Invisible multistage methane tank capable of producing methane evenly

A biogas digester and balanced technology, applied in gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problems of short service life of biogas digesters, inconvenient use and maintenance, unstable gas supply, etc., to achieve stable gas production and use The effect of simple maintenance and continuous air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

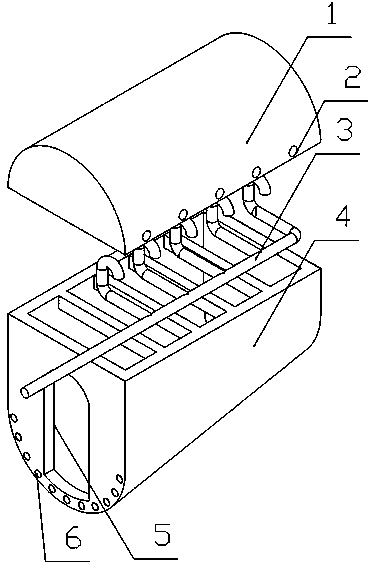

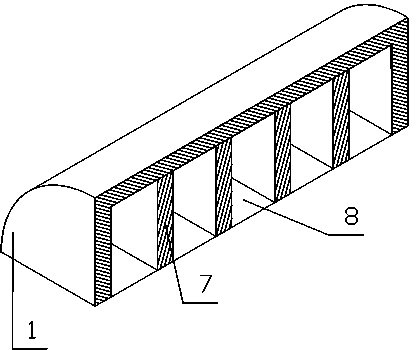

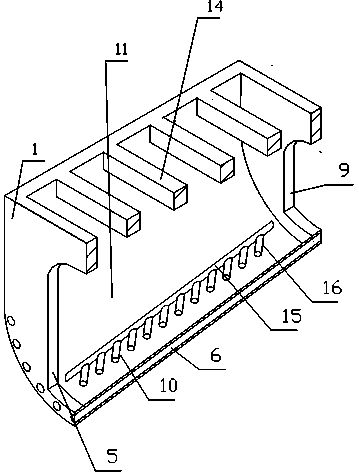

[0042] Embodiment: a kind of invisible multi-stage balanced gas production biogas digester, see Figure 1 to Figure 9 , comprising a pool body, an arched pool top 1 and a gas collecting pipe 3, a certain number of partitions 7 dividing the pool top 1 into at least two independent gas collection chambers 8 are arranged in the arched pool top 1; The gas collection pipe 3 includes a trunk pipe located outside the biogas tank, branch pipes corresponding to the number of the gas collection chamber 8, and a check valve is installed on the gas delivery pipe of each gas chamber toward the lower section, and one end of the branch pipe is connected to the main pipe. A cut-off valve is provided at the connection, and the other end penetrates into the pool body and leads to the corresponding air collection chamber 8 through the underside of the vaulted pool roof. During the operation of the biogas digester, the biogas generated is collected by the branch pipe, and then collected to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com