Fireflooding and flue gas reinjection gravity driving collaborative exploitation method for high-inclination-angle thick oil reservoir

A technology for heavy oil reservoirs and production methods, which is applied in the fields of production fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of unsatisfactory development effect, increased air injection speed, uneven live line advancement, etc. Reservoir recovery, increasing production area, and avoiding the effects of uneven advancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

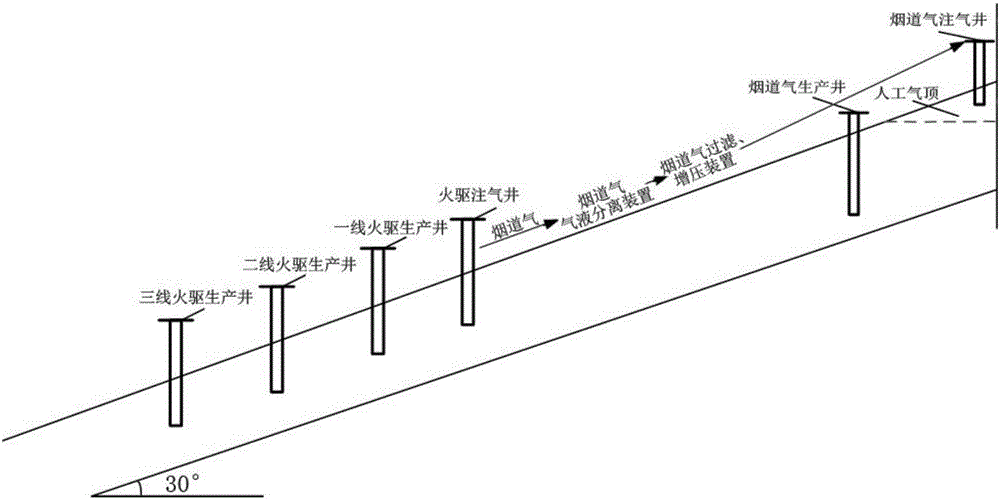

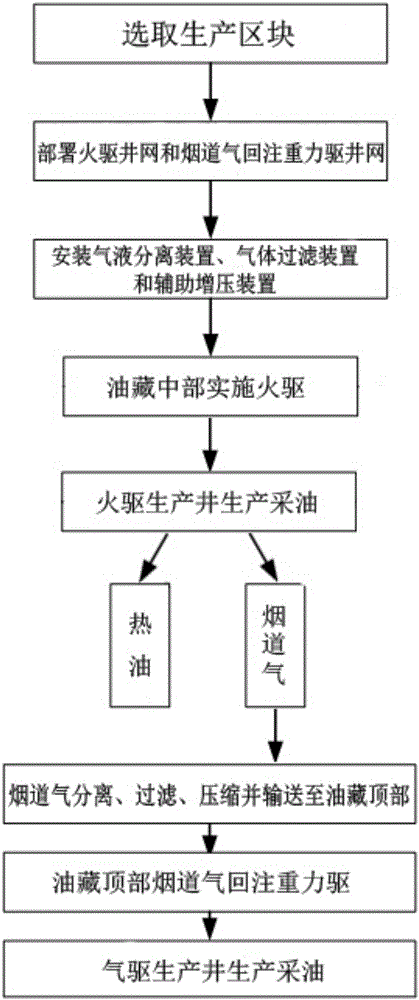

[0052] This embodiment provides a method for synergistic production of fire flooding and flue gas recovery gravity flooding in heavy oil reservoirs with high dip angles. The flow chart is as follows figure 1 As shown, it includes the following steps:

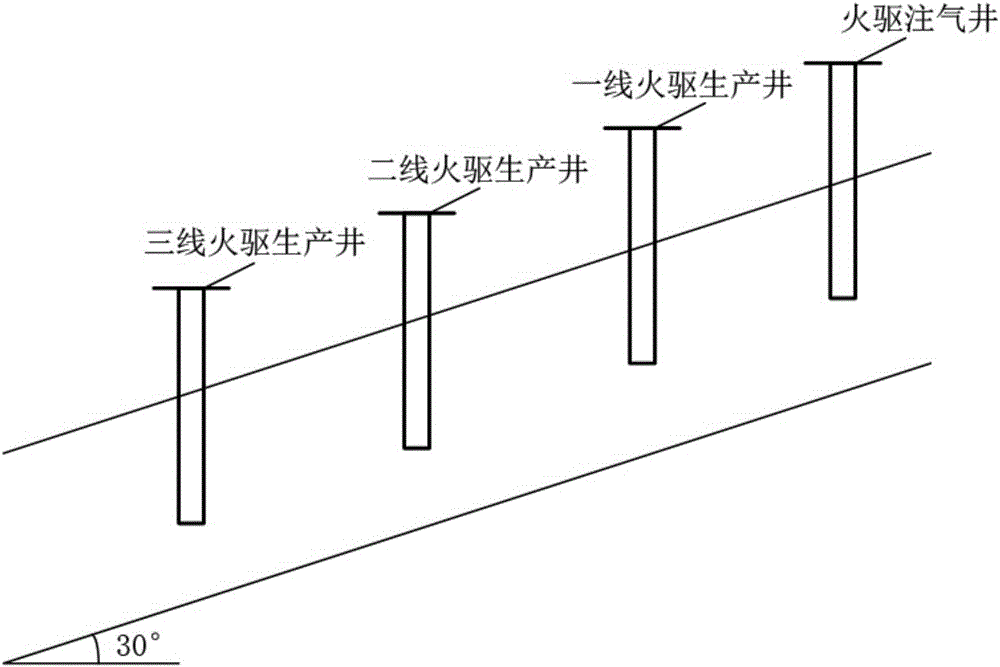

[0053] (1) Select the production block. The reservoir conditions of the production block are: the dip angle of the oil layer is 30°, the thickness of the oil layer is 15m, and the permeability of the oil layer is 580×10 -3 μm 2 , the viscosity of crude oil under reservoir conditions is 250mPa·s-300mPa·s, and the initial oil saturation is 70%.

[0054] (2) Deploy a fire-flooding linear flooding well pattern in the middle of the oil reservoir in the production block. The fire-flooding linear flooding well pattern includes a row of fire-flooding gas injection wells and a row of fire-flooding production wells (the first-line fire-flooding production wells) ; The number of wells in each row is 5. Such as figure 2 As shown, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com