Shale gas sand removing separation system and method

A separation system and separation method technology are applied in the field of shale gas wellhead sand removal and separation systems, which can solve the problems of carrying impurities, poor reliability, clogging of liquid outlet pipelines, etc., so as to facilitate operation and management, reduce quantity and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

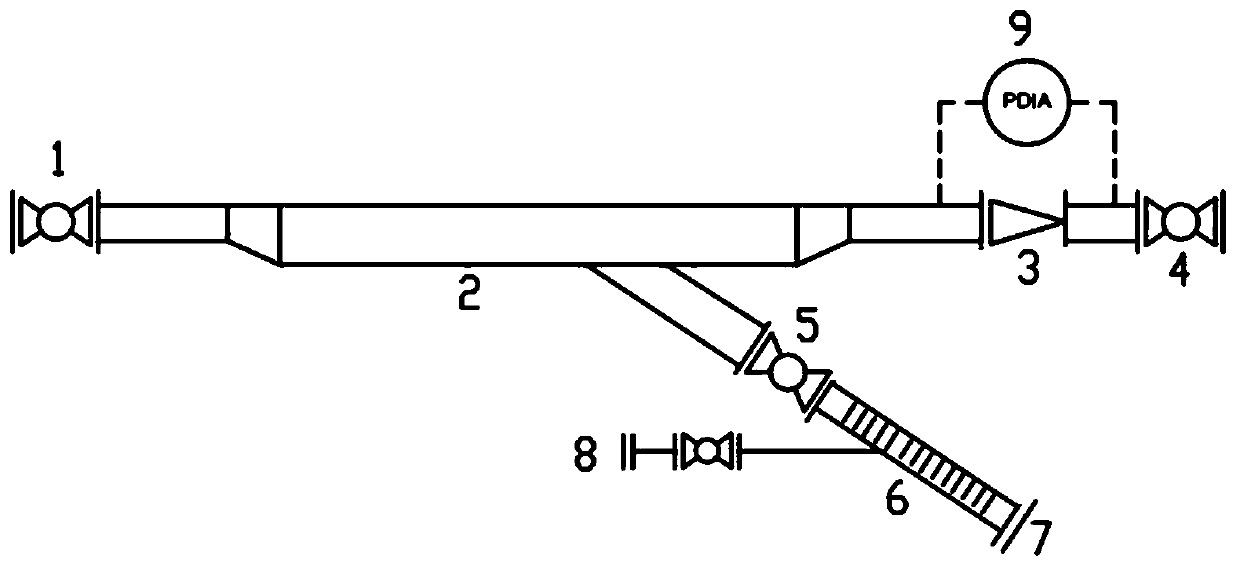

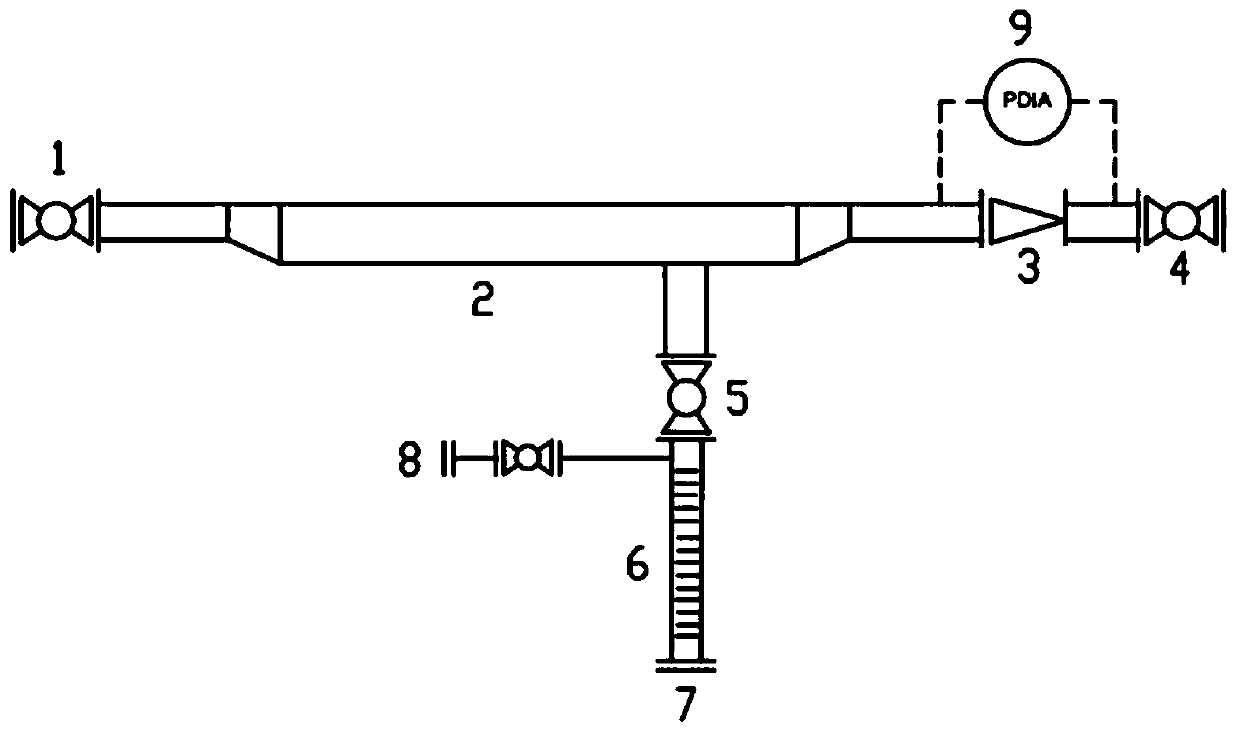

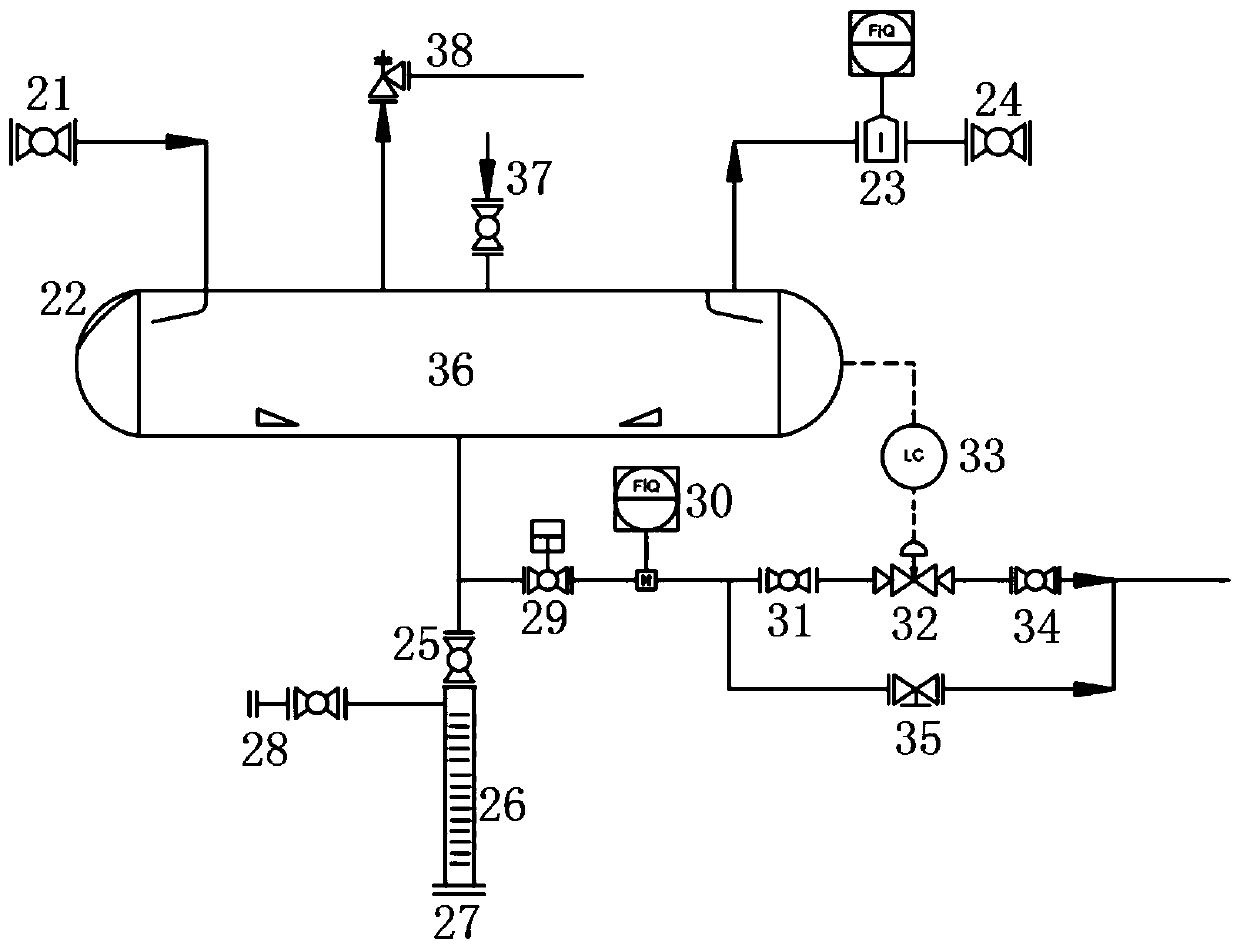

[0026] A shale gas sand removal and separation system, comprising a sand removal filter unit and a separation metering unit, the sand removal filter unit mainly includes a sand removal diameter expansion pipe section, a conical filter element, a sand removal flushing port, a sight tube, and a sand removal port , Import and export shut-off valves, etc., to meet the requirements of sand removal and filtration. The separation and metering unit mainly includes a separator body, a sand removal flushing port, a sight pipe, a sand removal port, a gas phase flowmeter, a liquid phase flowmeter, an inlet and outlet shut-off valve, and a liquid phase emergency shut-off valve to meet gas-liquid separation measurement and Further sand removal requirements. The outlet shut-off valve of the sand removal filter unit is connected with the inlet shut-off valve of the separation and metering unit through a short pipe to realize gas-liquid separation and metering after sand removal.

[0027] Bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com