Internal circulation fishpond and circulating water treatment process

A technology of internal circulation and fish ponds, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of complex grading fishing operations, complex pipeline layout, and low utilization rate of land area, so as to achieve low investment and reduce processing load The effect of reducing water pump energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

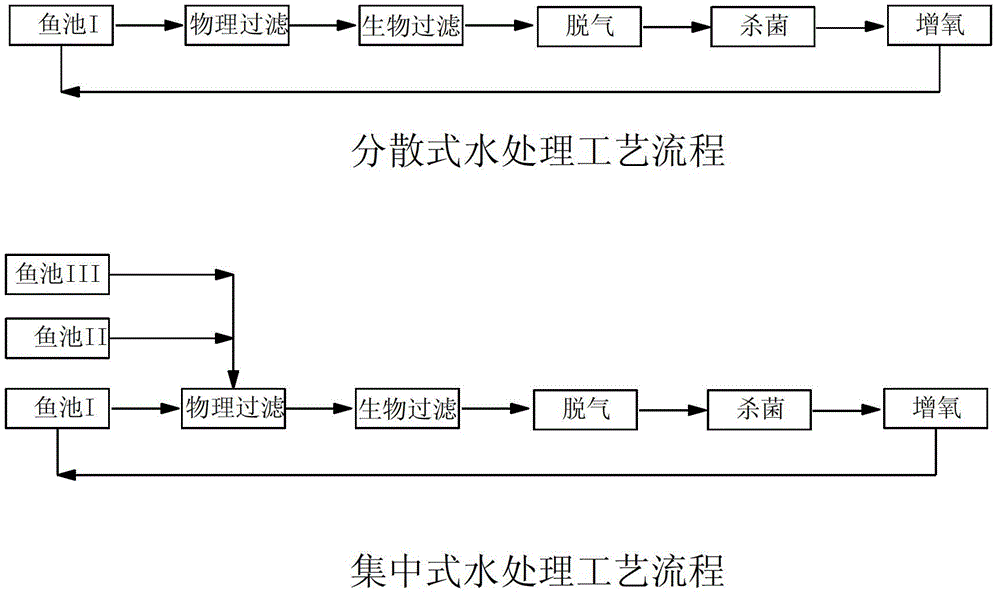

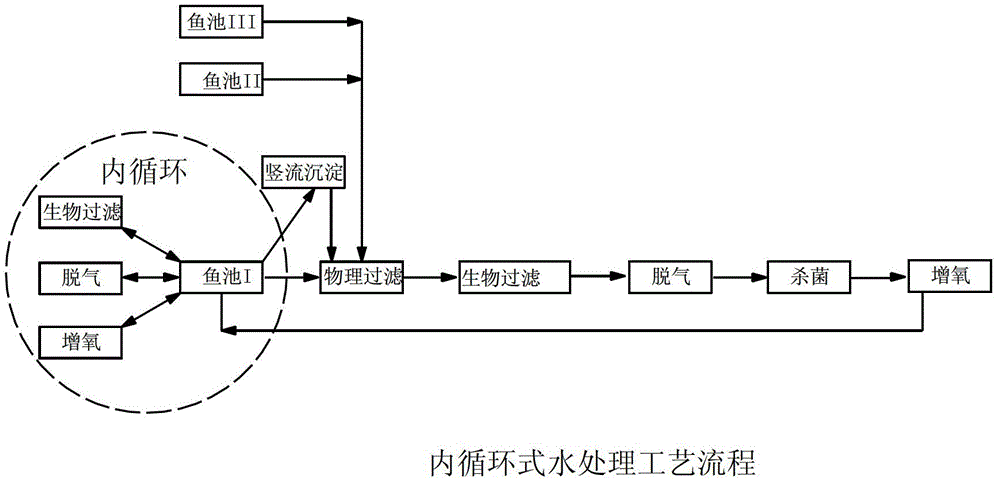

[0045] In the prior art, the water treatment process of centralized and decentralized farming is as follows: figure 1 . The decentralized water treatment process is that the water in a single fish pond is pumped out, and then returned to the fish pond after successively undergoing physical filtration, biological filtration, degassing, sterilization and oxygenation.

[0046] The centralized water treatment process is: the water in multiple fish ponds (fish ponds I, II, II) is pumped out and collected together, and then returned to each fish pond after successively undergoing physical filtration, biological filtration, degassing, sterilization and oxygenation.

[0047] Inner circulation fishpond of the present invention is:

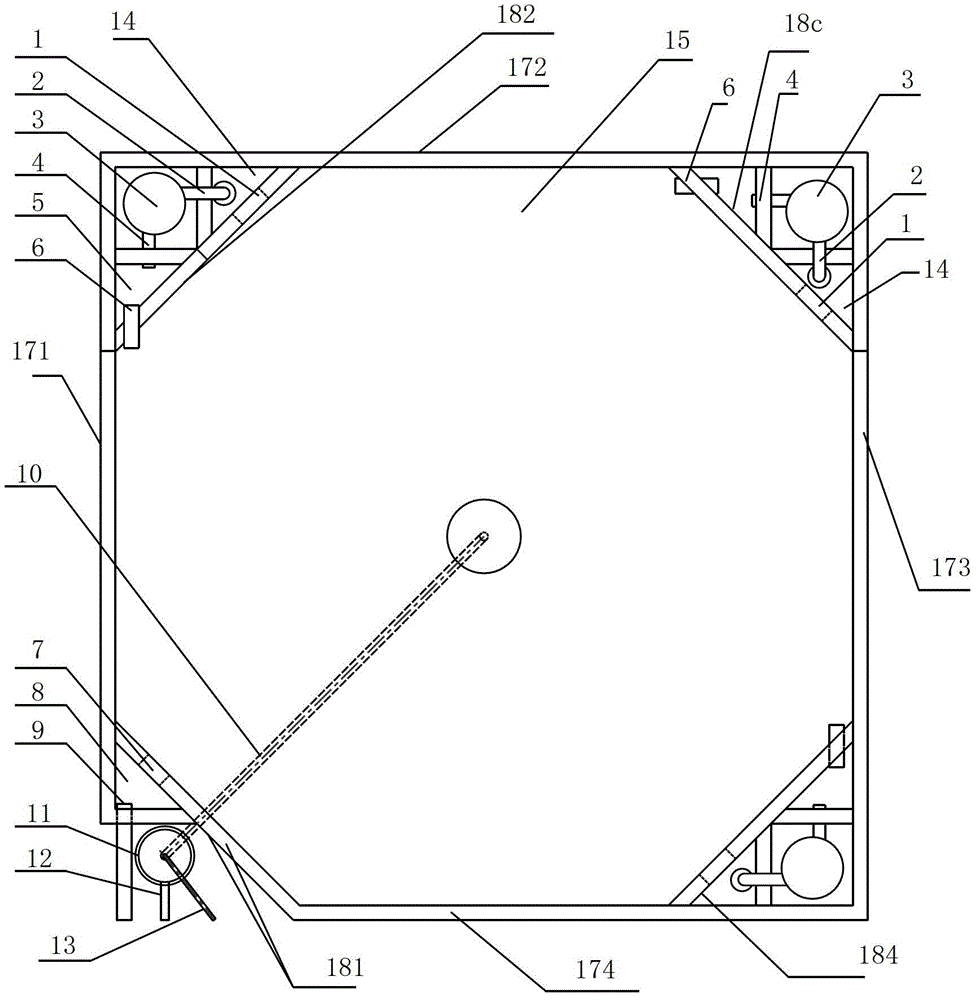

[0048] Such as image 3 As shown, the structure of the inner circulation fish pond (fish pond I) includes a central fish pond 15. The shape of the central fish pond is an octagon with four cut corners. , the long side of the outer wall b, the short side ...

Embodiment 2

[0067] Such as Image 6 As shown, the central fish pond is a circle, and the rectangle circumscribed by the central fish pond has four corners. A sedimentation system is set on one of the corners, and the structure and working principle of the sedimentation system are the same as those in Embodiment 1.

[0068] An internal circulation system is set on the remaining three corners, and the structure and working principle of the internal circulation system are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com