Double-base synergistic flame-retardant polyformaldehyde composite material and preparation method thereof

A technology of composite materials and polyoxymethylene, which is applied in the field of phosphaphenanthrene and polyphosphazene double base synergistic flame-retardant polyoxymethylene composite materials and its preparation, can solve the problem of decreased mechanical properties and poor compatibility of polymer matrix or reinforced materials and other issues, to achieve excellent interfacial compatibility, flame retardant performance and interfacial cohesion enhancement, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

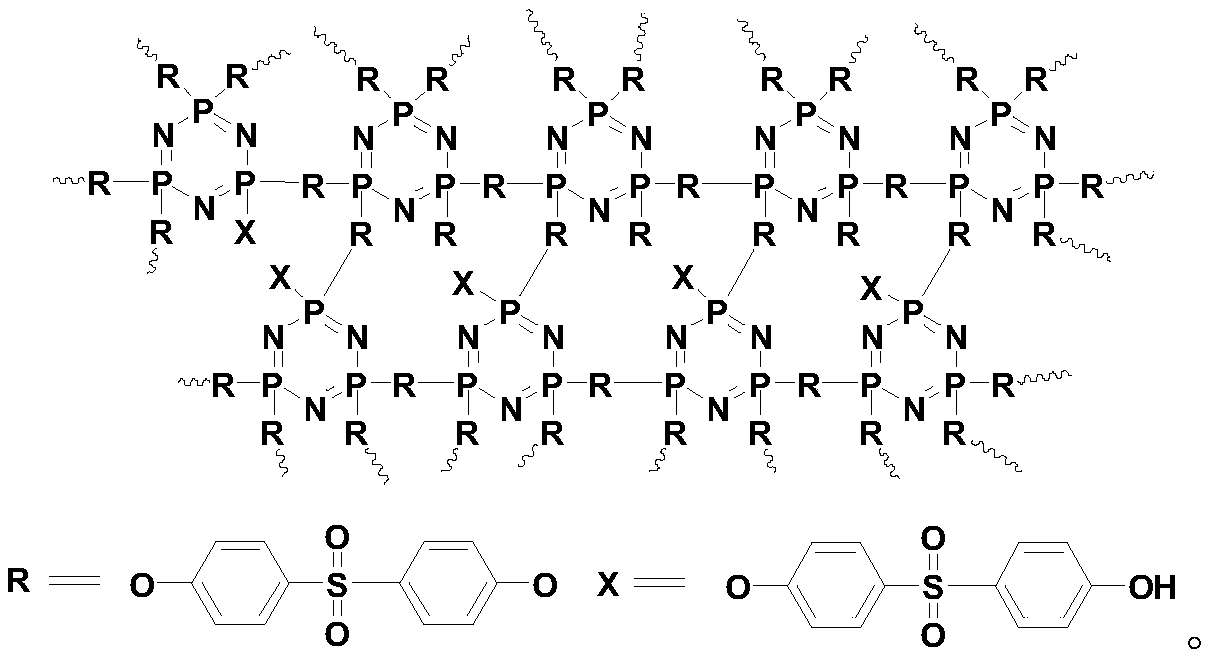

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a double-base synergistic flame-retardant polyoxymethylene composite material, comprising the following steps:

[0030] S1, 90kg of polyoxymethylene, 2.5kg of reactive phosphaphenanthrene, 2.5kg of reactive polyphosphazene, 5kg of styrene-acrylonitrile grafted glycidyl methacrylate and 0.5kg of bis(2,4 - Dicumylphenyl) pentaerythritol diphosphite was dried at 80° C. and then mixed to obtain a mixture. The drying time is 1-4h, until there is no obvious moisture.

[0031] S2. The mixture in step S1 is blended and extruded through a twin-screw extruder at 160-175 ° C, and then cooled to room temperature, followed by traction and pelletizing to obtain polylactic acid, phosphaphenanthrene and polyphosphorus Nitrile double base synergistic flame retardant composite material.

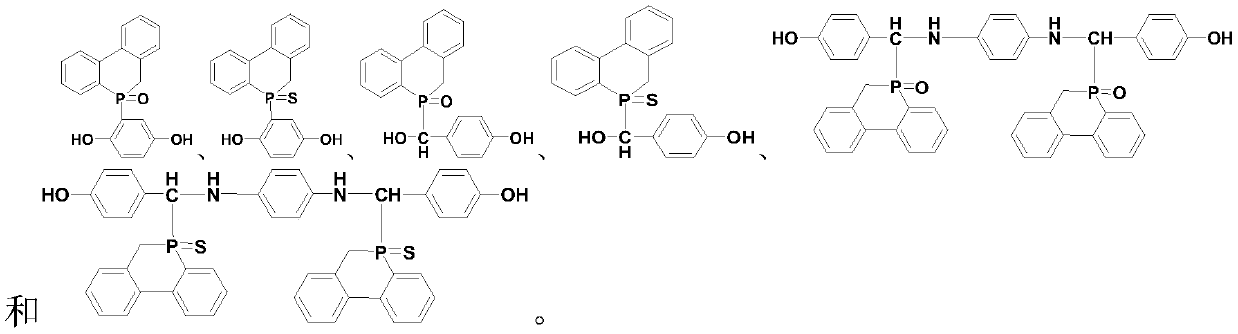

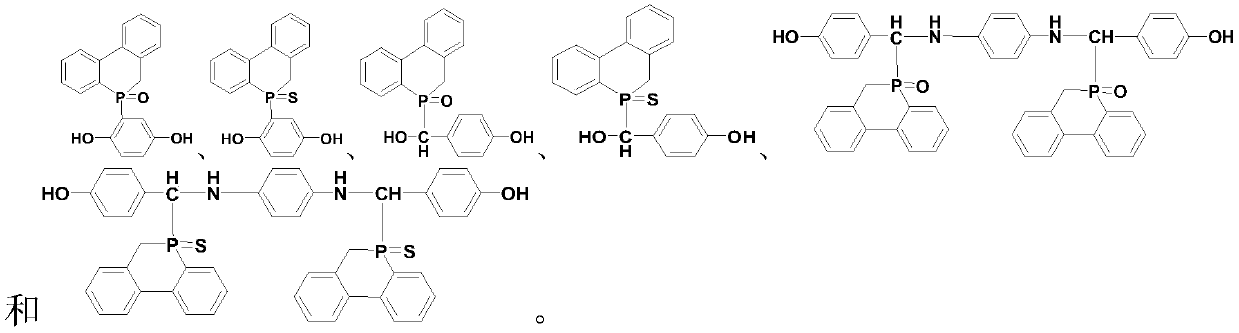

[0032] Described vapor phase flame retardant is reactive type phosphaphenanthrene, (DOPO) 2 -P-PPD-PH), the structure of which is shown below.

[0033]

Embodiment 2

[0035] The difference from Example 1 is that in step S1, 1.5 kg is used for the gas phase flame retardant, and 1.5 kg is used for the condensed phase flame retardant.

Embodiment 3

[0050] A method for preparing a double-base synergistic flame-retardant polyoxymethylene composite material, comprising the following steps:

[0051] S1, 80kg of polyoxymethylene, 2kg of reactive phosphaphenanthrene, 2kg of reactive polyphosphazene, 5kg of polyethylene grafted glycidyl methacrylate and 0.5kg of bis(2,4-dicumylbenzene Base) pentaerythritol diphosphite was dried at 75°C and then mixed to obtain a mixture. The drying time is 1-4h, until there is no obvious moisture.

[0052] S2. The mixture in step S1 is blended and extruded through a twin-screw extruder at 160-175 ° C, and then cooled to room temperature, followed by traction and pelletizing to obtain polylactic acid, phosphaphenanthrene and polyphosphorus Nitrile double base synergistic flame retardant composite material.

[0053] Described vapor phase flame retardant is reactive type phosphaphenanthrene, (DOPO) 2 -P-PPD-PH), the structure of which is shown below.

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com