Oxygen and nitrogen mixing type high-precision proportioning device and method

A high-precision, oxygen-nitrogen technology, applied in the direction of material thermal development, to achieve the effects of stable gas source, simple process and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

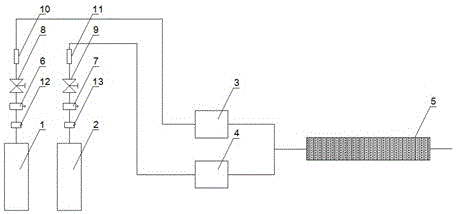

[0031] The oxygen and nitrogen mixing high-precision proportioning device includes an oxygen cylinder 1, a nitrogen cylinder 2, an oxygen mass flow controller 3, a nitrogen mass flow controller 4 and a proportioning bin 5; in the working state, the oxygen cylinder 1 outputs Oxygen, after the flow is adjusted by the oxygen mass flow controller 3, the oxygen is delivered to the proportioning chamber 5, and at the same time, the nitrogen cylinder 2 outputs nitrogen, and after the flow is adjusted by the nitrogen mass flow controller 4, the nitrogen Transported into the proportioning chamber 5, oxygen and nitrogen are output after being mixed and proportioned by the proportioning chamber 5.

[0032] An oxygen stabilizing valve 6, an oxygen stabilizing valve 8 and an oxygen gas resistance 10 are also equipped between the oxygen cylinder 1 and the oxygen mass flow controller 3, and the nitrogen cylinder 2 and the nitrogen mass flow controller 4 A nitrogen pressure stabilizing valve ...

Embodiment 2

[0042] The difference from Embodiment 1 is:

[0043] The cylindrical mesh has a length of 235 mm, a diameter of 30 mm, and a mesh diameter of 0.1 mm.

Embodiment 3

[0045] The difference from Embodiment 1 is:

[0046] The oxygen cylinder 1 and the nitrogen cylinder 2 are high-pressure gas cylinders, an oxygen pressure reducing valve 12 is also equipped between the oxygen cylinder 1 and the oxygen mass flow controller 3, and the nitrogen cylinder 2 and the nitrogen mass flow controller 3 A nitrogen pressure reducing valve 13 is also installed between the flow controllers 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com