Sand-slag co-removal efficient pretreatment system and process

A pretreatment and high-efficiency technology, which is applied in the direction of reversed device, filter separation, fixed filter element filter, etc., which can solve the problem of low filtration accuracy and interception efficiency, reduced sewage treatment effect, equipment and pipelines. Wear and other problems, to achieve the effect of improving the removal rate, reducing land occupation and civil construction costs, and reducing civil construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

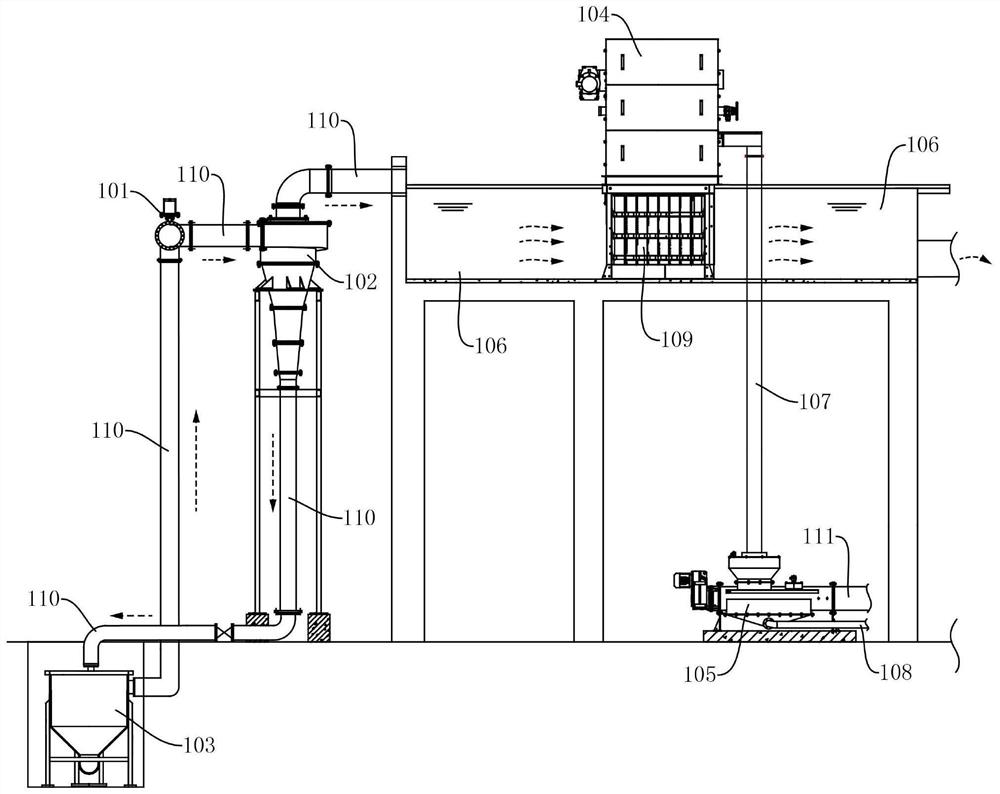

[0037] see figure 1 In this embodiment, a high-efficiency pretreatment system for co-removal of sand and slag is provided, including a slag removal unit and a sand removal unit. The slag removal unit includes a delivery pump 101, a hydrocyclone 102, and a sand-water separator 103. The unit comprises an orifice grill apparatus 104, a constructed flow channel 106, and a screw press 105, wherein,

[0038] In this embodiment, the upper part of the hydrocyclone 102 is provided with an overflow port and a water inlet, and the lower end of the hydrocyclone 102 is provided with a sand outlet, and the delivery pump 101 is connected to the water inlet of the hydrocyclone 102 through the pipeline 110 connected, such as figure 1 As shown, the delivery pump 101 is used to pressurize the sewage to be treated. On the one hand, the upstream sewage to be treated can smoothly enter the hydrocyclone 102 under the delivery of the delivery pump 101; The device 102 needs a pressure of about 0.06-...

Embodiment 2

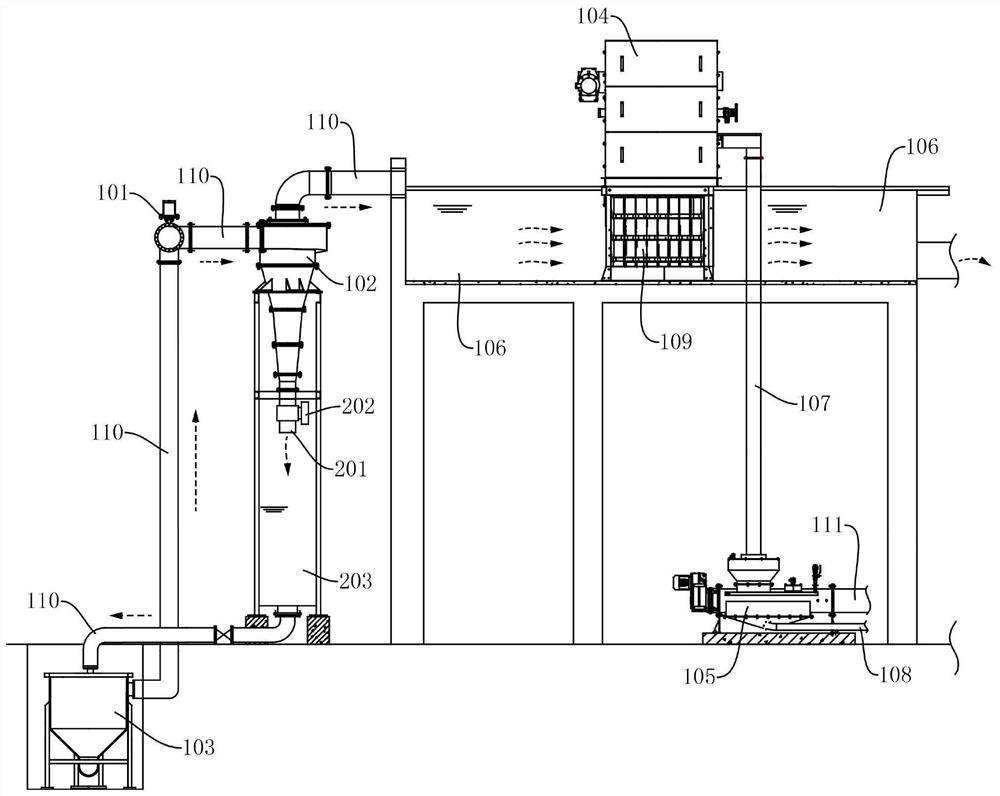

[0053] In order to solve the problem of increasing the concentration of sand discharged from the grit chamber at the bottom of the hydrocyclone 102, the main difference between this embodiment 2 and the above-mentioned embodiment 1 is that in the high-efficiency pretreatment system for co-removing sand and slag provided by this embodiment, there is also including the controller and valve 202, such as figure 2 As shown, the sand outlet is connected with a sand discharge pipe 201, the valve 202 is installed on the sand discharge pipe 201, and the underflow box 203 is arranged below the sand discharge pipe 201, as figure 2 As shown, to undertake the sand-water mixture;

[0054] The controller is connected with the valve 202, and the controller is used for controlling the opening / closing of the valve 202 at regular intervals, and controlling the duration of the valve 202 being kept open. That is, in this embodiment, by setting the controller and the valve 202, the controller ca...

Embodiment 3

[0059] According to the high-efficiency pretreatment system for co-removal of sand and slag provided in Example 2, this embodiment provides a high-efficiency pretreatment process for co-removal of sand and slag, including the following process:

[0060] 1. Use the delivery pump 101 to input the sewage into the hydrocyclone 102, and the hydrocyclone 102 uses centrifugal force to settle and separate the sand and grid residue in the sewage to form a sand-water mixture, and the sewage after separating the sand-water mixture is input into the orifice grid Grid equipment 104, to utilize the orifice grid equipment 104 to further intercept the sand and grid slag in the sewage, to achieve the purpose of efficiently intercepting sand and grid slag; the water output in the orifice grid equipment 104 is input into the subsequent treatment unit, and The screen residue water separated from the orifice grid equipment 104 is sent to the screw press 105 to separate the screen residue and water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com