Electrolytic machining technique and device for small bore diameter inner wall surface fine groove

A processing technology and processing device technology, applied in the field of electrolytic processing technology and devices, can solve the problems of low processing efficiency and forming precision, difficult tool electrode preparation, unstable processing process, etc., and achieve good curing performance, easy process, and solidification fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (annular groove)

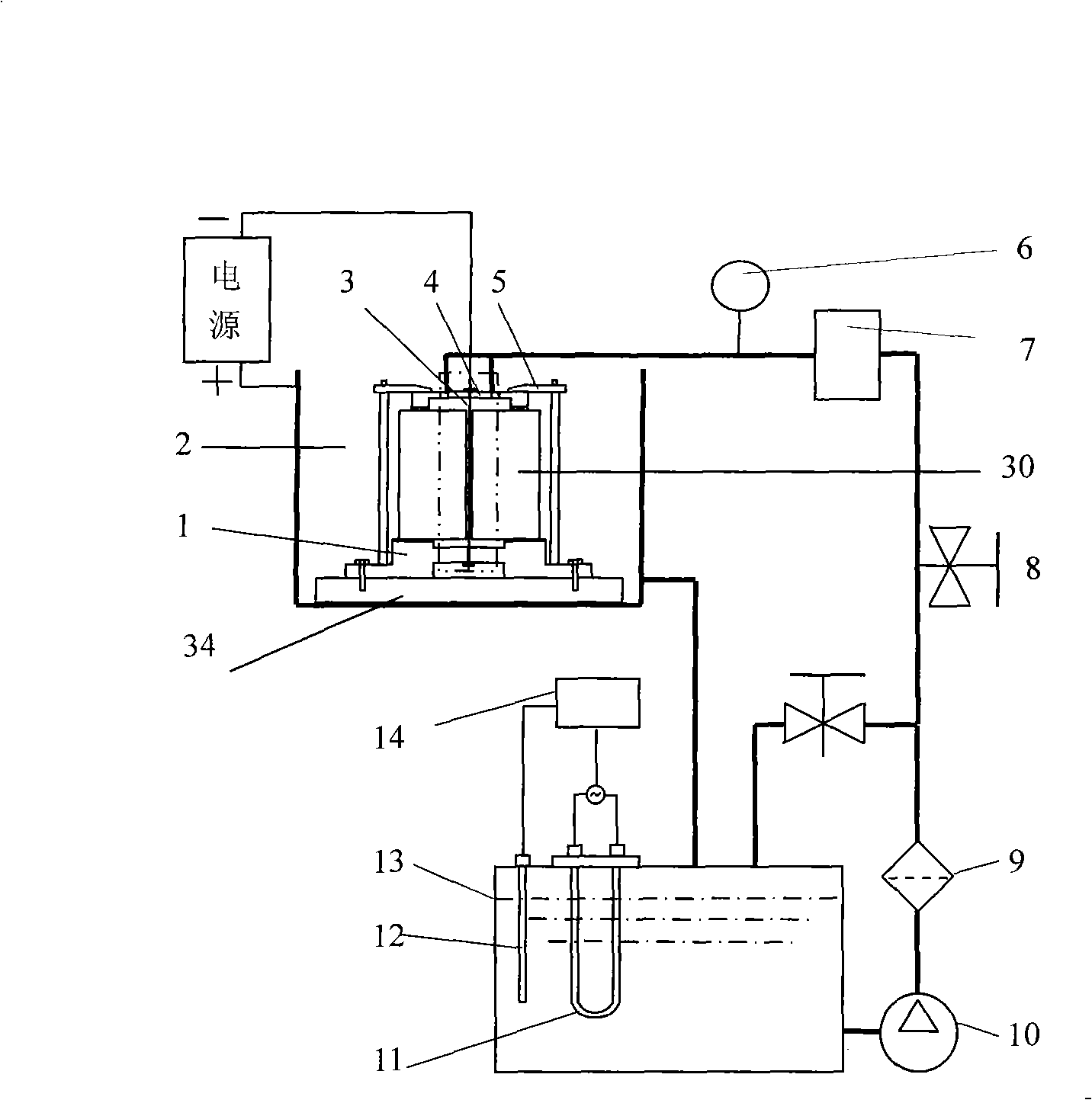

[0035] Such as figure 1 Shown, a kind of electrolytic processing device of micro-groove on the wall surface of small aperture, electrolytic processing device comprises electrolytic cell, electrolyte storage tank and the power supply that is electrically connected with electrolytic cell, described electrolyte storage tank is connected with vacuum pump and circulating pipeline. The electrolytic cell is circulated, and the electrolytic cell includes a processing chamber 2, a base 34 fixed on the bottom of the processing chamber 2, an upper cover plate 4 for fixing a prefabricated workpiece 30 with a light hole, a lower cover plate 1 and a clamp 5. The lower cover plate 1 is fixed on the base, the clamp is connected to the lower cover plate 1, the upper cover plate 4 and the prefabricated workpiece with light holes pass through the pressing plate of the clamp 5 and the lower cover plate 1 Fixing, the upper cover plate 4 and the lower cover p...

Embodiment 2

[0044] Embodiment 2 (spiral groove)

[0045] The device and process flow used in this embodiment are the same as those in Embodiment 1.

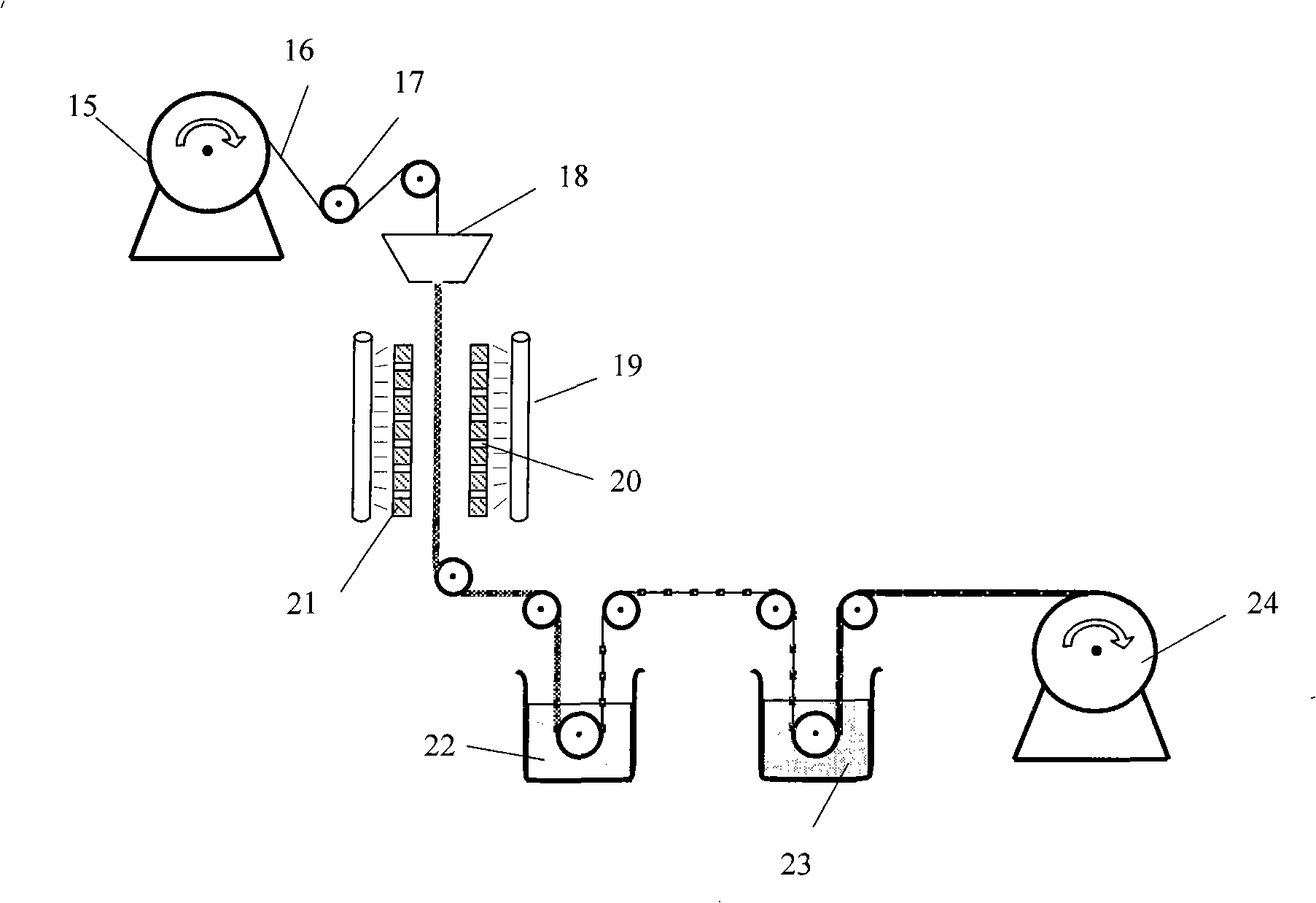

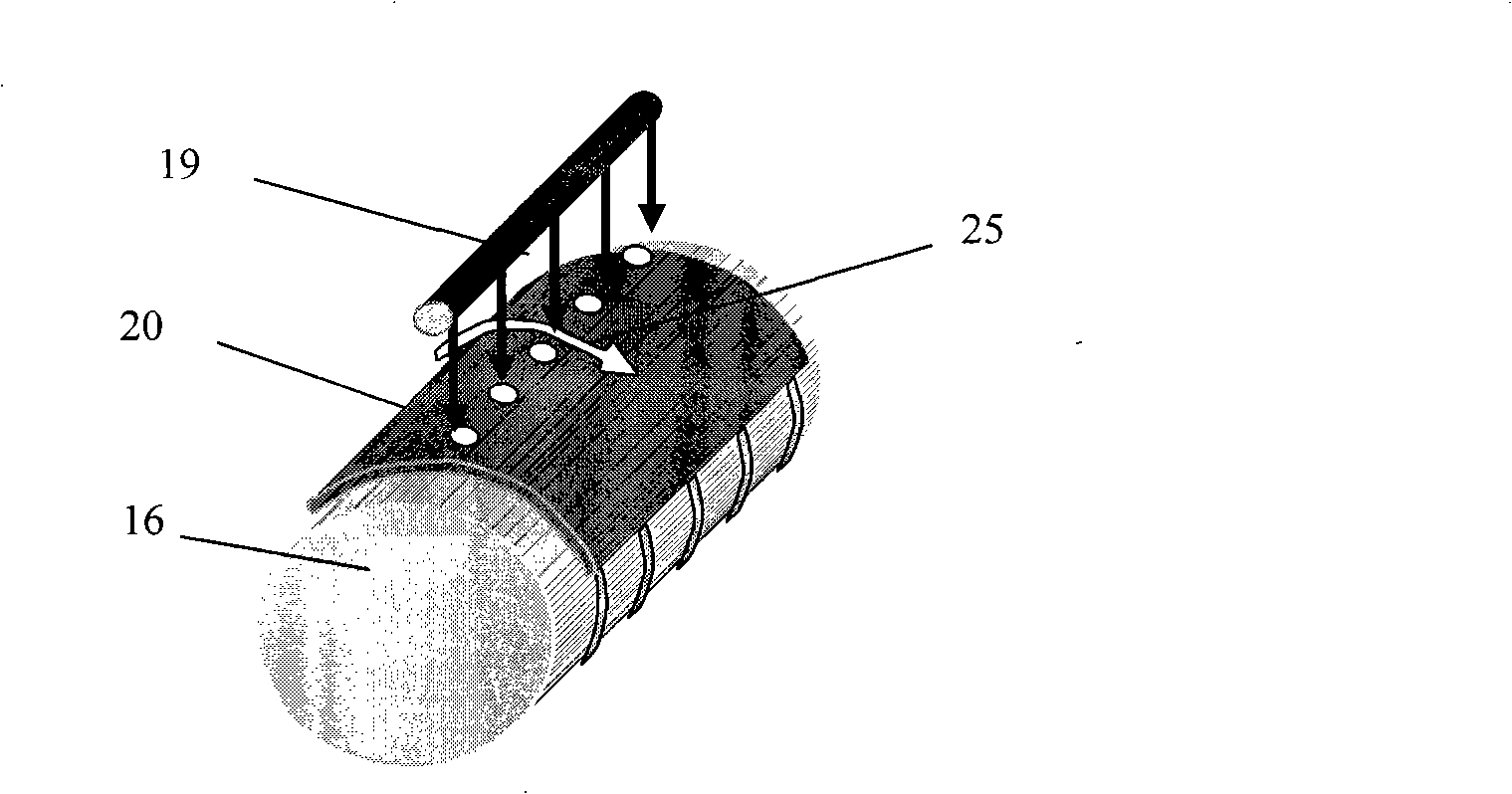

[0046] The parameter conditions used in each step of this embodiment are as follows: the conductive metal wire used is 300 μm stainless steel wire, the epoxy resin insulating glue is 623A-80UV glue, the ultraviolet light intensity is controlled to 2KW, the metal wire is kept still, and the ultraviolet light lamp is adjusted 19. The relative movement 25 of the mask plate 21 and the metal wire 16 is shown in Figure 2(c), the curing time is about 2 seconds, and the cathode of the micro-forming tool used for processing the spiral micro-groove is prepared, as shown in Figure 3 ( As shown in b), the thickness of the insulating layer is about 50 microns.

[0047] The electroforming metal is nickel, the electroplating solution is nickel sulfamate, the temperature of the electroplating solution is controlled at 30°C, the concentration of the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com