Preparation of high-loading self-supporting thick electrode and application of high-loading self-supporting thick electrode in sodium ion battery

A self-supporting electrode and self-supporting technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of long diffusion path of sodium ions, poor rate performance, slow diffusion, etc., and achieve excellent cycle performance , increase energy density, improve the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

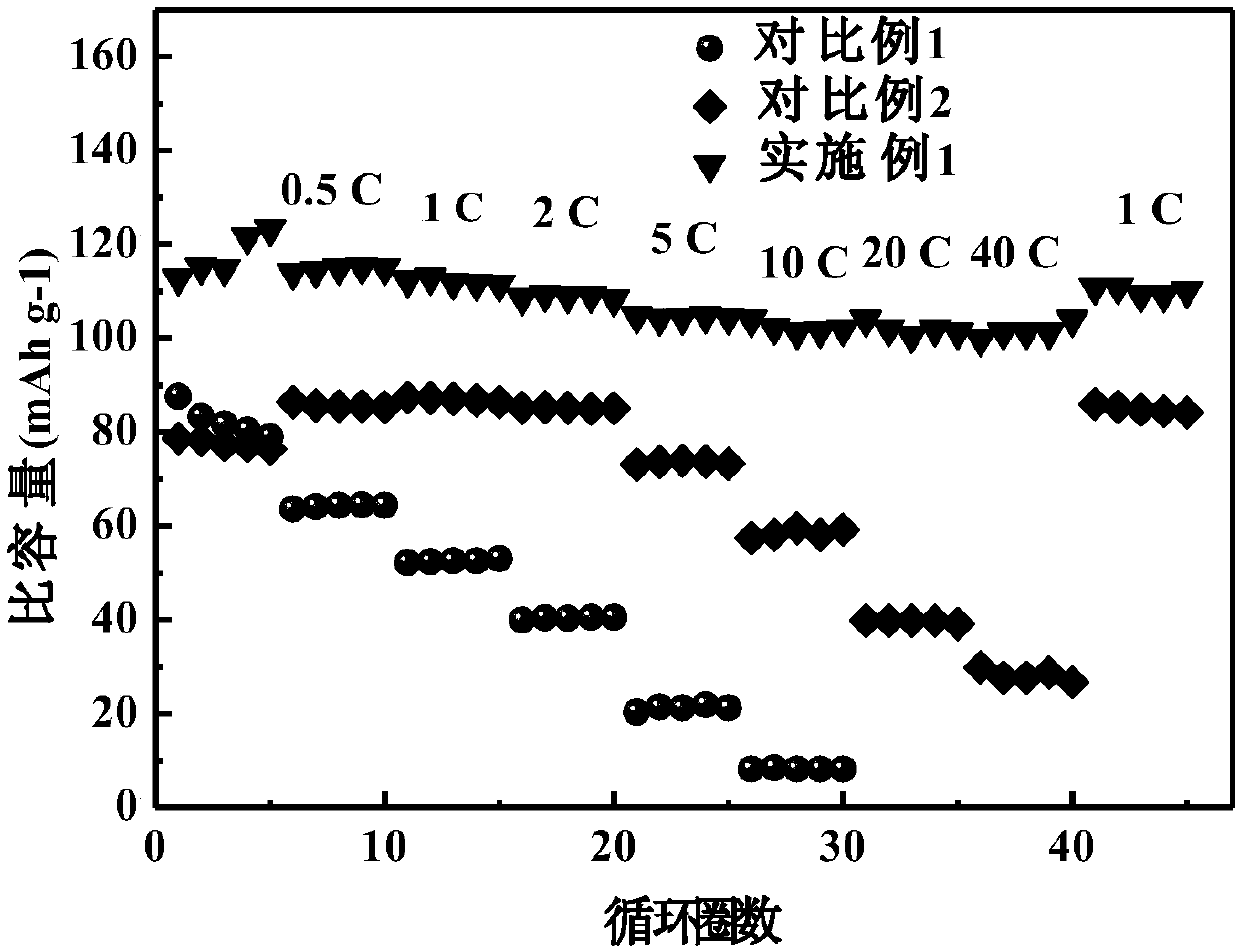

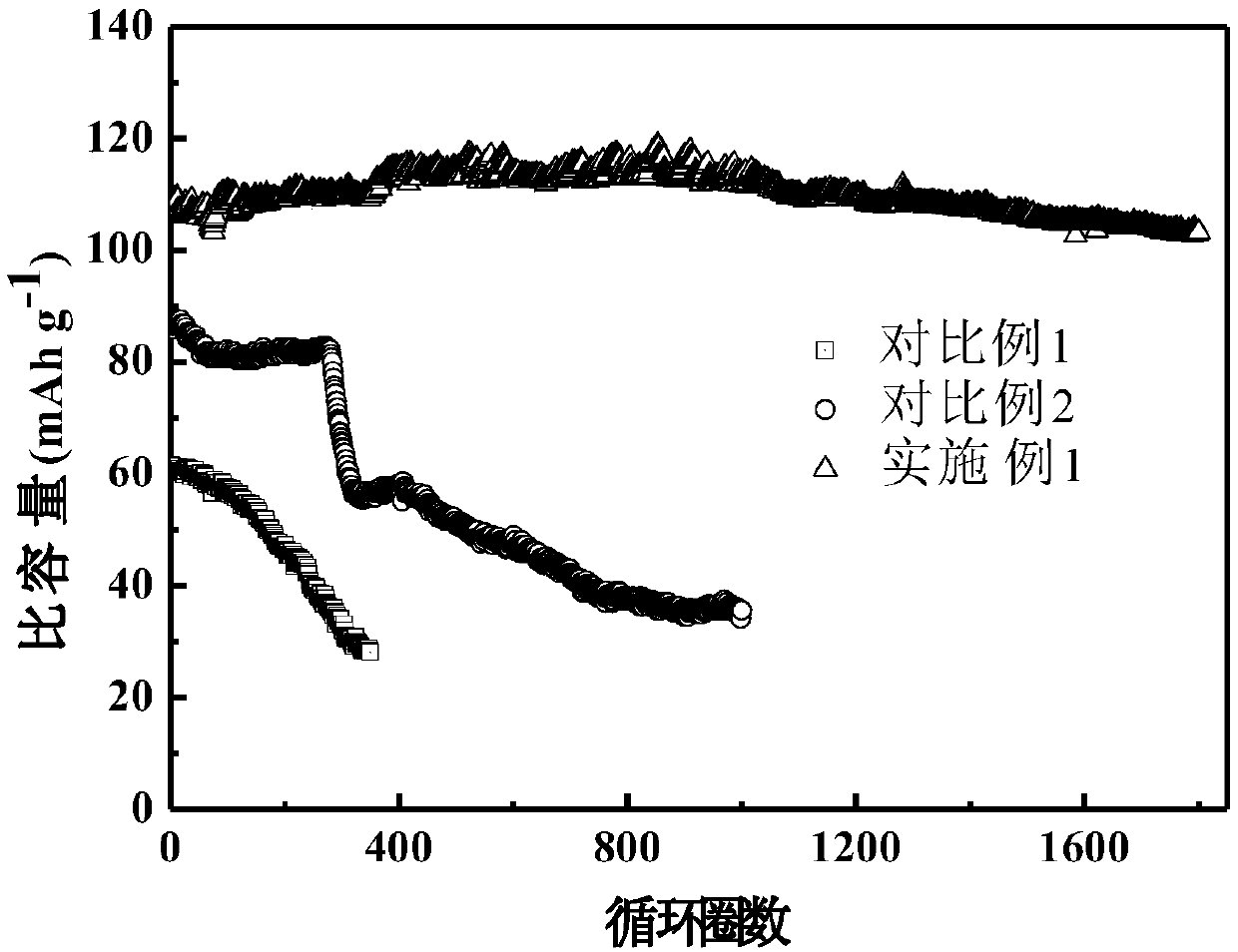

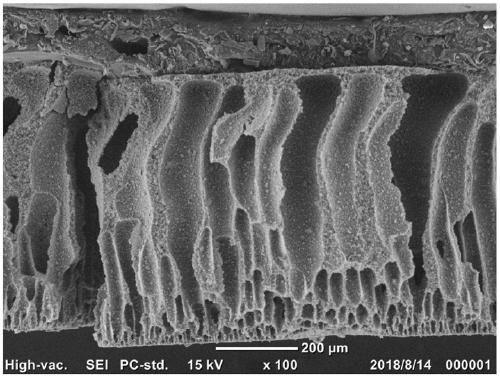

[0036] Embodiment 1: (preparation Na 3 V 2 (PO 4 ) 3 @3DFLC-1 self-supporting electrode)

[0037] Weigh 5 g of polyacrylonitrile (organic polymer resin) and add it into 45 g of DMF, and stir for 5 hours until completely dissolved to form a 10% resin solution. Add 10 g of Na to the resin solution 3 V 2 (PO 4 ) 3 (electrode material), stirred for 12 hours, then ultrasonicated for 3 hours, and then stirred for 24 hours to obtain a uniformly dispersed mixed solution. Spread the mixed solution on a glass plate, volatilize for 1mins, set the thickness of the film to 1000μm, and then immerse it in a mixed solution of water and ethanol (1:1 in mass ratio) for 180 minutes, and solidify to form a porous composite membrane. The composite film was pre-calcined at 300 °C for 3 h in an air atmosphere, and then calcined at 800 °C for 4 h in an argon atmosphere to obtain 12 mg cm -2 , 600 μm thick Na 3 V 2 (PO 4 ) 3 @3DFLC-1 self-supporting electrode. The prepared Na 3 V 2 (PO...

Embodiment 2

[0038] Embodiment 2: (preparation Na 3 V 2 (PO 4 ) 3 @3DFLC-2 self-supporting electrode)

[0039] Weigh 5 g of polyacrylonitrile (organic polymer resin) and add it into 45 g of DMF, stir for 6 hours until completely dissolved, and form a 10% resin solution. Add 40 g of Na to the resin solution 3 V 2 (PO 4 ) 3 (electrode material), stirred for 12 hours, then ultrasonicated for 3 hours, and then stirred for 24 hours to obtain a uniformly dispersed mixed solution. Spread the mixed solution on a glass plate, volatilize for 1mins, set the thickness of the film to 1000μm, and then immerse it in a mixed solution of water and ethanol (1:1 in mass ratio) for 180 minutes, and solidify to form a porous composite membrane. The composite film was pre-calcined at 300 °C for 3 h in an air atmosphere, and then calcined at 800 °C for 4 h in an argon atmosphere to obtain 45 mg cm -2 , 600 μm thick Na 3 V 2 (PO 4 ) 3 @3DFLC-2 self-supporting electrodes. The battery assembly is the ...

Embodiment 3

[0040] Embodiment 3: (preparation Na 3 V 2 (PO 4 ) 3 @3DFLC-3 self-supporting electrode)

[0041] Weigh 5 g of polyacrylonitrile (organic polymer resin) and add it into 45 g of DMF, stir for 4 hours until completely dissolved, and form a 10% resin solution. Add 10 g of Na to the resin solution 3 V 2 (PO 4 ) 3 (electrode material), stirred for 12 hours, then ultrasonicated for 3 hours, and then stirred for 24 hours to obtain a uniformly dispersed mixed solution. Spread the mixed solution on a glass plate, volatilize for 1mins, set the film thickness to 1000μm, and then immerse in the mixed solution of water and ethanol (mass ratio 1:15) for 180 minutes, and solidify to form a porous composite membrane. The composite film was pre-calcined at 300 °C for 3 h in an air atmosphere, and then calcined at 800 °C for 4 h in an argon atmosphere to obtain 12 mg cm -2 , 600 μm thick Na 3 V 2 (PO 4 ) 3 @3DFLC-3 self-supporting electrodes. The battery assembly is the same as in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com