Surface hydrophilization modification method of polyvinylidene fluoride hollow fiber membrane

A polyvinylidene fluoride and fiber membrane technology, applied in the field of materials, can solve problems such as poor compatibility, loss of raw materials, and cumbersome processes, and achieve the effects of improved anti-pollution, easy process control, and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

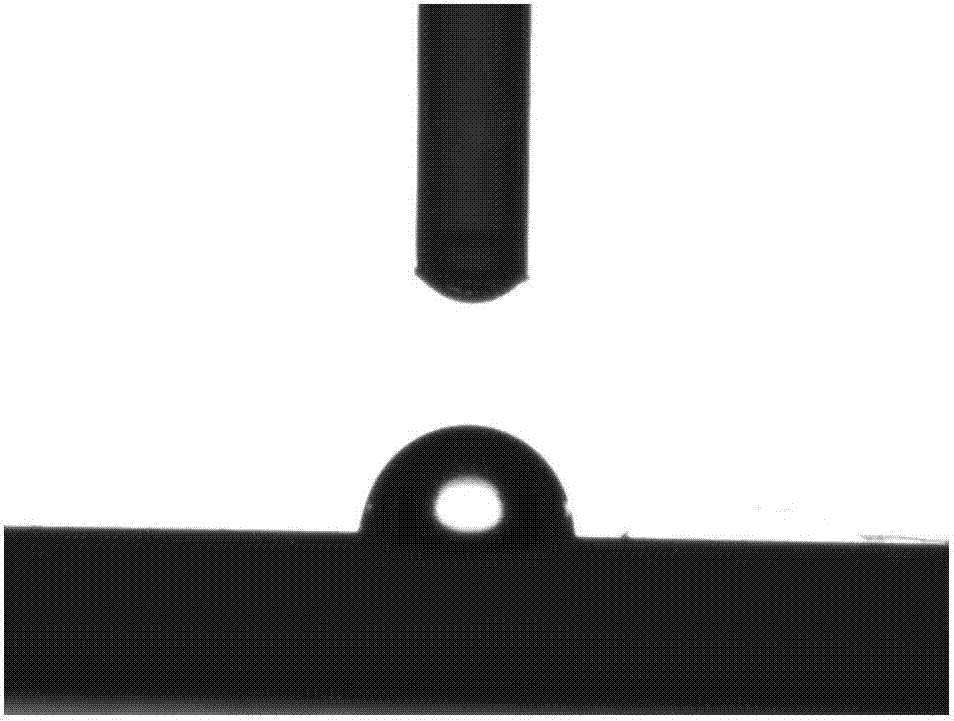

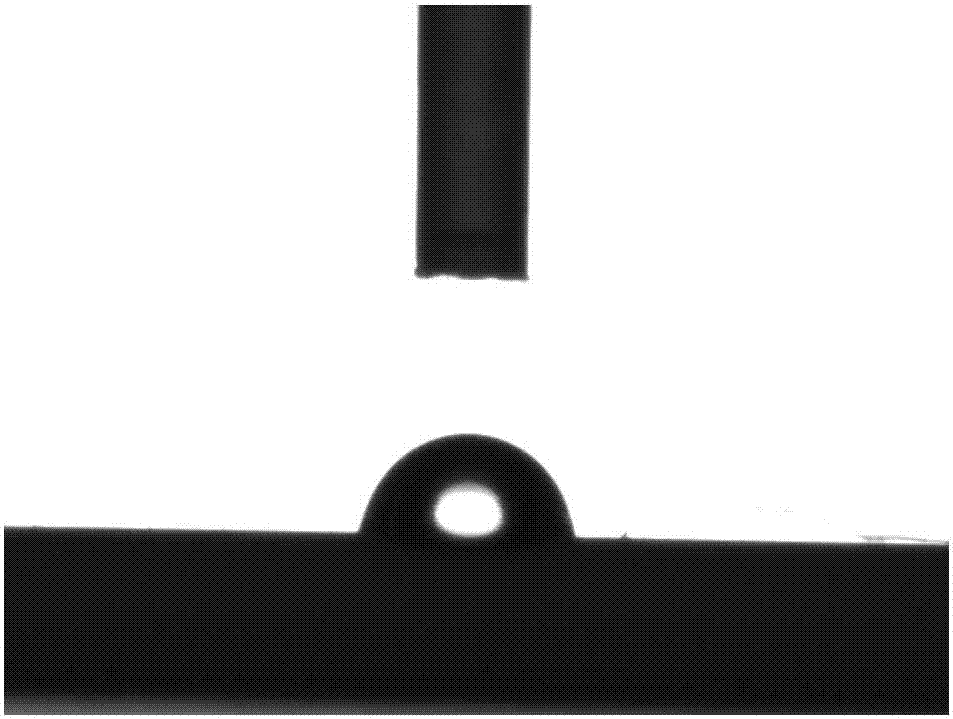

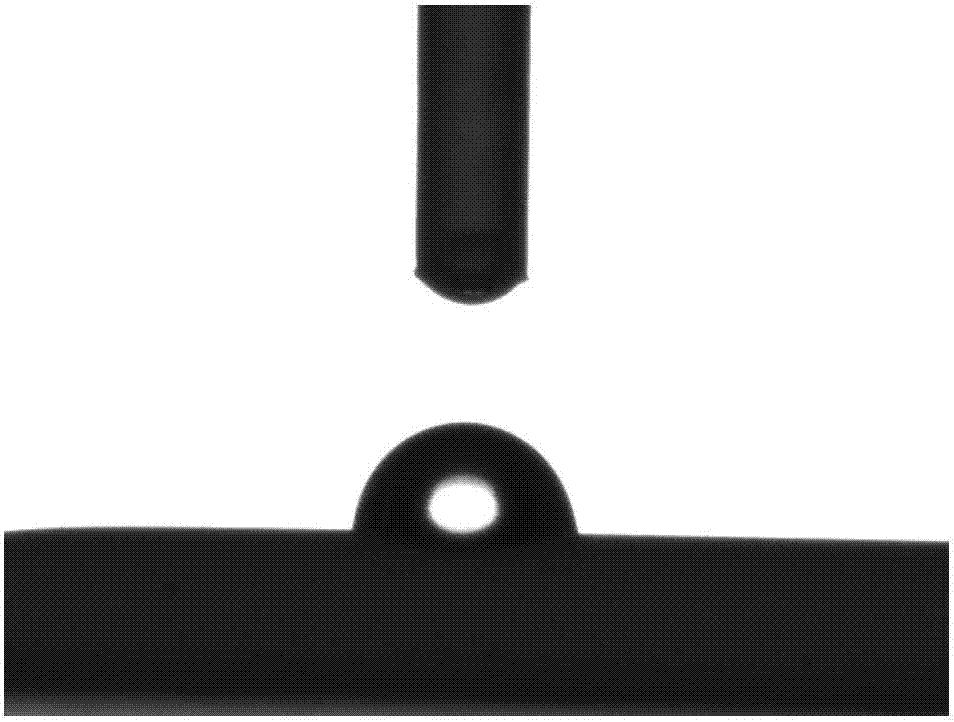

Image

Examples

Embodiment 1

[0035] (1) Clean the PVDF hollow fiber ultrafiltration membrane: soak the PVDF hollow fiber ultrafiltration membrane in absolute ethanol for 24 hours, then rinse repeatedly with deionized water;

[0036] (2) Prepare lye: add solid potassium hydroxide to a mixture of ethanol and deionized water at a mass ratio of 1:1 and stir evenly to make lye. The mass fraction of potassium hydroxide in the solution is 5 wt.%.

[0037] (3) The hollow fiber ultrafiltration membrane cleaned in step (1) is completely immersed in the alkali solution prepared in step (2), and placed in an environment of 60° C. for 5 minutes.

[0038] (4) Take out the hollow fiber ultrafiltration membrane after alkali treatment in step (3) and repeatedly wash it with deionized water under ultrasonic vibration until it is no longer alkaline, and place the alkali treatment hollow fiber ultrafiltration membrane after cleaning in ethanol Infiltrate and set aside.

[0039] (5) Solution preparation for modification: the...

Embodiment 2

[0044] (1) Clean the PVDF hollow fiber ultrafiltration membrane: soak the PVDF hollow fiber ultrafiltration membrane in absolute ethanol for 24 hours, then rinse repeatedly with deionized water;

[0045] (2) Prepare lye: add potassium hydroxide solid to ethanol and deionized water in a mixture of ethanol and deionized water with a mass ratio of 1:1 and stir evenly to make lye, with a mass fraction of potassium hydroxide of 10wt.%.

[0046] (3) The hollow fiber ultrafiltration membrane cleaned in step (1) is completely immersed in the alkali solution prepared in step (2), and placed in an environment of 60°C for 10 minutes.

[0047] (4) Take out the hollow fiber ultrafiltration membrane after alkali treatment in step (3) and repeatedly wash it with deionized water under ultrasonic vibration until it is no longer alkaline, and place the alkali treatment hollow fiber ultrafiltration membrane after cleaning in ethanol Infiltrate and set aside.

[0048] (5) Solution preparation fo...

Embodiment 3

[0053] (1) Clean the PVDF hollow fiber ultrafiltration membrane: soak the PVDF hollow fiber ultrafiltration membrane in absolute ethanol for 24 hours, then rinse repeatedly with deionized water;

[0054] (2) Prepare lye: add potassium hydroxide solid to ethanol and deionized water in a mixture of ethanol and deionized water with a mass ratio of 1:1 and stir evenly to prepare lye, with a mass fraction of potassium hydroxide of 20wt.%.

[0055] (3) The hollow fiber ultrafiltration membrane cleaned in step (1) is completely immersed in the lye prepared in step (2), and placed in an environment of 60° C. for 120 minutes.

[0056] (4) Take out the hollow fiber ultrafiltration membrane after alkali treatment in step (3) and repeatedly wash it with deionized water under ultrasonic vibration until it is no longer alkaline, and place the alkali treatment hollow fiber ultrafiltration membrane after cleaning in ethanol Infiltrate and set aside.

[0057] (5) Solution preparation for modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com