Vertical vibrating sand removal device

A vertical, vibrating motor technology, applied in the field of casting core sand removal devices, can solve the problems of core sand not being discharged in time, the mechanism is shaking, and the sand removal efficiency is low. Sand efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with specific embodiments.

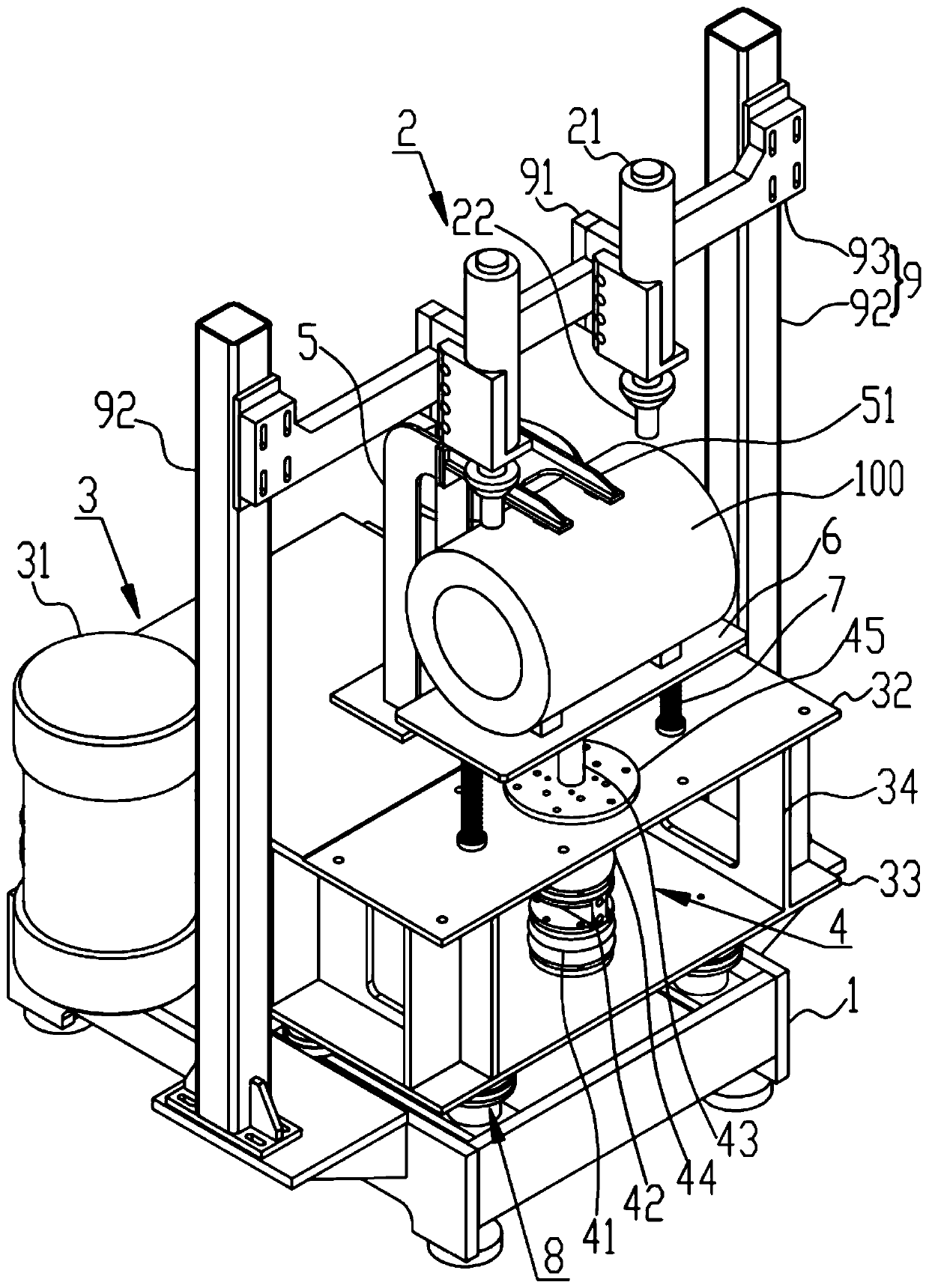

[0022] like figure 1 As shown, a vertical vibrating sand removal device according to an embodiment of the present invention includes a base 1 , a hammering mechanism 2 , a vibrating mechanism 3 , an air spring lifting mechanism 4 and an upper clamping seat 5 . The vertical vibrating sand removal device is mainly used to remove the core sand in the casting 100. The casting 100 includes the motor casing, the aluminum alloy cylinder head of the automobile engine, the supercharger, etc., and the device is mainly used in the company for removing the motor casing. sand.

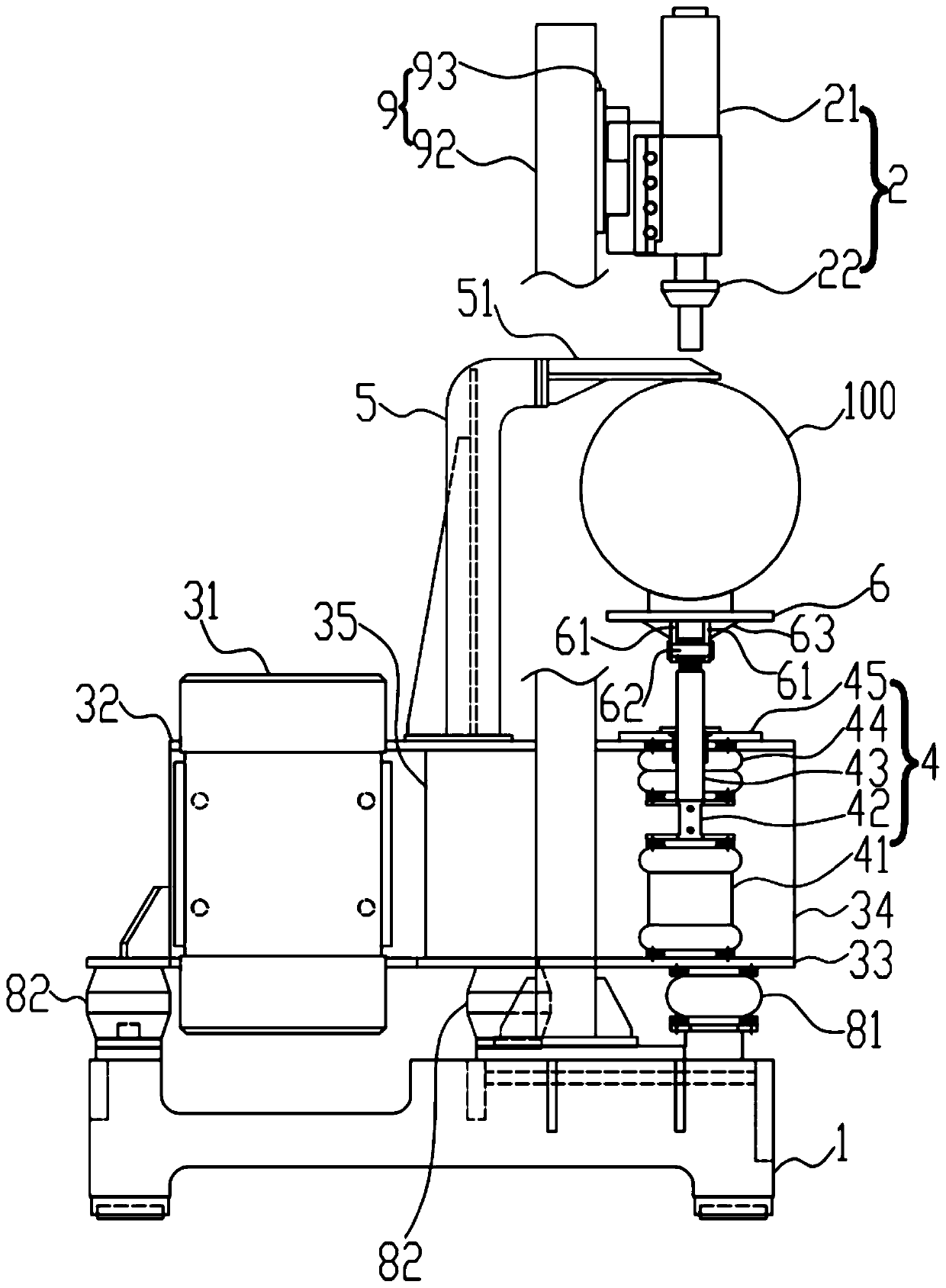

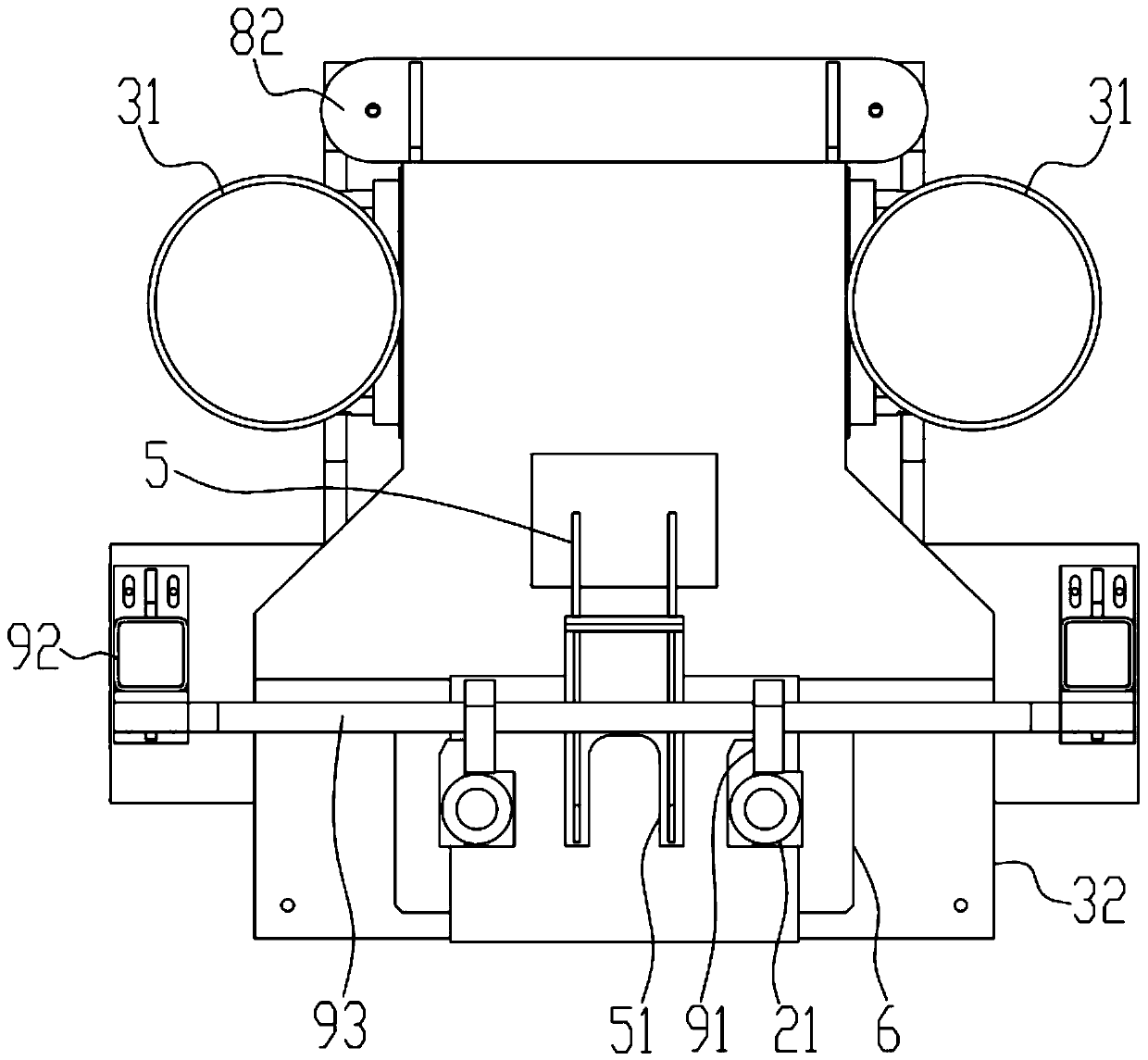

[0023] like figure 2 and 3 As shown, the vibration mechanism 3 includes a vibration motor 31 , an upper support 32 , a lower support 33 , and a plurality of vertical plates 34 connecting the upper support 32 and the lower support 33 . The upper frame 32 and the lower frame 33 overlap on the vertical project...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com