Method for catalyzing, oxidizing and degrading 2-chloroethyl ethyl sulfide through multi-niobium-vanadium-oxygen clusters

A technology of chloroethyl ethyl sulfide and catalytic oxidation, which is applied in the field of catalytic chemistry, can solve the problems of uncontinuous use of catalyst, low conversion efficiency, low product selectivity, etc., and achieves low preparation cost, mild conditions, and easy acquisition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of described hydrated niobium pentoxide is as follows:

[0037] Dissolve 1 g of niobium pentoxide in a mixed solution of 10 mL of nitric acid and hydrofluoric acid, add excess ammonia water, stir to obtain a precipitate of hydrated niobium pentoxide, wash the solid with deionized water until the pH value of the water is 7, and then Vacuum drying at 50°C to obtain hydrated niobium pentoxide; wherein the molar ratio of nitric acid and hydrofluoric acid is 1:3.

[0038] The K 7 Hb 6 o 19 13H 2 O was prepared as follows:

[0039] Mix 1g of niobium pentoxide with 1g of potassium hydroxide, bake in a muffle furnace at 1000°C for 24 hours, wash the obtained solid three times with 20ml of deionized water, and dry naturally to obtain K 7 Hb 6 o 19 13H 2 O.

Embodiment 1

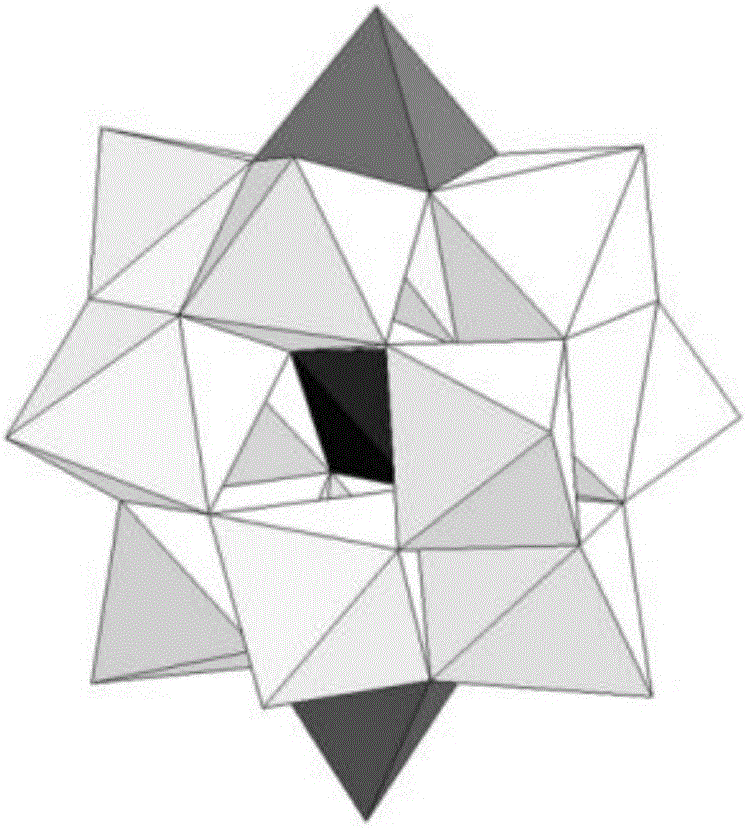

[0041] A TMA 9 [PNb 12 o 40 (VO) 2 ] the method for catalytic oxidation degradation 2-chloroethyl ethyl sulfide, the method concrete steps are as follows:

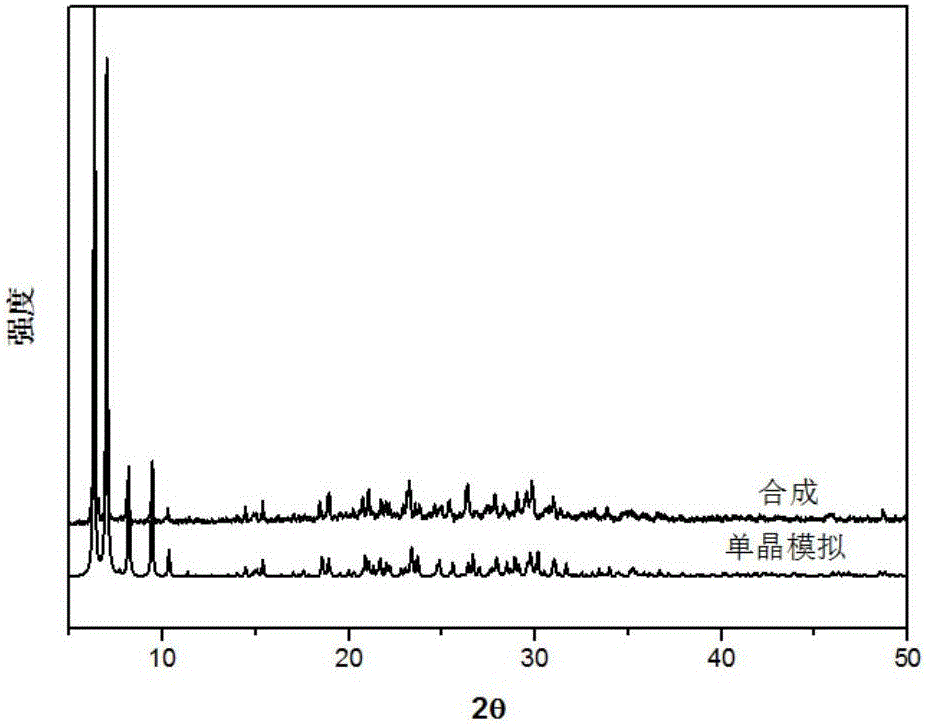

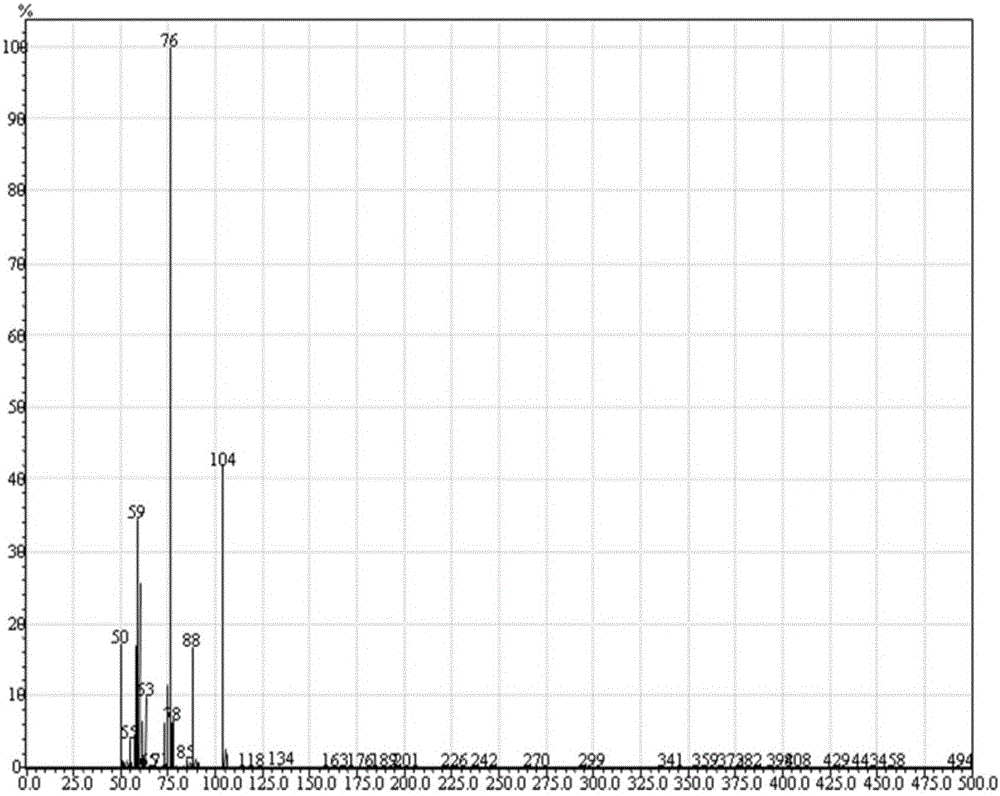

[0042] (1) Take by weighing 100mg hydrated niobium pentoxide and 100mg vanadyl phosphate solid respectively and join in the polytetrafluoroethylene liner of stainless steel reactor, add 5g mass concentration and be the tetramethylammonium hydroxide aqueous solution of 25%, stir to make Mix well, adjust the pH value to 10 with phosphoric acid, and stir at room temperature for 1 hour. Seal the reaction kettle, put it in an oven, react at 160°C for 3 days, naturally cool to 20°C, filter the reaction solution, wash the filtrate with 20ml of isopropanol 3 times, and place it at room temperature for 2 days to evaporate the solvent and precipitate a solid. Filter, obtain light yellow solid after drying; Carry out XRD test to light yellow solid, test result is as follows figure 2 As shown, it can be seen that the result of t...

Embodiment 2

[0045] A TEA 9 [PNb 12 o 40 (VO) 2 ] the method for catalytic oxidation degradation 2-chloroethyl ethyl sulfide, the method concrete steps are as follows:

[0046] (1) Take by weighing 100mg niobium pentoxide hydrate and 100mg vanadyl phosphate solid respectively and join in the polytetrafluoroethylene liner of stainless steel reactor, add 5g mass concentration and be the tetraethylammonium hydroxide aqueous solution of 20%, stir to make Mix well, adjust the pH value to 11 with phosphoric acid, and stir at room temperature for 1 hour. Seal the reaction kettle, put it in an oven, react at 120°C for 4 days, cool naturally to 25°C, filter the reaction solution, wash the filtrate with 20ml of isopropanol 3 times, and place it at room temperature for 2 days to evaporate the solvent and precipitate a solid. Filter and dry to obtain a light yellow solid; carry out XRD test on the light yellow solid, it can be seen that the result of the light yellow solid is consistent with that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com