Graphene-based negative electrode material for lithium-ion battery

A negative electrode material and ion battery technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems that affect the quality and performance of composite materials, cannot fully meet the volume expansion of non-carbon active materials, and reduce the volume performance of negative electrode materials. Achieve the effects of ensuring electronic conductivity, green and pollution-free preparation process, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

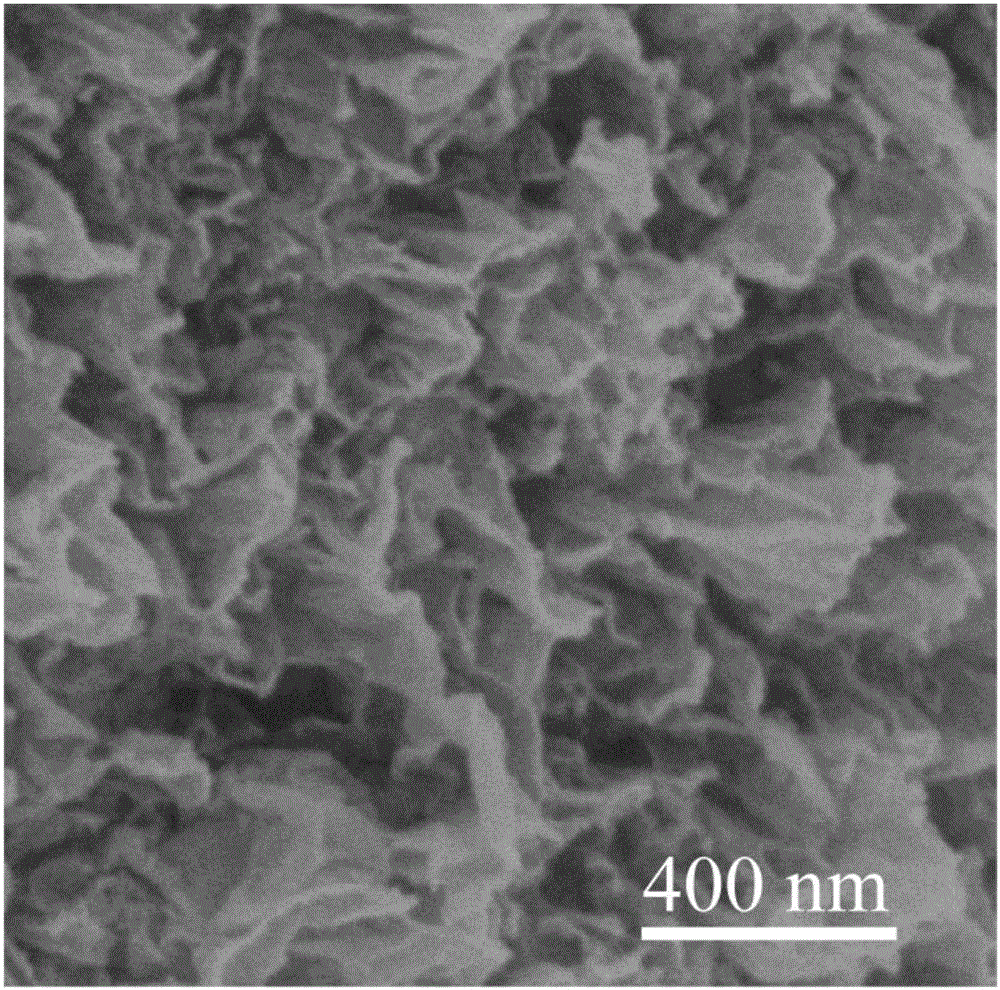

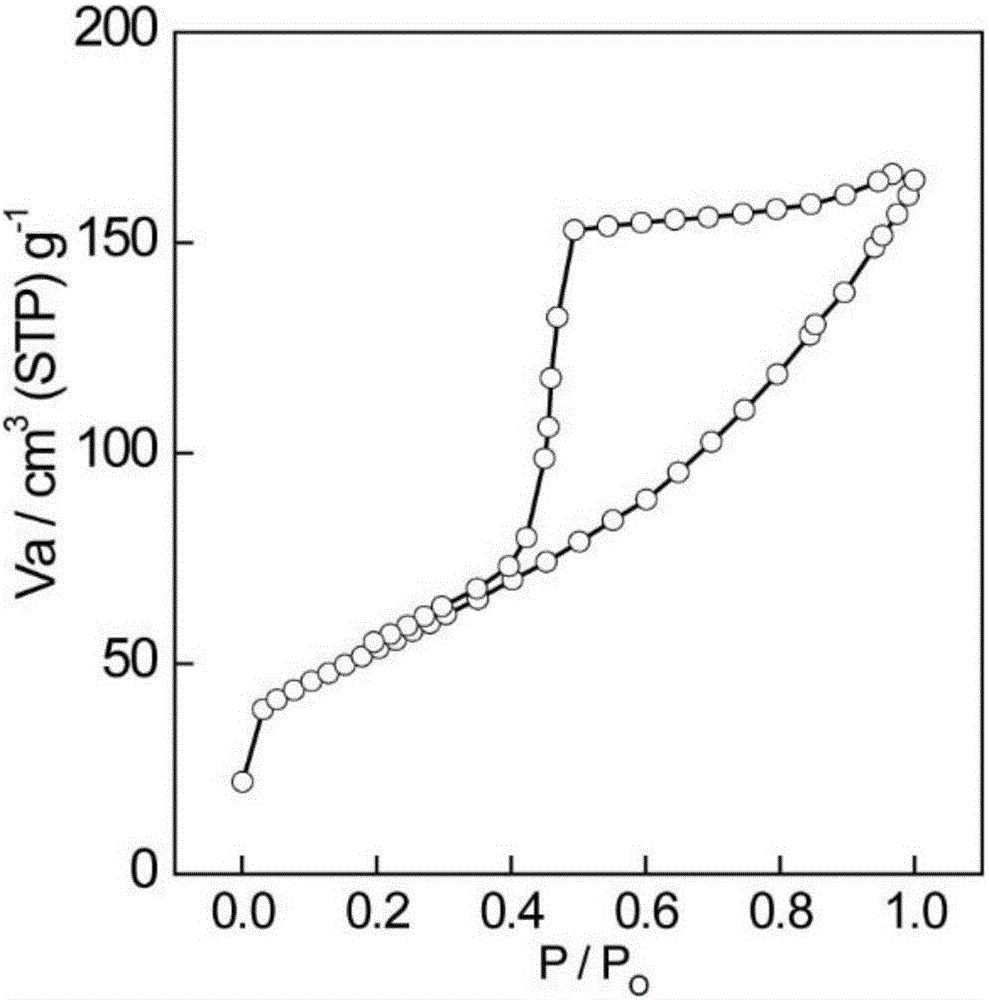

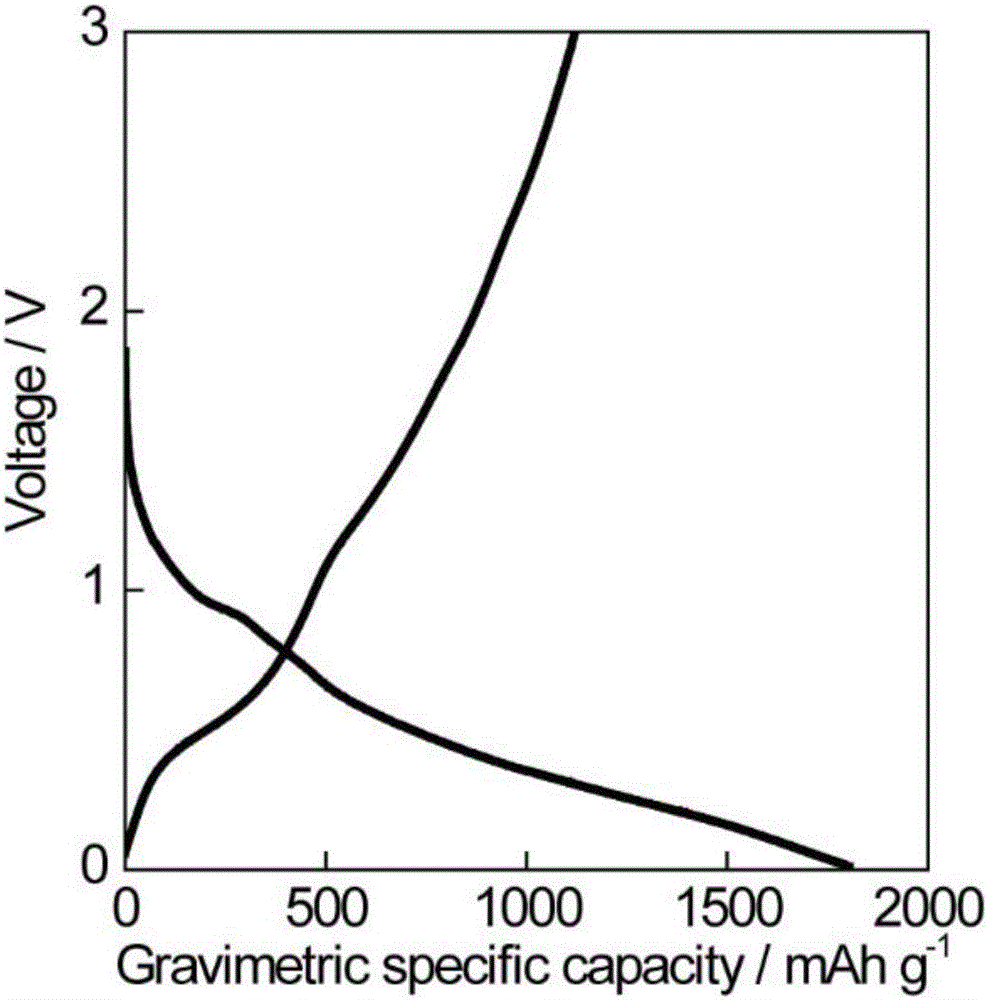

[0036] This embodiment provides a graphene-based lithium-ion battery negative electrode material, the negative electrode material is a three-dimensional porous graphene-non-carbon material composite electrode material, which includes three-dimensional porous graphene and a non-carbon material loaded on the three-dimensional porous graphene, The negative electrode material has a rich pore structure, and its specific surface area is 191m 2 / g, the pore volume is 0.25cm 3 / g, the bulk density is 2.18g / cm 3 , and the sum of the volumes of the pores in the negative electrode material is 2.59 times the sum of the volumes of the non-carbon materials.

[0037] Among them, the non-carbon material is tin dioxide, and the mass ratio of three-dimensional porous graphene to tin dioxide is 1:2.

[0038] The preparation method of the negative electrode material at least comprises the following steps:

[0039] In the first step, take 78.5mL of 2mg / mL graphene oxide dispersion and place it ...

Embodiment 2

[0047] The difference with embodiment 1 is:

[0048] The specific surface area of the three-dimensional porous graphene-tin dioxide composite electrode material is 256 m 2 / g, the pore volume is 0.19cm 3 / g, the block density is 2.46g / cm 3 , and the sum of the volumes of the pores in the negative electrode material is 1.98 times the sum of the volumes of the non-carbon materials.

[0049] Among them, the non-carbon material is tin dioxide, and the mass ratio of three-dimensional porous graphene to tin dioxide is 1:2.

[0050] In the preparation method of this negative electrode material, the consumption of graphene oxide dispersion liquid is adjusted to 83.5mL, Na 2 S 2 o 3 ·5H 2 The consumption of O is adjusted to 0.10g, and the consumption of hydrochloric acid is adjusted to 1.5mL, and the rest are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0052] The difference with embodiment 1 is:

[0053] The specific surface area of the three-dimensional porous graphene-tin dioxide composite electrode material is 228m 2 / g, the pore volume is 0.21cm 3 / g, the bulk density is 2.32g / cm 3 , and the sum of the volumes of the pores in the negative electrode material is 2.25 times the sum of the volumes of the non-carbon materials.

[0054] Among them, the non-carbon material is tin dioxide, and the mass ratio of three-dimensional porous graphene to tin dioxide is 1:2.

[0055] In the preparation method of this negative electrode material, the consumption of graphene oxide dispersion liquid is adjusted to 82.5mL, Na 2 S 2 o 3 ·5H 2 The amount of O was adjusted to 0.21g, and the amount of hydrochloric acid was adjusted to 2.5mL. The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com