Device and method for comprehensively utilizing heat produced by decomposition of phosphorous gypsum in circulating fluid bed

A circulating fluidized bed and phosphogypsum technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of reducing and unfavorable weak reduction-monoxide double atmosphere conditions, increasing the difficulty and cost of acid production process, etc. To achieve the effect of improving the decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

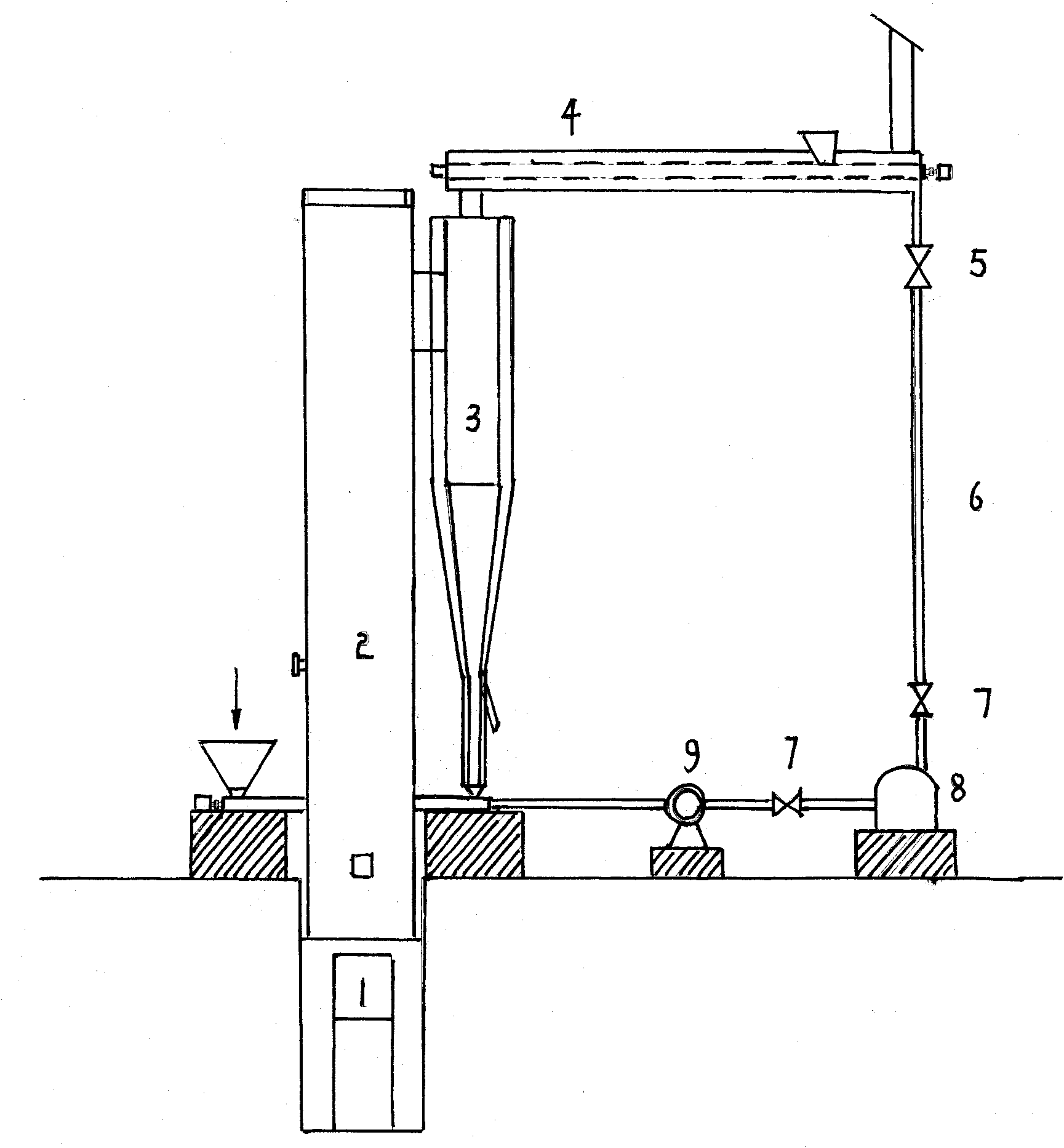

Image

Examples

Embodiment 1

[0023] Raw material 1 Phosphogypsum

[0024] The main components of phosphogypsum are shown in the table below

[0025] Element

SO 3

CaO

SiO 2

Al 2 o 3

Fe 2 o 3

MgO

Total P 2 o 5

Total F

Na 2 o

K 2 o

content(%)

40.86

29.82

9.43

0.236

0.132

0.055

1.17

0.52

0.043

0.086

9.65

[0026] Raw material 2 raw coal

[0027] The carbon content of raw coal is 63.9%, the ash content is 28.67%, and the calorific value is 24.22MJ / kg. The raw material is collected in Chuxiong, Yunnan.

Embodiment approach

[0029] Under the condition of maintaining normal operating temperature (1000~1200℃), the phosphogypsum is evenly transported into the fluidized bed through the screw drying feeder at 930kg / h, and the fluidizing air volume is 700~800m 3 / h, the flue gas circulation rate is 10%, after multiple cycles of roasting, the clinker is mainly CaO, and the flue gas contains a high concentration of SO 2 .

[0030] Implementation results:

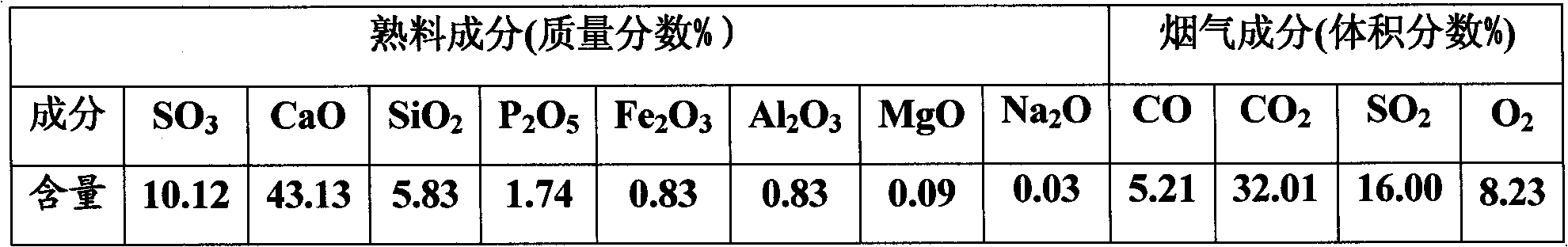

[0031] The clinker composition and flue gas composition analysis are as follows:

[0032]

[0033] Combined with data analysis, it can be known that CaSO 4 The decomposition rate is about 81.2%, SO 2 The volume fraction is 16.00%.

Embodiment 2

[0035] Raw material 1 Phosphogypsum

[0036] The main components of phosphogypsum are shown in the table below

[0037] Element

SO 3

CaO

SiO 2

Al 2 o 3

Fe 2 o 3

MgO

Total P 2 o 5

Total F

Na 2 o

K 2 o

content(%)

40.86

29.82

9.43

0.236

0.132

0.055

1.17

0.52

0.043

0.086

9.65

[0038] Raw material 2 raw coal

[0039] The carbon content of raw coal is 73.9%, the ash content is 28.67%, and the calorific value is 24.22MJ / kg. The raw material is collected in Chuxiong, Yunnan.

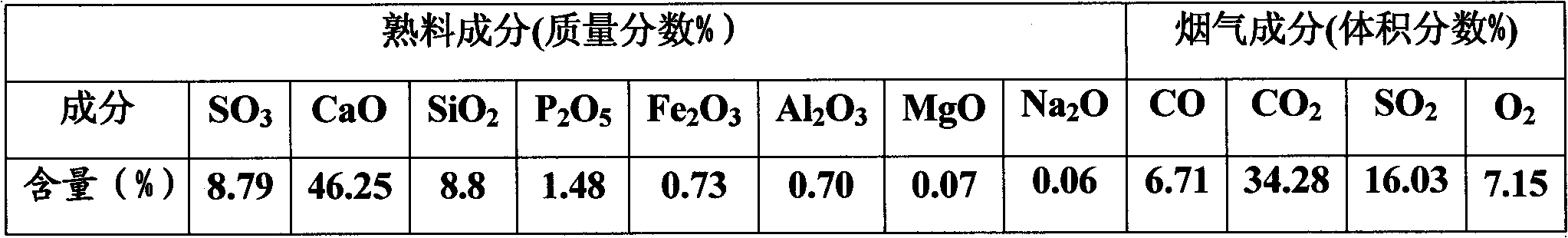

[0040] method of execution:

[0041] Under the condition of maintaining normal operating temperature (1000~1200℃), the phosphogypsum is evenly transported into the fluidized bed through the screw drying feeder at 930kg / h, and the fluidizing air volume is 700~800m 3 / h, the flue gas (120-200°C) circulation rate is 20%, after repeated cycles of roasting, the cli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com