Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

288results about How to "Mild method conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

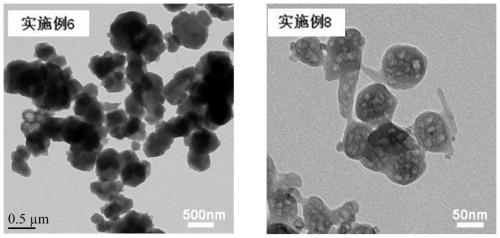

Magnetic gold nanoparticle composite material, and preparation method and application thereof

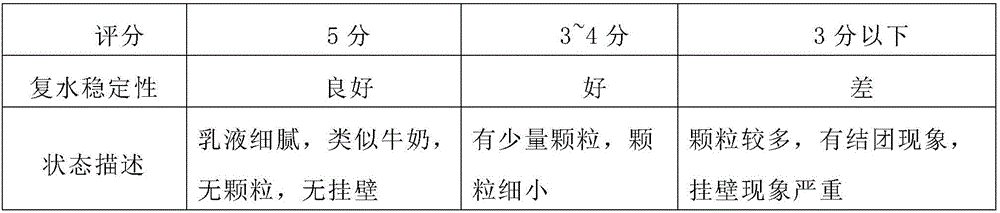

InactiveCN102974314AEasy to controlGood reproducibilityOther chemical processesAlkali metal oxides/hydroxidesMicrosphereMagnetite Nanoparticles

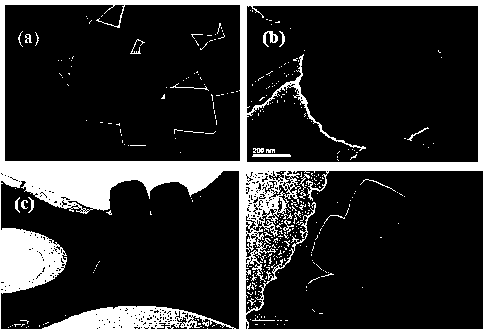

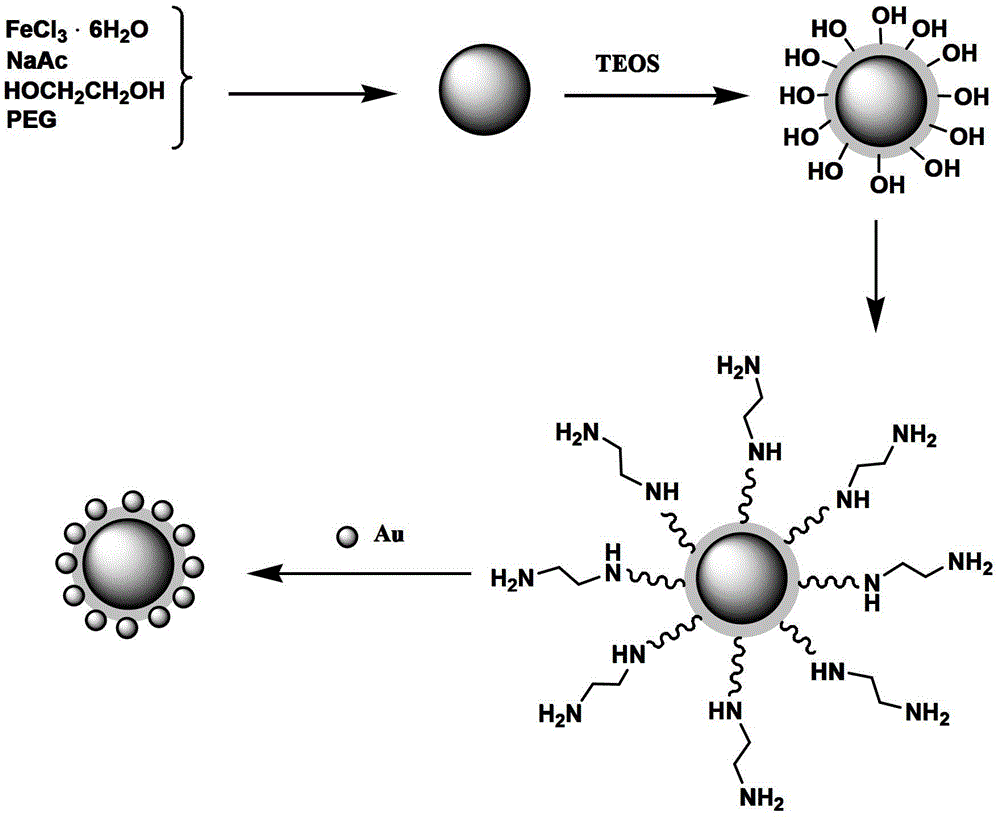

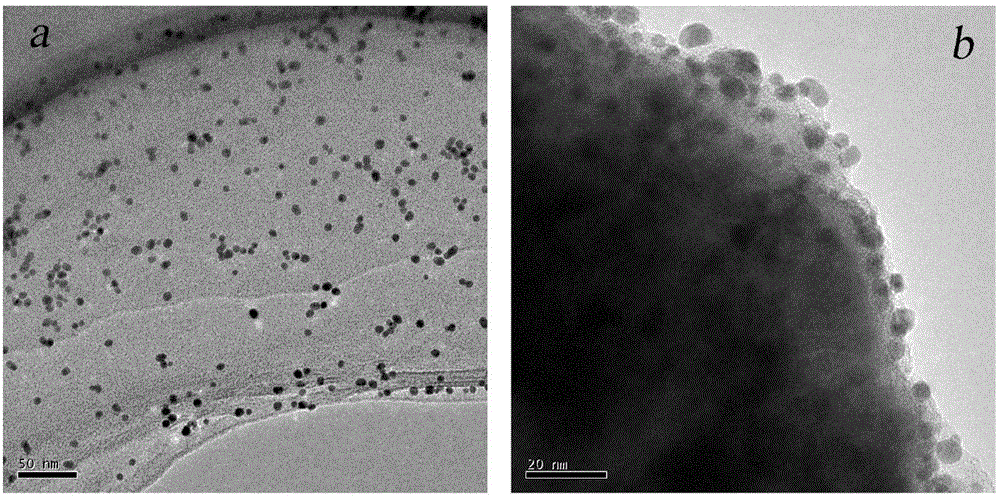

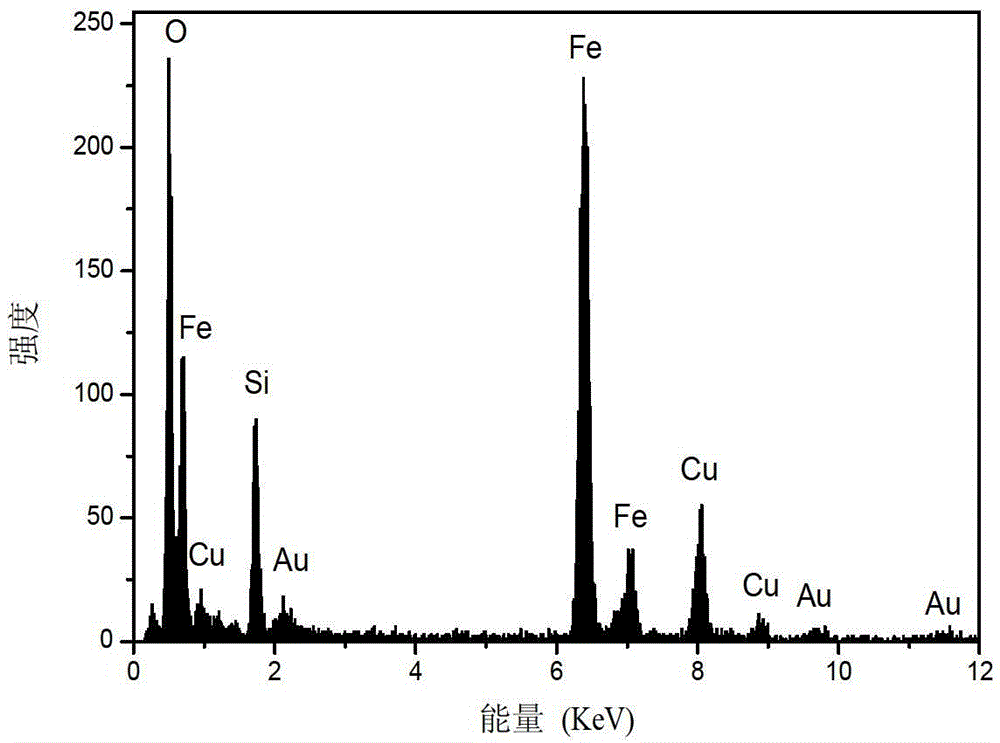

The invention discloses a magnetic gold nanoparticle composite material, and a preparation method and application thereof. The preparation method comprises the following steps: synthesizing ferroferric oxide magnetic microspheres, adding tetraethoxyl silicon to implement hydrolysis and polymerization on the magnetic microsphere surfaces, adding N-(2-aminoethyl)-3-aminopropyltrimethoxysilane to obtain surface-modified double-amino-group Fe3O4 / SiO2 magnetic microspheres, and compounding the surface-modified double-amino-group magnetic microspheres with gold nanoparticles. The chelation action of the double amino groups is utilized to adsorb the gold nanoparticles more firmly; and the material combines the surface selectivity of the gold nanoparticles and the superparamagnetism of the magnetic nanoparticles, can extract benzopyrene in water, and can implement quick and efficient separation.

Owner:TIANJIN UNIV

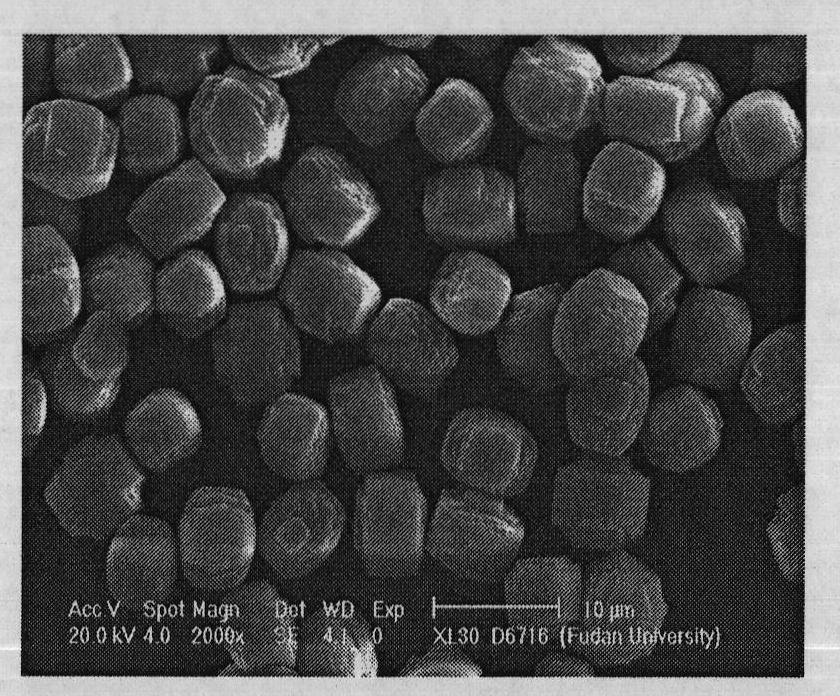

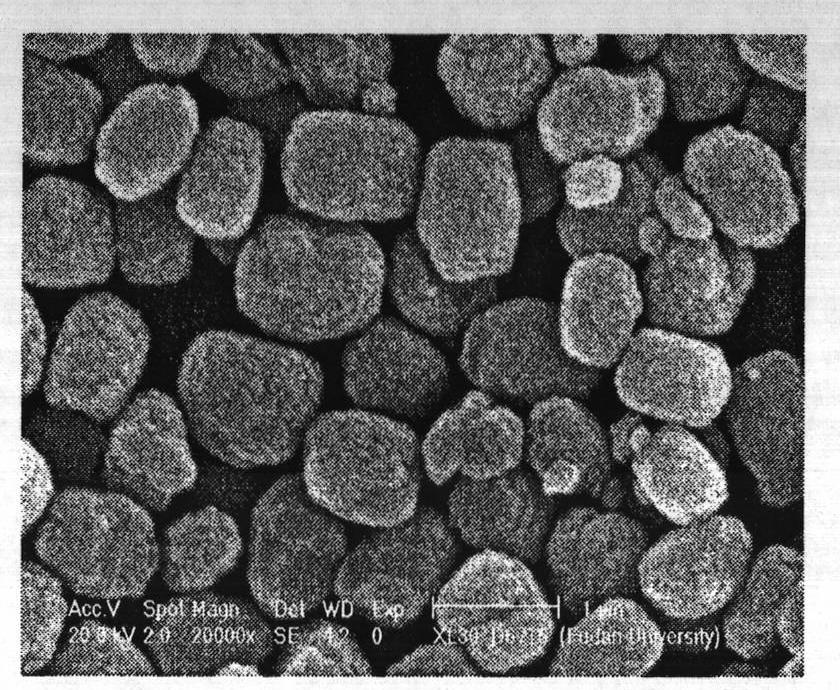

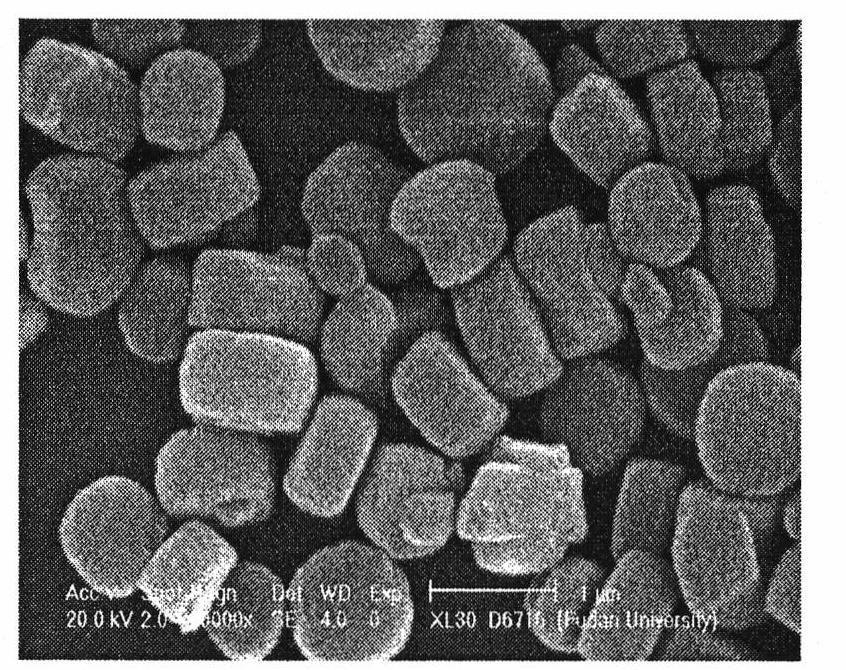

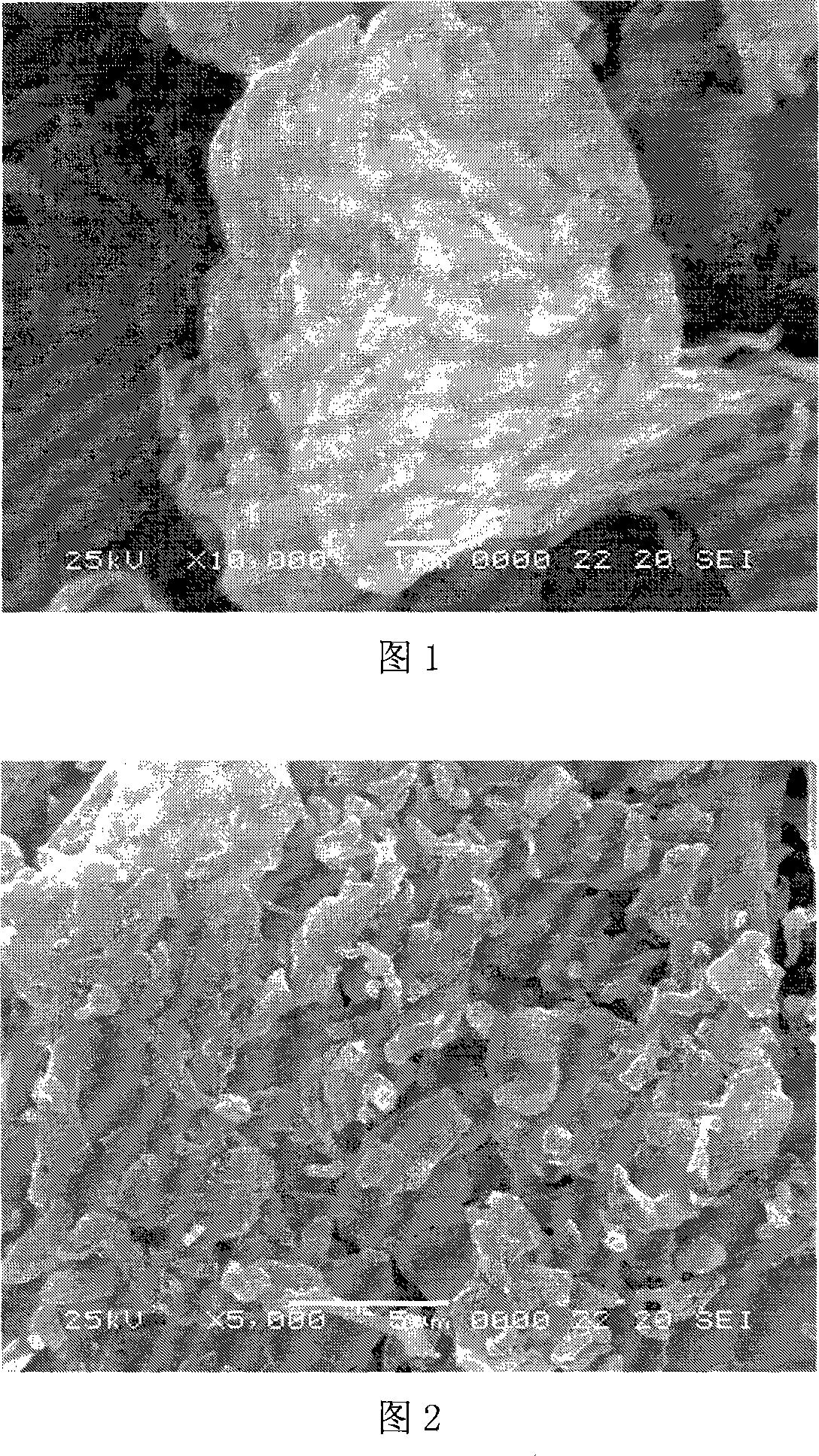

Method for adjusting surface hole diameter of ZSM-5 molecular sieve by surface dealuminizing and compensating silicon

InactiveCN101857243ASmall surface pore sizeMaintain skeleton structurePentasil aluminosilicate zeolitePore diameterFluosilicates

The invention belongs to the technical field of zeolite molecular sieves, in particular to a method for adjusting a surface hole diameter of a ZSM-5 molecular sieve by surface dealuminizing and compensating silicon. The invention accurately controls the surface hole diameter of the molecular sieve by using the treating measure of dealuminizing and compensating silicon on the ZSM-5 zeolite molecular sieve with ammonium fluosilicate solution. An ultrathin layer enriched with silicon is formed on the surface of the ZSM-5 zeolite molecular sieve treated by the method so that the hole caliber on the surface of the molecular sieve is shrunk. The ZSM-5 zeolite molecular sieves with different hole caliber shrinkage level can be selectively obtained by changing different treating conditions. The SM-5 zeolite molecular sieves modified by the method can be used for absorbing a mixture of three isomerides of P-, M-and O-Xylene.

Owner:FUDAN UNIV

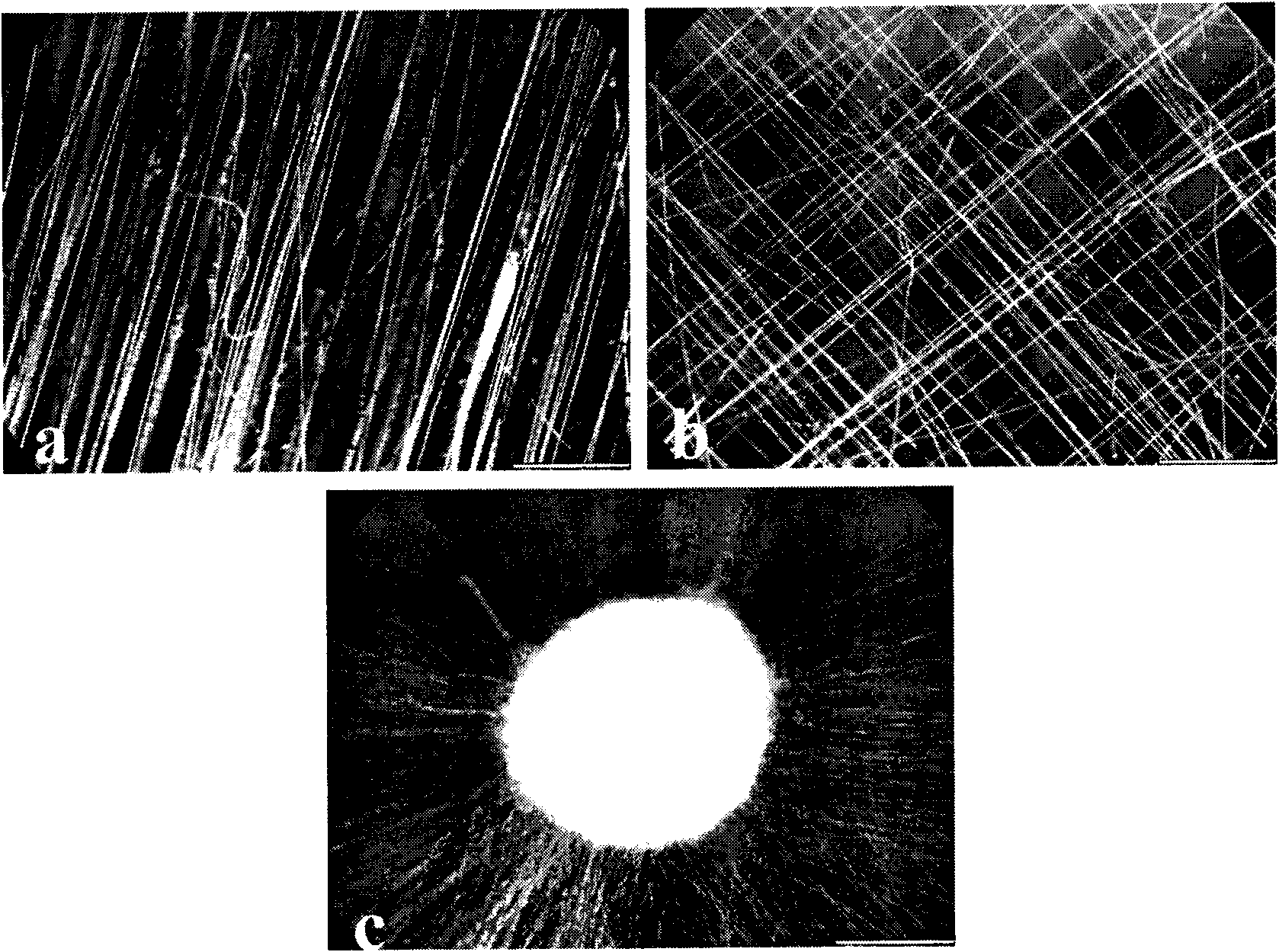

Method for preparing sheet-like microcrystal cellulose and modification processing method

InactiveCN101070352AMaintain physical propertiesMaintain mechanical propertiesAcetic acidDispersed media

This invention relates to preparation method of a flakiness microcrystalline cellulose, as well as its surface reshaping method. The process: in water disperse medium, take reaction with sulfuric acid to gain flakiness microcrystalline cellulose, then surface by acetic acid esterification or SAA absorption modifing, repass wash, filter , dryness, gain the product. The mass ratio of water and cellulose is 3 to 25:1, sulfuric acid volumetric concentration for 30 to 80%, temperature for 10 - to 85 deg, time for 5 to 120 minutes. The mass ratio of acetic ester modifier or SAA and microcrystalline cellulose is 0.1 to 5: 100. The modifier not only keep the favorable physics and mechanical property of cellulose, but also improve dispersibility, greatly advance consistency with high molecular material, broaden the application area.

Owner:LUDONG UNIVERSITY +1

Method for preparing flaky nano copper powder

The invention discloses a method for preparing flaky nano copper powder, comprising the following steps: compounding a copper salt aqueous solution with a surfactant to obtain a mixed solution A, wherein the water in the copper salt aqueous solution and the surfactant form a surfactant compound system; (2) compounding a reducing agent aqueous solution with the surfactant which is the same as that used in step (1) to obtain a mixed solution B, wherein the water in the reducing agent aqueous solution and the surfactant form the surfactant compound system; (3) mixing the mixed solution B obtained in step (2) and the mixed solution A obtained in step (1) by stirring at the temperature of 20 DEG C to 80 DEG C, and reacting completely with stirring; and (4) carrying out solid and liquid separation on the product, washing the solid, and carrying out vacuum drying to obtain the flaky nano copper powder. The method of the invention has mild condition, simple process, short production period, low equipment investment and low preparation cost, and is easy to realize industrial production. The prepared flaky nano copper powder has consistent appearance, uniform size and good dispersibility.

Owner:尊领科技集团有限公司 +1

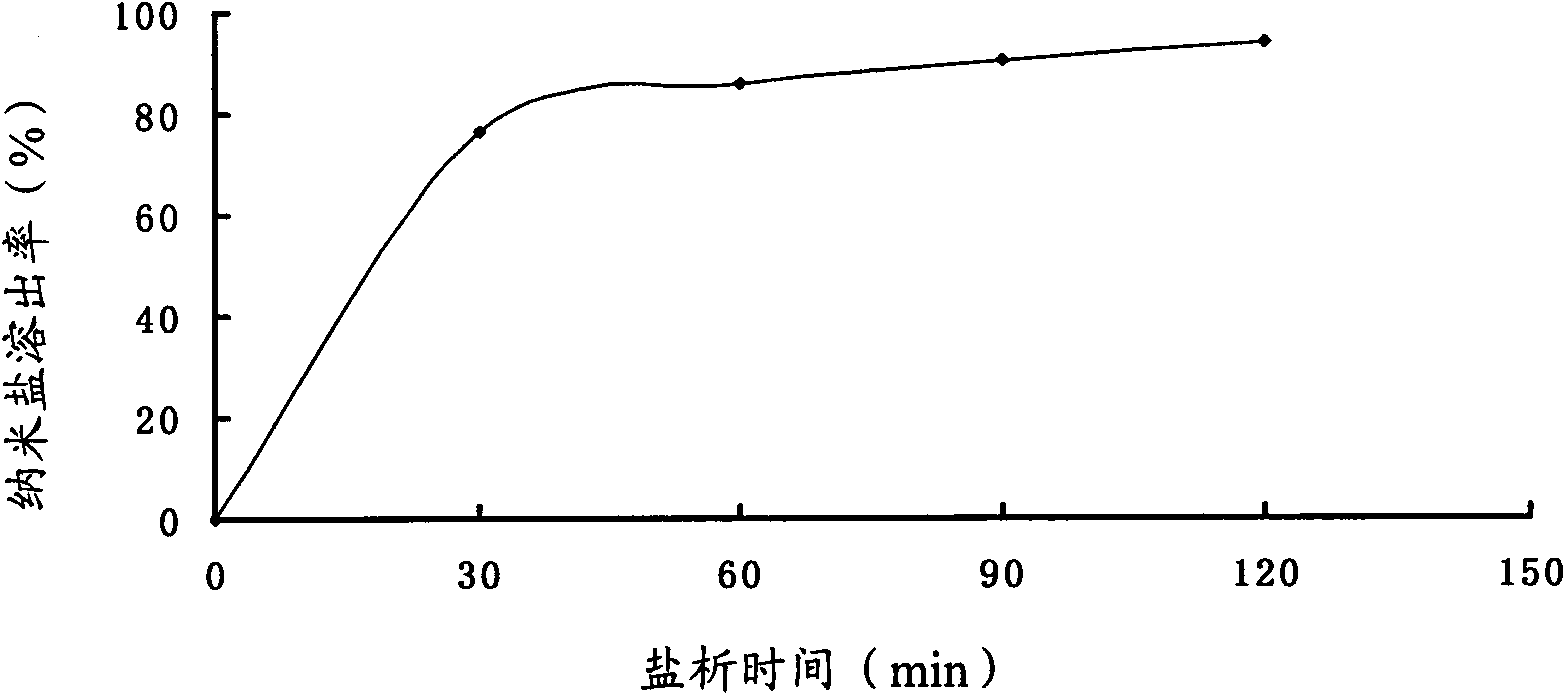

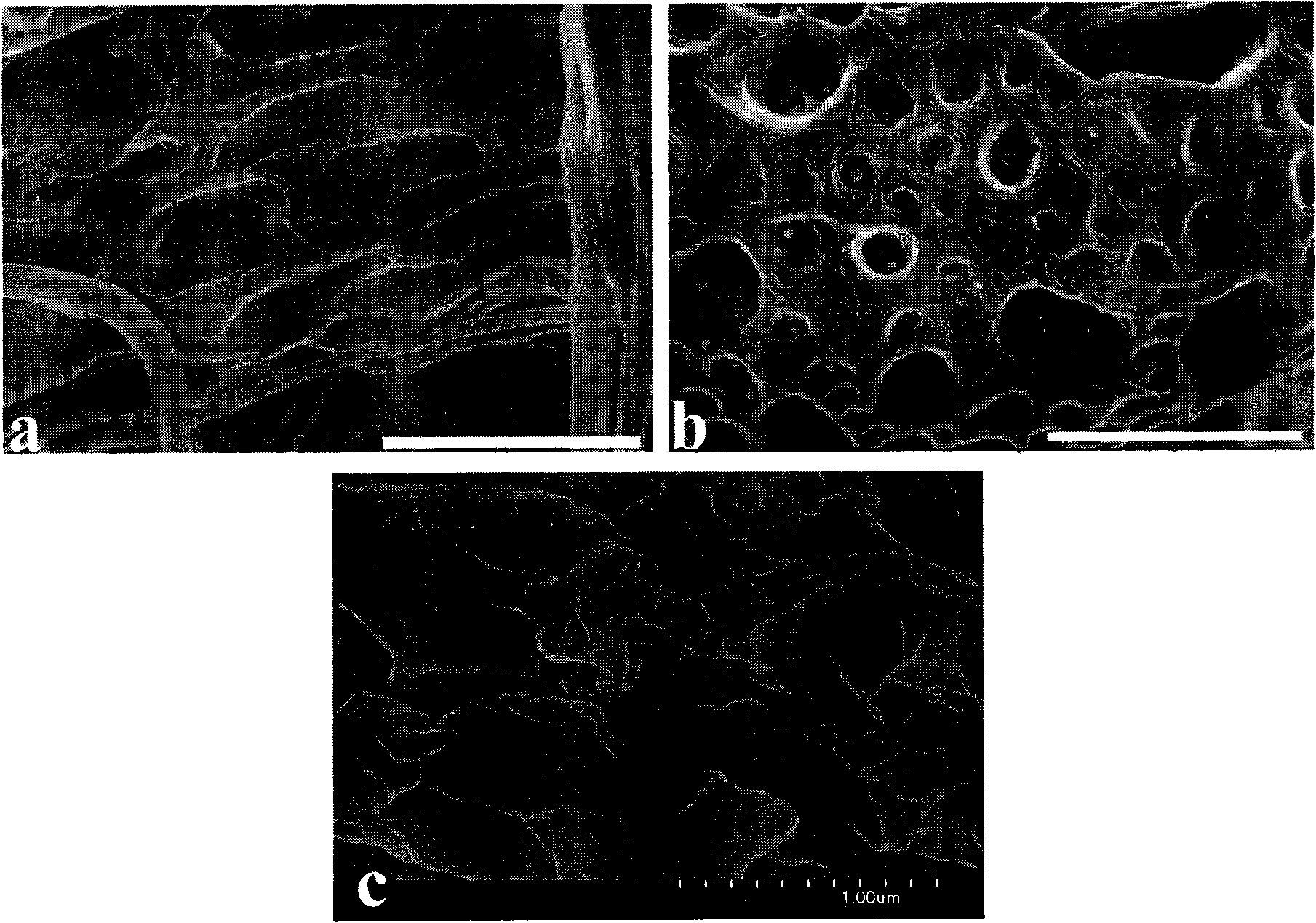

Preparation of porosity electrospun fiber

InactiveCN101586256AChange apertureChange surface roughnessArtificial filament physical treatmentElectro-spinningFiberTissue repair

The invention discloses a preparation method of porosity electrospun fiber, suspending nano salt uniformly into polymer solution and proceeding electrospinning to obtain polymer / nano salt composite electrospun fiber, then using elution solution of the nano salt to proceed salt out, removing the nano salt and producing holes to obtain the porosity electrospun fiber. The method is provided with simple operation, low cost and less environmental pollution which is suitable for industrial production; the obtained porosity electrospun fiber has good shape, and can change pore diameter and surface roughness of electrospun fiber conveniently by changing particle diameter and dosage of nano salt, which can be used for preparing medicine molecular vehicle, tissue engineering stand, tissue repair replacement etc. The invention has wide application foreground.

Owner:JIANGSU CHANGJIYONG BIOTECH CO LTD

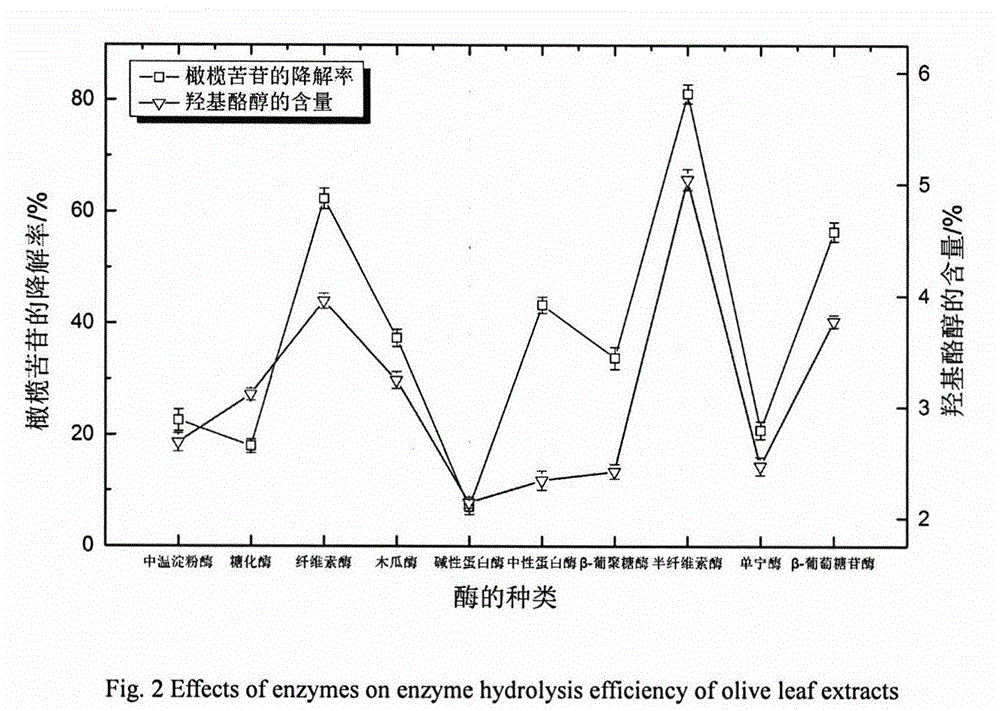

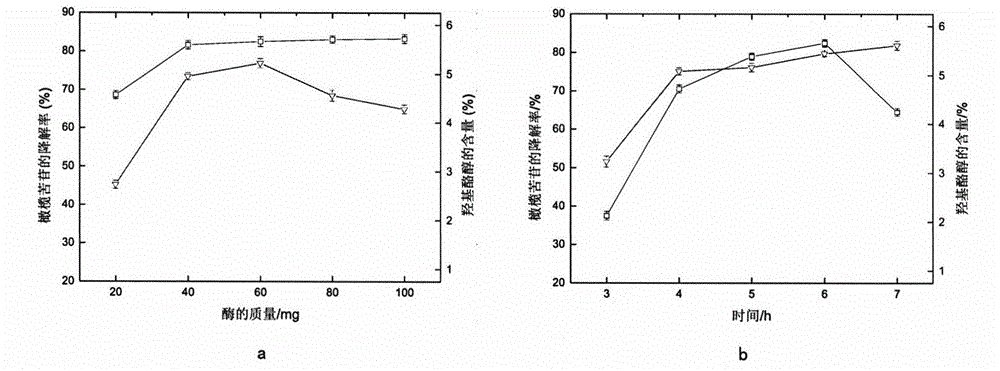

Method of using crude extract of olive leaf oleuropein to prepare hydroxytyrosol

ActiveCN104926615AReduce usageMild method conditionsOrganic chemistryOrganic compound preparationHydroxytyrosolOlive leaf

The invention discloses a method of using crude extract of olive leaf oleuropein to prepare hydroxytyrosol. Compared with acid hydrolysis and alkali hydrolysis, the enzymolysis process for crude extract of olive leaf oleuropein is mild in method condition, and consumption of acid and alkali catalysts is reduced in the whole process. Hemicellulase is selected from ten enzymes as an enzyme best in oleuropein degrading effect by taking oleuropein degrading rate and hydroxytyrosol content as indexes, optimal process conditions include 60 DEG C of temperature, 5.5 of pH value, 40mg of enzyme amount and 6h of time, obtained HT content is 6.07%, and OE degrading rate is 85.28%.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

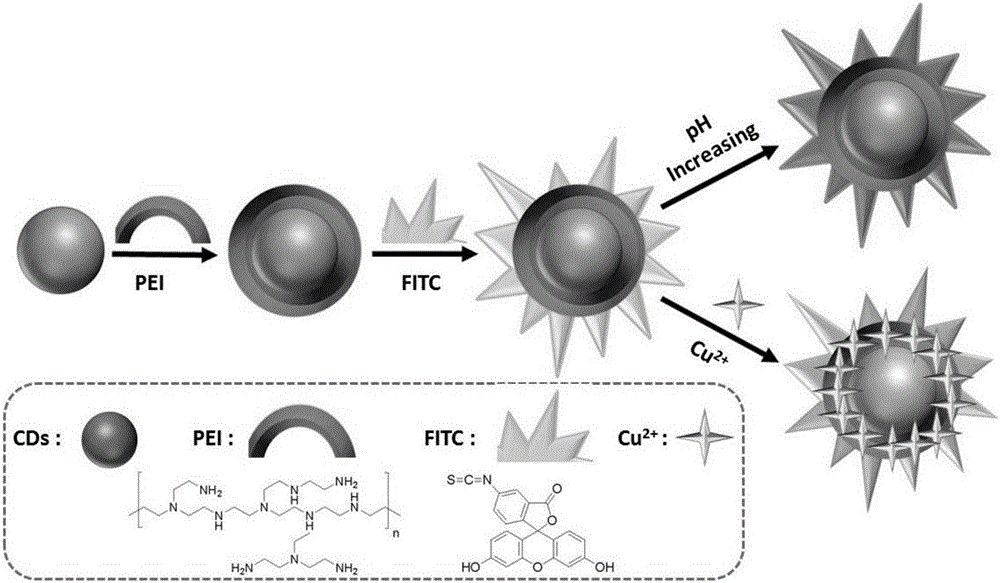

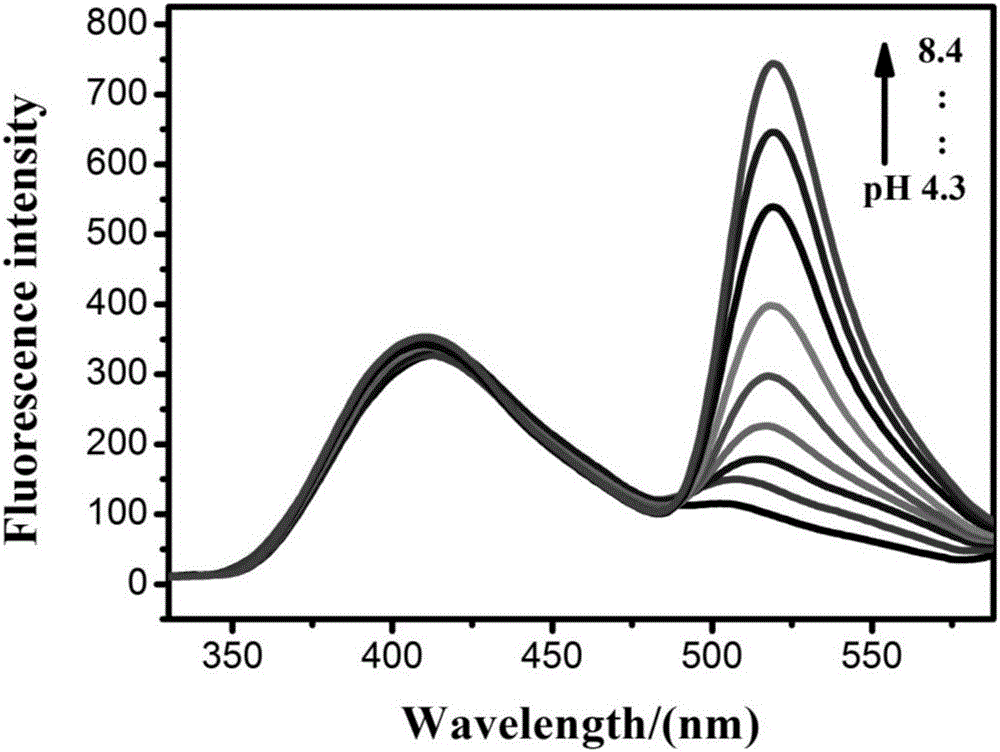

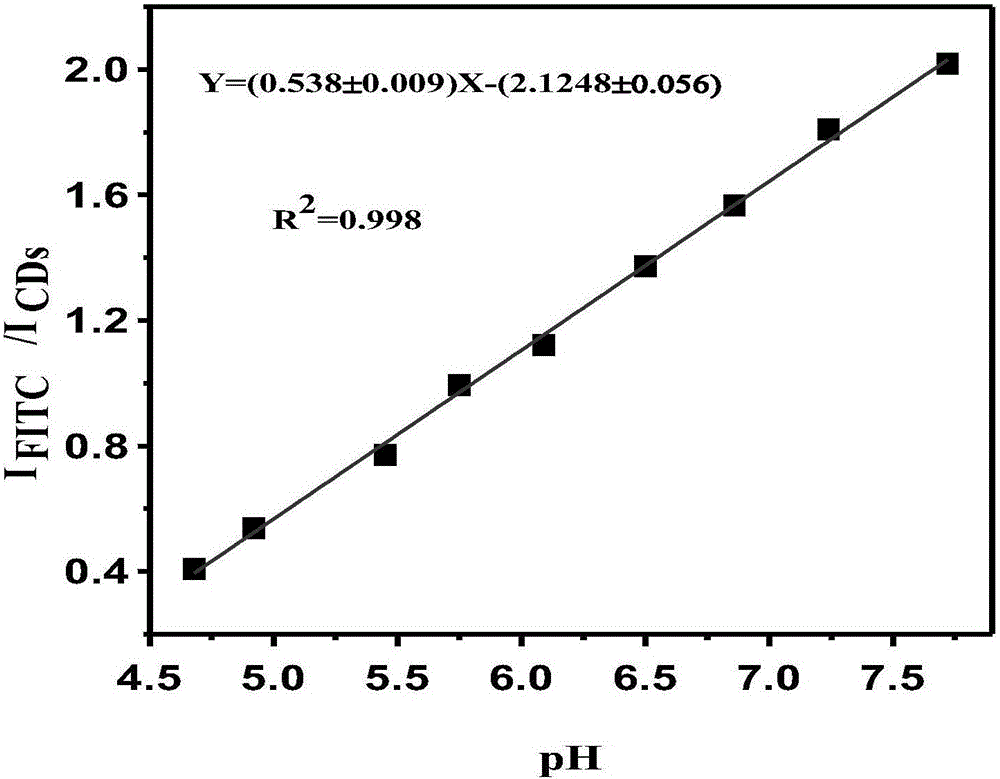

Application of PEI modified carbon dot-FITC compound as rate fluorescent pH probe and Cu2+ fluorescent probe

ActiveCN106085410AExcellent optical propertiesHigh quantum yieldFluorescence/phosphorescenceLuminescent compositionsModified carbonResponsivity

The invention discloses application of a PEI modified carbon dot-FITC compound as a rate fluorescent pH probe and a Cu2+ fluorescent probe. Cherry tomatoes are used as raw materials, carbon dots with fluorescence insensitive to pH changes are prepared through hydro-thermal synthesis, then CDs are modified with PEI, amidogen on PEI react with isothiocyanic acid radicals on FITC molecules, and the compound is formed. The responsivity of fluorescence of FITC in the compound to the pH changes is high, and a rate probe based on CDs and FITC fluorescence is used for pH detection; amidogen on PEI and Cu2+ are subjected to coordination, so that the fluorescence intensity of CDs and FITC is reduced along with increase of the concentration of Cu2+ in a solution, and Cu2+ detection is achieved. According to the constructed fluorescent probe, selected materials are novel, the advantages of being high in sensitivity, good in selectivity, easy to operate, wide in linear range, low in detecting limit and the like are achieved, and the constructed fluorescent probe can be used for efficient detection of the pH and Cu2+ in the aqueous solution and a biological sample.

Owner:QINGDAO UNIV

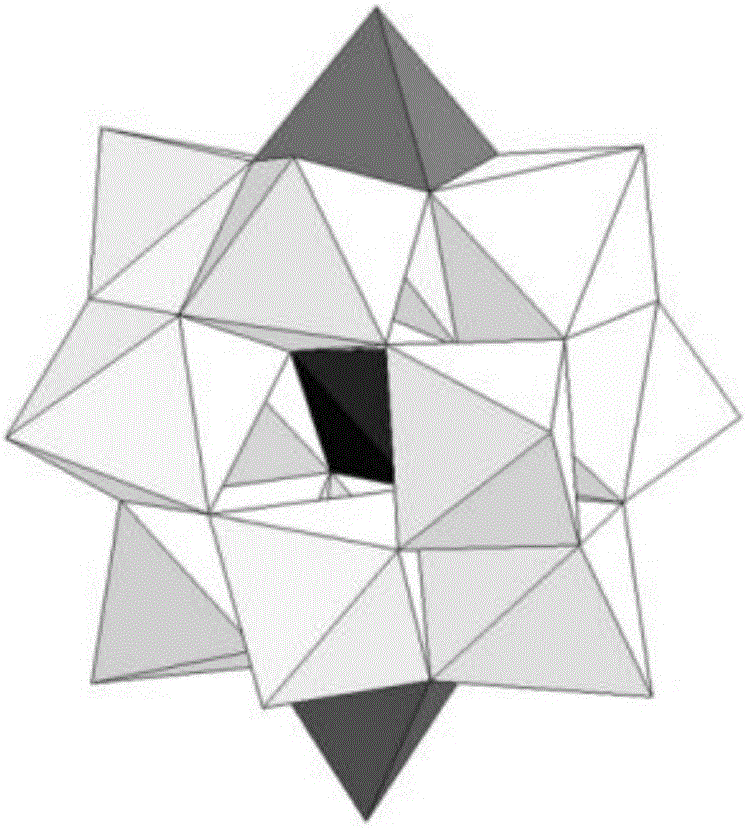

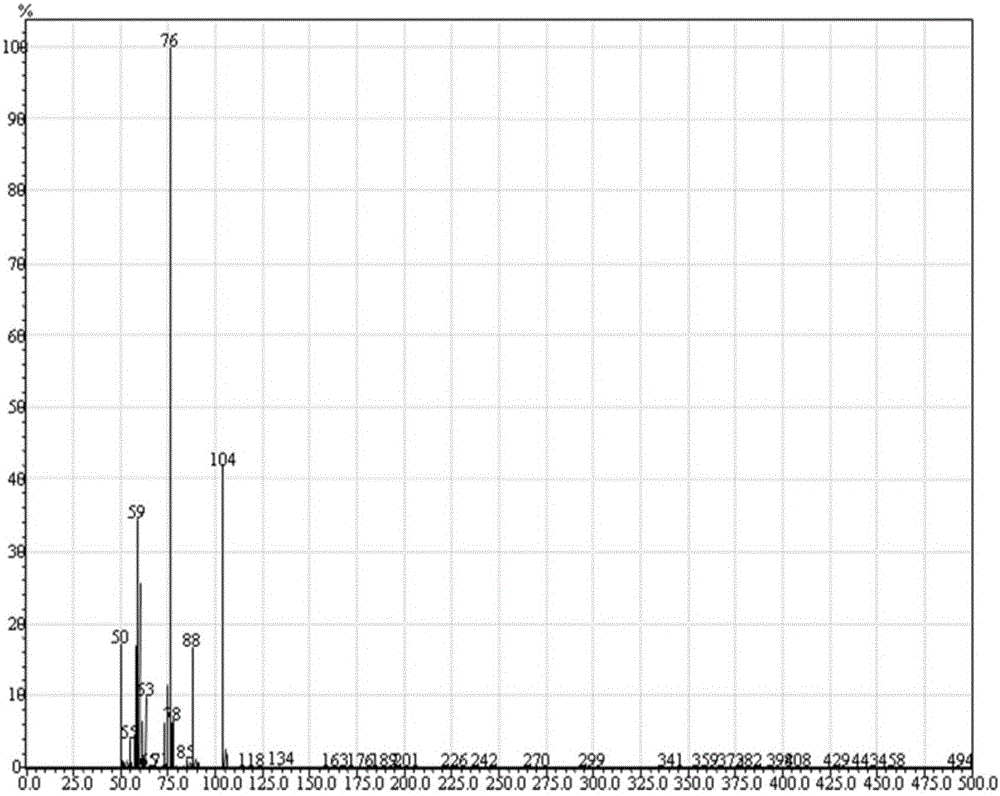

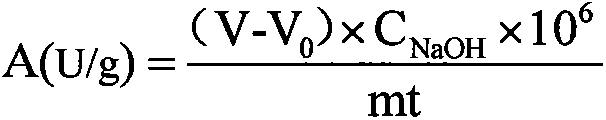

Synthetic method for imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde compounds

The invention discloses a novel synthetic method for 3-formyl-imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde, and effective application of the method into synthesis of Necopidem and Saripidem. According to the invention, a 3-formyl-imidazole[1,2-a]pyridine system is established by using a cheap and low toxic Cu-catalyed O2 activated intramolecular olefin under dehydrogenation ammoxidation; conditions for the method are mild, reaction substrates are easily available, a catalytic system is simple, operation is simple, tolerance of functional groups is good, and the method is economical and effective and has very important scientific values and realistic significance.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI

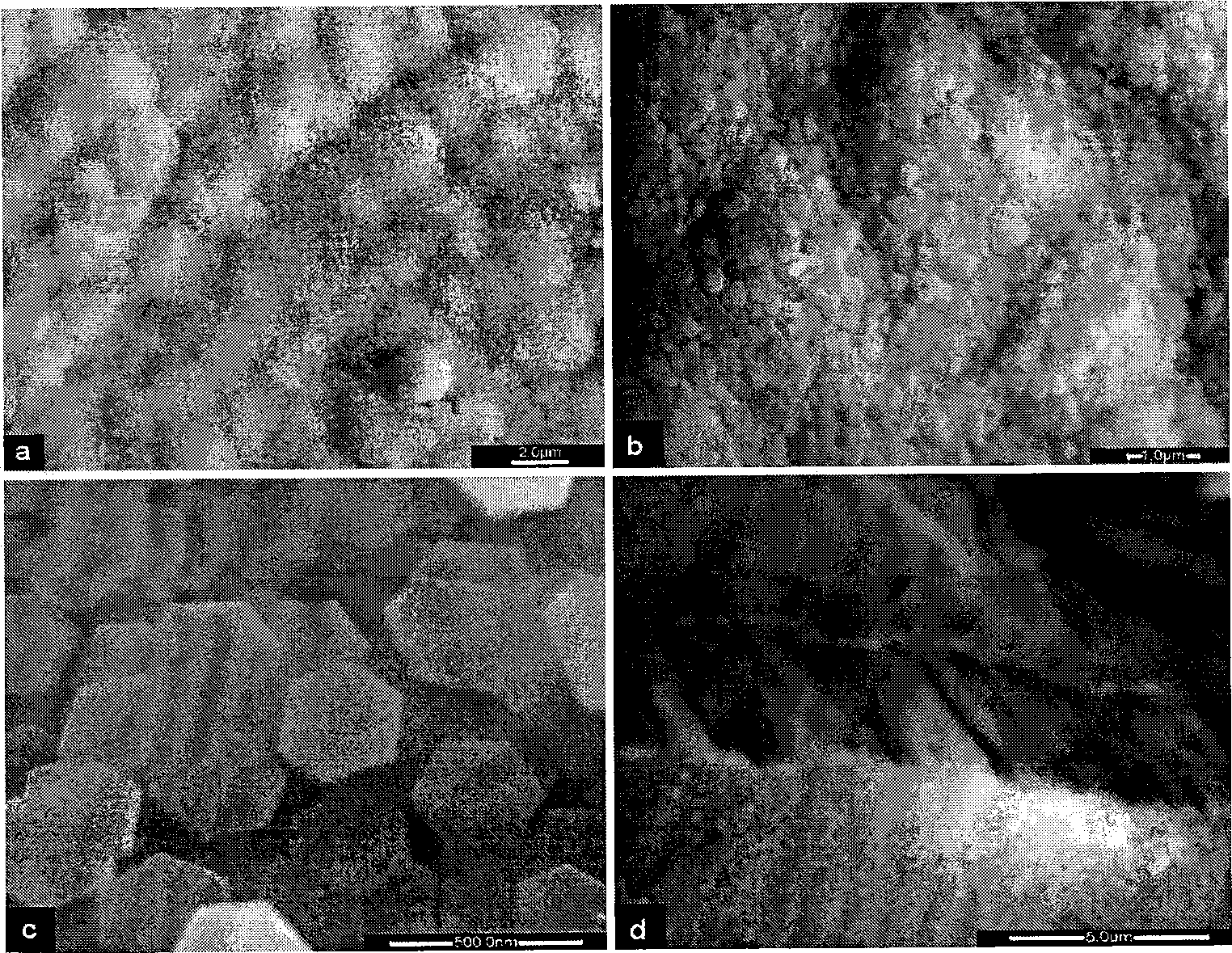

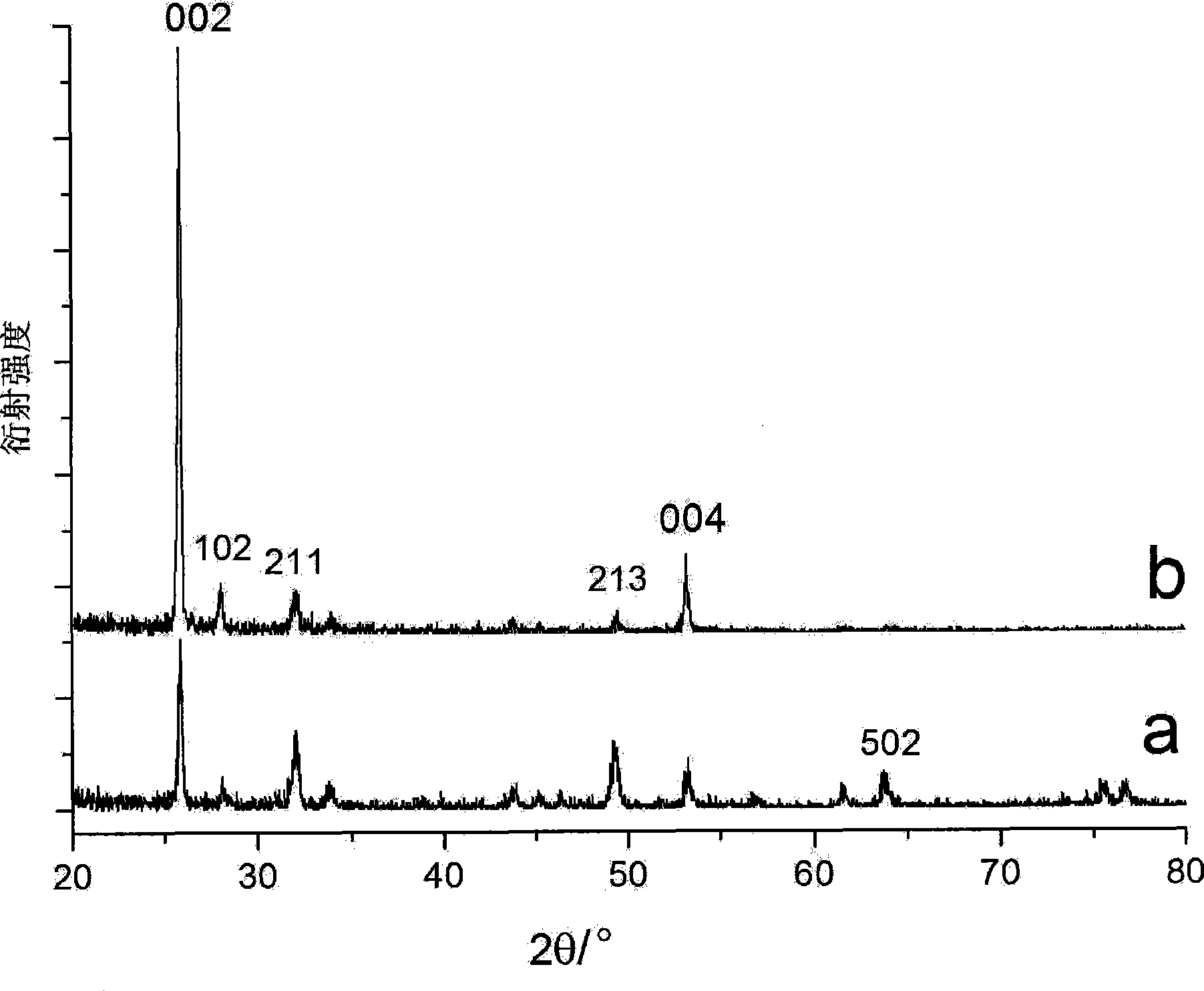

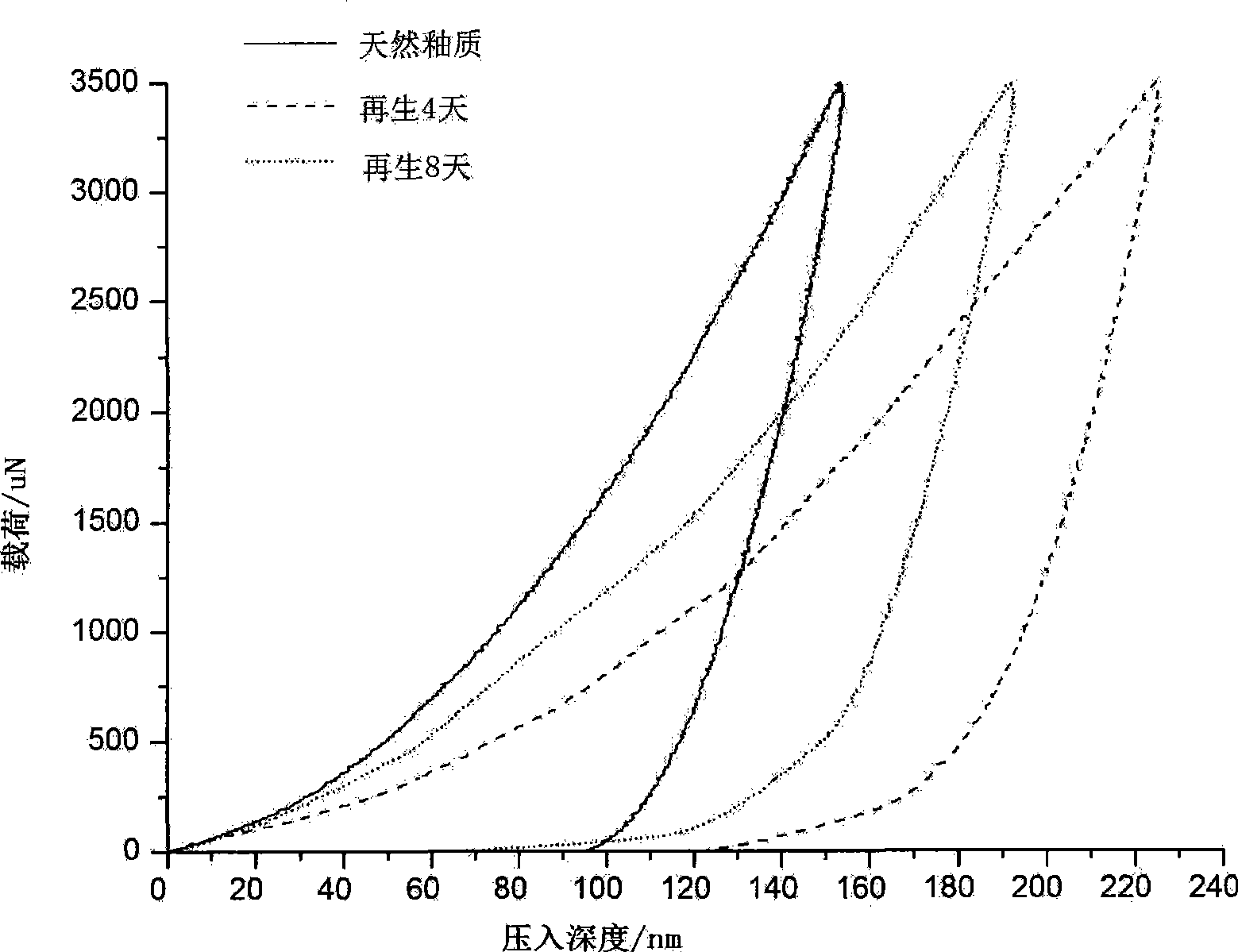

Method for preparing dental prosthetic material

InactiveCN101444454AMild conditionsSimple processImpression capsDentistry preparationsPhosphoric acidFissure sealant material

The invention discloses a method for preparing a dental prosthetic material. The method comprises the following steps: 1) an enamel is soaked with a phosphoric acid solution or a blend solution of hydrogen peroxide and phosphoric acid for treatment; and 2) the enamel in the step 1) is laid in an HEDTA-Ca-P solution, and a fluorine ion solution is added into the HEDTA-Ca-P solution so that the enamel covered with the prosthetic material is obtained after the reaction. The method for preparing the dental prosthetic material is characterized in that the conditions are mild, the process is simple, the raw materials are cheap, the method has the clinical application value, the prior dental prosthetic material prepared is hopefully replaced by the dental prosthetic material prepared to repair dental caries or enamel damage caused by other dental diseases, and the dental prosthetic material can be also as taken as a pit and fissure sealant material used for preventing dental caries.

Owner:PEKING UNIV

Method for catalyzing, oxidizing and degrading 2-chloroethyl ethyl sulfide through multi-niobium-vanadium-oxygen clusters

InactiveCN105879289AImprove conversion rateLow toxicityMetal/metal-oxides/metal-hydroxide catalystsNiobiumCatalytic oxidation

The invention discloses a method for catalyzing, oxidizing and degrading 2-chloroethyl ethyl sulfide through multi-niobium-vanadium-oxygen clusters and belongs to the field of catalytic chemistry. The method includes the steps that the 2-chloroethyl ethyl sulfide, a vanadium-cap type multi-niobium-vanadium-oxygen cluster catalyzing agent or a mixed multi-niobium-vanadium-oxygen cluster catalyzing agent and absolute methanol are added to a reaction vessel to be fully dissolved, a H2O2 aqueous solution is added dropwise, a reaction is conducted for a period of time under the stirring condition, and catalyzing, oxidizing and degrading of the 2-chloroethyl ethyl sulfide are completed. The conversion efficiency and product selectivity of the 2-chloroethyl ethyl sulfide are high, and the used multi-niobium-vanadium-oxygen cluster catalyzing agent can be used continuously; and furthermore, the conditions in the method are gentle, and the reaction can be conducted at the normal temperature under the normal pressure.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

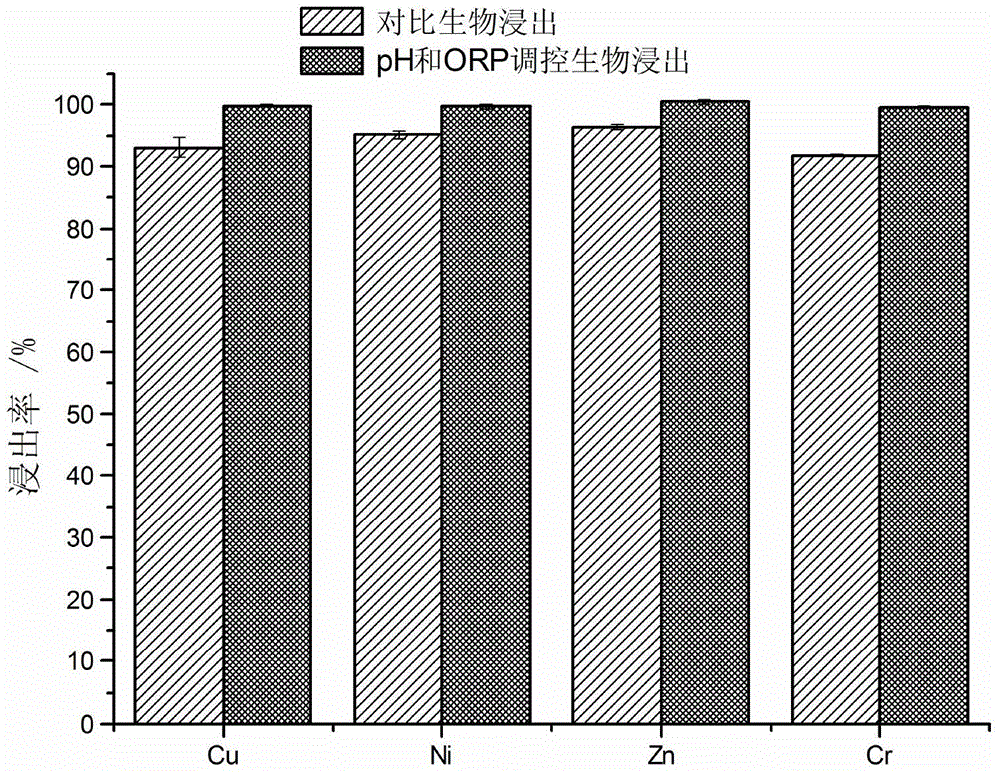

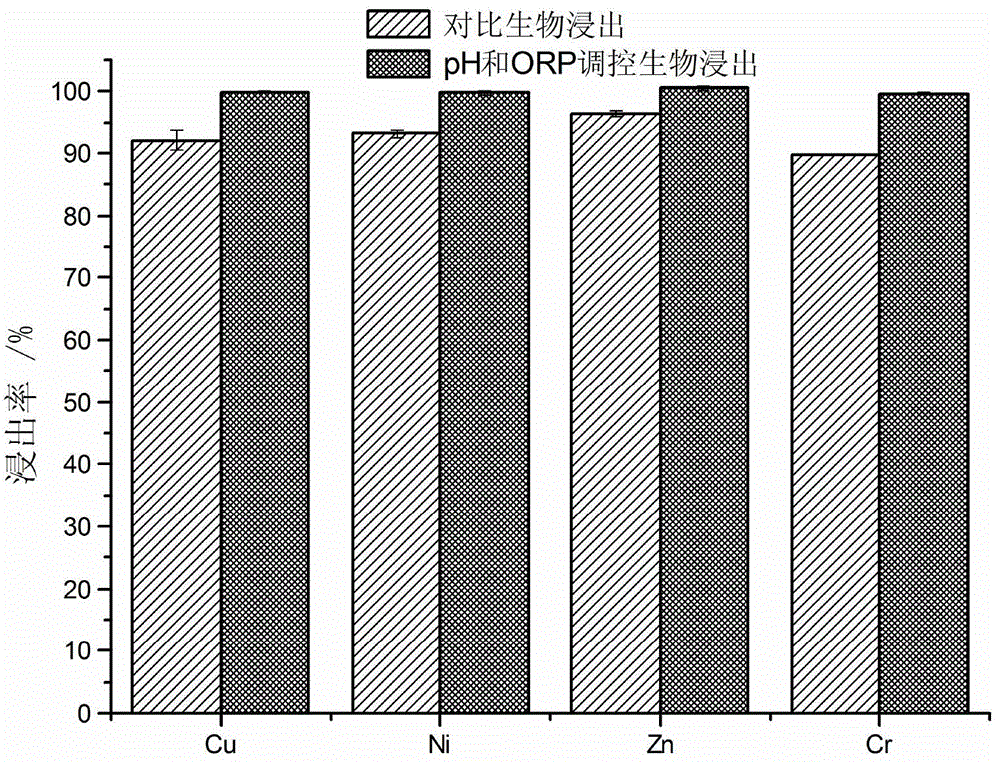

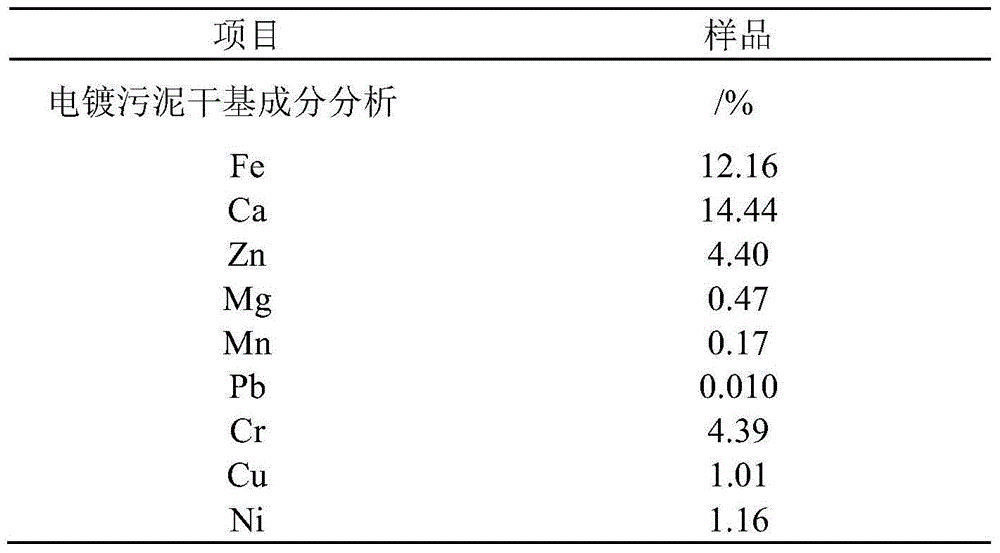

Method for biologically leaching heavy metal from heavy metal-contained waste based on pH and potential co-regulation

ActiveCN104862474AAvoid interactionEfficient DissolutionProcess efficiency improvementCo-regulationSludge

The invention discloses a method for biologically leaching heavy metal from a heavy metal-contained waste based on pH and potential co-regulation. The method comprises the following steps: in a process of leaching out the heavy metal-contained waste by an acidophilic iron oxide microbial agent, the pH value of the leaching system is controlled within 1.0-4.0 in the whole process; meanwhile, an oxidizing agent is combined with a reducing agent to regulate the redox potential of the leaching system, so that the redox potential of the leaching system is controlled within 420-650 mV; the pH value of the leaching system is gradually increased phase by phase in the leaching process; the redox potential of the leaching system is gradually increased phase by phase; the total leaching time is within 8 hours; and finally, the efficient leaching of the heavy metal from the heavy metal-contained waste by the acidophilic iron oxide microbial agent is realized. The method can accelerate biologic leaching of metal from sludge to shorten the leaching time and to reduce the acid consumption, and can greatly improve the biologic leaching efficiency.

Owner:厦门资生环保科技有限公司

Preparation method of novel organic modified sepiolite and application of organic modified sepiolite

ActiveCN106861641ASimple ingredientsLow costOther chemical processesDrilling compositionEngineeringOil phase

The invention discloses a preparation method of novel organic modified sepiolite. The method comprises the following steps of first carrying out purification on sepiolite raw ore, and then carrying out modification by adopting a cationic modifier and an anionic modifier, so as to obtain the organic modified sepiolite, wherein, based on 10 parts by weight of purified sepiolite, the use level of the cationic modifier is 1 to 2.5 parts by weight; the molar weight of the adopted anionic modifier is equal to that of the cationic modifier. The method provided by the invention has the advantages that conditions are mild and not harsh, and the method is easy to realize, and is also easy for large-scale production and application; the obtained organic modified sepiolite has favorable dispersity, favorable thixotropy and high viscosity in an organic system (oil phase); moreover, the obtained organic modified sepiolite has high temperature resistance, that is, has structural stability in a high-temperature organic system (oil phase), and meets the use requirement of oil-based drilling fluid.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

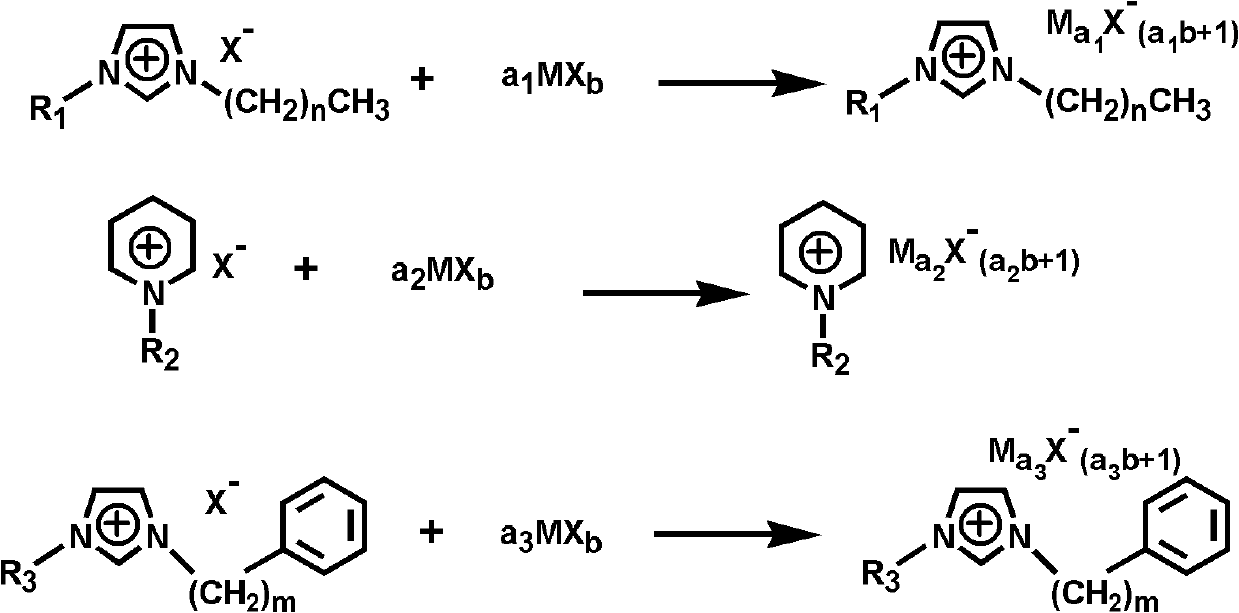

Metal base ionic liquid catalyst and method for degrading polyethylene glycol terephthalate by using the same

InactiveCN102513153AReduce dosageMild method conditionsPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterPolyethylene glycol

The invention discloses a metal base ionic liquid catalyst and a method for degrading polyethylene glycol terephthalate by using the same, relating to an ionic liquid catalyst and a method for degrading polyester materials. The invention solves the technical problems that the existing ionic liquid catalysts for degrading PET have large dosage and long reaction time. The metal base ionic liquid catalyst is a combination of one or several of the followings. The method comprises the following steps: weighing raw materials and adding in a reactor, heating up to 90-210 DEG C and stirring for 0.5-5 h to complete the degradation of polyethylene glycol terephthalate. The method has the advantages of mild reaction conditions, small catalyst dosage, quick reaction speed, easy recovery, and no secondary pollution, wherein the PET conversion rate reaches 60-100 % in 0.5-5 h, and the monomer yield reaches 20-90 %. The invention can be used for degradation and reclamation of waste polyethylene glycol terephthalate.

Owner:HARBIN NORMAL UNIVERSITY

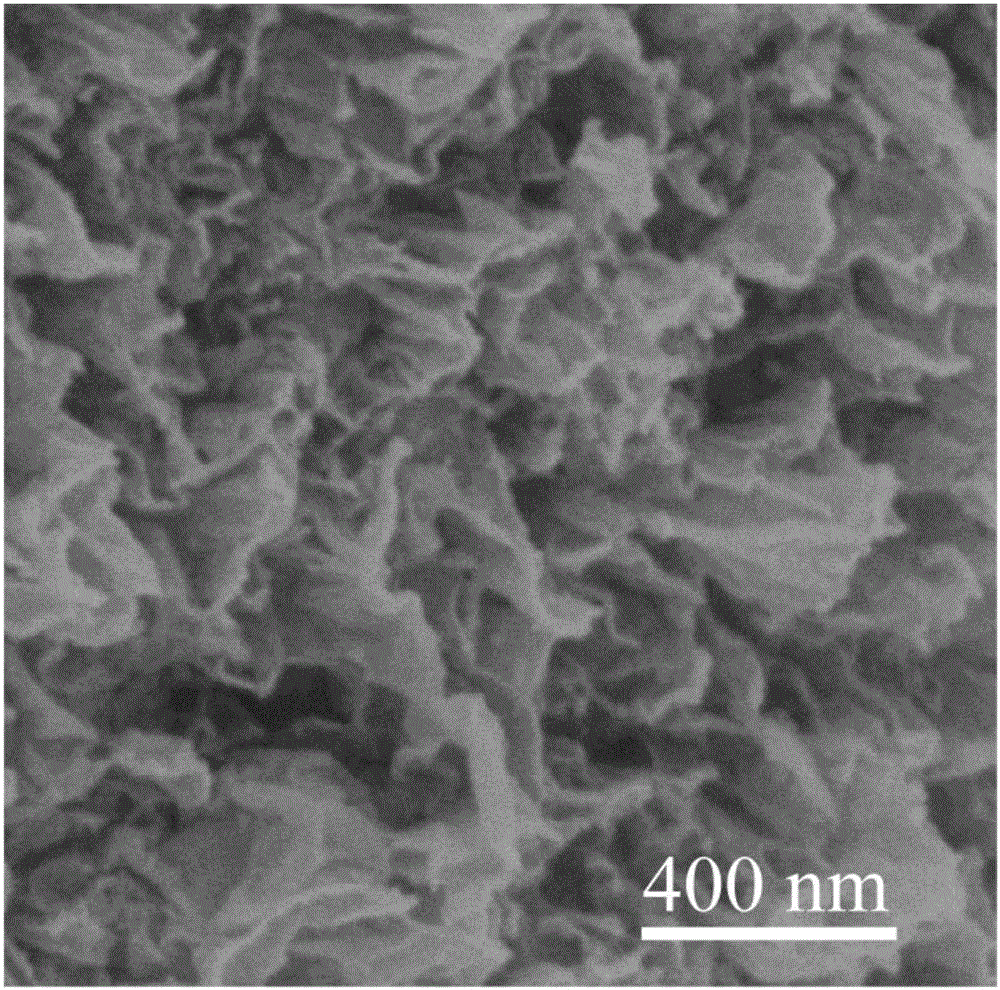

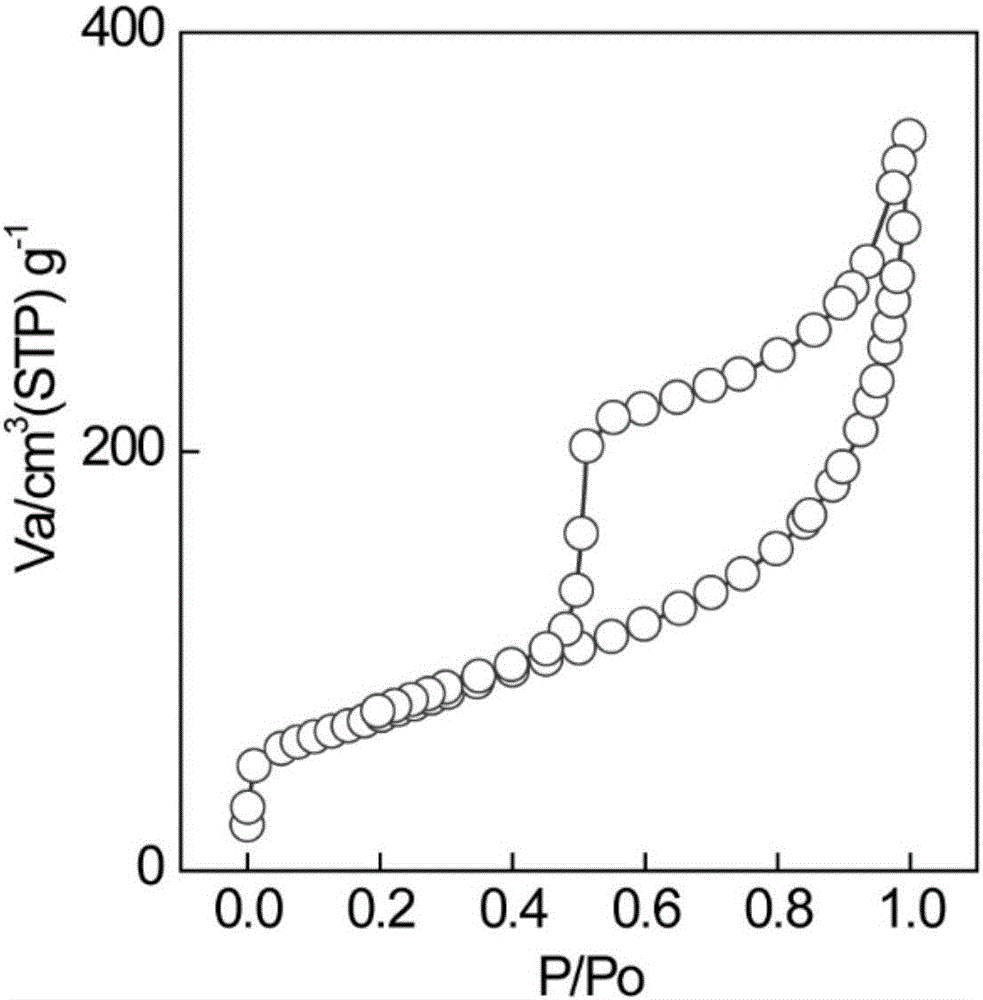

Graphene-based negative electrode material for lithium-ion battery

The invention belongs to the technical field of lithium-ion batteries, and particularly relates to a graphene-based negative electrode material for a lithium-ion battery. The negative electrode material is a three-dimensional porous graphene-non-carbon material composite electrode material and comprises three-dimensional porous graphene and a non-carbon material loaded on the three-dimensional porous graphene; and the negative electrode material has an abundant porous structure, the specific surface area is 170-400m<2> / g, the pore volume is 0.18-1.2cm<3> / g, the block density is 0.6-3.0g / cm<3>, and the volume sum of pores in the negative electrode material is 1.9-4 times of that of the non-carbon material. Compared with the prior art, the problem of volume expansion of a non-carbon active component in the material is solved; the density of the composite material is optimized; and the ion transmission property and electronic conductivity of the composite material are ensured. The material has the advantages of being novel in structure, good in conductivity, high in electrochemical lithium storage capacity and good in cycle performance; and meanwhile, the preparation method is simple, low in cost and suitable for industrialization.

Owner:TIANJIN UNIV

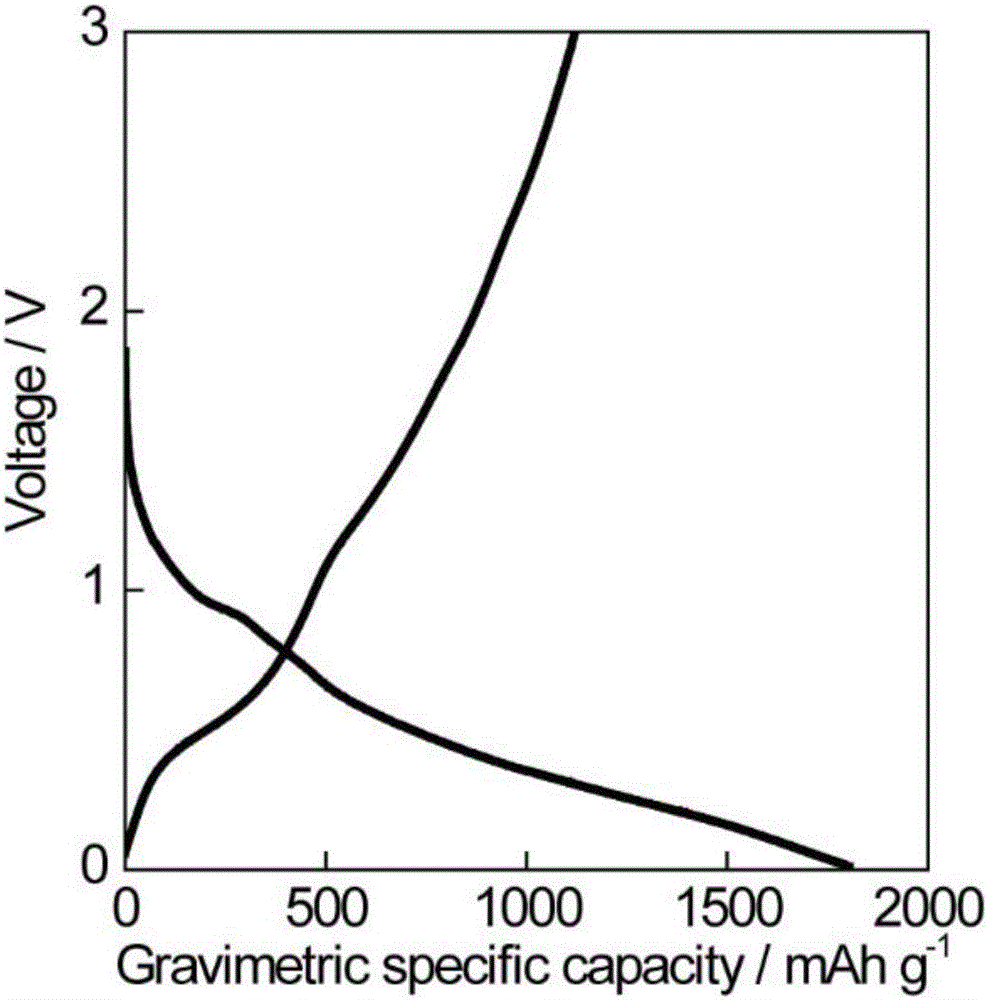

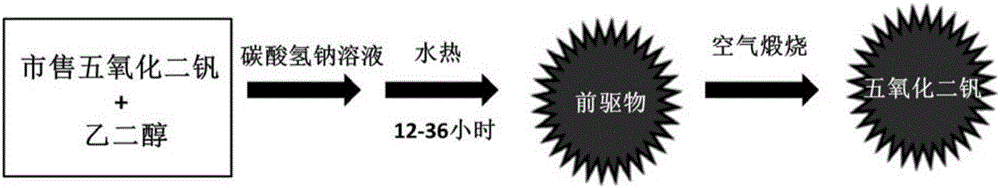

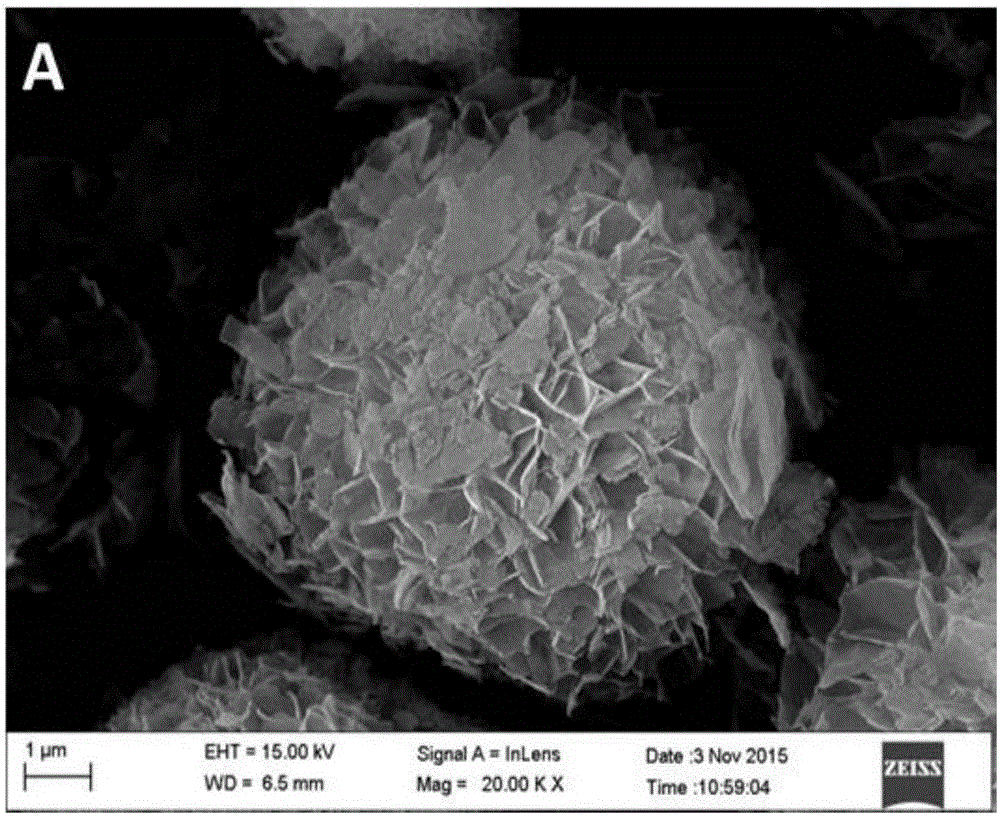

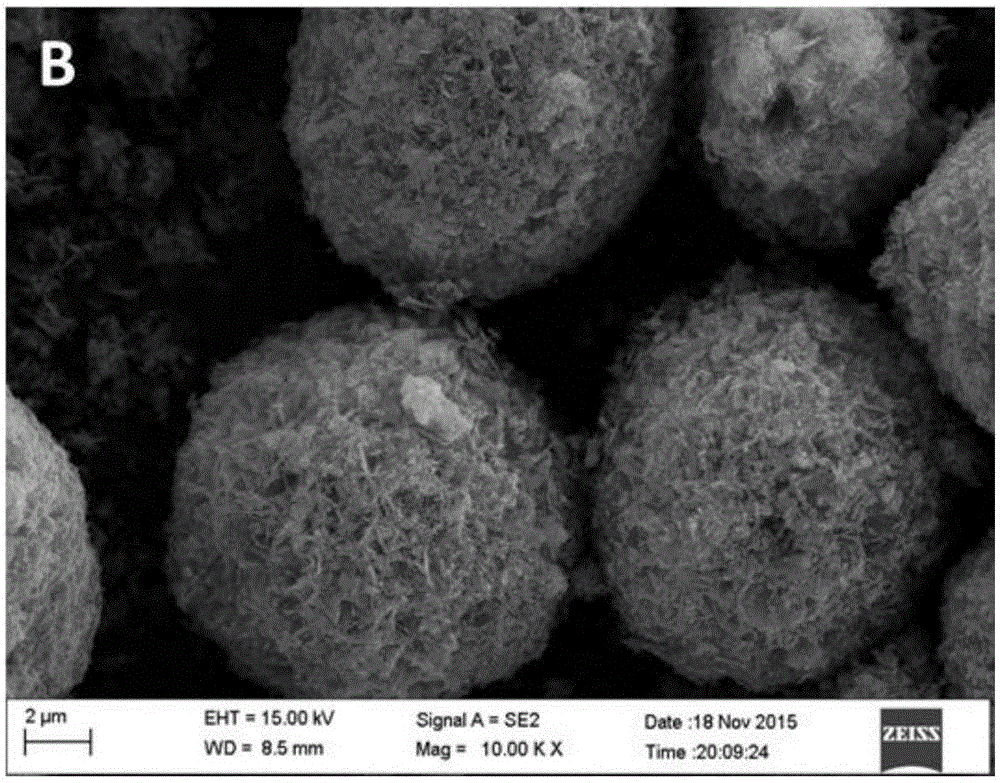

Vanadium pentoxide micro-nano particles and preparation method and application thereof

InactiveCN105948120AConvenient sourceLow costMaterial nanotechnologyVanadium oxidesAir atmosphereMicro nano

The invention provides micro-nano particles; the micro-nano particles are vanadium pentoxide micro-nano particles and are formed by self assembly of nano sheets. The invention also provides a preparation method of the micro-nano particles, wherein the method comprises the following steps: 1) adding vanadium pentoxide to ethylene glycol, stirring to mix evenly, and forming a suspension A; 2) adding a sodium bicarbonate solution to the suspension A to form a suspension B; 3) heating the suspension B, and then standing and cooling at room temperature, to obtain a precursor containing a black precipitate; 4) carrying out centrifugal separation of the mixed solution containing the precursor and formed in the step 3), washing, and drying, to obtain a flower-shaped vanadium oxide precursor formed by nanosheet self-assembling; and 5) calcining the precursor obtained in the step 4) in an air atmosphere to obtain the micro-nano particles. The invention also provides an application of the micro-nano particles in the fields of new energy resources, environmental detection, food and medicines.

Owner:NORTHEASTERN UNIV

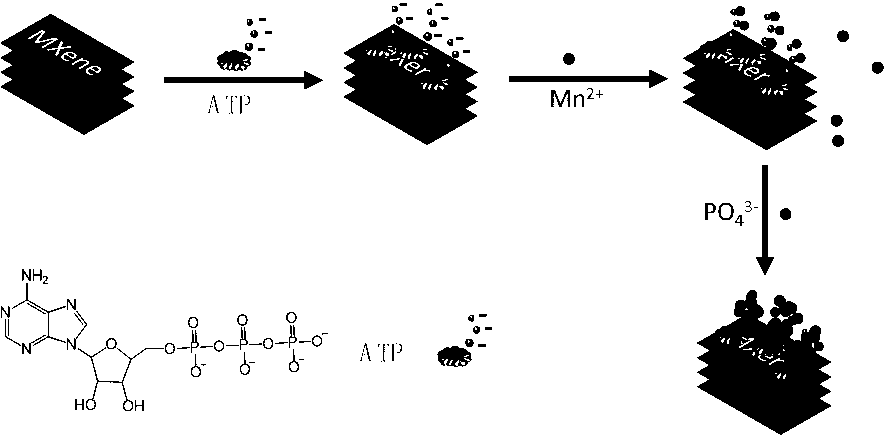

Preparation and application of Mxene-Mn3(PO4)2 composite electrode material

InactiveCN108614023AUniform porous structureHigh economic valueMaterial electrochemical variablesMedical diagnosisNanocomposite

The invention discloses preparation and application of an Mxene-Mn3(PO4)2 composite electrode material. The preparation is characterized in that two-dimensional Ti3C2 nanosheets are synthesized from aTi3AlC2 ceramic material as a raw material, and ATP (adenosine triphosphate) is used as a template to induce synthesis of Mn3(PO4)2 nanoparticles. The Ti3C2 / Mn3(PO4)2 nanocomposite synthesized with the method integrates good conductivity of Ti3C2 and biological mimetic enzyme activity of Mn3(PO4)2, and the composite material has excellent conductivity and catalytic performance by complementary advantages of the two raw materials, and is the excellent electrode material for preparing superoxide dismutase. The composite material can be used for constructing biosensors and has excellent application prospects in the fields of medical diagnosis, medical research and the like.

Owner:SOUTHWEST UNIVERSITY

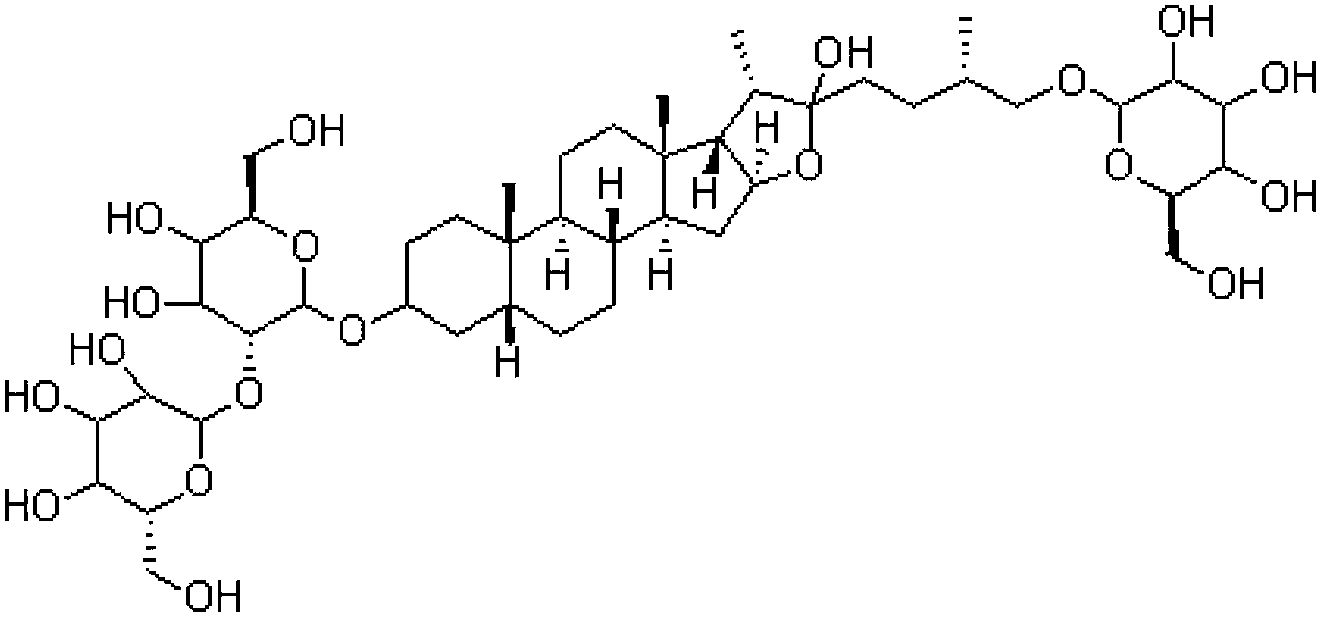

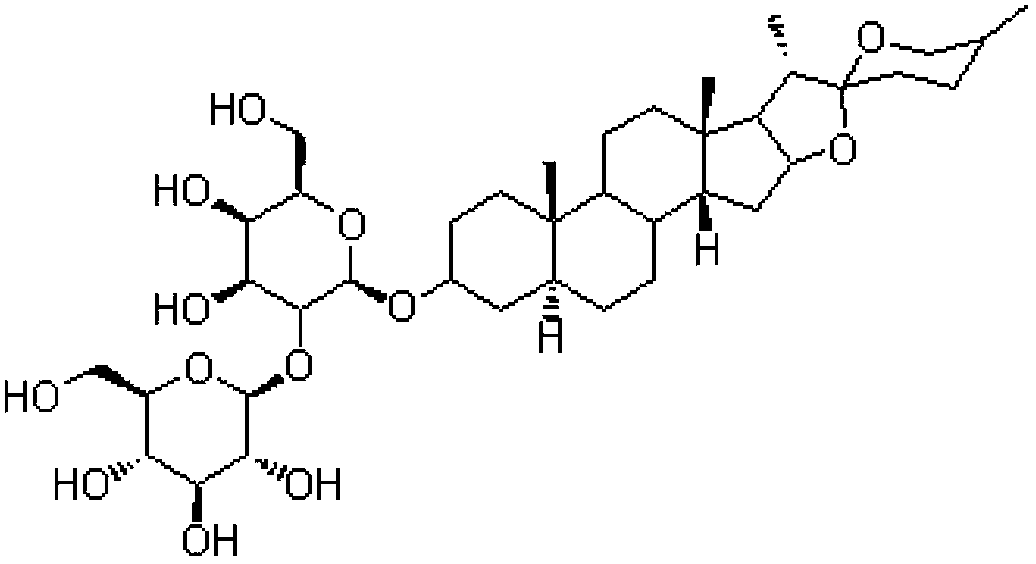

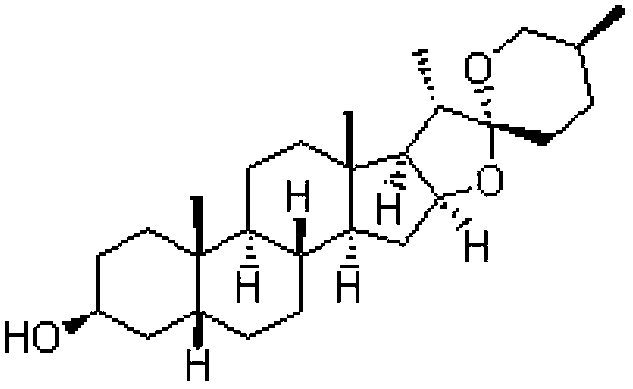

Preparation method of timosaponin A III

The invention discloses a preparation method of timosaponin A III. The method is used for preparing timosaponin A III by using commercially-available traditional Chinese medicine rhizoma anemarrhenae decoction slices or freshly collected rhizoma anemarrhenae roots and stems or fibrous roots as materials through a combined process of alcohol extraction, enzymolysis, extraction, resin and silicagel column chromatography, and crystallization. The purity of timosaponin A III prepared by the method disclosed by the invention is higher than 90%, therefore, the preparation method is suitable for largely preparing timosaponin A III.

Owner:SHANGHAI UNIV OF T C M

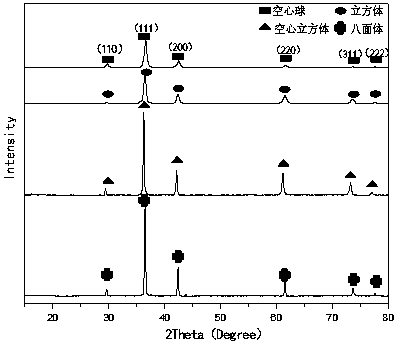

Preparation method of cubic cuprous oxide nano material

InactiveCN104030339AHigh purityMild method conditionsMaterial nanotechnologyCopper oxides/halidesBlue VitriolFluid phase

The invention discloses a preparation method of a cubic cuprous oxide nano material. The method is characterized by successfully obtaining the cubic cuprous oxide material by using blue vitriol as a copper source and glucose as a reducing agent and using a liquid phase reduction method and a hydrothermal method. The preparation method has the beneficial effects that the raw materials needed for preparation are rich, are low in costs and do not produce wastes; the preparation process is simple and has good repeatability; the prepared cubic cuprous oxide nano material is widely applied to photocatalysis, gas sensitive materials, antibacterial materials and the like.

Owner:ZHEJIANG SCI-TECH UNIV

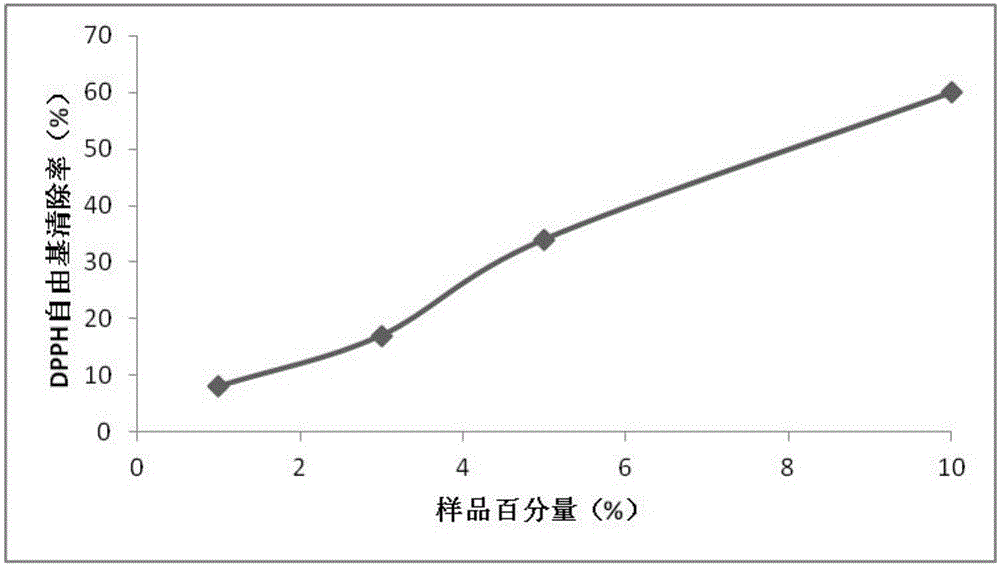

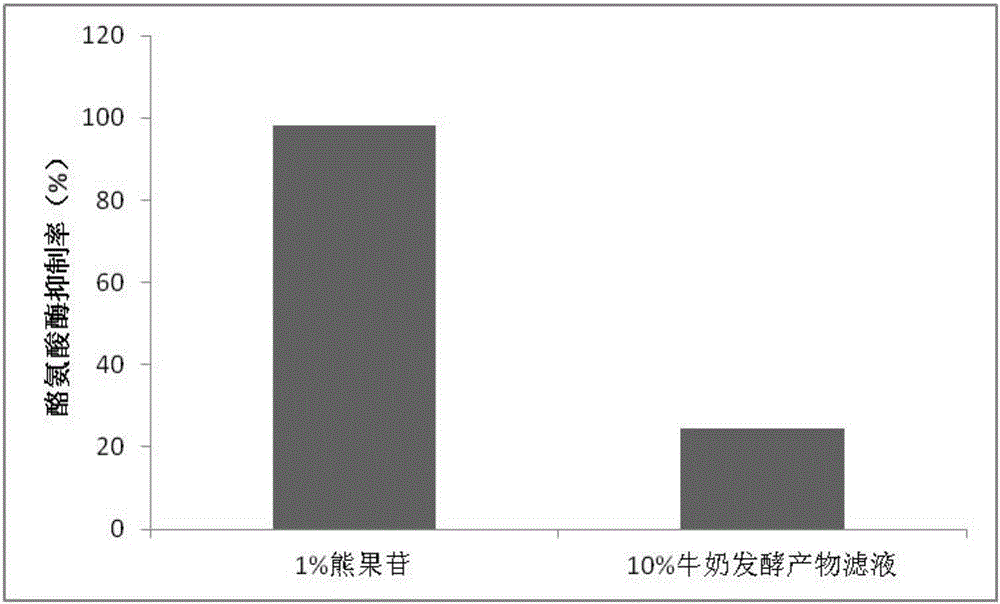

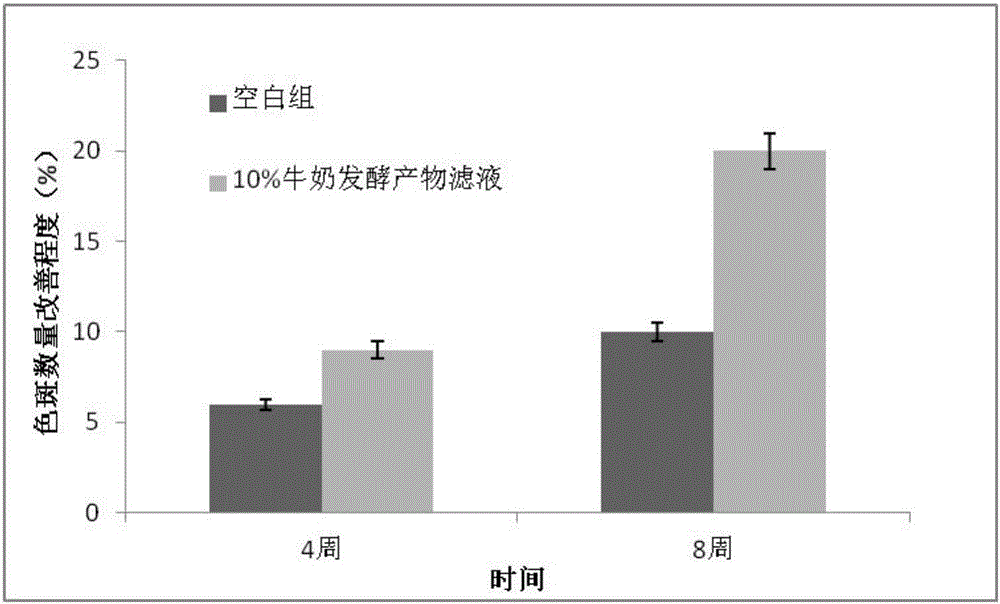

Milk fermented product filtrate as well as preparation method and application thereof

InactiveCN106309309ASimplify production stepsReduce manufacturing costCosmetic preparationsToilet preparationsAdditive ingredientBULK ACTIVE INGREDIENT

The invention relates to a milk fermented product filtrate as well as a preparation method and application thereof. The milk fermented product filtrate comprises active ingredients extracted after fermentation of a milk culture medium and probiotics, wherein the probiotics is a mixture of lactobacillus and bifidobacterium; and the dosage of the probiotics is 40-80g per ton. According to the invention, water and milk are proportionally mixed according to proportion to obtain the milk culture medium, then the probiotics is added into the milk culture medium for fermentation in specific conditions, and finally, the fermented product is treated to obtain the milk fermentation product filtrate. Without any chemical component, the milk fermented product filtrate can be directly used as cosmetics such as mask, essence and toner while causing zero load on skin; and moreover, the fermented ingredient contains micro-molecule polypeptide which is easily sufficiently absorbed by skin. In the invention, by adopting edible probiotics for fermentation, the milk fermented product filtrate is beneficial to skin health and avoids the pollution of enzymes, chemicals and the like; and moreover, the conditions are mild, the operation is easy, the production steps are simplified, the production cost is lowered, and industrial production is facilitated.

Owner:JIANGSU WECARE BIOTECHNOLOGY CO LTD

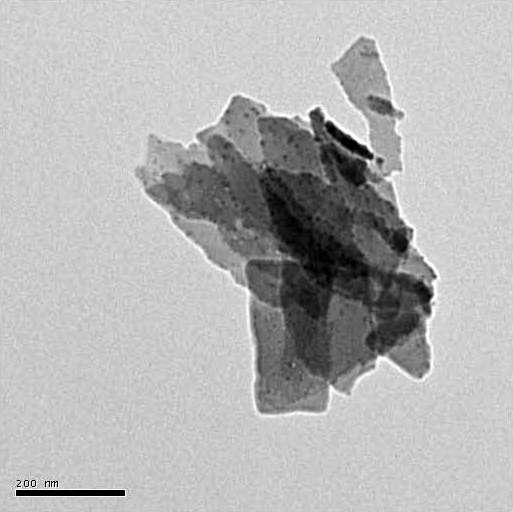

Magnetic composite microsphere as well as preparation method and application thereof

InactiveCN103354144ASettling fastMild method conditionsOrganic/organic-metallic materials magnetismMicroballoon preparationMagnetic compositeMicrosphere

The invention discloses a magnetic composite microsphere as well as a preparation method and an application thereof. The magnetic composite microsphere has an autologous active epoxy group with the content ranging from 0.1 mmol / g to 2.0 mmol / g, the diameter of the magnetic composite microsphere ranges from 50 nm to 150 nm, the magnetic composite microsphere is regularized, Fe3O4 nano particles are packaged in a network structure of a polymer, the content of Fe3O4 in the microsphere accounts for 20%-70%, and the specific saturation magnetization ranges from 20 emu / g to 60 emu / g. Simultaneously, the preparation method of the magnetic composite microsphere is provided, the method is mild in condition, convenient to operate and simple in device; and the prepared magnetic composite microsphere can covalently bind biomolecules through the autologous active epoxy group, can rapidly settle under the action of a magnetic field, and has high separation efficiency, low cost, simple process and industrialized application value.

Owner:NINGXIA UNIVERSITY

Method for preparing chitosan oligosaccharide by adopting cellulase spray-drying

The invention belongs to the field of an oligosaccharide preparation method, and particularly relates to a method for preparing chitosan oligosaccharide by adopting cellulase spray-drying. The methodfor preparing the cellulase spray-drying comprises the following steps: dissolving a chitosan in an acetic acid-sodium acetate buffering solution, preparing a chitosan solution, adding a cellulase solution into the chitosan solution to perform enzymolysis, after the enzymolysis, dialyzing filtrate by adopting a dialysis method, concentrating a dialysis solution, and spray-drying. The method for preparing the chitosan oligosaccharide by adopting the cellulase spray-drying is mild in condition, simple, rapid, short in preparation time, low in price of cellulase, easy in obtaining the cellulase and low in production cost, and the prepared chitosan oligosaccharide is uniform in molecular weight distribution and uniform and consistent in color.

Owner:GUANGDONG PHARMA UNIV

Method for changing solidifying crucible bottom layering manner in electron-beam polycrystalline silicon purification

InactiveCN106894084AReduced power to irradiate solidified cruciblesImprove qualityPolycrystalline material growthSingle crystal growth detailsCrucibleElectron

A method for changing solidifying crucible bottom layering manner in electron beam polycrystalline silicon purification belongs to the field of electron-beam melting and comprises the following steps: layering 3 Kg of polycrystalline silicon wafers (with thickness of 7-10 mm) at the bottom of a solidifying crucible, and layering 5 Kg of polycrystalline silicon fragments on the polycrystalline silicon wafers; preheating electron guns; gradually increasing the power of an electron gun for irradiating a smelting crucible to 250 KW and the power of an electron gun for irradiating the solidifying crucible to 50 KW, and melting silicon; increasing the power of the electron gun for irradiating the solidifying crucible to 200 KW, and melting silicon; turning off the electron gun for irradiating the smelting crucible, outpouring silicon liquid, and increasing the power of the electron gun for irradiating the solidifying crucible to 250 KW; increasing the power of the electron gun for irradiating the smelting crucible to 250 KW, and melting and smelting silicon; and turning off the electron gun for irradiating the smelting crucible, outpouring silicon liquid, turning on the electron gun, keeping the power at 250 KW for 10 min, keeping the power at 200 KW for 2 min, keeping the power at 150 KW for 3 min, keeping the power at 120 KW for 5 min, keeping the power at 100 KW for 7 min, keeping the power at 80 KW for 8 min, keeping the power at 50 KW for 12 min, keeping the power at 30 KW for 16 min, keeping the power at 20 KW for 20 min, decreasing the power to 0 KW, and reducing the electron beam for solidifying. The method disclosed by the invention can increase product yield, and reduce the energy consumption of electron beam polycrystalline silicon purification.

Owner:DALIAN UNIV OF TECH QINGDAO NEW ENERGY MATERIALS TECH RES INST CO LTD

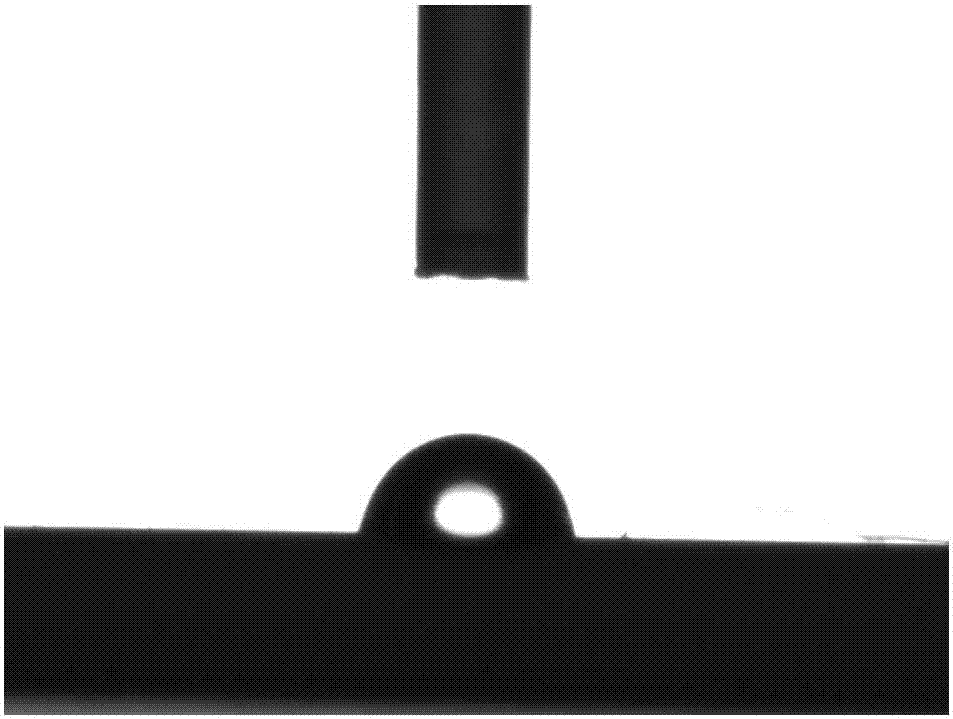

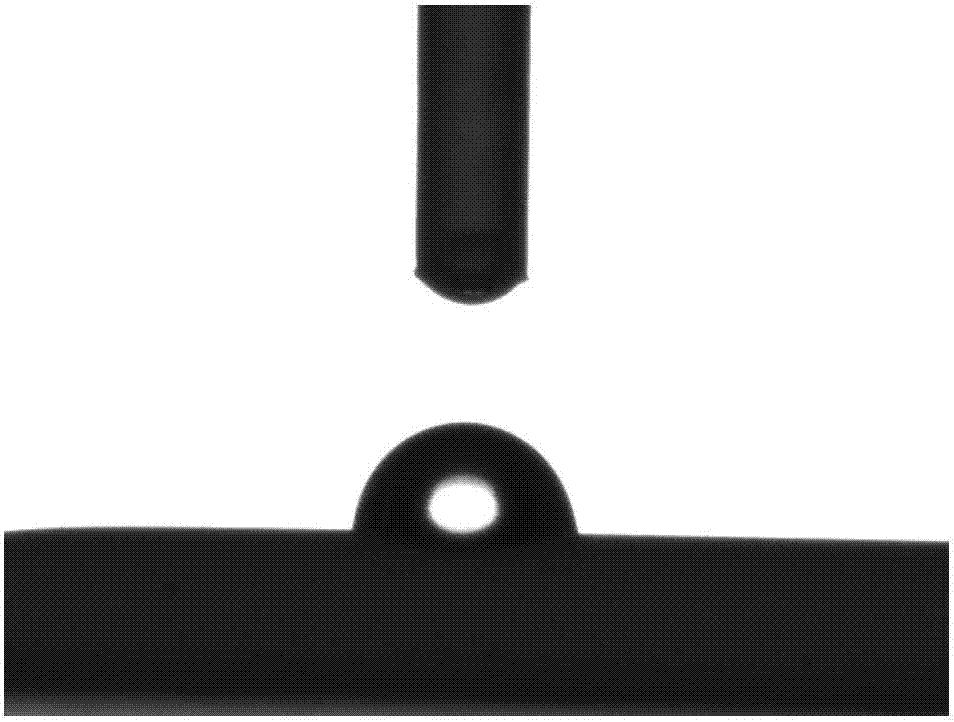

Surface hydrophilization modification method of polyvinylidene fluoride hollow fiber membrane

ActiveCN107998897AEasy to controlMild method conditionsMembranesSemi-permeable membranesFiberHydrophilization

The invention discloses a surface hydrophilization modification method of a polyvinylidene fluoride hollow fiber membrane, belongs to the field of materials, and discloses a method for performing hydrophilic modification on the surface of the polyvinylidene fluoride hollow fiber membrane by using an efficient click chemistry method. A hydrophilic group is introduced into the surface of the membrane to improve the anti-fouling performance of the surface of the membrane. The method is mild in condition and simple, and the process is easy to control. The method comprises the following specific steps: firstly, treating the membrane with strong alkali to generate an elimination reaction to remove a C-F bond, thus forming C=C double bonds; and then anchoring the hydrophilic group of a sulfhydrylcompound to the surface of the membrane by using the S-H bond and C=C double bonds in the sulfhydryl compound in an ultraviolet environment and under the action of a photoinitiator. The polyvinylidene fluoride membrane is low in surface energy and cannot form a hydrogen bond with water molecules; after the hydrophilic group is introduced into the surface of the membrane, the hydrophilicity and the pollution tolerance of the membrane are substantially improved.

Owner:BEIJING UNIV OF CHEM TECH

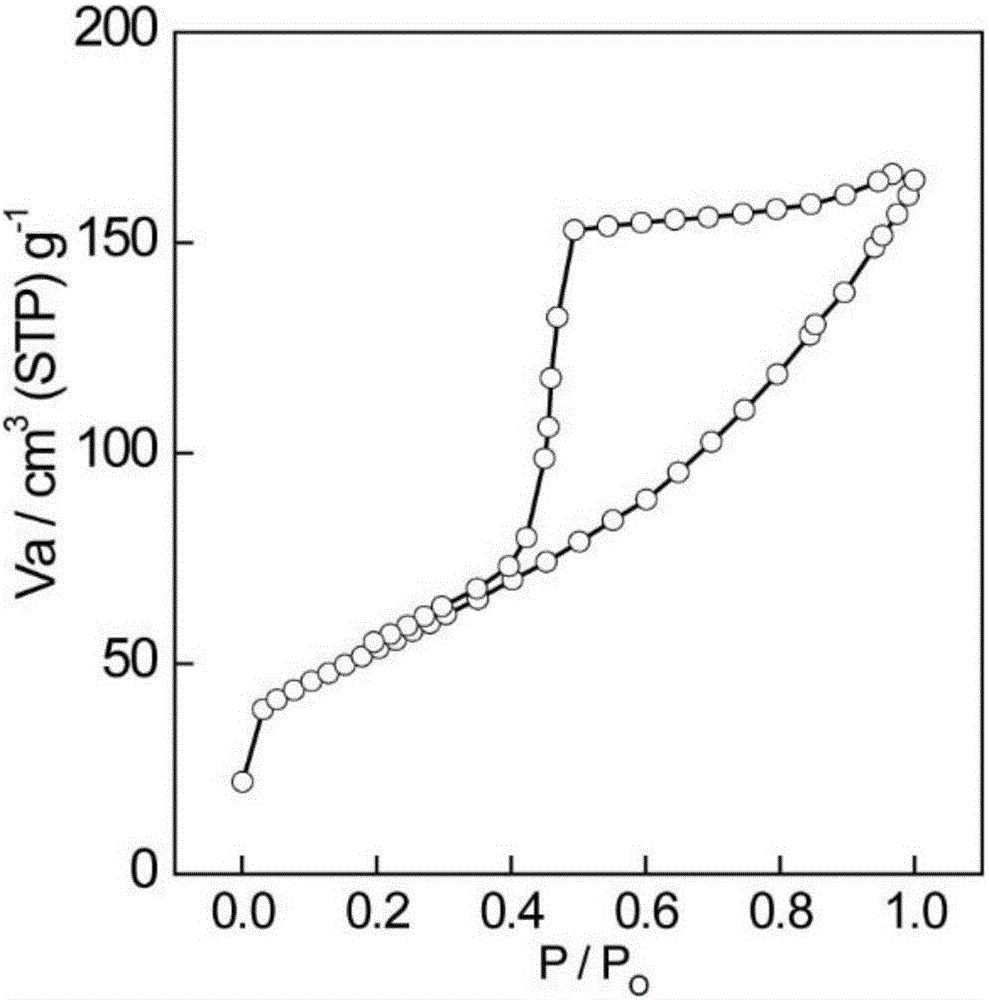

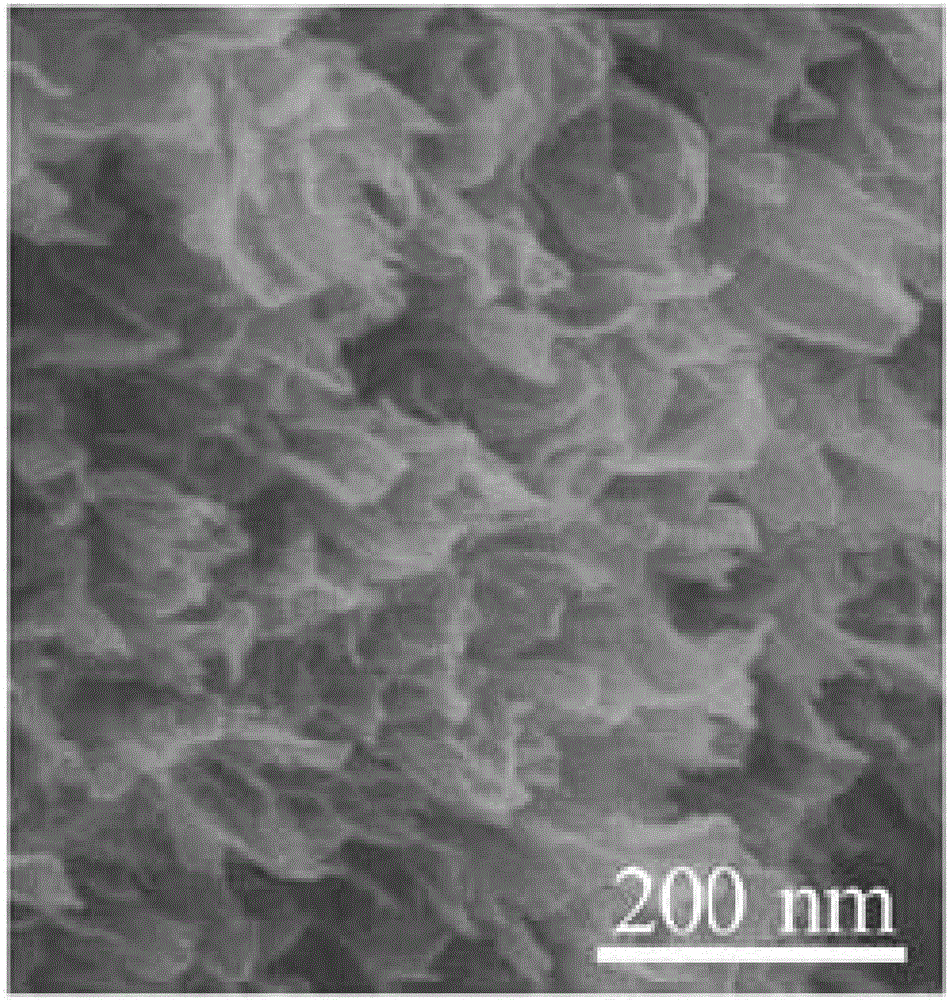

Method for regulating and controlling three-dimensional graphene holes with aid of sulfur used as template

InactiveCN106829932AAchieve dense shrinkageMild method conditionsCell electrodesGraphenePorous grapheneCvd graphene

The invention belongs to the technical field of graphene, and particularly relates to a method for regulating and controlling three-dimensional graphene holes with the aid of sulfur used as a template. The method at least includes steps of adding sulfur-containing substances and acid into graphene dispersion liquid and sufficiently stirring the sulfur-containing substances, the acid and the graphene dispersion liquid to obtain mixed dispersion liquid; adding the mixed dispersion liquid obtained at the first step into a hydrothermal reaction kettle and carrying out hydrothermal reaction; sufficiently soaking hydrogel obtained at the second step in deionized water, removing impurities and then removing water; carrying out desulfurization treatment on to-be-treated products obtained at the third step to obtain three-dimensional porous graphene macroscopic bodies. Compared with the prior art, the method has the advantages that the sulfur is led into the three-dimensional graphene macroscopic bodies as the template in hydrothermal procedures, and the pore sizes of the three-dimensional graphene macroscopic bodies can be increased after the sulfur is removed by means of simple heat treatment; the leading quantity of the sulfur is accurately controlled, accordingly, pore structures of the macroscopic bodies can be accurately regulated and controlled on a large scale, and the macroscopic bodies can be applied to different energy storage devices.

Owner:TIANJIN UNIV

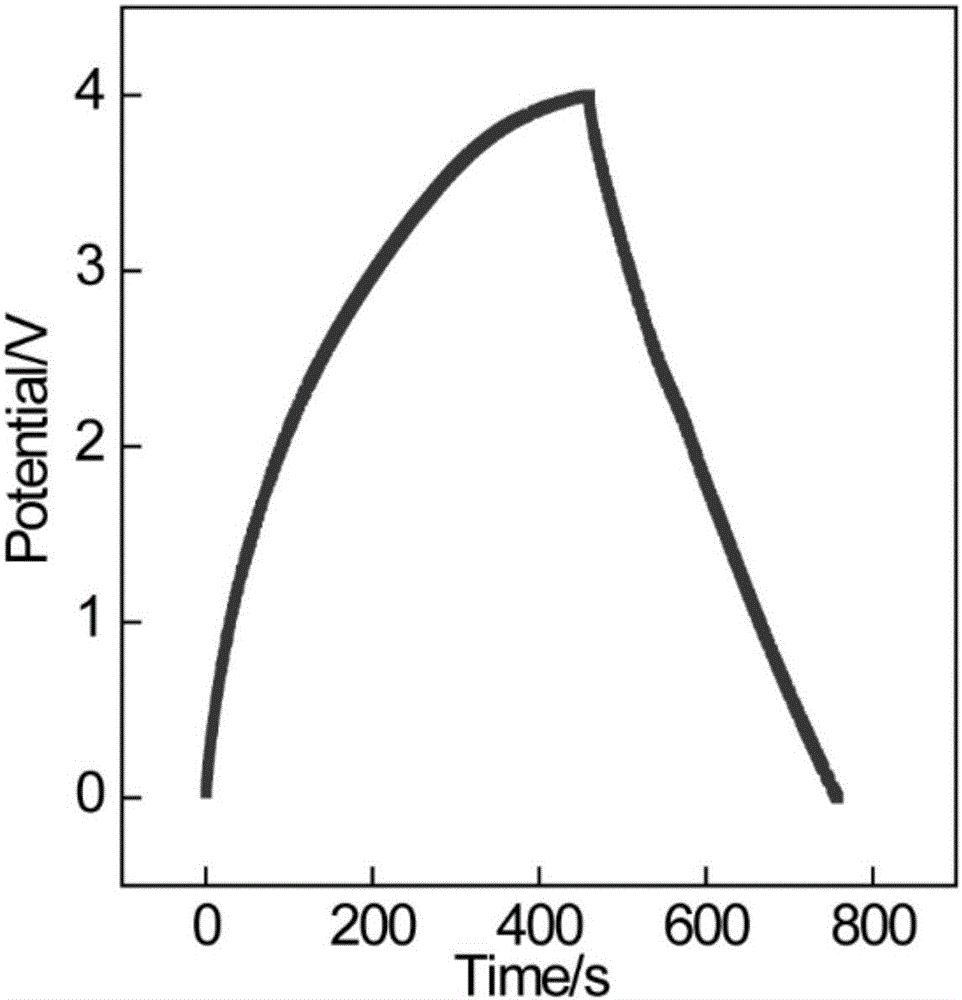

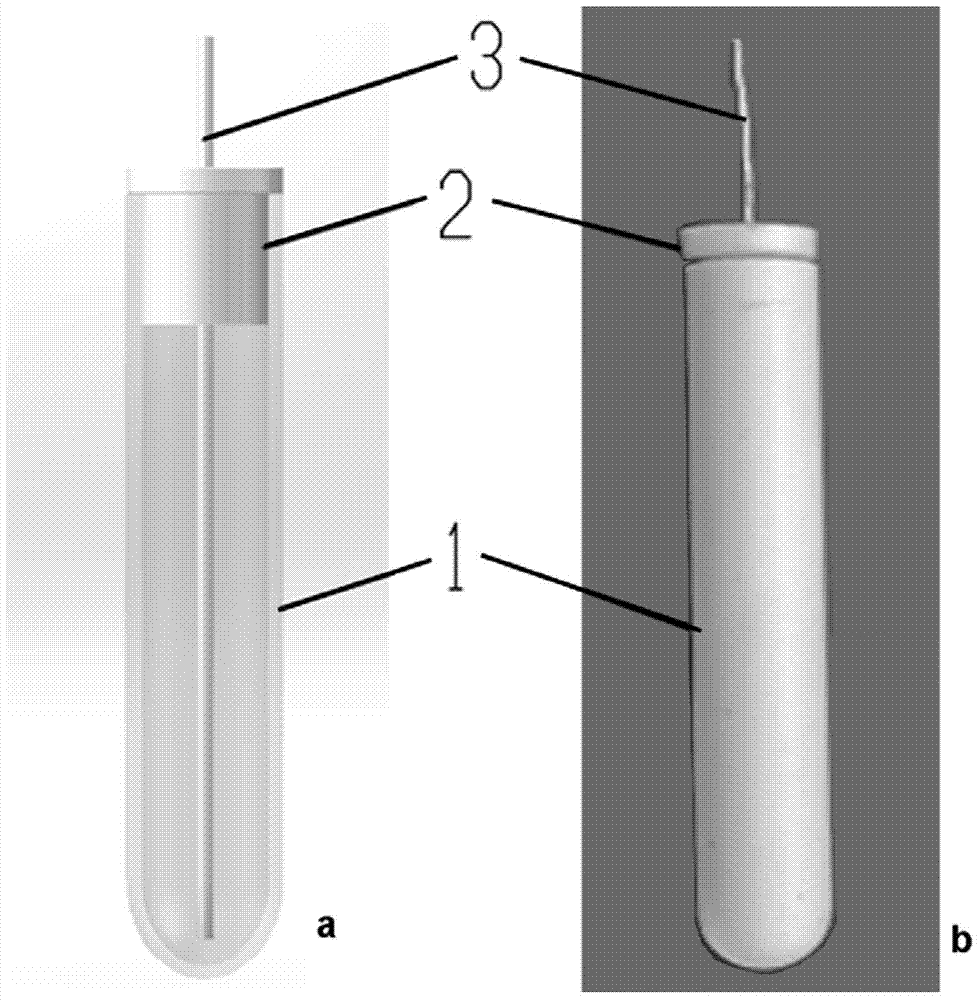

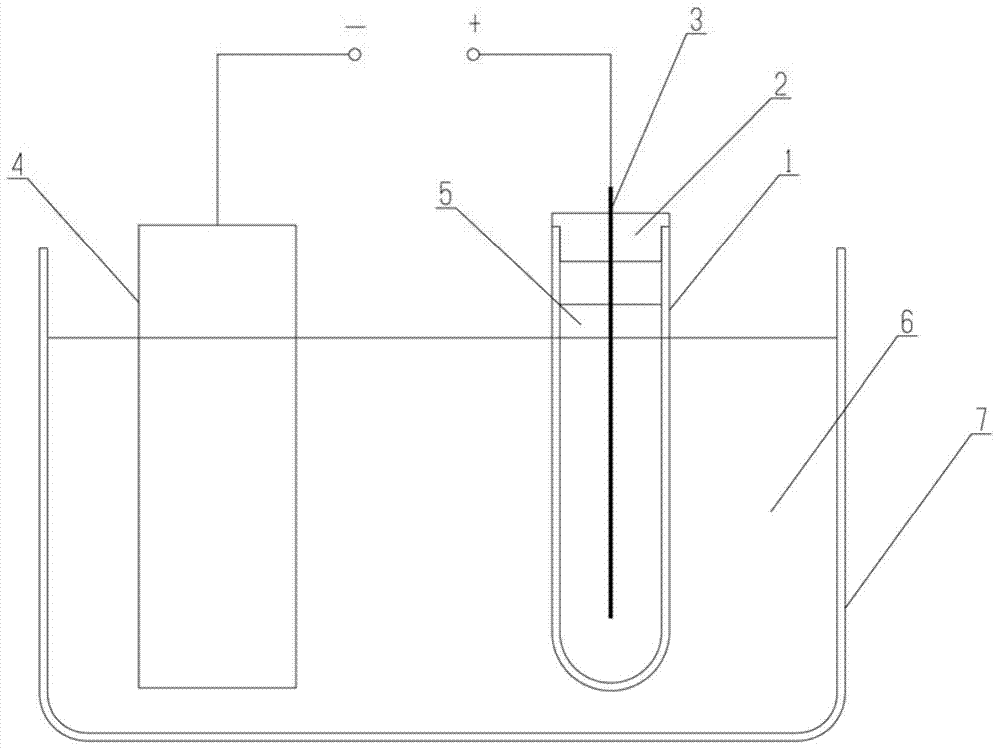

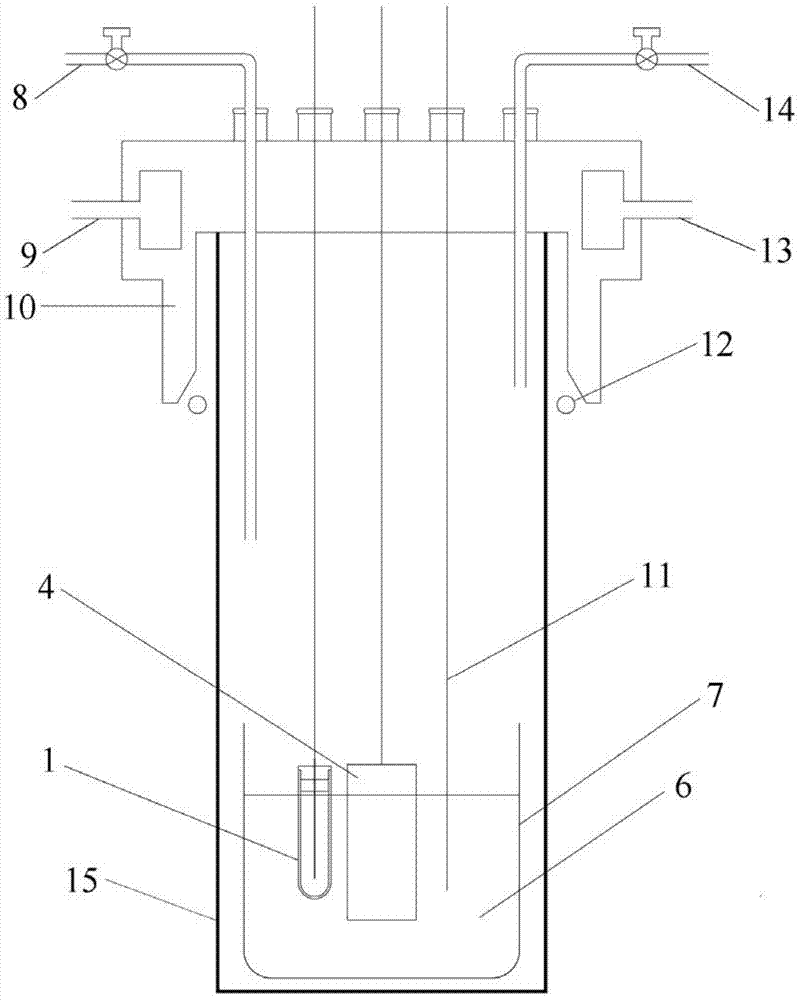

Deoxidized anode, fluoride fused salt electrolysis deoxidizing device and electrolytic method

InactiveCN103572318AIncrease oxygen contentLow oxygenElectrode shape/formsElectrolysisGibbs free energy

The invention discloses a deoxidized anode, a fluoride fused salt electrolysis deoxidizing device and an electrolytic method. The deoxidized anode comprises a zirconium oxide solid electrolyte container, a sealing material and an electrode lead, wherein the zirconium oxide solid electrolyte container is used for containing a deoxidizer; the sealing material is used for sealing the zirconium oxide solid electrolyte container; the electrode lead penetrates through the sealing material and extends into the zirconium oxide solid electrolyte container to contact with the deoxidizer; a zirconium oxide solid electrolyte comprises zirconium oxide and a stabilizing agent; the stabilizing agent is one or more of yttrium oxide, magnesium oxide and calcium oxide; the mole percentage of the stabilizing agent is 5%-30%; the deoxidizer is a metal which achieves reacted Gibbs free energy less than 0 when being reacted with oxygen. According to the electrolytic method, the zirconium oxide is adopted as the deoxidized anode, the condition is easy to control, the cost is low, and the electrolyzed impurity oxygen is easily separated from fluoride fused salt.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI +1

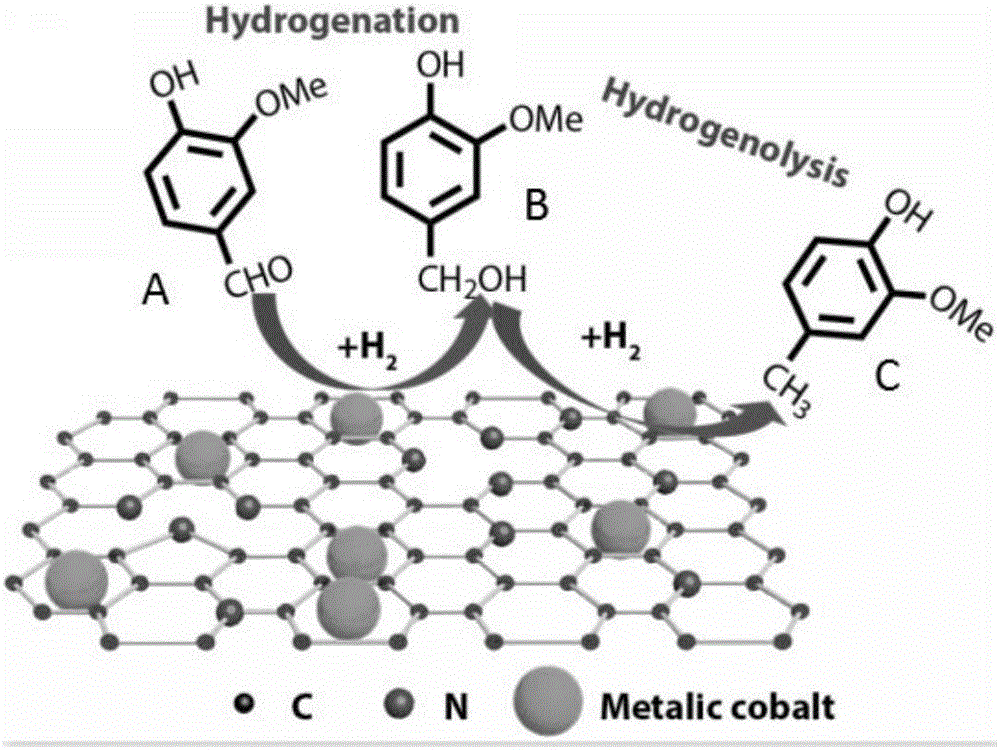

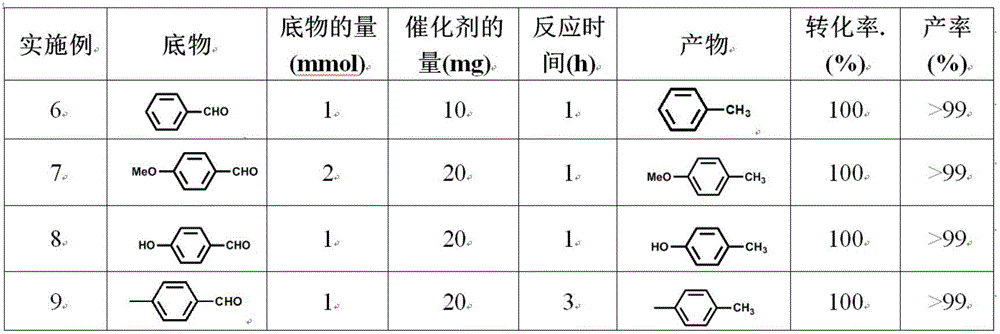

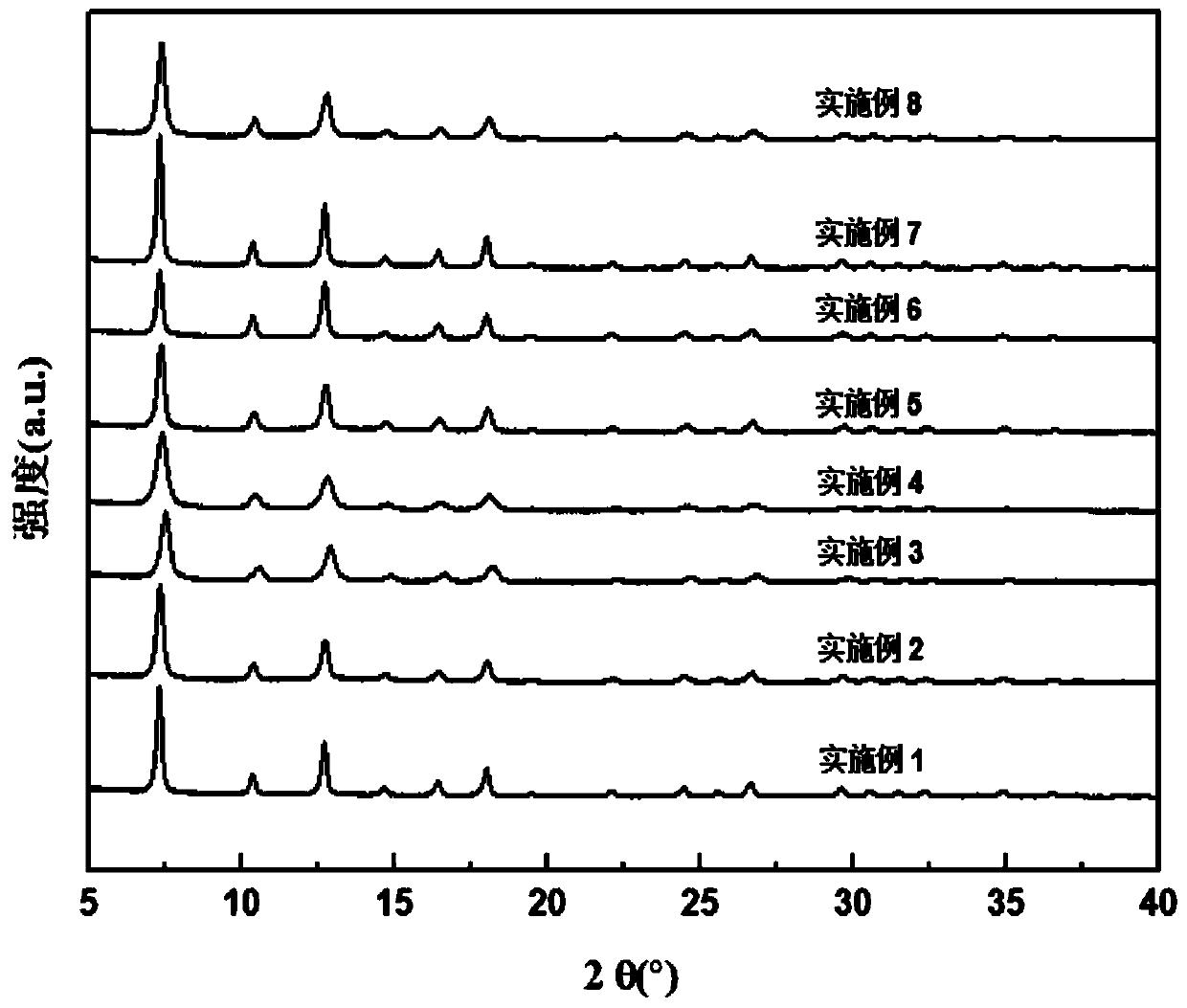

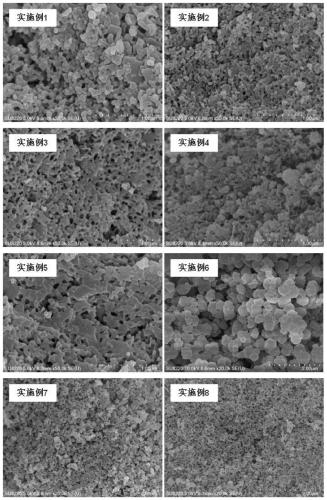

Method for reducing carbonyl into methylene at normal temperature and normal pressure

InactiveCN106542972AMild conditionsCost pollution-freeAmino preparation from aminesOrganic compound preparationSolventCatalytic hydrogenation

The invention discloses a method for reducing carbonyl into methylene at normal temperature and normal pressure. The method includes the following steps that a carbonyl compound, a nitrogen doped carbon material loaded palladium catalyst and a solvent are added into a reaction container, the ratio of the carbonyl compound to the nitrogen doped carbon material loaded palladium catalyst is (1-5) mol:(10-40) g, hydrogen is introduced, reacting is carried out for 0.5-20 h at normal temperature and normal pressure, and carbonyl can be reduced into methylene through catalytic hydrogenation. The reaction formula of the reaction is shown in the specification. The method is simple, easy to operate, mild in condition, high in conversion rate, good in selectivity, low in cost and free of pollution to the environment.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

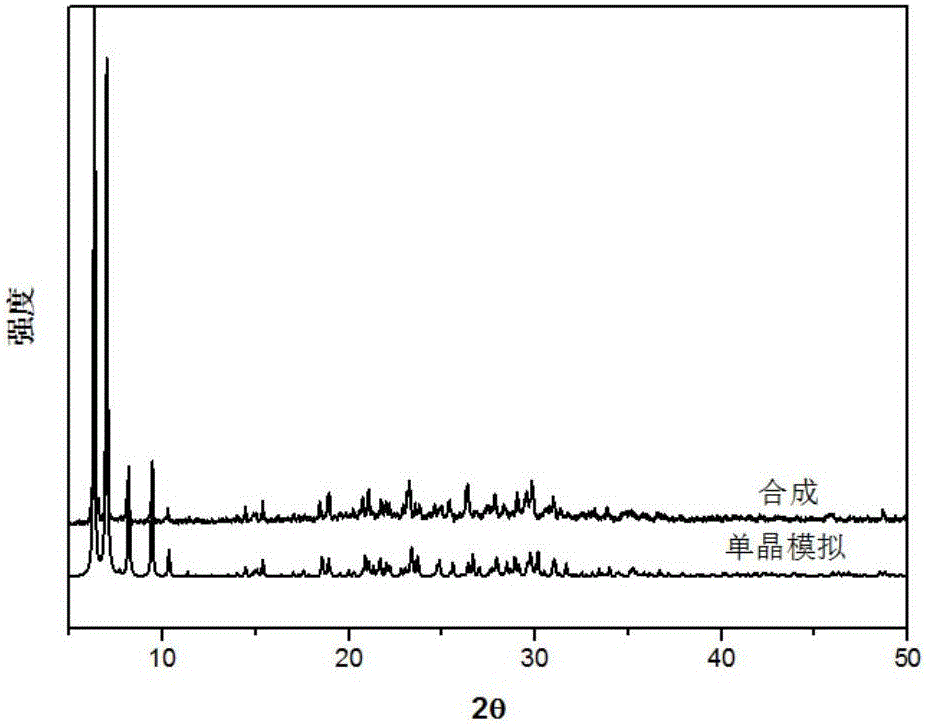

Hierarchical porous zeolite imidazate skeletal material, and preparation method thereof

ActiveCN110105580AMild conditionsShort timeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventMetal-organic framework

The invention belongs to the technical field of metal organic skeletal material, and discloses a hierarchical porous zeolite imidazate skeletal material, and a preparation method thereof. The preparation method comprises following steps: 1, a deep eutectic solvent and water are mixed so as to obtain a mixed solvent; 2, a metal salt, and a surfactant are dissolved in the mixed solvent so as to obtain a homogeneous solution, wherein the metal salt is one or a mixture of more than one components selected from zinc salts or cobalt salts; 3, an imidazole derivative is added into the homogeneous solution, and heating stirring is carried out so as to obtain a suspension solution; and 4, the suspension solution is subjected to centrifugation, washing, and drying so as to obtain the hierarchical porous zeolite imidazate skeletal material. The preparation method is simple; the reaction conditions are mild; preparation process is rapid; no environment pollution is caused; the prepared material ishigh in specific surface area and porosity, and possesses a hierarchical porous structure. The obtained hierarchical porous zeolite imidazate skeletal material possesses excellent catalytic activityin CO2 and epoxide cycloaddition reaction.

Owner:SOUTH CHINA UNIV OF TECH

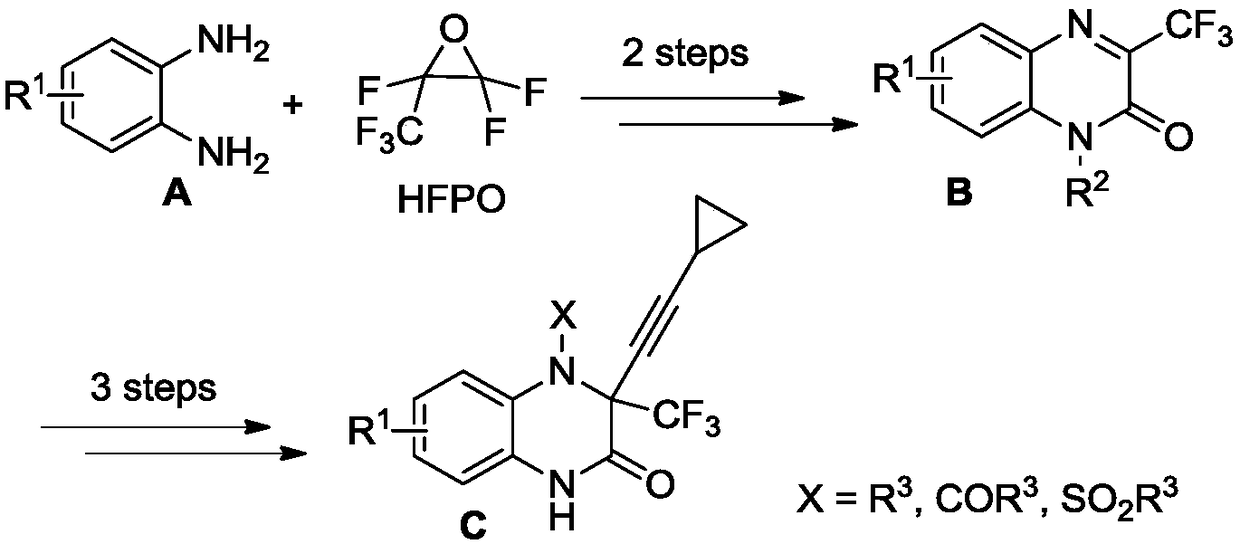

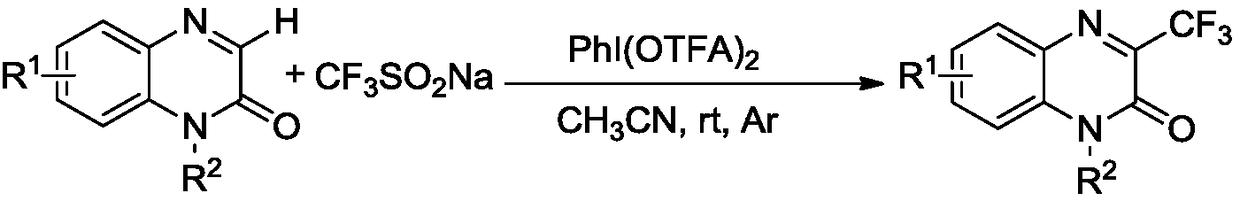

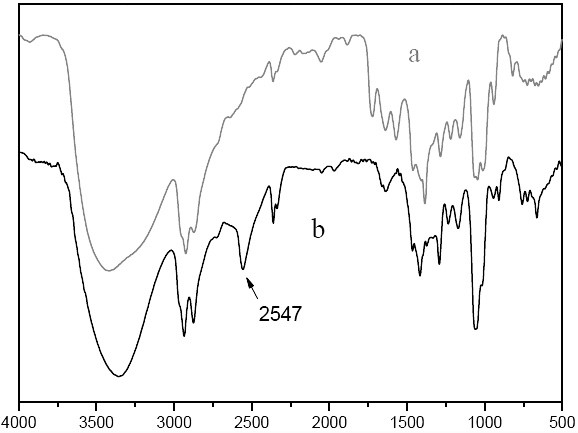

3-trifluoromethyl quinoxalinone compound preparation method

The invention discloses a 3-trifluoromethyl quinoxalinone compound preparation method which comprises the following steps of in an inert gas atmosphere, adding a quinoxalinone compound, sodium trifluoromethanesulfinate and an oxidant in a solvent, performing reaction for 6-18 h at the temperature of 0-75 DEG C, and performing column chromatography separation and purification to obtain 3-trifluoromethyl substituted quinoxalinone compound. The 3-trifluoromethyl quinoxalinone compound preparation method provided by the invention is low in reagent cost, mild in reaction condition and simple in aftertreatment and is suitable for industrial production.

Owner:HEBEI UNIV OF TECH

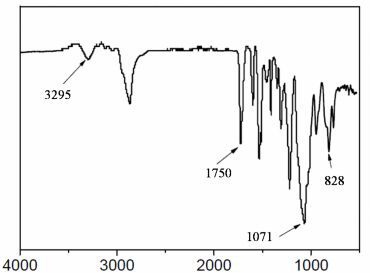

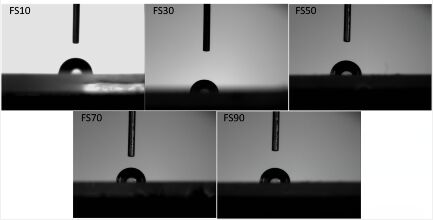

Novel method for preparing hydrophobic self-healing hyperelastic polyurethane elastomer

The invention discloses a novel method for preparing a hydrophobic self-healing hyperelastic polyurethane elastomer. The preparation method comprises the steps: firstly, taking mercaptan and small-molecular fluoroalcohol as raw materials to prepare a gemini-type chain extender containing disulfide bonds and rich fluorine atoms; and then, feeding the raw materials of isocyanate, polyhydric alcoholand the gemini chain extender at a time to react, and thus preparing the polyurethane elastomer containing alternately distributed short hard segment nodes through a 'one-pot boiling' method. The preparation method is simple and easy to operate, low in cost and short in consumed time, the prepared polyurethane elastomer has excellent hydrophobicity, self-healing performance and superelasticity andcan be repaired at the temperature of 40 DEG C, meanwhile, the tensile strength of the polyurethane elastomer can reach 12.469 MPa, the breaking elongation of the polyurethane elastomer can reach 747.2%, and the polyurethane elastomer can restore to 96.5% of the original after being stretched 1000 times under 500% strain.

Owner:UNIV OF JINAN

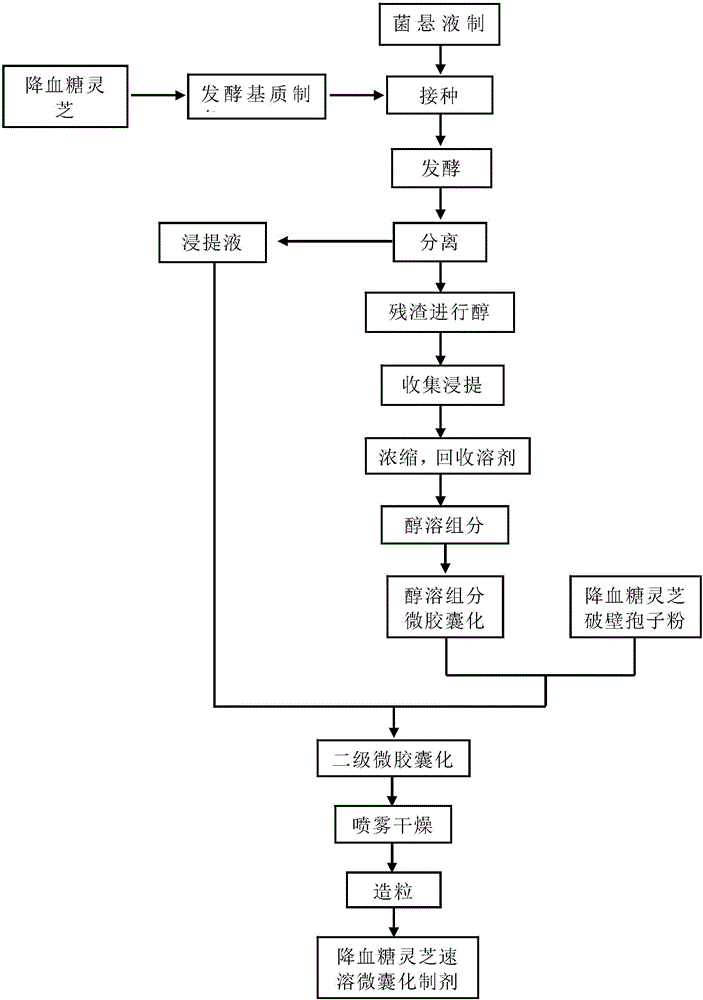

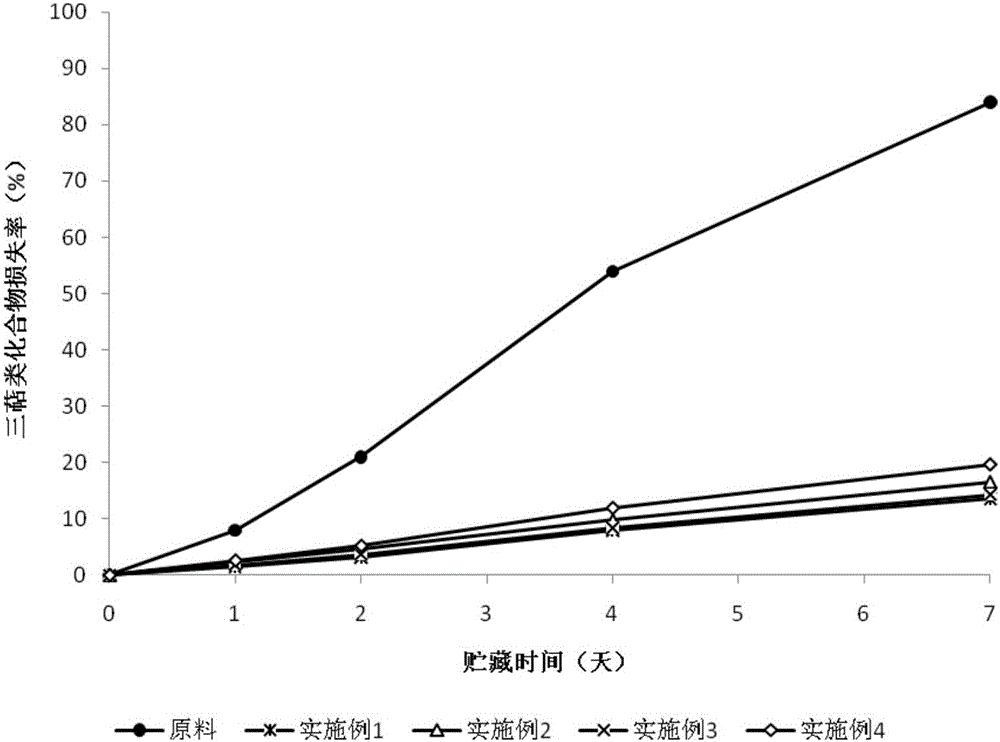

Blood-glucose-lowering ganoderma lucidum instant micro-encapsulated preparation and preparation method thereof

ActiveCN105998093AImprove resource utilizationMild conditionsMetabolism disorderMacromolecular non-active ingredientsWater dispersibleMonascus

The invention discloses a blood-glucose-lowering ganoderma lucidum instant micro-encapsulated preparation and a preparation method thereof. The method includes the specific steps of conducting monascus fermentation, water extraction, alcohol extraction, multi-stage micro-encapsulation, spray drying and granulating processes with blood-glucose-lowering ganoderma lucidum sporocarp and conidial powder as raw materials to prepare the blood-glucose-lowering ganoderma lucidum instant micro-encapsulated preparation. The blood-glucose-lowering ganoderma lucidum instant micro-encapsulated preparation prepared through the method brings the medicinal value of monascus and ganoderma lucidum into full play, functional components in blood-glucose-lowering ganoderma lucidum are efficiently enriched, the preparation process is green and mild, industrial production is easy, the obtained product has good water dispersity, storage stability and blood glucose lowering function, the use convenience of the product and the bioavailability in human bodies are effectively improved, guarantees are provided for development, application and consumption of the blood-glucose-lowering ganoderma lucidum product, and the preparation has great significance in promoting the development of the blood-glucose-lowering ganoderma lucidum industry and promoting the national health.

Owner:RIZHAO POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method for imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde compounds Synthetic method for imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde compounds](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/fe80eb46-8b88-4348-acbc-81f181076c99/BDA0000087034270000022.PNG)

![Synthetic method for imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde compounds Synthetic method for imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde compounds](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/fe80eb46-8b88-4348-acbc-81f181076c99/BDA0000087034270000023.PNG)

![Synthetic method for imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde compounds Synthetic method for imidazole[1,2-a]pyridine and 2-butyl-5-chloro-1H-imidazole-4-carboxaldehyde compounds](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/fe80eb46-8b88-4348-acbc-81f181076c99/BDA0000087034270000024.PNG)