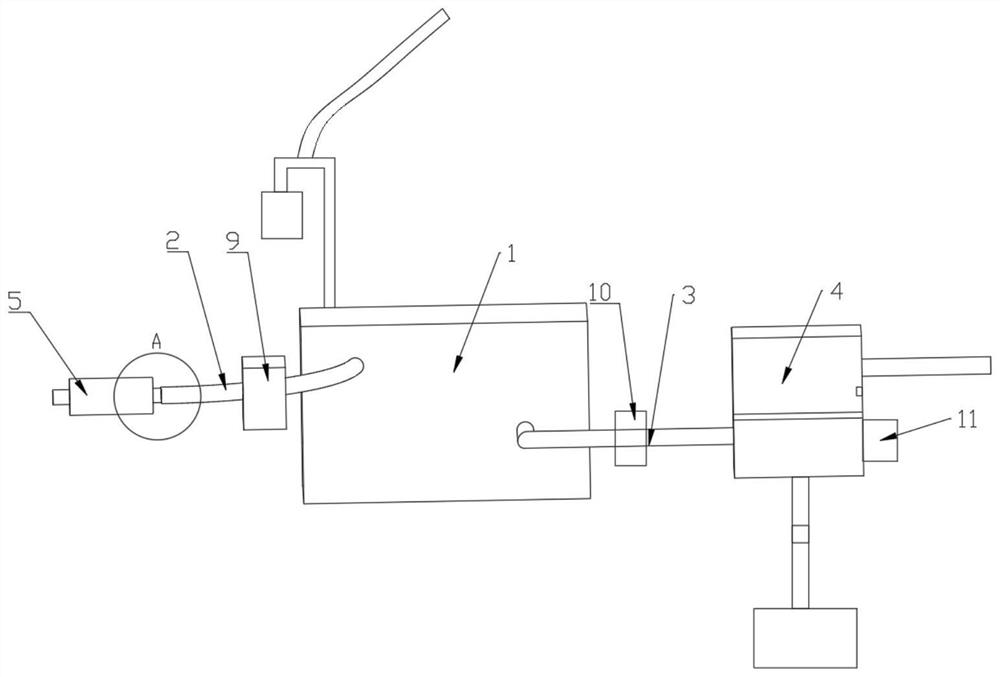

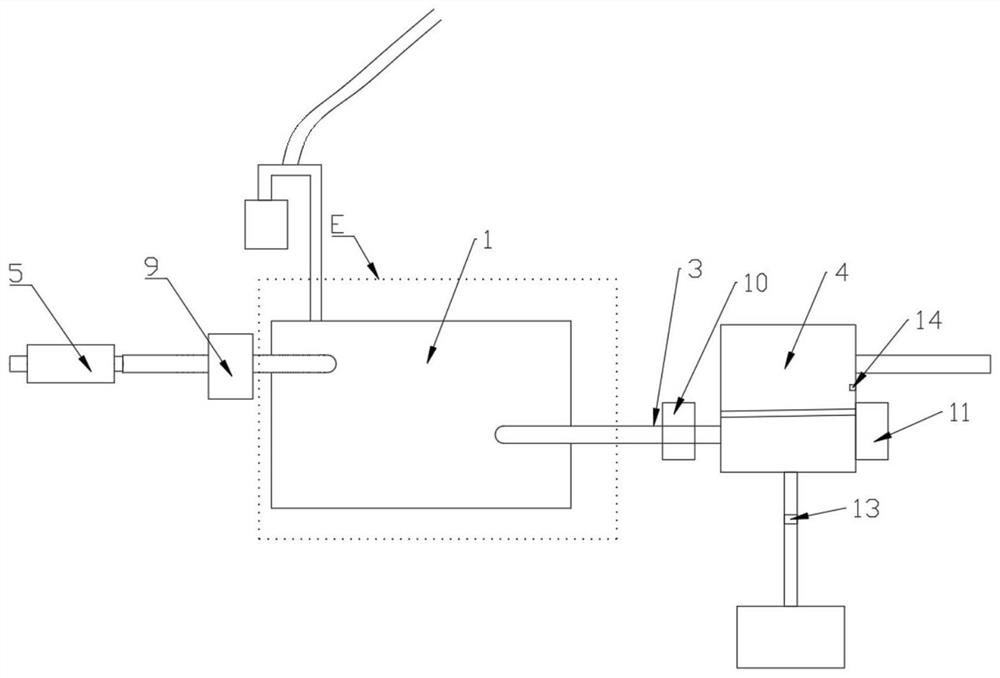

Engine vent gas catalytic cleaner activation evaluating system

InactiveCN101138702AStable gas sourceGood repeatabilityDispersed particle separationMaterial analysisGas concentrationAirspeed

An engine exhaust catalyzed purifier activity evaluation system comprises a gas distribution subsystem, a temperature control subsystem, a reaction subsystem, a gas analysis subsystem, and a data acquisition and control subsystem. An output end of the gas distribution subsystem is connected with the reaction subsystem, the gas analysis system, the temperature control system and the reaction subsystem respectively. The reaction subsystem is connected with the gas analysis subsystem. The data acquisition and control subsystem is connected with the gas distribution subsystem, the reaction subsystem, the temperature control subsystem and the gas analysis subsystem. As a high-precision flow controller is used to collocate a simulated exhaust gas as a gas source, the catalyst can carry out an activity evaluation experiment in the artificially-controllable atmosphere. The system is provided with the stable gas source, the good repeatability, the high automation, and the precise temperature control, and can realize the flexible control of different temperature rising speeds at a plurality of sections. An exhaust analyzer can measure the concentration of gas in the front or back of the catalyst. The system is provided with the function of ignition temperature characteristic experiment, air-fuel ratio characteristic experiment and air-speed characteristic experiment simultaneously or respectively.

Owner:TIANJIN INTERNAL COMBUSTION ENGINE RES INST

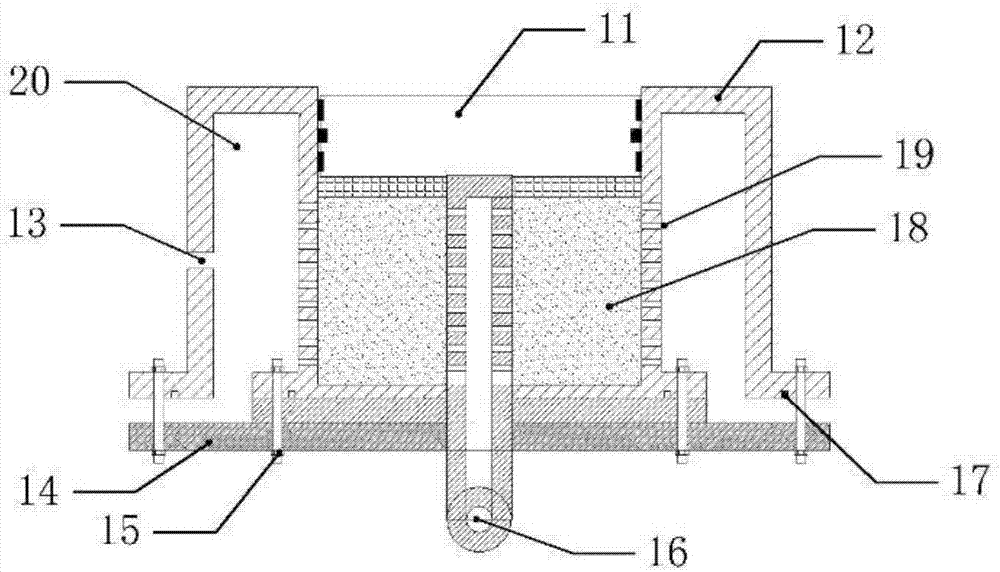

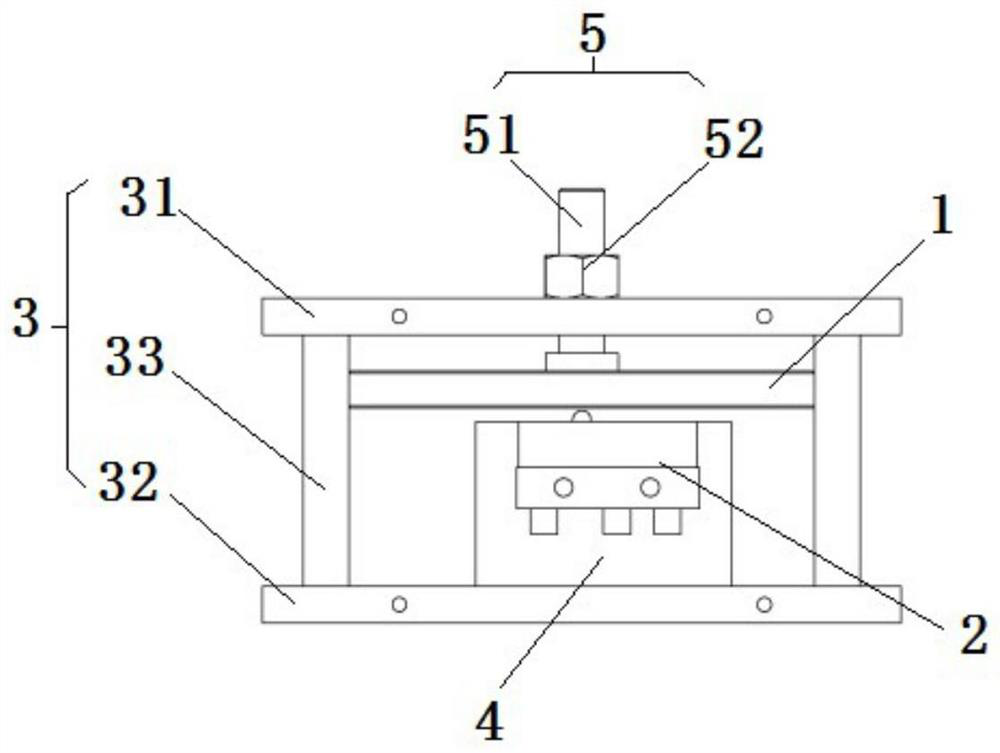

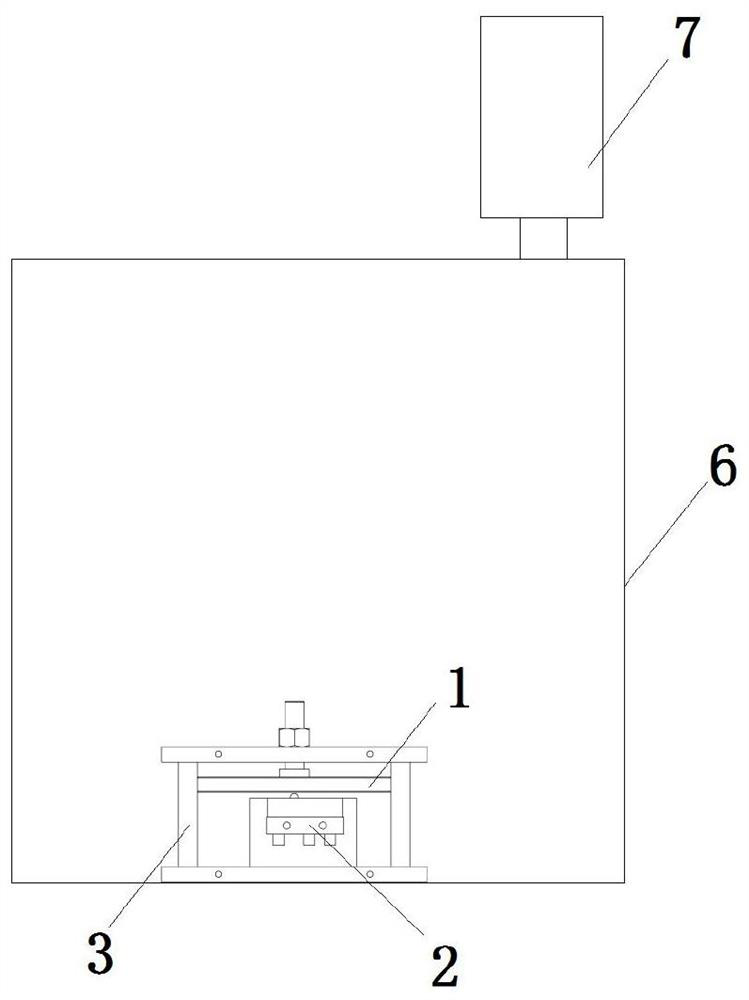

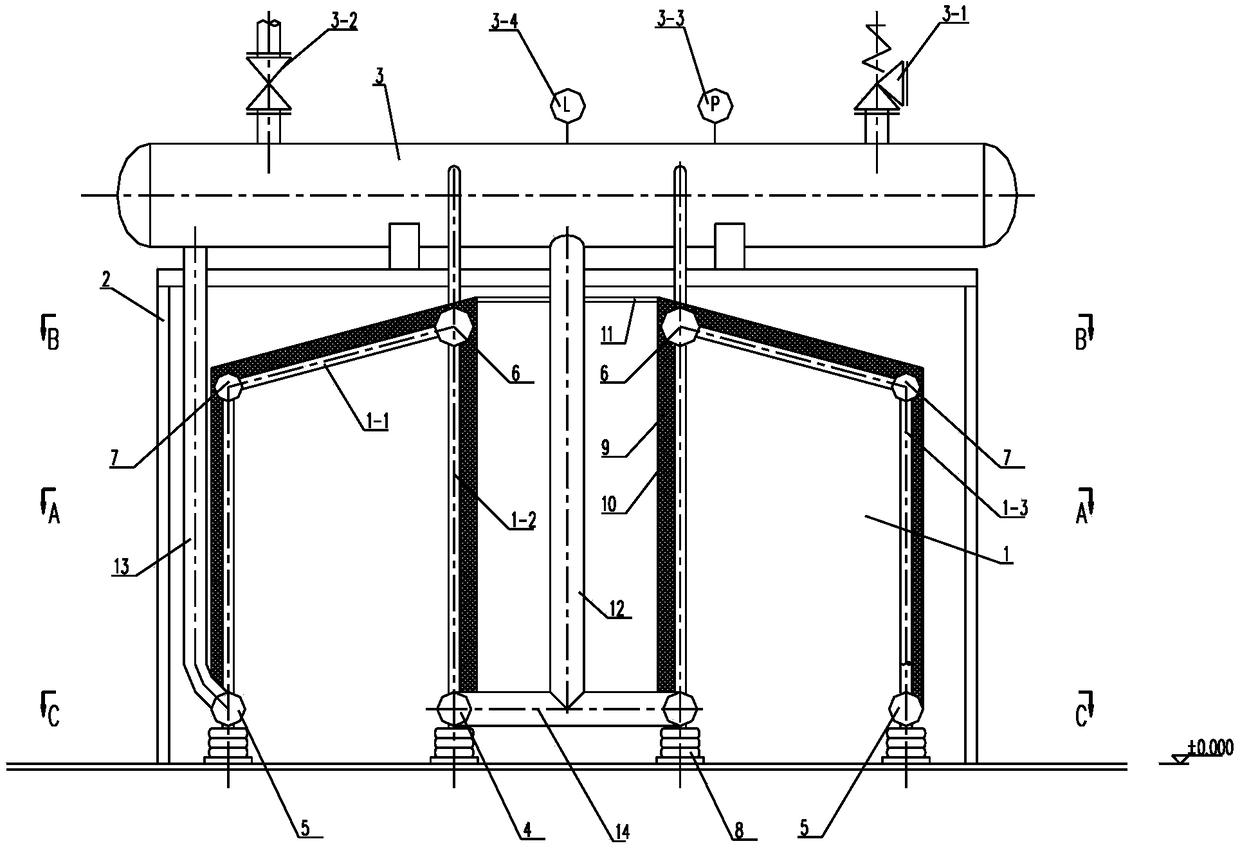

A coal rock non-linear permeability coefficient testing device and method

InactiveCN107101928AAchieve sealingInto the uniformPermeability/surface area analysisControl systemSteel bar

The invention belongs to the technical field of coal mine safety, and relates to a coal rock non-linear permeability coefficient testing device and method. The device includes a coal sample sealer, an inlet end pressure control system, an outlet end pressure control system and a vacuum pipeline system. The coal sample sealer comprises a thermostatic bath and a gas chamber. The gas chamber is disposed in the thermostatic bath. A seal cavity is mounted in the gas chamber. A hollow cylindric steel bar penetrates the middle of the seal cavity. The lower part of the steel bar, which protrudes out of the seal cavity, is adopted as a connection gas outlet end. A bent top cover is hermetically mounted on the seal cavity. The annular surface of the top cover is evenly provided with a plurality of sieve holes. An upper seal check block is disposed on the top cover. The gas chamber has a cylindric structure. The side surface of the gas chamber is provided with a side chamber valve. The inlet end pressure control system and the vacuum pipeline system are connected to the side chamber valve. The outlet end pressure control system is communicated with the connection gas outlet end. A problem that mine gas treatment lacks theoretical directions is overcome. The basis for formulating a reasonable drainage and mining scheme for mines is provided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

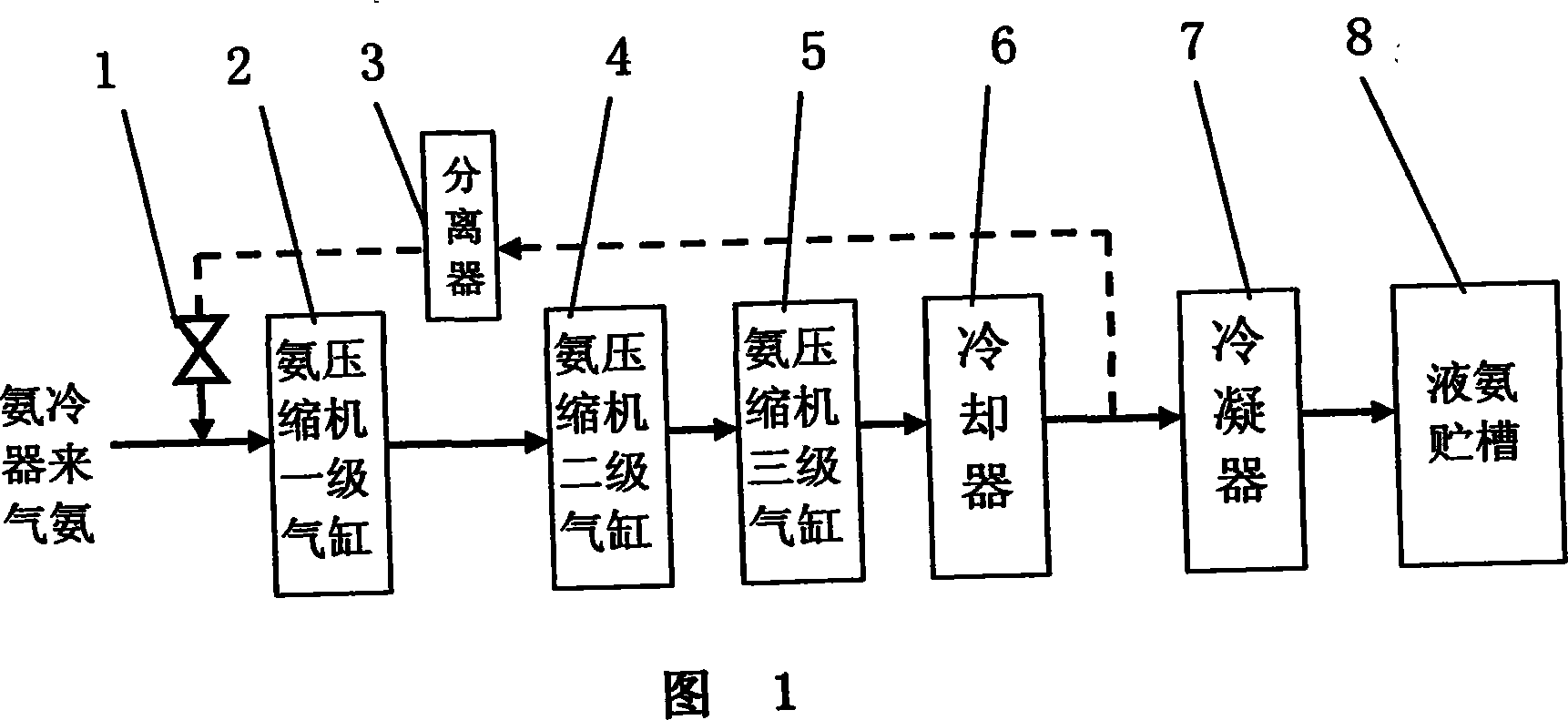

Centrifugal compressor ammonia compressor rapid vibration-prevention method and device

This invention discloses centrifuge type ammonia compressor turbulence vibration prevention method and its device. The ammonia gas at ammonia compressor outlet opening is fed back to ammonia compressor inlet opening and mix with compressed ammonia gas. The mixed flow rate is larger than rated minimal inlet opening flow rate of ammonia compressor. Return pipe can be arranged out of any stage of cylinder outlet opening of ammonia compressor. This invention can protect compressor rotor.

Owner:SICHUAN MEIFENG CHEM IND

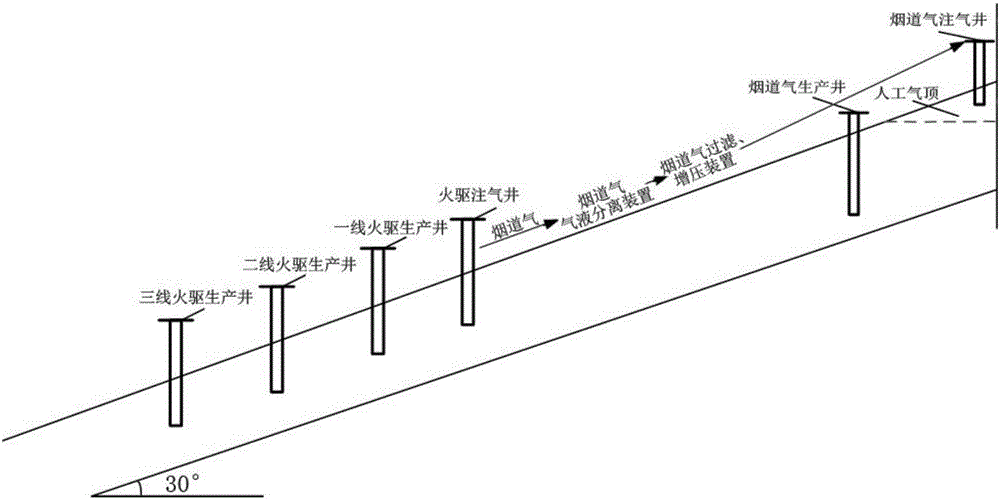

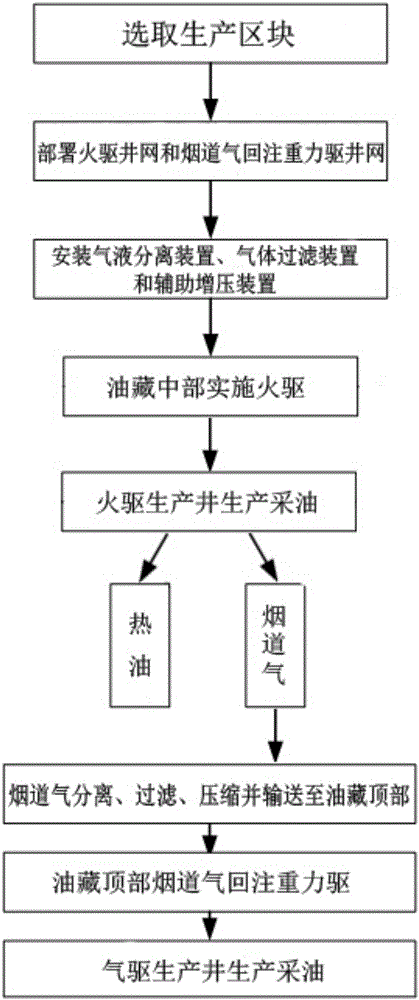

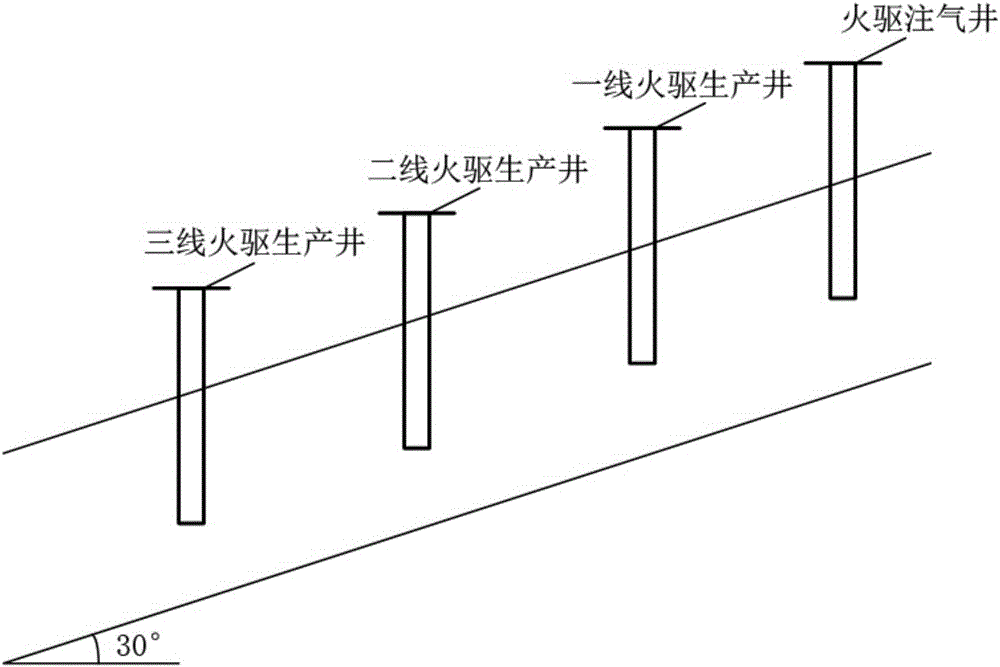

Fireflooding and flue gas reinjection gravity driving collaborative exploitation method for high-inclination-angle thick oil reservoir

The invention provides a fireflooding and flue gas reinjection gravity driving collaborative exploitation method for a high-inclination-angle thick oil reservoir. The exploitation method comprises the following steps: selecting a production block, and respectively arranging a fireflooding linear flooding well pattern and a flue gas reinjection gravity driving well pattern at the middle part and the top of the production block; installing a ground facility, and paving a conveying pipeline; injecting air from a fireflooding gas injection well to an oil layer and igniting, extracting hot oil and flue gas which are generated by combustion from a fireflooding production well, separating and filtering the flue gas, then reinjecting the filtered flue gas into a flue gas injection well, and producing and extracting oil through a gas driving production well. The exploitation method can avoid the shortcomings of non-uniform fire line boosting and small use area due to single fireflooding, and the use area of the oil reservoir is enlarged; under the collaborative action of the fireflooding and flue gas reinjection gravity driving, the oil recovery ratio can be increased; furthermore, through the flue gas generated by the fireflooding, a stable gas source can be supplied to top gas injection; by reinjection of the flue gas, discharge of tail gas can be reduced, the operation cost is reduced, the air pollution is relieved, and the environment is protected.

Owner:PETROCHINA CO LTD

Method for supercritical extraction of balsam pear oil using carbon dioxide

The invention discloses a method for supercritical extraction of balsam pear oil using carbon dioxide, which is aimed at solving the problems of solvent recovery and solvent residual for the conventional solvent method employed in balsam pear oil extraction. The method for supercritical extraction of balsam pear oil can be carried out at normal temperature.

Owner:BEIHAI ANTAI BIO TECH

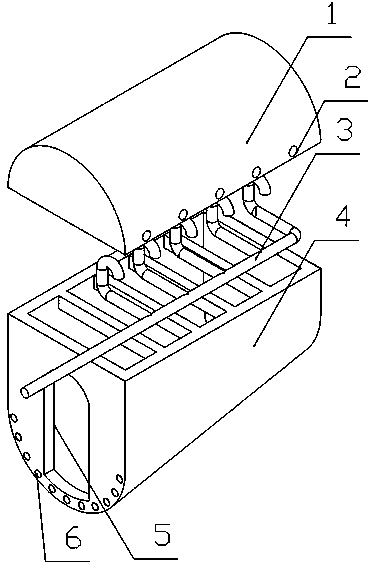

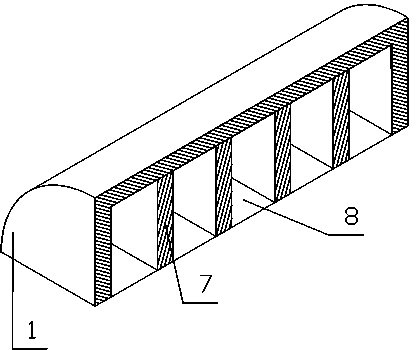

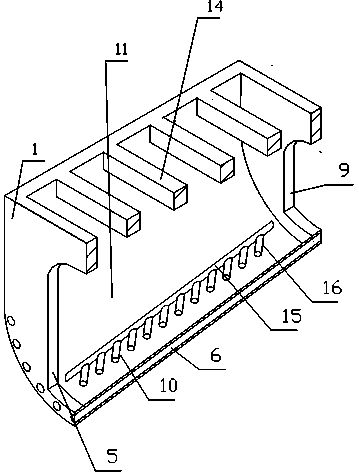

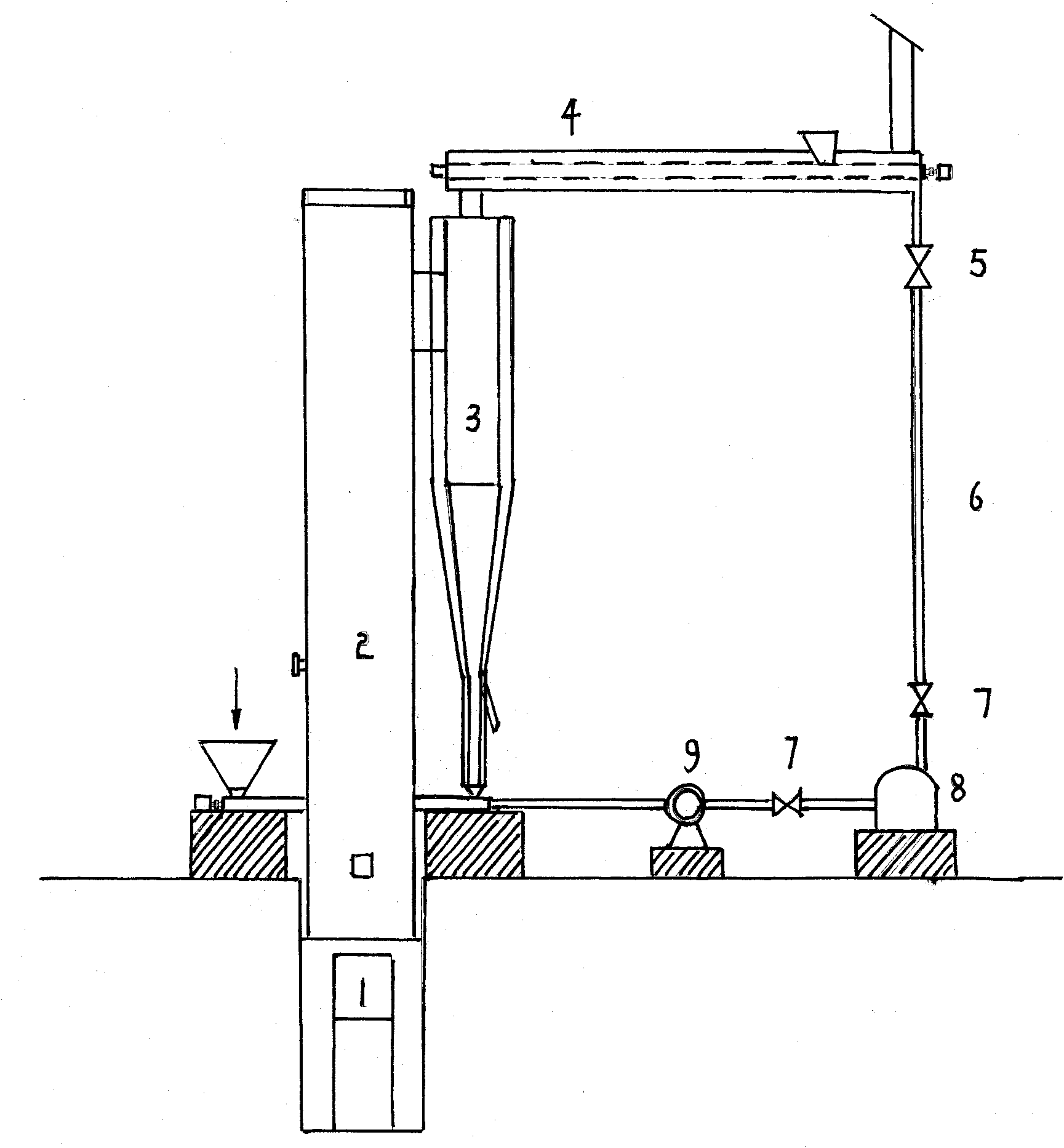

Invisible multistage methane tank capable of producing methane evenly

ActiveCN103923822AReduce stressExtended service lifeGas production bioreactorsWaste based fuelMethaneWaste management

The invention relates to an invisible multistage methane tank capable of producing methane evenly, which aims at solving the technical problem that the existing methane tank has short service life, has low yield of methane, provides methane unstably and is inconvenient to use and maintain. The methane tank comprises a tank wall and a tank bottom below the wall, wherein the joint of the tank wall and the tank bottom of the methane tank is smoothly connected; the methane tank also comprises an arch tank top, which is internally provided with clapboards dividing the tank top into at least two air collection chambers; the methane tank is also provided with a spraying and stirring mechanism, which comprises a liquid pump, an air inlet pipeline and an air outlet pipeline. The invisible multistage methane tank has the beneficial effects of having long service life as smooth arc transition reduces stress at the joint, being capable of maintaining on line, producing methane evenly, and occupying small land; in addition, the tank top has a plurality of air chambers and a plurality of sets of air outlet pipes, so that if one air chamber leaks air, the other air chambers are not affected, the continuity of methane supply is improved; the spraying and stirring mechanism washes the methane tank at the right time, so as to avoid crusting and increase the yield of methane.

Owner:郭群然

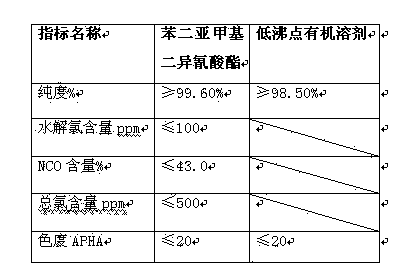

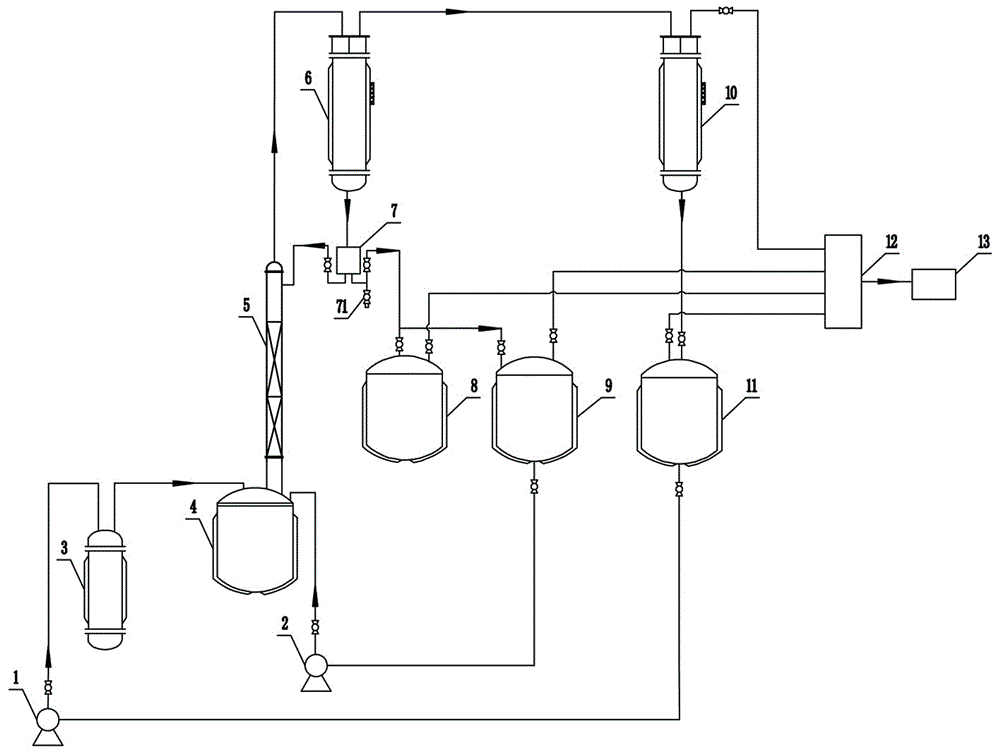

Xylylene diisocyanate rectification apparatus and rectification method thereof

ActiveCN103990291AEasy to recycleEasy to useChemical industryIsocyanic acid derivatives purification/separationXylyleneReboiler

The invention provides a xylylene diisocyanate rectification apparatus and a rectification method thereof. The apparatus comprises an organic solvent heater, a crude product reboiler, a rectifying tower, a first order condenser, a finished product pot, a crude solvent reception pot, a high vacuum set and a tail gas processing system, and the above components are connected according to a specific order to form a closed loop. The rectification apparatus has the advantages of scientific design, reasonable structure, energy saving, low production cost and reliable production quality. The method utilizes an organic solvent, provides a stable gas source for rectification, reduces the pressure drop of xylylene diisocyanate in the rectifying tower, and improves the separation efficiency and the product purity; and the organic solvent can be easily separated from xylylene diisocyanate, and does not form a new impurity. The method has the advantages of scientific design, simple operation, good rectification effect and high product quality.

Owner:开封华瑞化工新材料股份有限公司

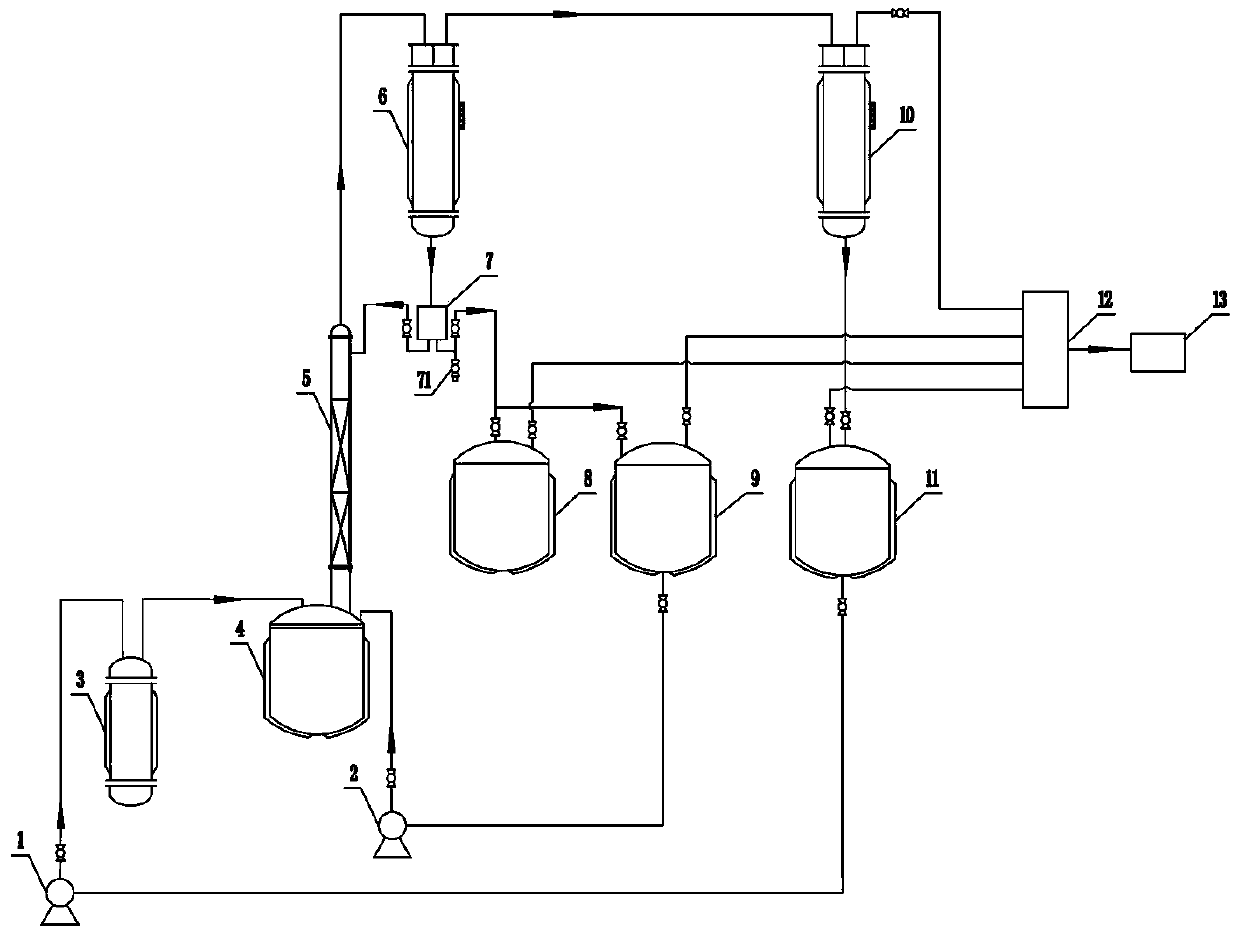

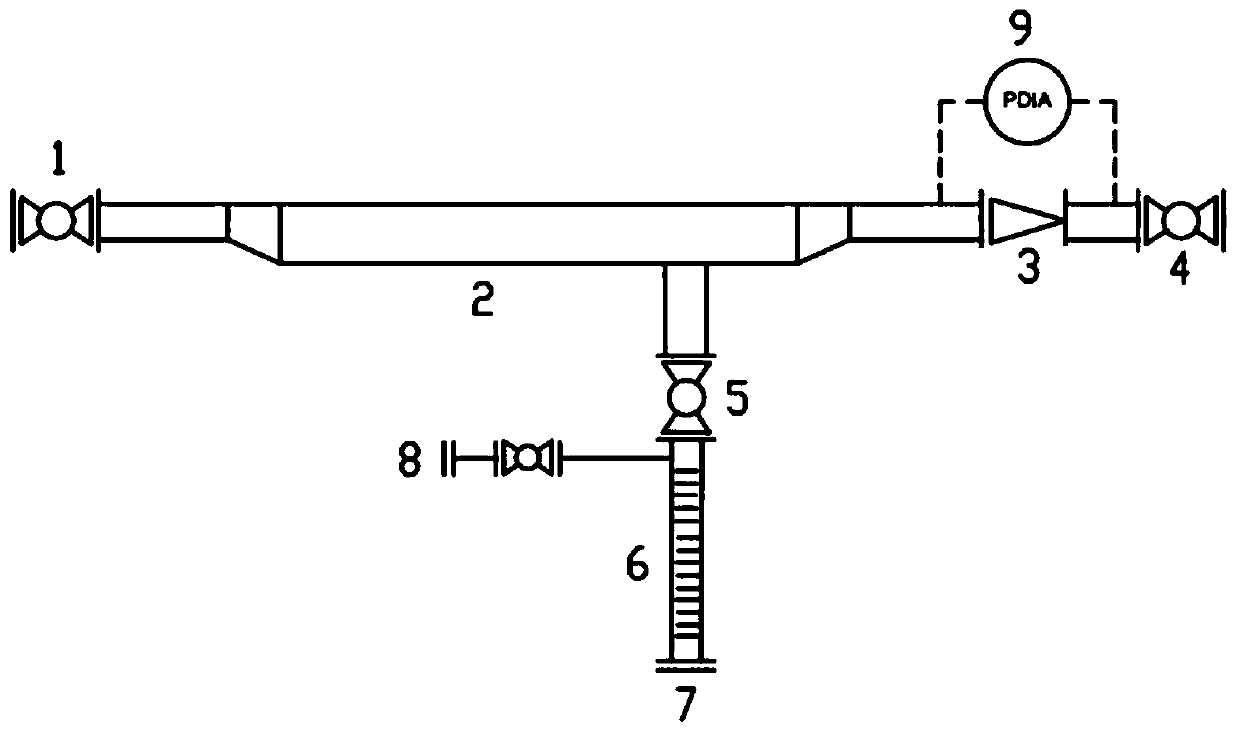

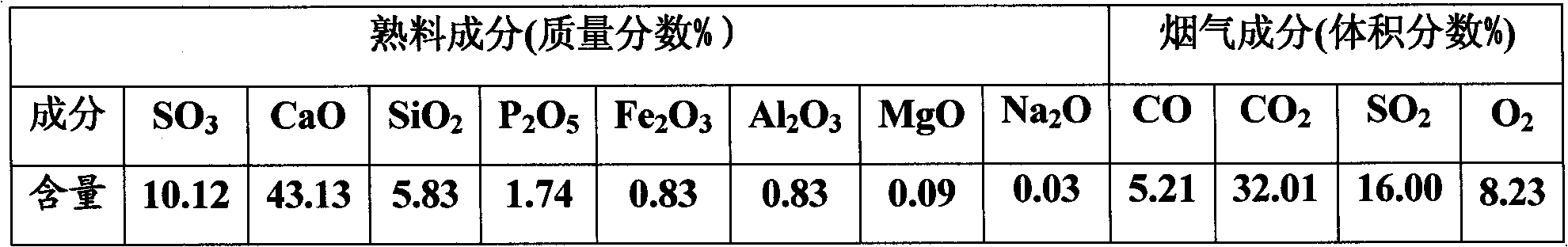

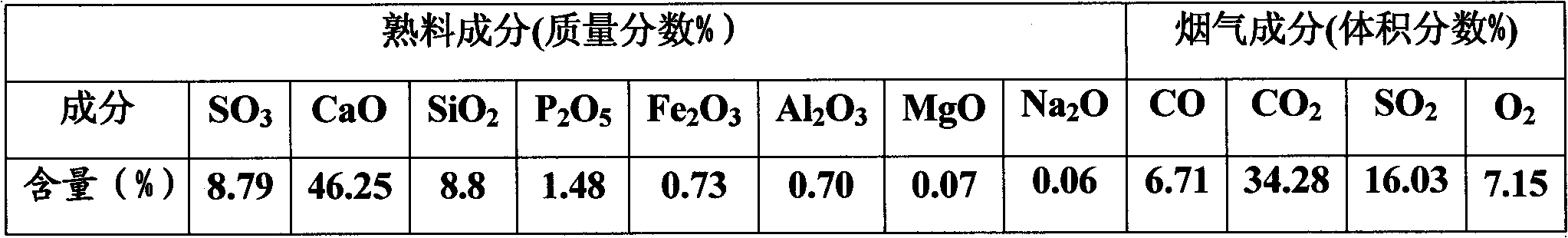

Simulated ship waste gas system for wet washing

InactiveCN104316657AStable outputPrecise regulation of total flowMaterial analysisTemperature controlFlue gas

The invention discloses a simulated ship waste gas system for wet washing. The system comprises a gas distributing and mixing subsystem, a temperature control subsystem, a wet washing subsystem and a flue gas analyzing subsystem, wherein the output end of the gas distributing and mixing subsystem is connected with the temperature control subsystem, the output end of the temperature control subsystem is respectively connected with the wet washing subsystem and the flue gas analyzing subsystem, and simulated flue gas is connected with the flue gas analyzing subsystem through a back pressure regulating valve after being processed by the wet washing reaction. The system has the benefits that the simulated ship waste gas system which is used for researching a wet washing technology under the man-made controlled condition in a laboratory is provided, the air pressure in the system is constant, and the flow output is stable. The precision of the harmful components in the simulated ship waste gas is high, the processing effect for the wet washing can be evaluated in a quantitative manner, and the reliability and the repeatability of the evaluated results are good. The amount of the required flue gas for the test is small, the testing time is short, and the testing cost is low.

Owner:DALIAN MARITIME UNIVERSITY

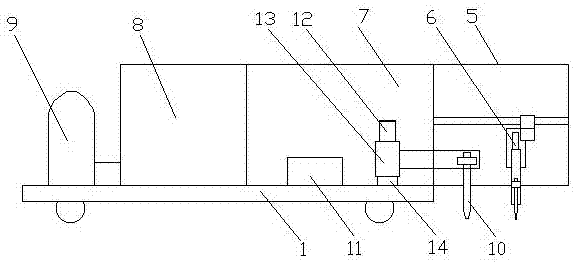

Method for cladding steel rail with alloy without cooling rate control

InactiveCN107999980AImproved corrosion and wear resistance propertiesImprove wear and corrosion resistanceWelding apparatusConstant speedCooling rates

The invention discloses a method for cladding a steel rail with an alloy without cooling rate control. The method is characterized by comprising the following steps that a, a steel rail cladding machine is put on the steel rail, a plasma welding gun moves at a constant speed, and the upper portion of the to-be-cladded portion is cladded with the alloy; b, a formed alloy strip is located on the inner side of the center of the tread face of the rail head of the steel rail, the width of the alloy strip ranges from 4 mm to 40 mm, and the thickness of a heat affected zone of the steel rail is controlled to range from 0.3 mm to 30 mm; c, a flame head is arranged above the alloy strip, liquefied gas and oxygen are directly mixed on the flame head, after the alloy strip obtained after cladding issubjected to standing for 2 s to 180 s, the flame head is started to move in the X-axis direction at a constant speed to carry out heating, and the fact that the structure of the heat affected zone ofthe heated steel rail is tempered sorbite or tempered sorbite and tempered troostite or tempered troostite is taken as the standard. By means of the method, the cladding applicability and cladding efficiency can be improved, and it can be guaranteed that the mechanical performance of the structure of the heat affected zone meets steel rail use after field steel rail cladding.

Owner:CHENGDU ZHONGGUI TECH CO LTD

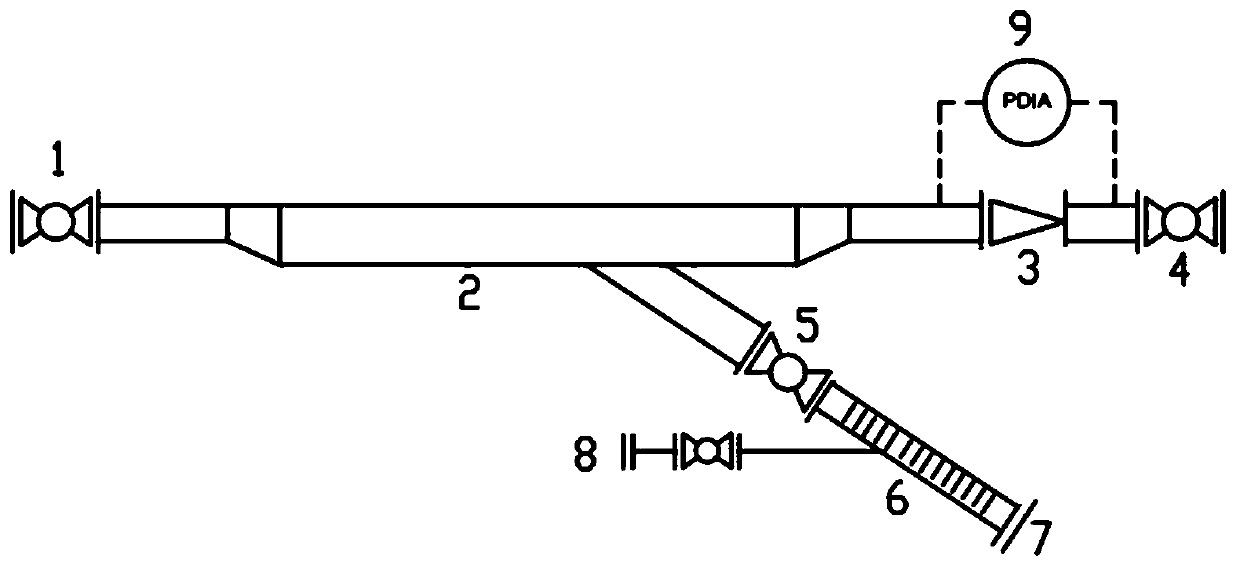

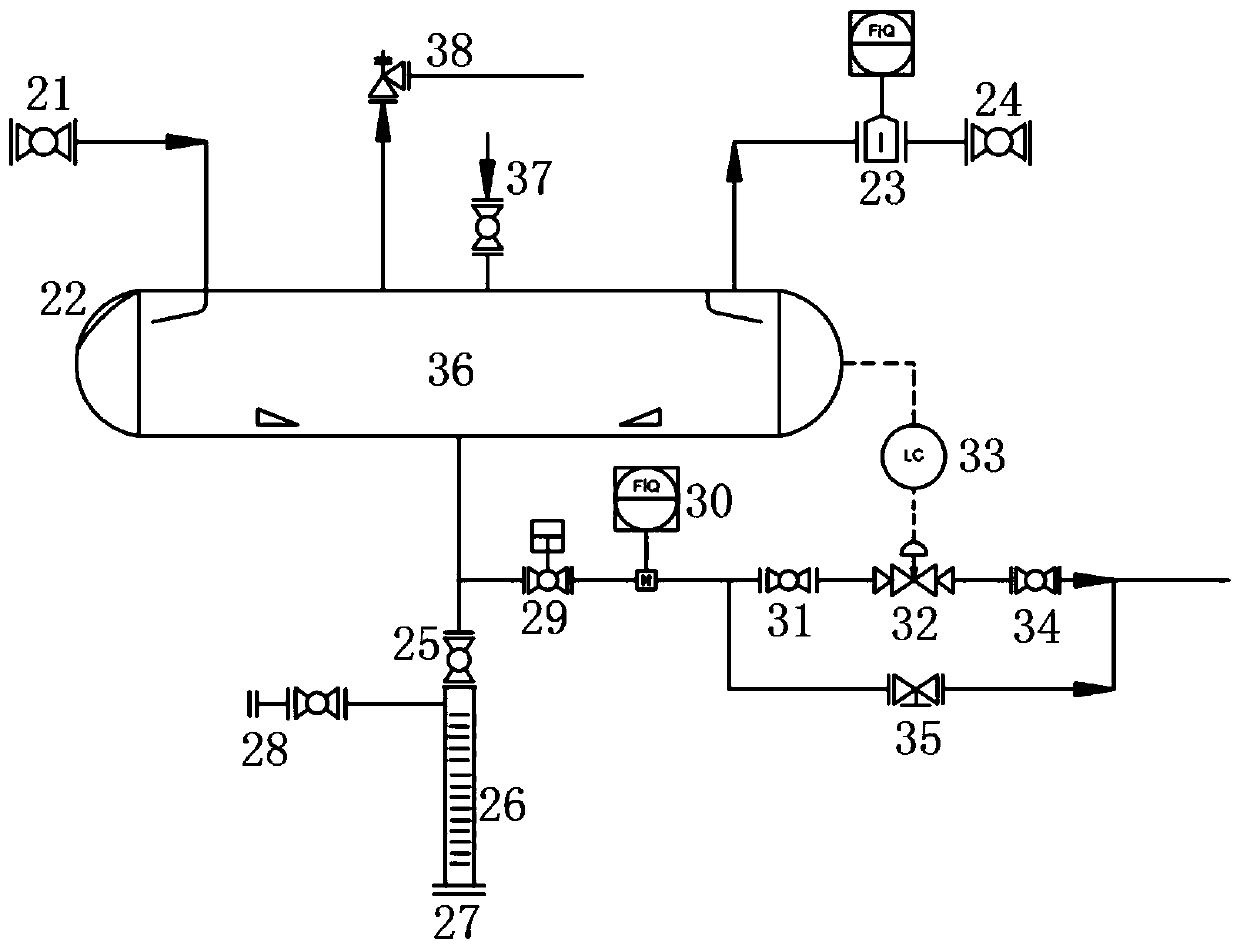

Shale gas sand removing separation system and method

PendingCN110130868AImprove sand removal efficiencyImprove sand removal effectFluid removalThree levelSoil science

The invention discloses a shale gas sand removing separation system and method. The shale gas sand removing separation system includes a sand removing filtering unit and a separation measuring unit, wherein sand removing filtering unit mainly includes a sand removing diameter expanding pipe section, a sand removing branch pipe, an inlet and outlet turn-off valve, a conical filtering element and differential pressure alarm, and gas liquid separation measuring after sand removing is realized; and the separation measuring unit mainly includes a separator, a virgin gas inlet turn-off valve, a gasphase outlet turn-off valve, a gas phase flowmeter, a blow-off pipeline, a sand removing branch pipe, a liquid phase outlet emergency turn-off valve, a liquid phase flowmeter, a liquid phase adjustingvalve and a front and back turn-off valve of the liquid phase adjusting valve, and requirements of gas liquid separation measuring and further sand removing are met. According to the shale gas sand removing separation system and method, the two units are combined for using, three-level sand removing processes such as sand settlement, filtering and separation are actually carried out, and the effect and efficiency of sand removing are greatly improved while sand removing equipment is simplified; and a visual pipe is arranged to effectively monitor the effect of sand removing in the settlementsection better, meanwhile, separating is carried out in the normal process of sand discharging so as to realize non-stop sand discharging, and operation is optimized and simplified.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Oxygen and nitrogen mixing type high-precision proportioning device and method

InactiveCN106841296AProportion precise controlSimple processMaterial heat developmentOxygen tankNitrogen

The invention provides an oxygen and nitrogen mixing type high-precision proportioning device. The oxygen and nitrogen mixing type high-precision proportioning device comprises an oxygen gas bottle, a nitrogen gas bottle, an oxygen gas mass and flow controller, a nitrogen gas mass and flow controller and a proportioning cabin; under a working state, oxygen gas is output by the oxygen gas bottle; after flow is adjusted by the oxygen gas mass and flow controller, the oxygen gas is conveyed into the proportioning cabin; meanwhile, nitrogen gas is output by the nitrogen gas bottle; after the flow is adjusted by the nitrogen gas mass and flow controller, the nitrogen gas is conveyed into the proportioning cabin; after the oxygen gas and the nitrogen gas are mixed and proportioned through the proportioning cabin, the mixed gas is output; the proportioning cabin comprises a cylindrical sealed pipe and is only provided with an input opening and an output opening which are used for inputting the oxygen gas and the nitrogen gas and outputting the mixed and proportioned gas; one section of cylindrical net is internally arranged, the length is 200mm to 240mm and the diameter is 28mm to 36mm; the diameter of net meshes is 0.03mm to 0.12mm. The oxygen and nitrogen mixing type high-precision proportioning device can be used for accurately controlling the proportion of oxygen and nitrogen; high-purity oxygen and nitrogen mixed gas with the oxygen concentration more than 3 percent and less than or equal to 21 percent is provided for a coal spontaneous ignition simulation device.

Owner:CCTEG CHINA COAL RES INST

Method for preheating canalization molten-salt section during producing alumina

ActiveCN101717103AStable gas sourceGuaranteed heating needsAluminium oxides/hydroxidesEvaporationMolten salt

The invention discloses a method for preheating a canalization molten-salt section during producing alumina and relates to a method for preheating a molten-salt heating section before pump starting of canalization molten-salt during producing alumina. The method is characterized in that the preheating of the canalization molten-salt section is realized in such a way that dead steam in a self-evaporation system is adopted to heat ore pulp in a canalization stripping pipe and molten salt in an interlayer of the canalization stripping pipe is preheated through the heated ore pulp. Compared with the prior art, the method for preheating a canalization molten-salt section during producing alumina adopts steam heating, low fault compared with electric tracing cords, lower investment and running cost than electric tracing, short heating time, can achieve temperature needed for the start of the canalization device in short time, can preheat the whole system through self-evaporation systems of a canalization system at all levels and is beneficial to establishing heat balance after the canalization device starts.

Owner:中铝矿业有限公司 +1

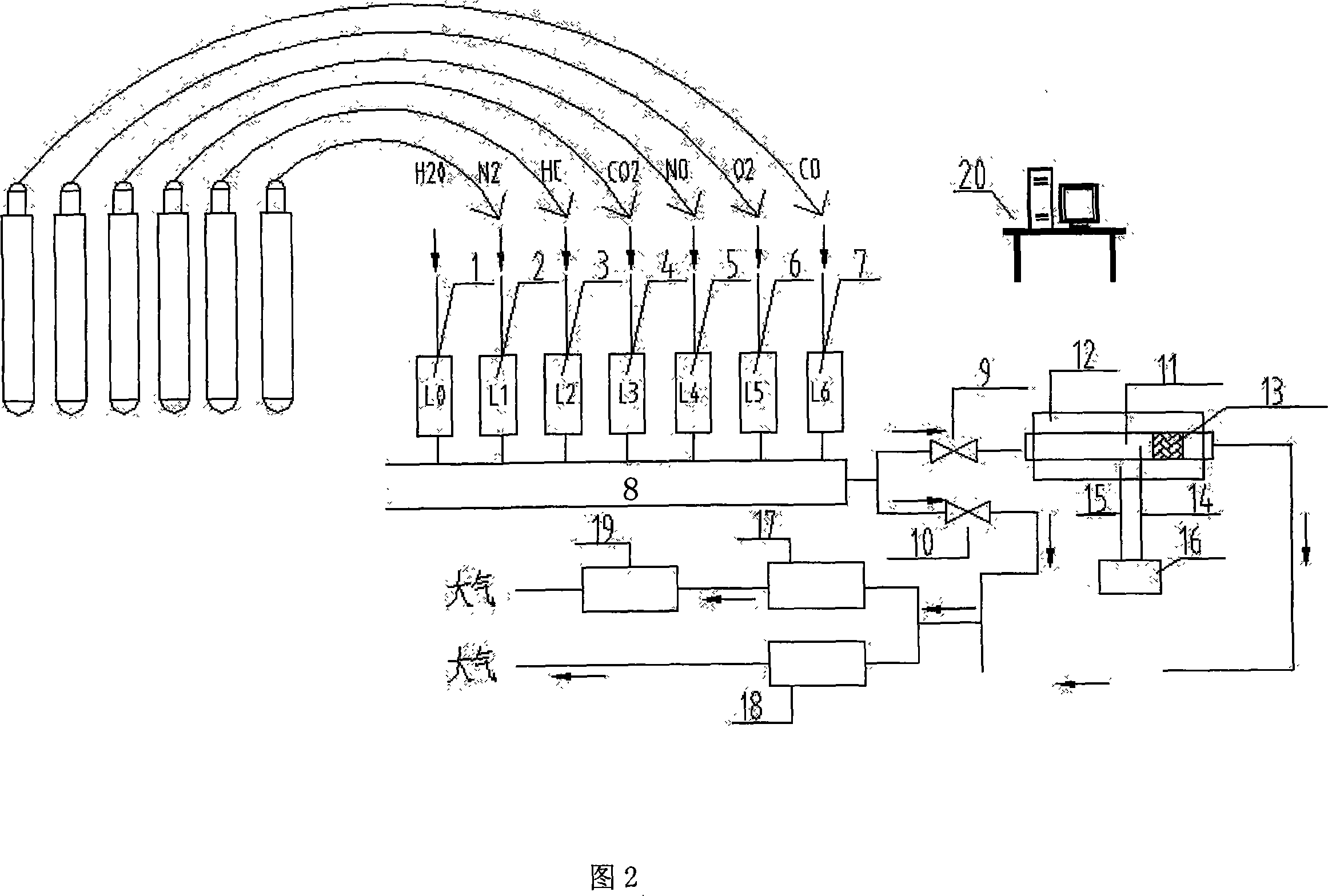

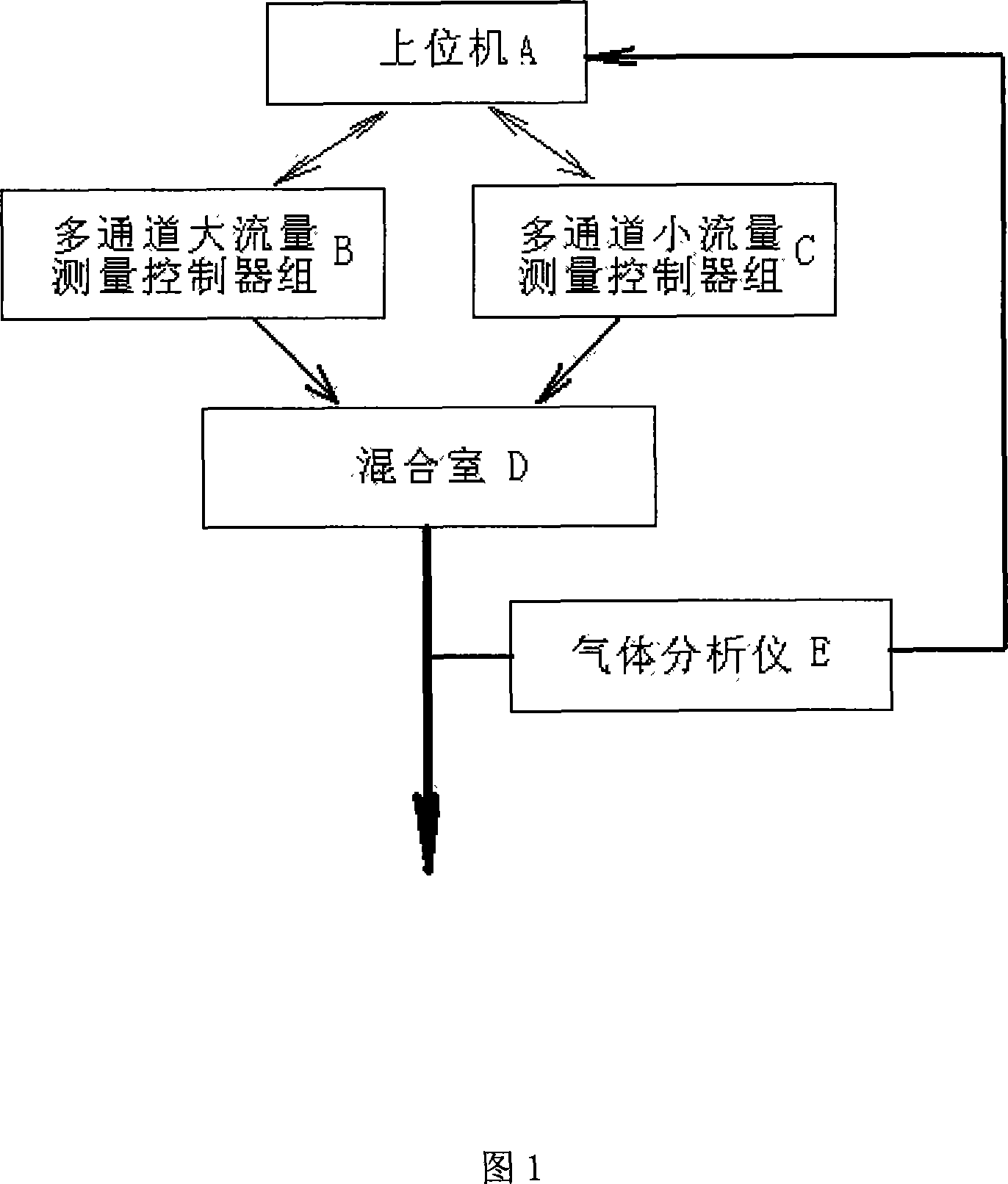

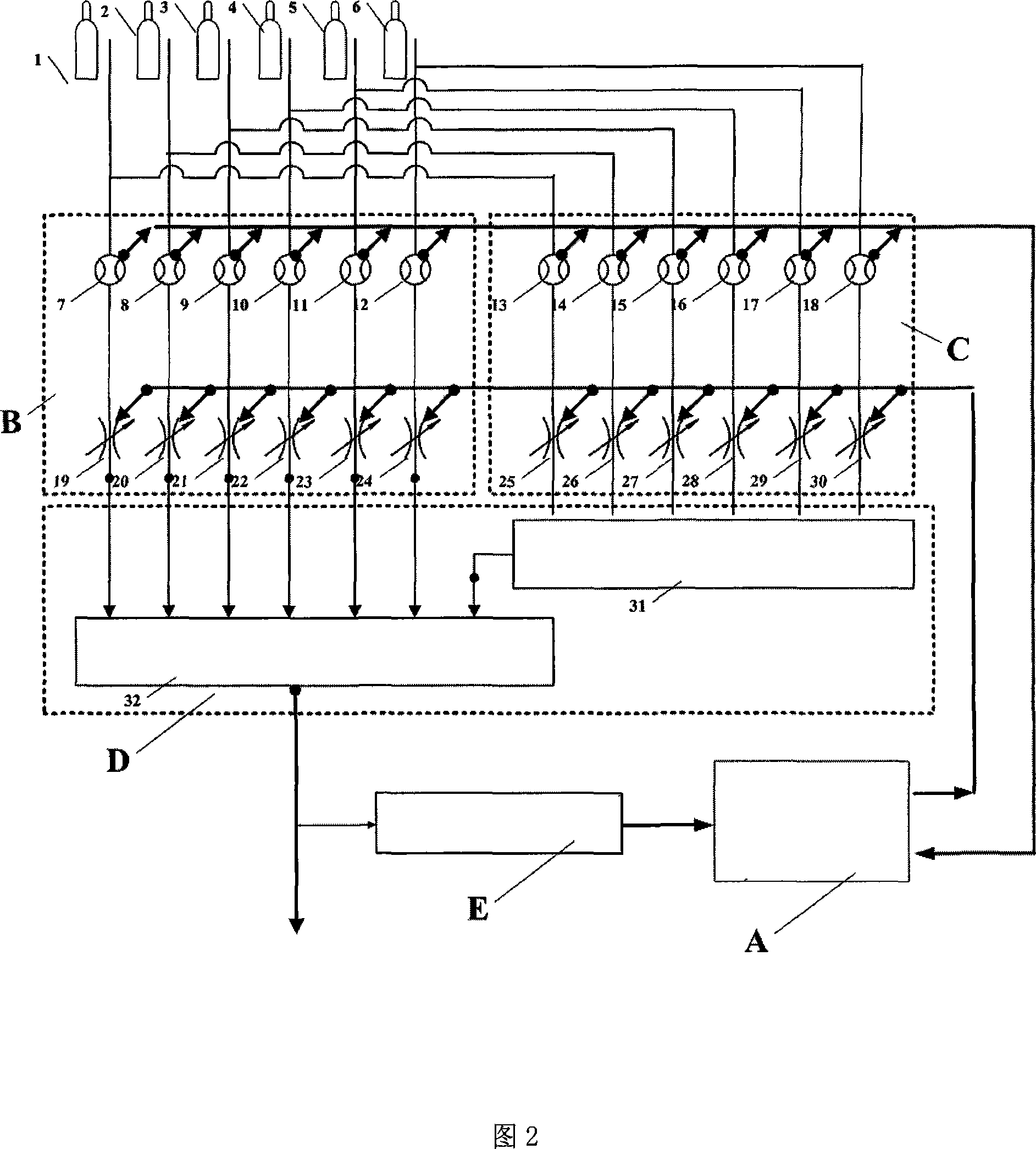

Multi-channel mixed gas formulating system

InactiveCN101138709AHigh degree of automationImprove gas distribution accuracyFlow mixersMixer accessoriesLoop controlClosed loop

The present invention is a multi-way mixed gas preparation system. The system is formed in the way that an input end of an upper computer is connected with a multi-way and large-flow measuring controller group and multi-way and small-flow measuring controller group respectively to control a gas flow; gas output ends of the multi-way and large-flow measuring controller group and the multi-way and small-flow measuring controller group are connected with a gas mixing chamber to mix gases; an input end of a gas analyzer is connected with an output end of the gas mixing chamber; an output end of the gas analyzer is connected with an input end of the upper computer to acquire a concentration signal. The present invention can both control a total flow of the mixed gas and reach the target component concentration requirement. Moreover, the present invention can realized the mixed preparation of multi-way and large-flow gases under a high-resolution closed-loop control condition. During a preparation course, the gas source is stable, the repeatability is good, the system automation is high, the operation is simple and convenient and the gas preparation precision is quite high.

Owner:TIANJIN INTERNAL COMBUSTION ENGINE RES INST

Safety production power generation technology by unstable gas source

InactiveCN102155255ATake advantage ofStable gas sourceInternal combustion piston enginesGaseous engine fuelsProcess engineeringEngineering

The invention discloses a safety production power generation technology by an unstable gas source. A mode of combing underground gas extraction by sources and the front gas inlet of a mine generator set with gas ignition by a small quantity of diesel oil via the generator set is adopted, and the gas with an unstable concentration can be used for ensuring that the generator set can normally operate. A gas source pipeline is improved, the underground air source is divided into a main gas source (main pipeline) and an assistant gas source, thus the gas source is stable. Along with the continuousexploitation of the mine, the concentration of the extracted gas is continuously lowered. When the concentration is 5-9%, the diesel oil ignition technology is adopted, and the low-concentration gas can be fully utilized.

Owner:山东新矿赵官能源有限责任公司

Method for generating electricity through extracting extremely low concentration gas from biogas development coal mine

InactiveCN109652150AEfficient developmentStable gas sourceGaseous fuelsEnergy inputElectricityEconomic benefits

The invention relates to a method for generating electricity through extracting extremely low concentration gas from a biogas development coal mine, belongs to the fields of energy development and pollutant emission reduction, and concretely relates to a method for generating electricity through collecting organic wastes surrounding the coal mine, producing biogas from the organic wastes and extracting the extremely low concentration gas (having a CH4 content of 5% or below) The environmental problem caused by direct emission of the extremely low concentration gas due to no effective utilization is mainly solved; and the generated electricity can be used in the coal mine factory, and generated heat can be used for the warming and long-term heating of a biogas fermentation tank, so the economic benefits of biogas development are increased. The method solves the problems of low utilization rate of the extremely low concentration gas, environmental pollution and poor safety of the miningarea, and a system for generating electricity through extracting extremely low concentration gas from the biogas development coal mine has the advantages of simplicity in operation and maintenance, high reliability, obvious energy generation benefit and strong innovation.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

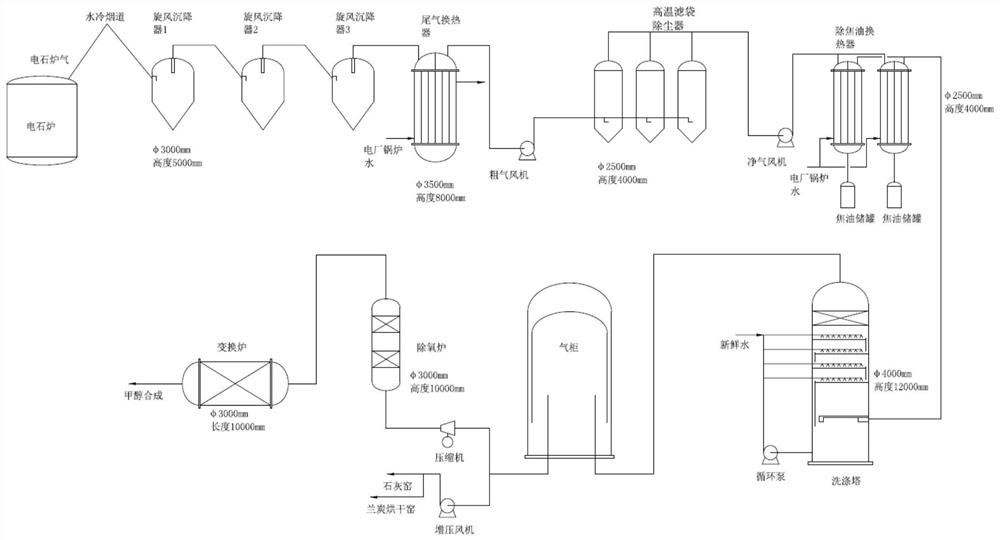

Calcium carbide furnace tail gas comprehensive utilization system and process

InactiveCN112705000ASolve the purificationSolve processingCombination devicesHydrogenProcess engineeringGas holder

The invention relates to a comprehensive utilization system and process for tail gas of calcium carbide furnace gas. The system comprises a water cooling flue, a cyclone settler, a tail gas heat exchanger, a high-temperature filter bag dust collector, a tar removal heat exchanger, a washing tower and a gas holder. According to the invention, a dry-process and wet-process purification treatment technology is adopted, tail gas generated by a plurality of calcium carbide furnaces can be treated at the same time, and the problem that follow-up furnace gas user production is unstable due to large fluctuation of gas quantity and components of a single calcium carbide furnace in a large-scale calcium carbide factory is solved. The purified and washed calcium carbide furnace tail can be used for calcining limestone and producing methanol, meanwhile, boiler water of a power plant is utilized for heat recovery, circulating water is replaced, energy is saved, meanwhile, emission of calcium carbide furnace gas is correspondingly reduced, and the calcium carbide furnace tail gas comprehensive utilization systemis environmentally friendly.

Owner:恒力石化(大连)炼化有限公司

Air pressure switch, pressure maintaining device and high-altitude balloon restraining and releasing device

ActiveCN111824385ARealize switch controlControl cut off actionBalloon aircraftsHigh-altitude balloonAir pump

The invention relates to the technical field of aerostats, and discloses an air pressure switch, a pressure maintaining device and a high-altitude balloon restraining and releasing device. The air pressure switch comprises a strain surface and a strain detection component. The strain surface is formed on a wall surface of a sealed container and is used for generating deformation in a preset direction when air pressures inside and outside the sealed container are different; and a detection end of the strain detection component corresponds to the strain surface and is used for outputting a trigger signal when a dependent variable of the strain surface reaches a preset value. The air pressure switch disclosed in the invention is simple in structure and low in cost; weather resistance is good;in a floating environment of a high-altitude balloon, a restraining device of the high-altitude balloon is controlled to be reliably released at a preset height; meanwhile, stable air pressure in thepressure maintaining device can be controlled to be maintained so that a stable air source is provided for related load equipment, and a problem that reliable control over a working state of a cutterand the working state of an air pump in the high-altitude balloon floating environment is generally difficult to implement through an existing control means is solved.

Owner:AEROSPACE INFORMATION RES INST CAS

Device and method for comprehensively utilizing heat produced by decomposition of phosphorous gypsum in circulating fluid bed

InactiveCN101880032ASave energyEasy to buildSulfur compoundsEnergy inputThermal energyHigh concentration

The invention discloses a device and a method for comprehensively utilizing heat produced by decomposition of phosphorous gypsum in a circulating fluid bed, namely, a novel fluidizing air supply device of an integrated device for utilizing the waste heat of a phosphorous gypsum decomposition circulating fluid bed and a method for reducing energy consumption and enhancing CaSO4 decomposition rate and SO2 concentration in the process of coproducing cement clinker and sulfuric acid by decomposing the phosphorous gypsum through the circulating fluid bed. A fluidizing air source consisting of air serving as a primary component and main circulating flue gas serving as a secondary component is adopted, a material is fed into a main furnace of the circulating fluid bed under the action of the gas force of circularly flowing flue gas and corresponding reformation is performed on an exhaust pipeline so as to fulfill the aim of exhausting and circulating the flue gas. A reaction atmosphere in the fluid bed can be controlled effectively and the phosphorous gypsum is decomposed under the condition of reduction-oxidation atmosphere, so that the decomposition efficiency of the phosphorous gypsum is improved. The comprehensive utilization of circulating flue gas having waste heat reduces energy loss in an air heating and material delivering process and further saves energy sources. Simultaneously, the circulating flue gas weakens the diluting effect of the fluidizing air on SO2 instead of a part of air, so that the aim of obtaining high-concentration SO2 is fulfilled.

Owner:KUNMING UNIV OF SCI & TECH

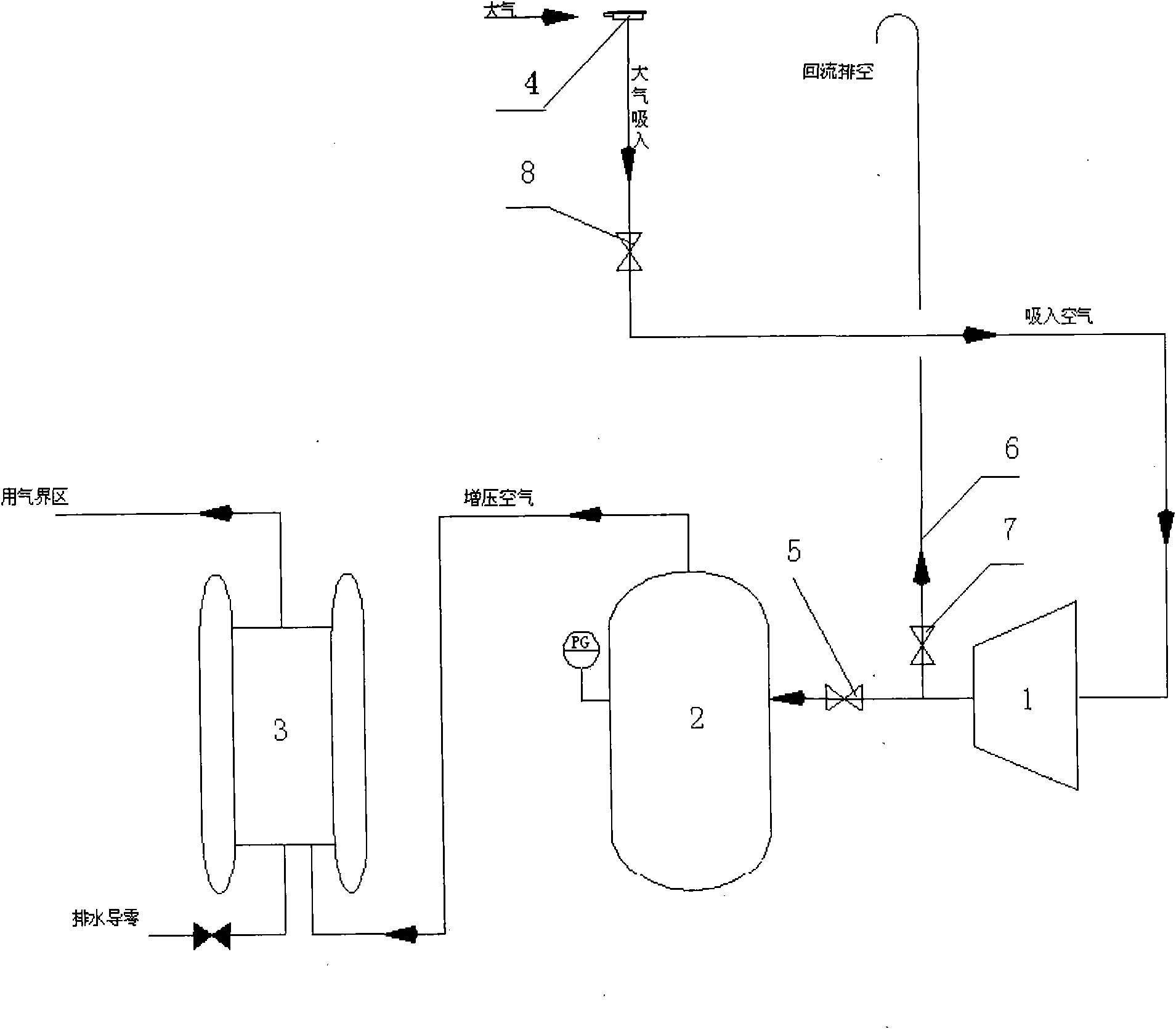

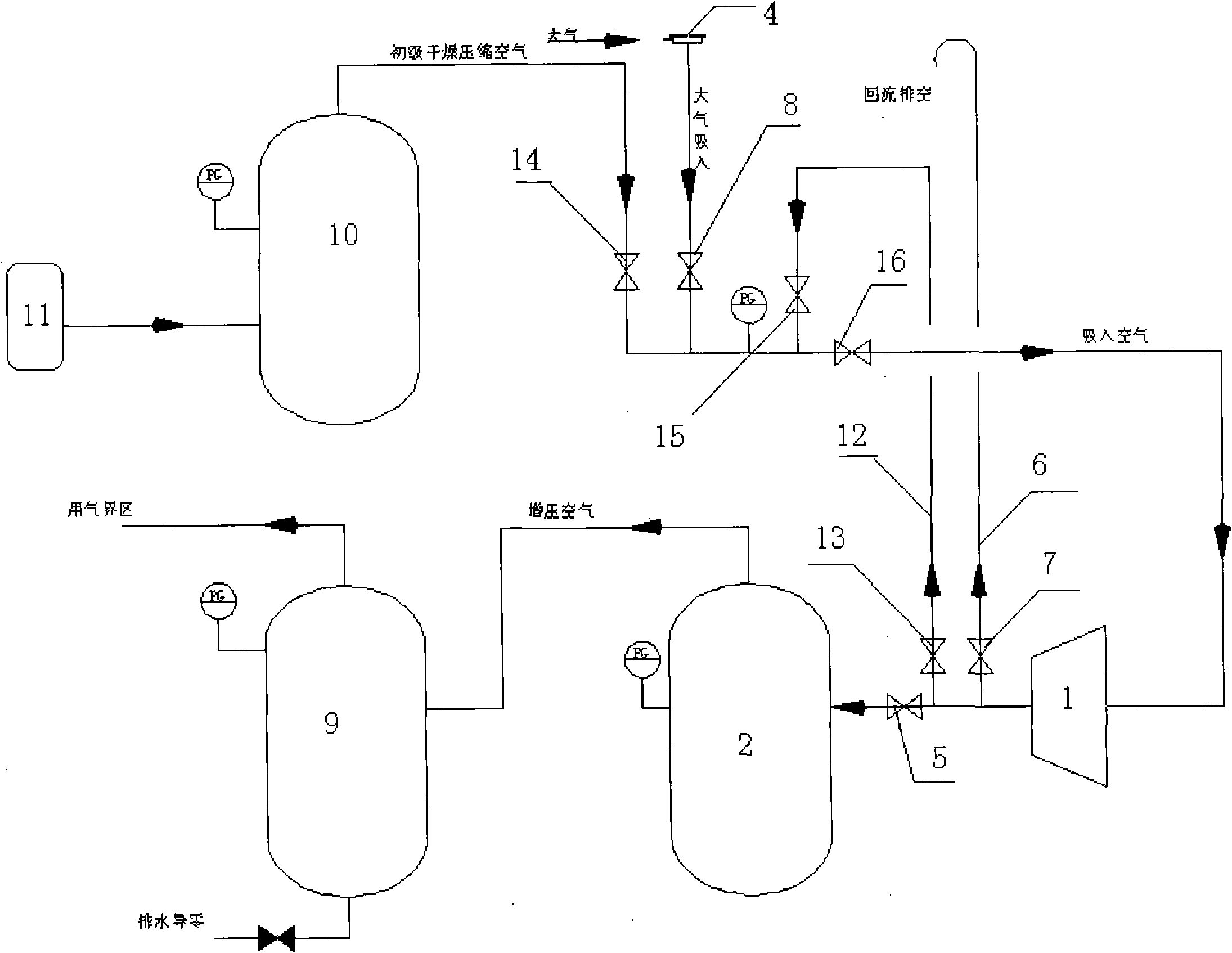

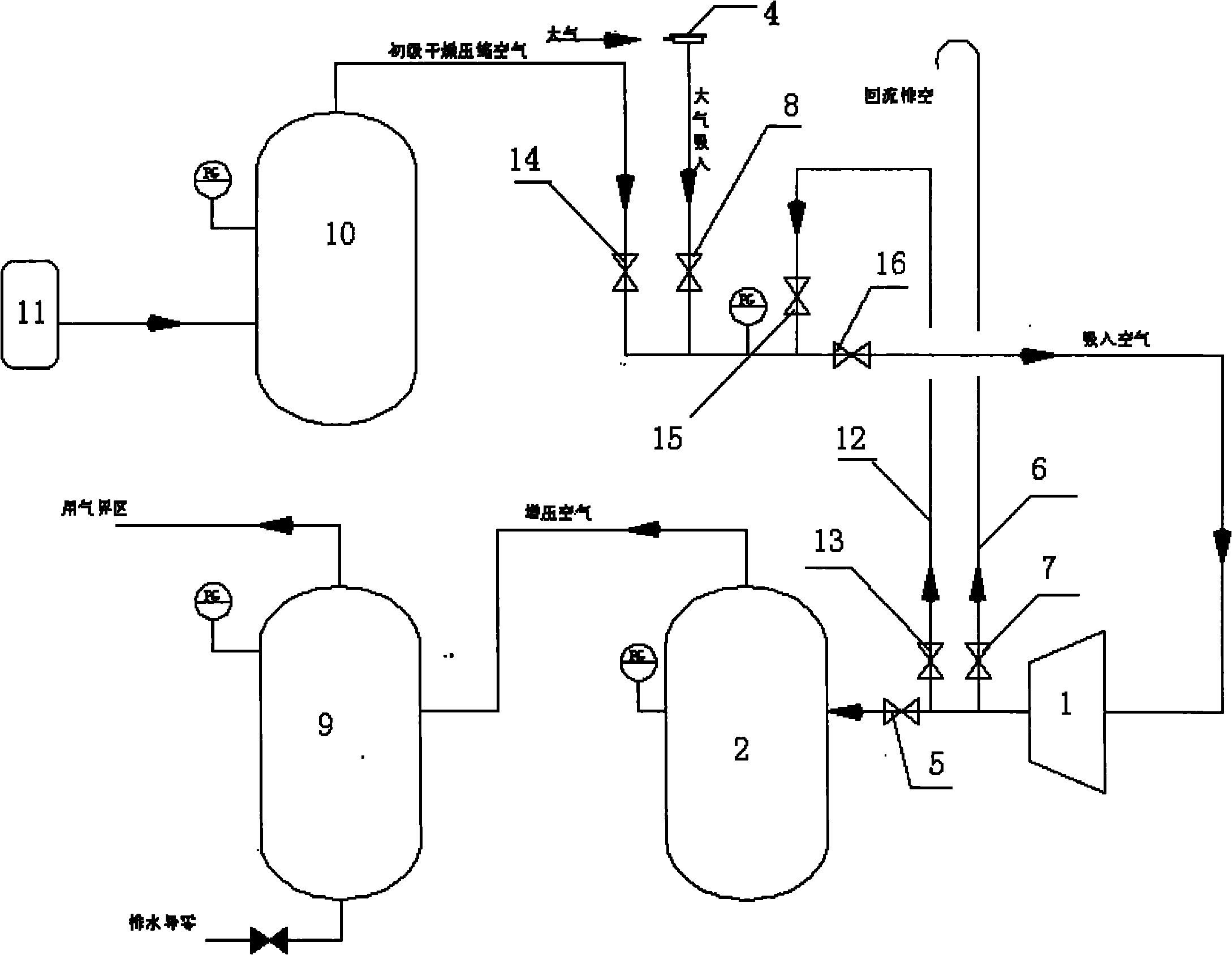

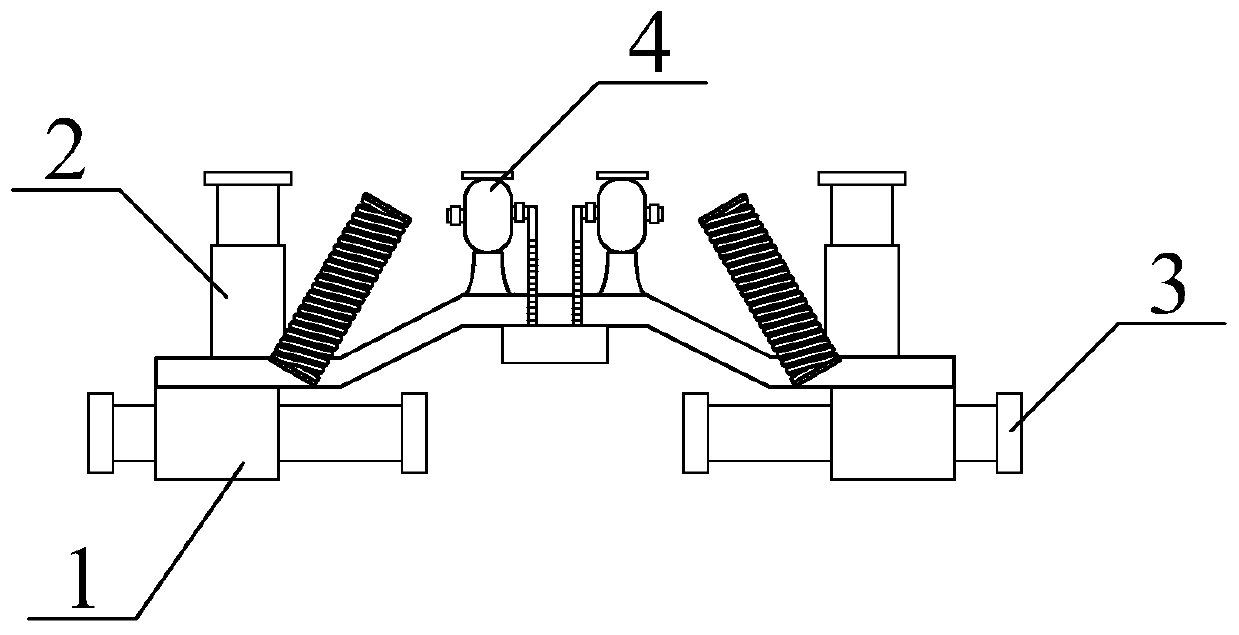

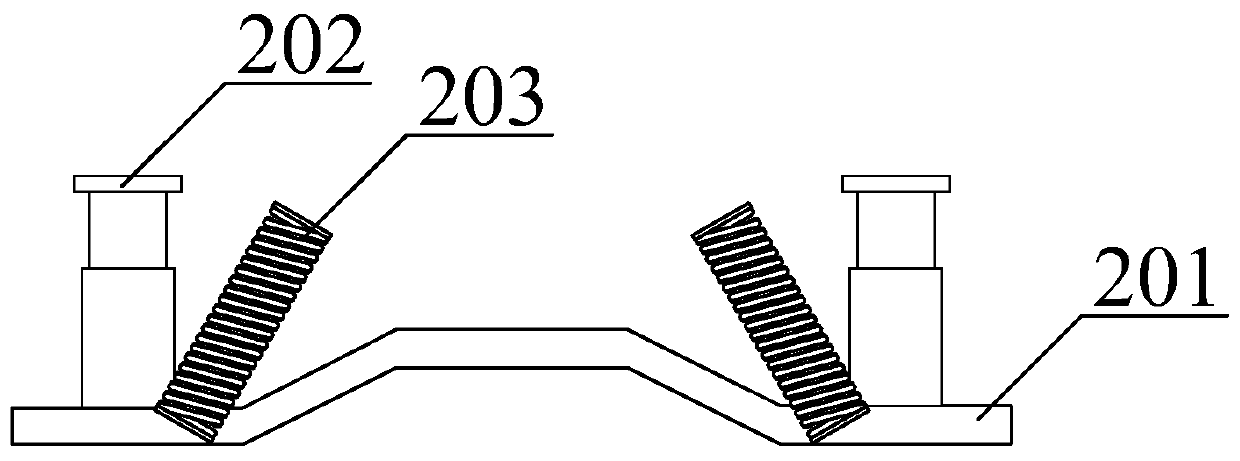

Pre-drying pressurizing suction device of normal-pressure suction air compressor and method thereof

InactiveCN101865121ASmall fluctuationReduce corrosionPositive displacement pump componentsPositive-displacement liquid enginesAtmospheric airAir filter

The invention relates to a pre-drying pressurizing suction device of a normal-pressure suction air compressor, comprising an air compressor, a constant-pressure air slot, a drier, an air filter and a first return pipe. Air enters the air filter and enters the air compressor through a pipeline, the air compressor is connected with the constant-pressure air slot through a pipeline, the constant-pressure air slot is connected with the drier through a pipeline, the output end of the air compressor is connected with the first return pipe, and the first return pipe is directly communicated with the air. The pre-drying pressurizing suction device also comprises a primary drying buffer slot, and primarily dried and compressed air output from the primary drying buffer slot enters the input end of the air compressor through a pipeline. In the invention, since the primary drying buffer slot can provide stable primarily dried and compressed air, the fluctuation of the air source of the air compressor is reduced, and the air source of an air compressed pot can be stabilized. In addition, the air compressed pot provides dried and purified primarily compressed air, thereby reducing the corrosion to the air compressor by the corrosive gas and greatly prolonging the overhaul period and the drainage time intervals.

Owner:蓝星化工有限责任公司

Novel automotive suspension device

InactiveCN111409407AImprove stabilityImprove comfortResilient suspensionsVehicle springsLow speedBuffer tank

The invention discloses a novel automotive suspension device. The device comprises a fixing sleeve, a damping assembly, a wheel connecting rod and an adjusting buffer assembly, through the adjusting buffer assembly, when an automobile runs at a high speed, an automobile control system controls an air compressor and a first electromagnetic valve to be powered on and operate, compressed gas is conveyed into a buffer tank, the buffer tank is hardened, when the air pressure detected by an air pressure detector of the buffer tank reaches an upper limit value, the automobile control system controlsan air compressor and a first electromagnetic valve to stop running, stability of automobile driving is improved, when an automobile runs on an uneven road surface at a low speed, the automobile control system controls a second electromagnetic valve to be electrified to operate, when the air pressure detected by the air pressure detector of the buffer tank reaches a lower limit value, the automobile control system controls the second electromagnetic valve to stop running, so the buffer tank is softened, the automobile running comfort is improved, and the novel automobile suspension device is simple in structure, convenient and fast to operate and convenient to popularize and apply in the market.

Owner:徐国华

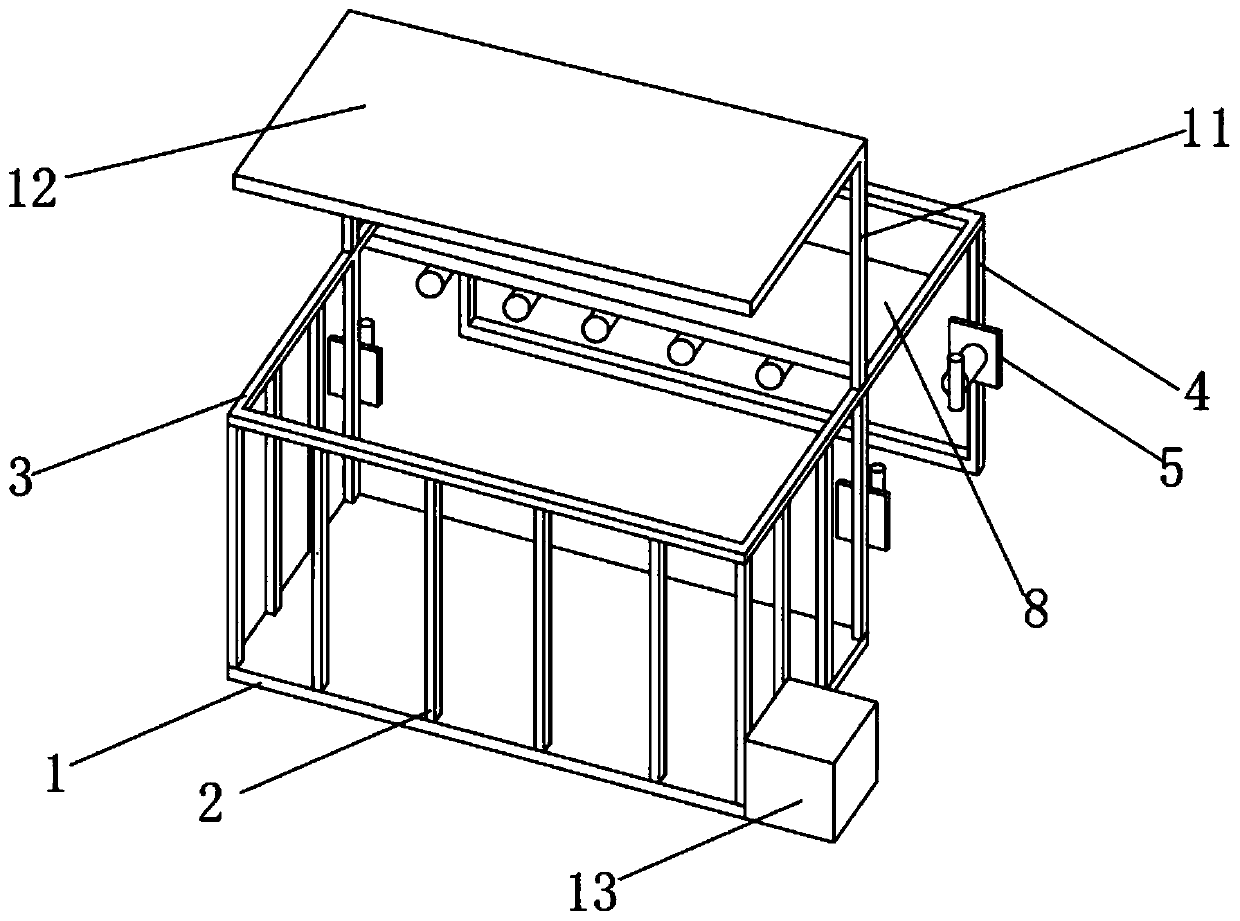

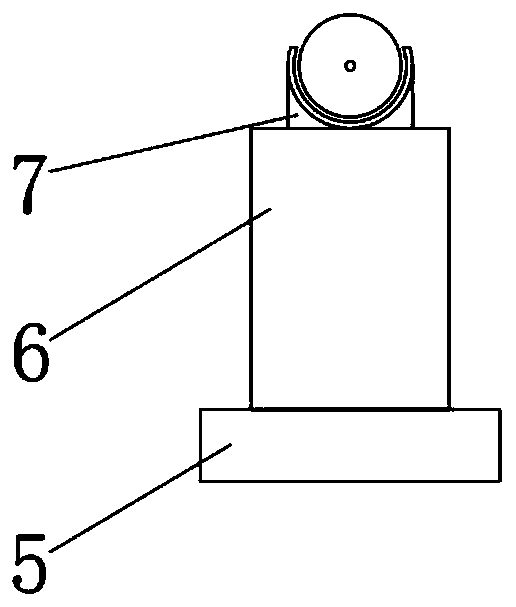

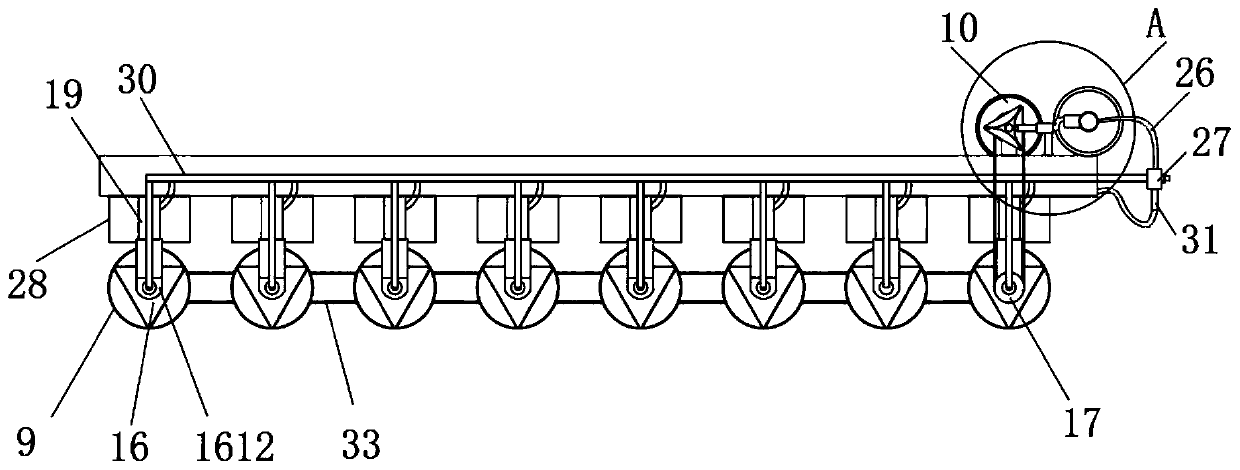

Rapid and stable bridge construction platform

InactiveCN111593668AEasy to move aroundImprove work efficiencyBridge erection/assemblyBuilding support scaffoldsArchitectural engineeringStructural engineering

The invention discloses a rapid and stable bridge construction platform. The rapid and stable bridge construction platform comprises a first connecting frame and a second connecting frame which are vertically arranged, a horizontally-arranged baffle is fixedly installed on the upper portion between the first connecting frame and the second connecting frame, a rolling mechanism is arranged below the baffle, the rolling mechanism consists of a plurality of groups of rotating rollers which are horizontally and uniformly distributed, the rotating roller is of a regular triangular prism structure,the corner of the regular triangular prism structure is of a chamfer structure, and a plurality of sets of sliding through holes and air outlet holes are formed in the plane of the chamfer structure.A user can conveniently move the device, the working efficiency of the user is improved, and the device can be conveniently moved and rapidly and stably placed.

Owner:王从飞

Material for manufacturing building decorative panel

The invention relates to the field of construction material, in particular to a material for manufacturing of a building decorative panel. The invention has the components and the weight proportion of 100 portions of phenolic resin, 2-10 portions of active agent, 2-10 portions of foaming agent and 3-10 portions of initiator. The invention (Phenolic Foam Plastic Plate) reduces building load and is convenient for installation construction, so as to have good thermal insulation and energy saving effect due to smaller thermal conductivity (0.030 W / m. k), more particularly, the invention can not release thick smoke during firing, which reduces air pollution, minimizes the toxic and harmful gas, and protects life and property safety of people.

Owner:CHANGZHOU WANGYUEXIN MATERIAL TECH

Waste heat recycling chamber for recycling waste heat of fused magnesium melting lump

PendingCN109443021AImprove waste heat recovery efficiencyEvenly heatedIncreasing energy efficiencyWaste heat treatmentSmall footprintCooling channel

The invention relates to a waste heat recycling chamber for recycling waste heat of fused magnesium melting lump. The waste heat recycling chamber comprises an annular waste heat recycling chamber anda heat storage container, wherein the annular waste heat recycling chamber is a closed annular space defined by a top water cooling wall, an inner annular water cooling wall and an outer annular water cooling wall jointly; the annular space is a moving cooling channel of the fused magnesium melting lump; a waste heat recycling chamber inlet and a waste heat recycling chamber outlet are formed inthe side face of the annular space, are adjacent to each other and are sealed through an inlet door and an outlet door separately; and the heat storage container is arranged above the annular waste heat recycling chamber and is connected with all water cooling walls of the annular waste heat recycling chamber through an ascending pipe and a descending pipe. Compared with a traditional tunnel typewaste heat recycling device, the waste heat recycling chamber has the advantages of being high in waste heat recycling efficiency, heating uniform in all heated surfaces, stable in thermal energy output, small in occupied area and energy-saving and environment-friendly.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

A multi-stage inflation device used in underground coal mines

InactiveCN103256478BVehicle mileage is no longer limitedImprove compression efficiencyContainer filling under pressureProcess engineeringBottle

The invention discloses a multi-stage inflation device used in a coal mine. The multi-stage inflation device comprises a pneumatic vehicle and an inflation device, wherein a gas multi-stage inflation device is used as the inflation device; a gas source gas inlet of the inflation device is divided into four parts through a four-way joint; one part is communicated with gas source gas inlets of a first pneumatic pressurization pump and a second pneumatic pressurization pump through a three-way joint I; the other parts are respectively communicated with driving gas inlets of the first pneumatic pressurization pump and the second pneumatic pressurization pump; gas outlets of the first pneumatic pressurization pump and the second pneumatic pressurization pump are gathered to form a gas path through a three-way joint III and then are sequentially communicated with a buffering tank, a gas bottle pressure gauge I, a pipeline switch IV and a gas source gas inlet of a third pneumatic pressurization pump; and a gas outlet of the third pneumatic pressurization pump is communicated with a gas outlet through an outlet pressure gauge II. The multi-stage inflation device performs inflation by using a gas source in an alley and is simple in structure, high in working efficiency, large in compression ratio and convenient and quick in inflation.

Owner:TAIYUAN UNIV OF TECH

Method for preheating canalization molten-salt section during producing alumina

ActiveCN101717103BStable gas sourceGuaranteed heating needsAluminium oxides/hydroxidesEvaporationMolten salt

Owner:中铝矿业有限公司 +1

Xylylene diisocyanate rectification device and rectification method thereof

ActiveCN103990291BEasy to recycleEasy to useChemical industryIsocyanic acid derivatives purification/separationXylyleneOrganic solvent

The invention provides a xylylene diisocyanate rectification apparatus and a rectification method thereof. The apparatus comprises an organic solvent heater, a crude product reboiler, a rectifying tower, a first order condenser, a finished product pot, a crude solvent reception pot, a high vacuum set and a tail gas processing system, and the above components are connected according to a specific order to form a closed loop. The rectification apparatus has the advantages of scientific design, reasonable structure, energy saving, low production cost and reliable production quality. The method utilizes an organic solvent, provides a stable gas source for rectification, reduces the pressure drop of xylylene diisocyanate in the rectifying tower, and improves the separation efficiency and the product purity; and the organic solvent can be easily separated from xylylene diisocyanate, and does not form a new impurity. The method has the advantages of scientific design, simple operation, good rectification effect and high product quality.

Owner:开封华瑞化工新材料股份有限公司

Novel artificial intelligence environment-friendly air compressor system

InactiveCN114856963ALower air intake air temperatureLower the temperaturePump testingPositive displacement pump componentsProcess engineeringAir compressor

The invention discloses a novel artificial intelligence environment-friendly air compressor system which comprises an air compressor, an air inlet pipeline is arranged on one side of the air compressor, an air outlet pipeline is arranged on the other side of the air compressor, an air inlet is formed in the end of the air inlet pipeline and extends to the outside, and a filtering device is arranged on the air inlet and movably connected to the air inlet. The refrigeration dryer is additionally arranged on the air inlet pipeline of the air compressor, so that the air temperature of the air inlet of the air compressor is reduced and is slightly lower than or equal to the temperature of the external use environment, and the refrigeration dryer is utilized for simple cooling, so that water is prevented from being generated.

Owner:张建武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com