Magnetic gold nanoparticle composite material, and preparation method and application thereof

A technology of gold nanoparticles and composite materials, which is applied in the field of preparation of magnetic Fe3O4-gold nanoparticle composite materials, can solve the problems of unfavorable storage, application, instability of composite materials, easy oxidation of thiol groups, etc., and achieve easy surface modification, Controllable process and mild method conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

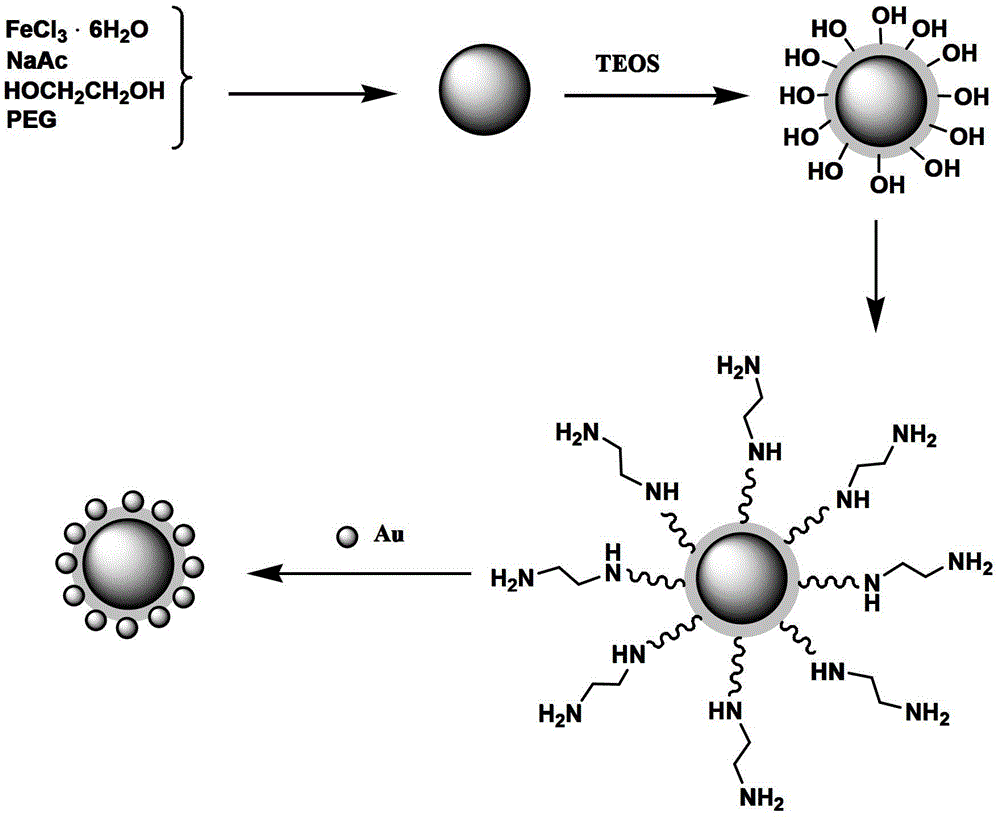

[0036] Embodiment 1: Magnetic gold nanoparticle composite material and preparation method thereof

[0037] (1) Fe 3 o 4 Preparation of magnetic microspheres:

[0038] Weigh 1.35g of FeCl3 6H 2 Dissolve O in 40 mL of ethylene glycol, add 3.6 g of anhydrous sodium acetate and 1 g of polyethylene glycol-6000 in sequence, and stir magnetically for 0.5 h. The resulting solution was charged into a 50 mL stainless steel reaction kettle. Put it in an oven and react at 200°C for 12h. The obtained product was washed successively with deionized water and ethanol, and dried under vacuum at 60° C. for 6 h.

[0039] During the heating reaction, heat to 200-300°C for 8-24 hours; the product obtained is washed with deionized water and absolute ethanol for 3-6 times, and dried in vacuum at 40-80°C to obtain tetraoxide with a particle size of 100-500nm Tri-Fe Magnetic Microspheres

[0040] (2) Fe 3 o 4 / SiO 2 Preparation of microspheres

[0041] 1gFe 3 o 4 Redisperse the magnetic m...

Embodiment 2

[0051] Example 2: Magnetic gold nanoparticle composite material is used to adsorb benzopyrene in environmental water samples

[0052]A series of standard solutions with benzopyrene mass concentrations of 0.1, 0.5, 1, 5, 10, 50, and 100 μg / L were prepared with acetonitrile for liquid chromatography (the instrument model is Shimazu HPLC-20A, and the manufacturer is Shimadzu Corporation, Japan, The instrument is configured with RF-20A xs fluorescence detector, CTO-20AC column thermostat, and SIL-20AC autosampler; the chromatographic column is a Spursil C18 column, and the manufacturer is Beijing Dicoma Technology Co., Ltd.; the mobile phase is acetonitrile, and the flow rate is 1ml / min, the injection volume is 20μL; the excitation / emission wavelength of the fluorescence detector is set to 384 / 406nm) for determination, the mass concentration x of the standard solution is the abscissa, the peak area y is the ordinate, and the minimum The linear regression is carried out by the squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com