High-efficiency copper-iron automatic flame brazing machine and brazing method thereof

A technology of flame brazing and welding methods, which is applied in the direction of welding equipment, tin feeding devices, auxiliary devices, etc., can solve the problems of high welding cost and expensive silver-based solder, and achieve the reduction of brazing cost and accurate and reliable flame temperature. control and reduce dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the content of the present invention more clearly, further description will be made below in conjunction with the accompanying drawings and specific embodiments:

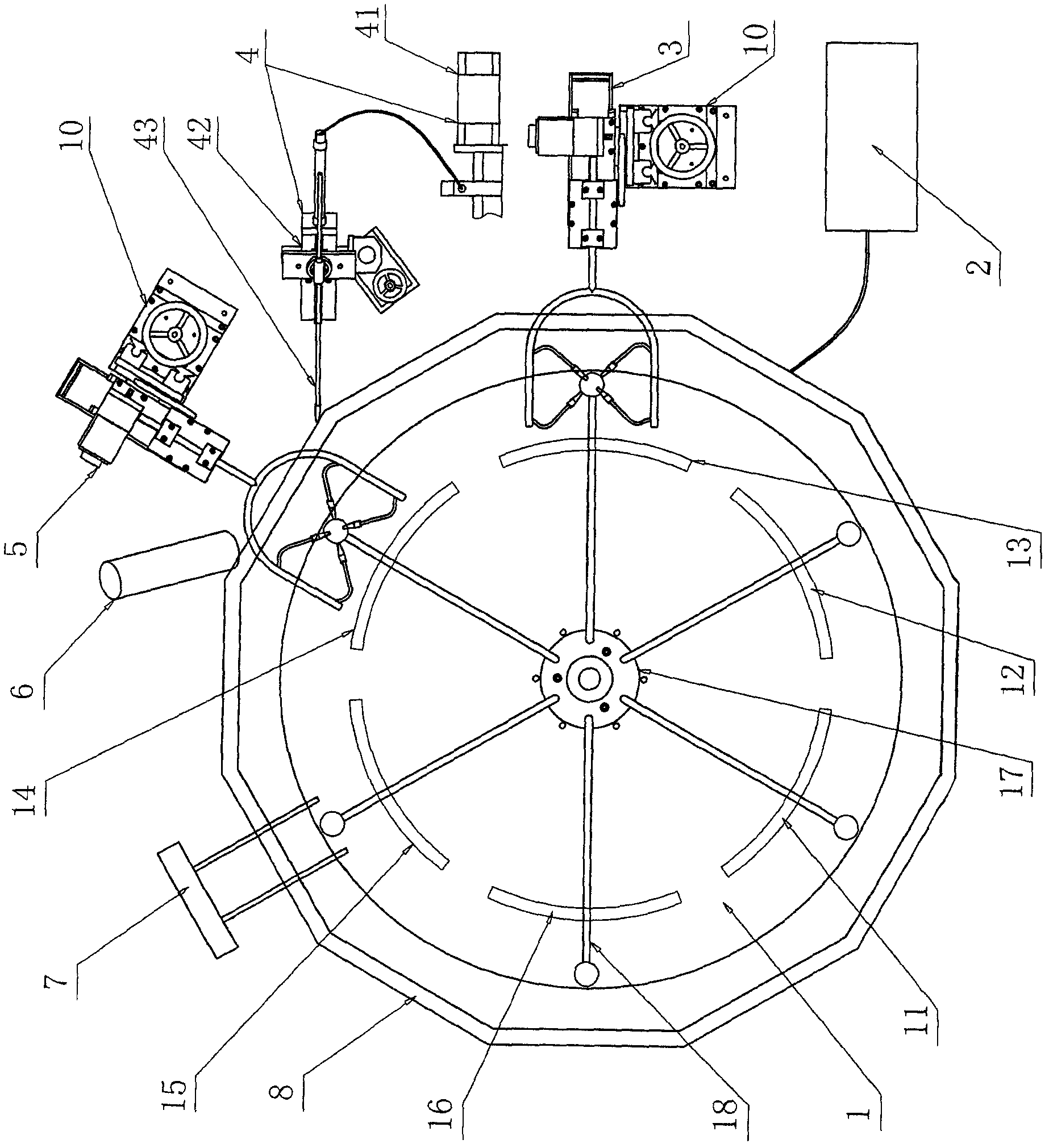

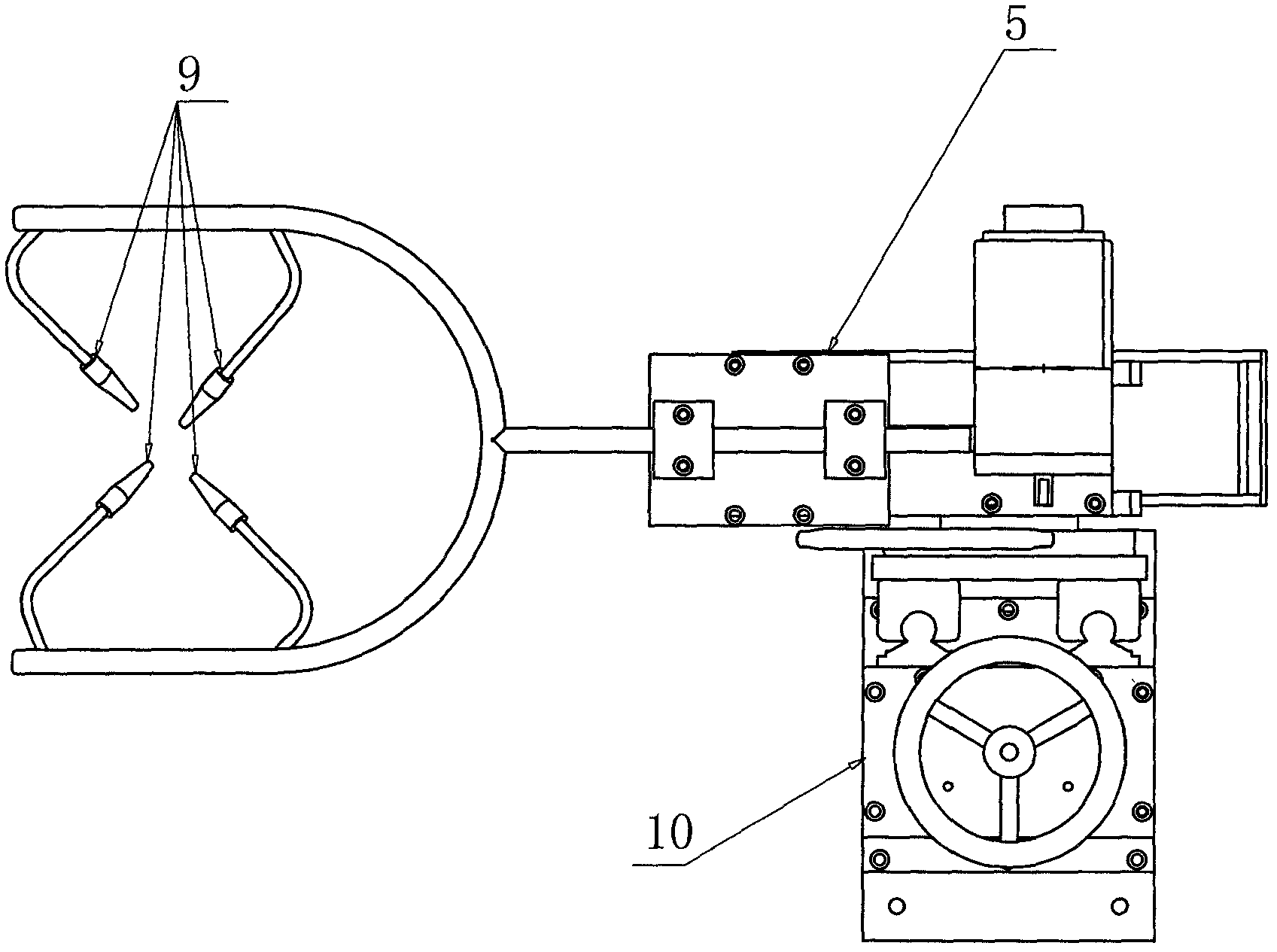

[0021] Such as figure 1 As shown, a high-efficiency copper-iron automatic flame brazing machine and its welding method include a turntable 1, a control system 2 and a flame welding mechanism 5. The turntable 1 includes a loading station 11, a sensing station 12, a preheating station 13, a welding station 14, a cooling station 15, and an unloading station 16; the corresponding preheating station 13 is equipped with a flame preheating mechanism 3; Corresponding to the welding station 14 is installed a temperature sensing device 6 for detecting the temperature of the weldment on the welding station.

[0022] The loading station 11, sensing station 12, preheating station 13, welding station 14, cooling station 15, and unloading station 16 on the turntable 1 are arranged in counterclockwise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com