Waste heat recycling chamber for recycling waste heat of fused magnesium melting lump

A technology of waste heat recovery and fused magnesium, which is applied in the field of waste heat recovery of fused magnesium lumps, can solve the problems affecting the waste heat recovery effect of the waste heat recovery device, the flow of steam and water in the waste heat recovery device is not smooth, and the rear heating surface cannot produce steam, etc. Improve waste heat recovery efficiency, save manufacturing costs, and reduce footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

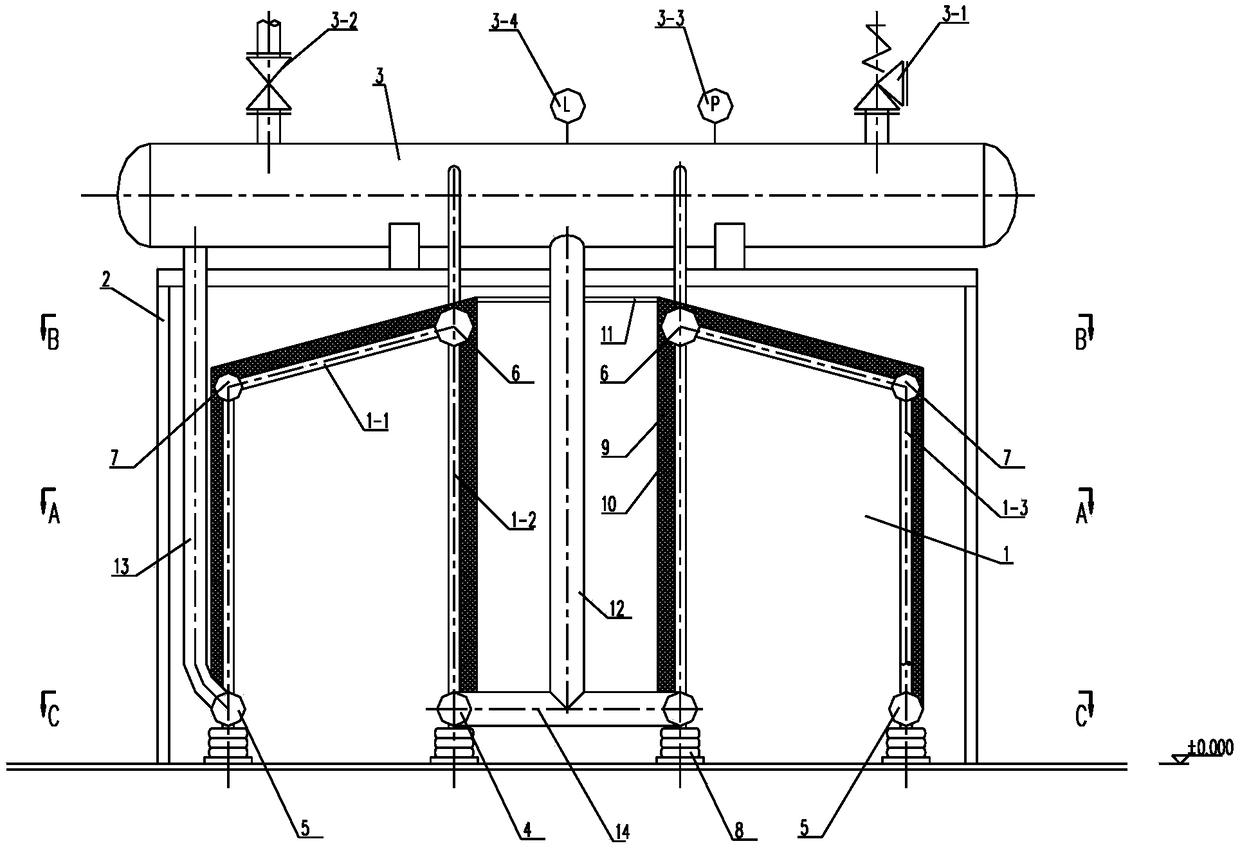

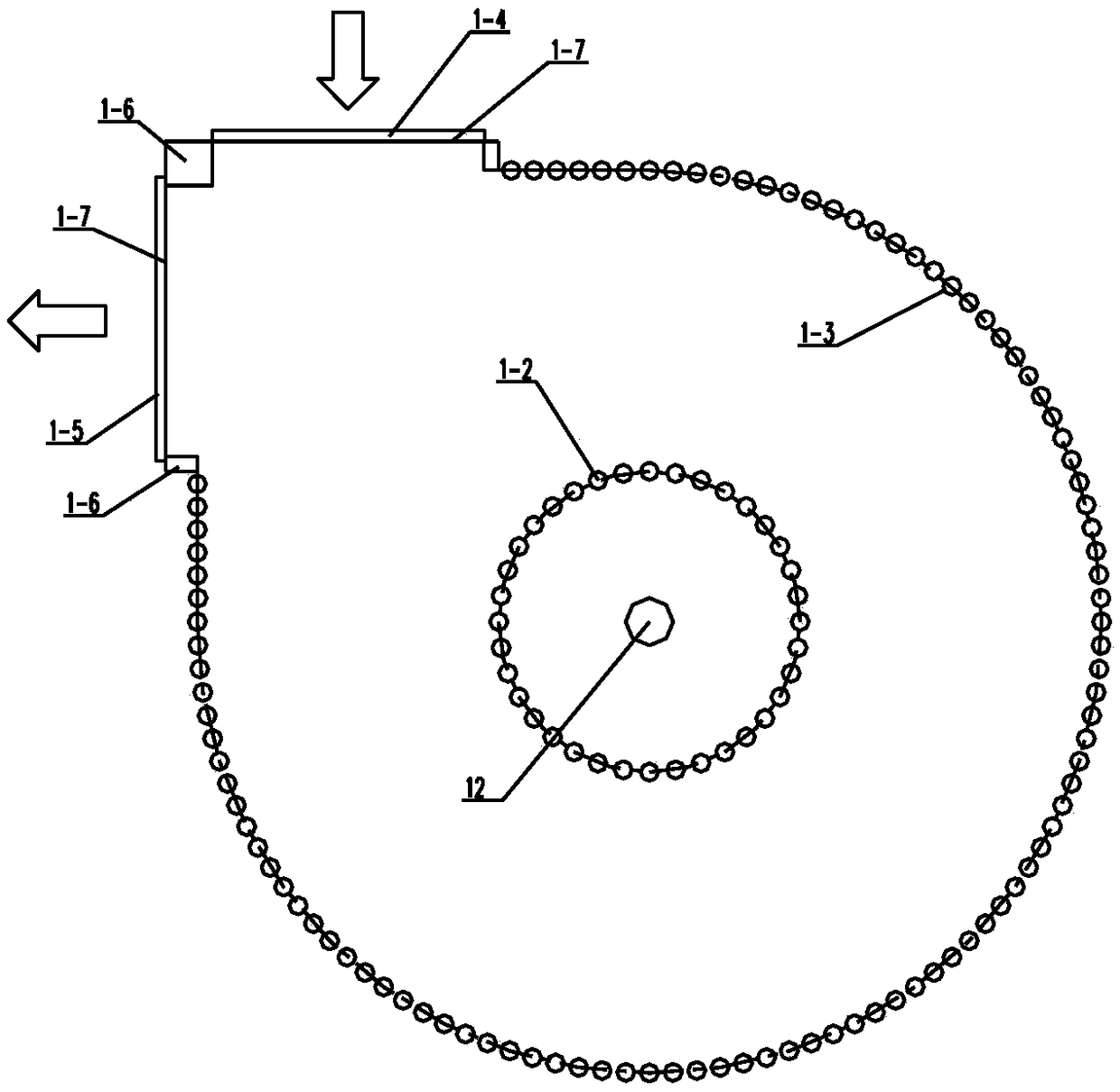

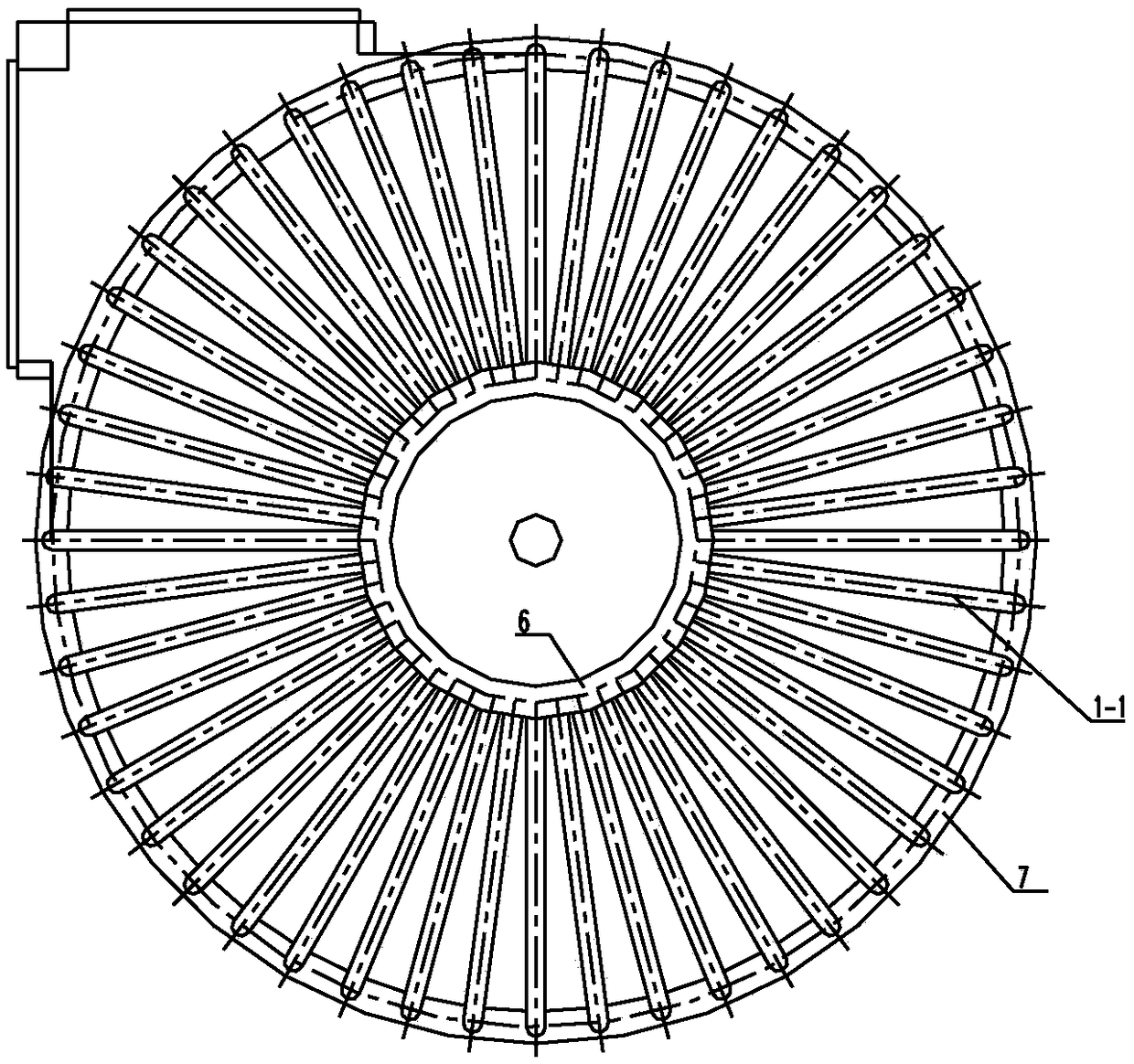

[0032] Such as Figure 1-Figure 4 As shown in the present invention, a waste heat recovery chamber for waste heat recovery of fused magnesia fused lumps includes an annular waste heat recovery chamber 1 and a heat storage container 3; the annular waste heat recovery chamber 1 consists of a top water-cooled wall 1-1, The inner ring water cooling wall 1-2 and the outer ring water cooling wall 1-3 together form a closed annular space, which is a moving cooling channel for the fused magnesium fused lump 15, and the side of the annular space is provided with waste heat recovery chamber inlet 1-4 and The outlets 1-5 of the waste heat recovery chamber, the inlets 1-4 of the waste heat recovery chamber and the outlets 1-5 of the waste heat recovery chamber are arranged adjacently, and are closed by the entrance door and the exit door respectively; a heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com