Pre-drying pressurizing suction device of normal-pressure suction air compressor and method thereof

A technology for inhaling air and inhaling devices, which is applied in the direction of mechanical equipment, machines/engines, liquid displacement machinery, etc. It can solve the problems of unable to control the pipeline pressure and increase the starting load of the air compressor, so as to prolong the maintenance period and reduce the supply Air load, the effect of reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

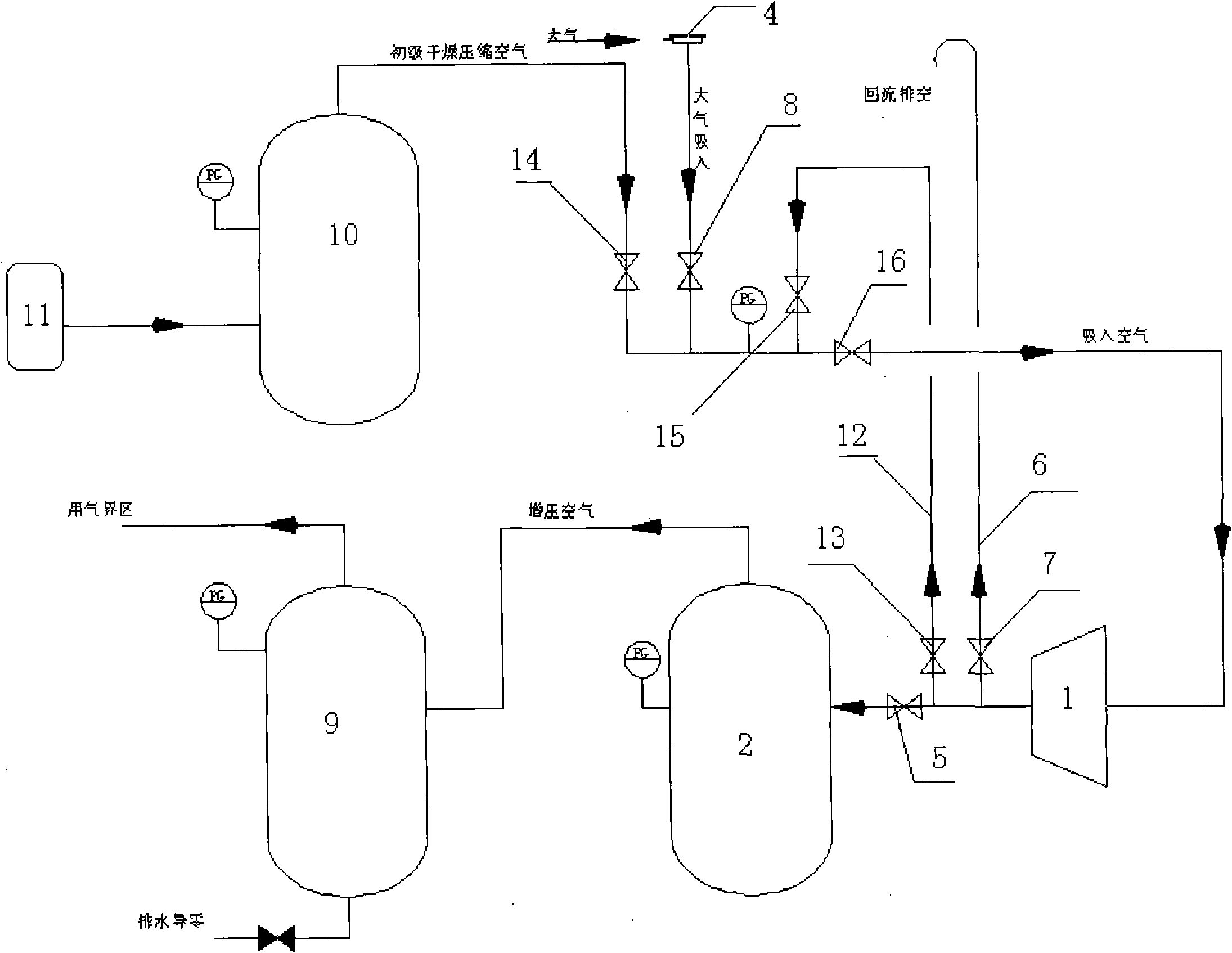

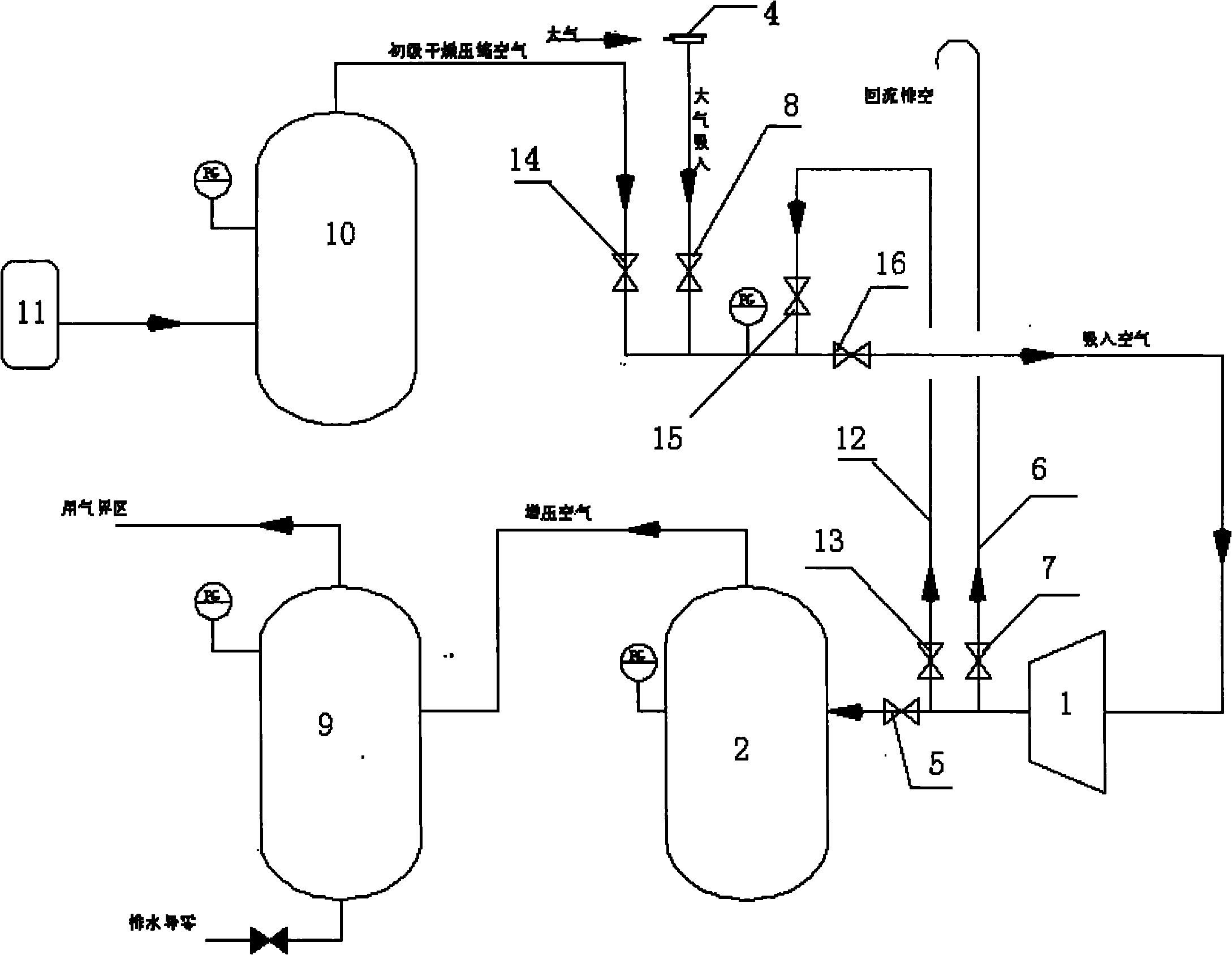

[0031] Combine below figure 2 , the present invention is further described:

[0032] A normal pressure suction air compressor pre-drying pressurized suction device, mainly including an air compressor 1, a stabilized air tank 2, an air filter 4 and a first return pipe 6; after the atmosphere enters the air filter 4, it passes through the pipeline Entering the air compressor 1, the air compressor 1 is connected to the stabilized air tank 2 through a pipeline, and the output end of the air compressor 1 is connected to the first return pipe 6, and the first return pipe 6 is connected to the It is directly connected to the atmosphere, and also includes a primary dry buffer tank 10, and the primary dry compressed air output from the primary dry buffer tank 10 enters the input end of the air compressor 1 through a pipeline. The input end of the primary drying buffer tank 10 is connected with an air tank 11 . The primary drying buffer tank 10 can provide stable primary dry compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com