Magnetic composite microsphere as well as preparation method and application thereof

A technology of magnetic composite microspheres and microspheres, which is applied in the preparation of microspheres, microcapsule preparations, and the magnetism of organic materials/organic magnetic materials. It can solve the problems of lack of specific functional groups, small specific surface of magnetic microspheres, There are many preparation procedures to achieve the effect of convenient operation, simple equipment and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

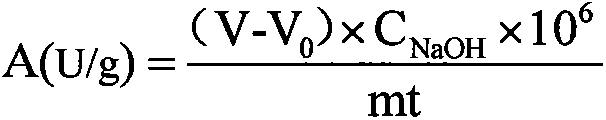

[0026] Disperse 1.0g of glycidyl methacrylate, 3.0g of cross-linking agent divinylbenzene, 0.8g of initiator dibenzoyl peroxide and 2.5g of ferric iron tetroxide nano-magnetic powder in 200ml of acetonitrile solvent, ultrasonic Disperse, mix evenly and transfer to a reaction device equipped with a fractionating column, a condenser tube and a liquid contact bottle, heat slowly until the solution boils and maintain a constant temperature, the solution gradually becomes turbid and the solvent begins to evaporate, and the polymerization time is controlled to stop the reaction within 2 hours. The obtained magnetic composite microspheres were separated from the solvent in a magnetic field, washed three times with tetrahydrofuran, acetone, and anhydrous ether, and dried in a vacuum oven at room temperature. The specific saturation magnetization of the prepared magnetic composite microspheres is 46.8emu / g, the surface active epoxy group content is 0.82mmol / g, and the hydrolysis activit...

Embodiment 2

[0028] Disperse 1.0g of glycidyl methacrylate and 3.0g of crosslinking agent ethylene glycol dimethacrylate and 0.8g of initiator azobisisobutyronitrile and 2.0g of ferroferric oxide nano-magnetic powder in 200ml of acetonitrile In the solvent, ultrasonically disperse, mix evenly and then transfer to the reaction device equipped with a fractionation column, a condenser tube and a liquid contact bottle, heat slowly until the solution boils and maintain a constant temperature, the solution gradually becomes turbid and the solvent begins to evaporate, and the polymerization time is controlled at 4h Stop responding. The obtained magnetic composite microspheres were separated from the solvent in a magnetic field, washed three times with tetrahydrofuran, acetone, and anhydrous ether, and dried in a vacuum oven at room temperature. The prepared magnetic composite microspheres had a specific saturation magnetization of 38.8emu / g, a surface active epoxy group content of 0.67mmol / g, and...

Embodiment 3

[0030] Disperse 2.0g of glycidyl methacrylate, 2.0g of cross-linking agent divinylbenzene, 1.2g of initiator dibenzoyl peroxide and 2.5g of ferric iron tetroxide nano-magnetic powder in 300ml of acetonitrile solvent, ultrasonic Disperse, mix evenly and transfer to a reaction device equipped with a fractionating column, a condenser tube and a liquid contact bottle, heat slowly until the solution boils and maintain a constant temperature, the solution gradually becomes turbid and the solvent begins to evaporate, and the polymerization time is controlled to stop the reaction within 2 hours. The obtained magnetic composite microspheres were separated from the solvent in a magnetic field, washed three times with tetrahydrofuran, acetone, and anhydrous ether, and dried in a vacuum oven at room temperature. The prepared magnetic composite microspheres had a specific saturation magnetization of 42.6emu / g, a surface active epoxy group content of 0.97mmol / g, and a hydrolytic activity (A)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com