Self-adhesive protective film for LCD optical polarizer and production method of self-adhesive protective film

A technology of self-adhesive protective film and production method, applied in the field of packaging, can solve the problems of poor peeling force, low temperature and humidity resistance, low light transmittance, etc., and achieves high fit, good weather resistance, and light transmittance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

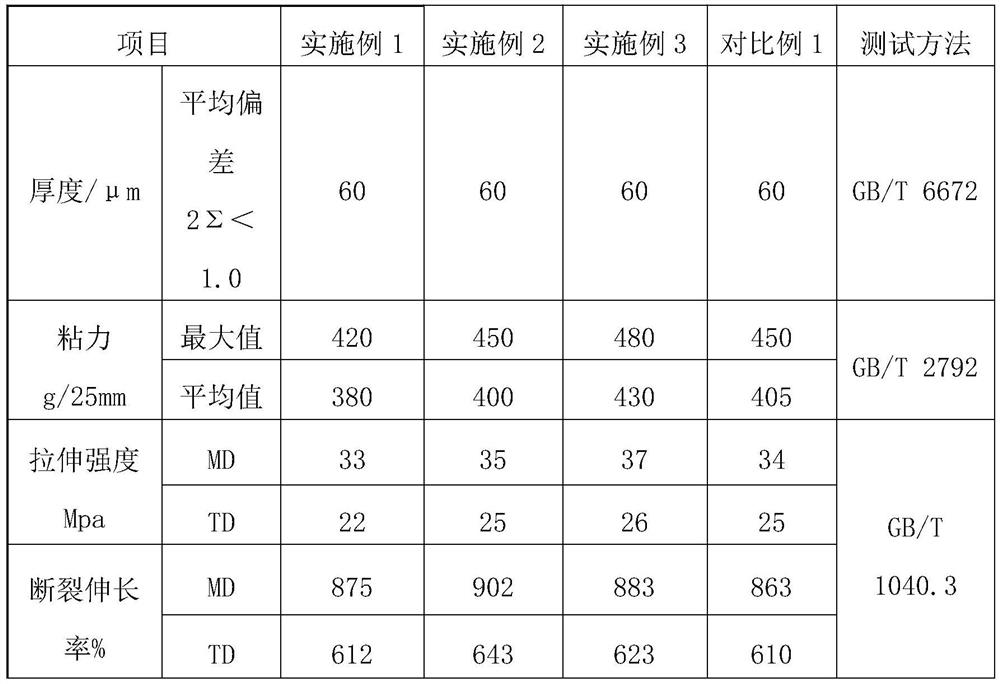

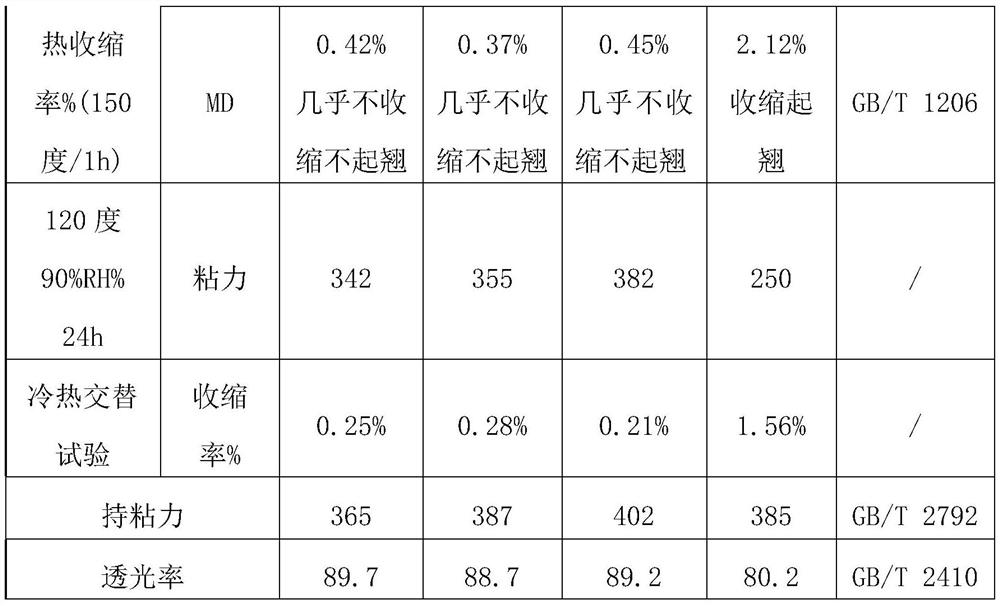

Examples

Embodiment 1

[0035] S1, weigh 130 parts by mass of polyethylene and 70 parts by mass of the polyolefin, the intermediate layer 250 parts of copolymerized polyethylene, and 50 parts by mass of polyethylene, and 370 parts by mass of the anti-adhesive layer copolymerized polypropylene. 28 parts by mass of low-density polypropylene and 2 parts by mass of the open agent, then put the particles used by the self-adhesive layer 1, the intermediate layer 2, and the release layer 3 into a multi-layered co-extension. Transmit to the extruder hopper via the vacuum suctioner, the weight system is proposed, and the feed screw is automatically filled with the feed screw, and then plasticized into a melt;

[0036] S2, the melt sequentially passes through the extrusion screw of the casting machine, the high-efficiency filter, the distributor of the castor, and the die of the casting machine, the casting roller, and the cooling roller of the casting machine to form a film;

[0037] S3, the film is traged by the...

Embodiment 2

[0039]S1, weighing 135 parts by mass of polyethylene and 65 parts by mass of polyolefin, 245 parts by mass of polypropylene, and 55 parts by mass of polyethylene, 365 parts by mass of block copolymer polypropylene , 30 parts by mass of low-density polypropylene and 5 parts by mass of the an open agent, then put the self-adhesive layer 1, the intermediate layer 2 and the obtained particles used in the release layer 3 into the multi-layer co-extrusion fluoride phase corresponding to the suction bucket Inside, via the vacuum suctioner is delivered to the extruder hopper, and the weight system is called, and the feed screw is automatically filled with the feed screw, and then plasticized into a melt;

[0040] S2, the melt sequentially passes through the extrusion screw of the casting machine, the high-efficiency filter, the distributor of the castor, and the die of the casting machine, the casting roller, and the cooling roller of the casting machine to form a film;

[0041] S3, the f...

Embodiment 3

[0043] S1, weigh 140 parts by mass of polyethylene and 60 parts by mass of polyolefin, intermediate layer 255 parts by mass of copolypropylene and 45 parts by parts of polyethylene, and a 380 parts by mass of the anti-adhesive layer 380 parts by mass. Copolymer polypropylene 18 parts by mass of low-density polypropylene and 2 parts by mass of an open agent, then the particles used from the self-adhesive layer 1, the intermediate layer 2, and the release layer 3 are inserted into a multi-layer co-extrusion fluid. Inside, via the vacuum suctioner is delivered to the extruder hopper, and the weight system is called, and the feed screw is automatically filled with the feed screw, and then plasticized into a melt;

[0044] S2, the melt sequentially passes through the extrusion screw of the casting machine, the high-efficiency filter, the distributor of the castor, and the die of the casting machine, the casting roller, and the cooling roller of the casting machine to form a film;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com