Metal base ionic liquid catalyst and method for degrading polyethylene glycol terephthalate by using the same

The technology of polyethylene terephthalate and ethylene phthalate is applied in the field of ionic liquid catalysts and degraded polyester materials, and can solve the problems of large amount of ionic liquid catalysts and long reaction time, etc. The catalyst dosage is small, the reaction speed is fast, and the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

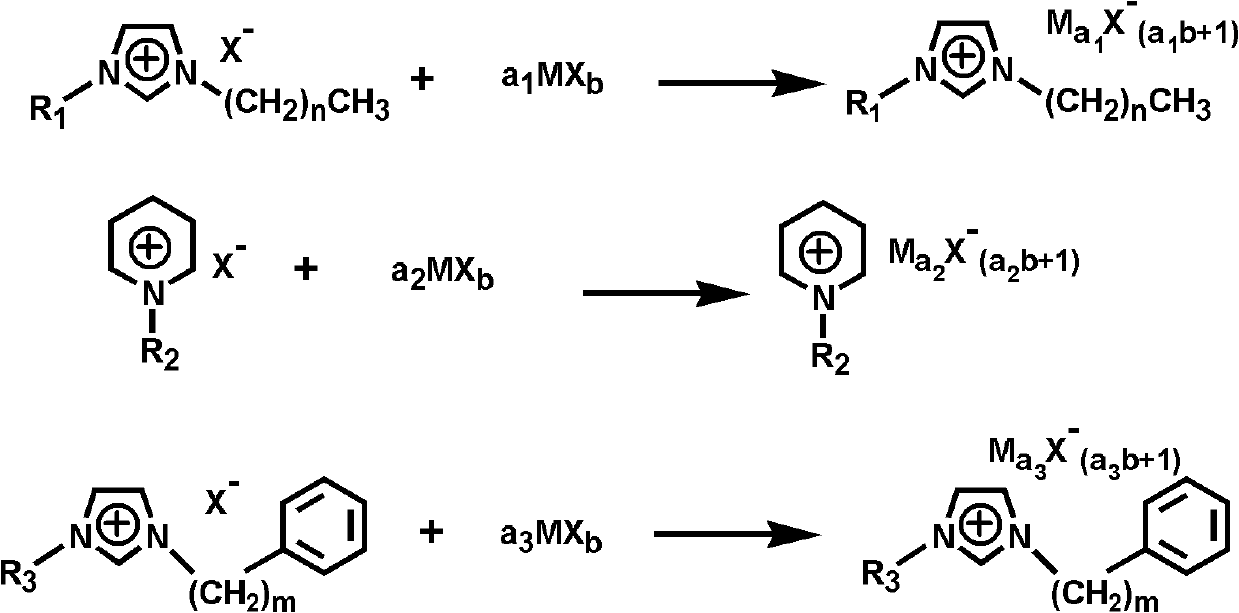

[0011] Specific embodiment one: the metal-based ionic liquid catalyst of the present embodiment is or a combination of several of them, where R 1 for C 1 ~C 10 the alkyl chain, R 2 for C 1 ~C 10 the alkyl chain, R 3 for C 1 ~C 10 The alkyl chain, the value of n is an integer from 1 to 9, the value of m is an integer from 1 to 5, and M is Al 3+ , Fe 2+ 、Ni 2+ , Pb 2+ , Zn 2+ , Mn 2+ , Mg 2+ , Ca 2+ 、Cu 2+ or Sn 2+ , X - for Br - , Cl - or H 3 CCOO - , a 1 The value of is 0.1~3, a 2 The value of is 0.1~3, a 3 The value of is from 0.1 to 3, and the value of b is the number of valence electrons of M.

[0012] When the metal-based ionic liquid catalyst is a composition, various metal-based ionic liquids are combined in any ratio.

[0013] This embodiment utilizes the principle of transesterification to degrade polyethylene terephthalate under the catalytic action of a metal-based ionic liquid catalyst. The dosage of the metal-based ionic liquid catalyst ...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is that R 1 for C 3 ~C 7 the alkyl chain. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is that R 2 for C 3 ~C 7 the alkyl chain. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com