High-conductivity aluminum alloy and heating processing technology thereof

An aluminum alloy, high-conductivity technology, applied in the direction of conductive materials, conductive materials, metal/alloy conductors, etc., can solve problems such as easy cracking or breaking, increased contact resistance, creep, etc., to reduce mechanical properties and improve electrical conductivity , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

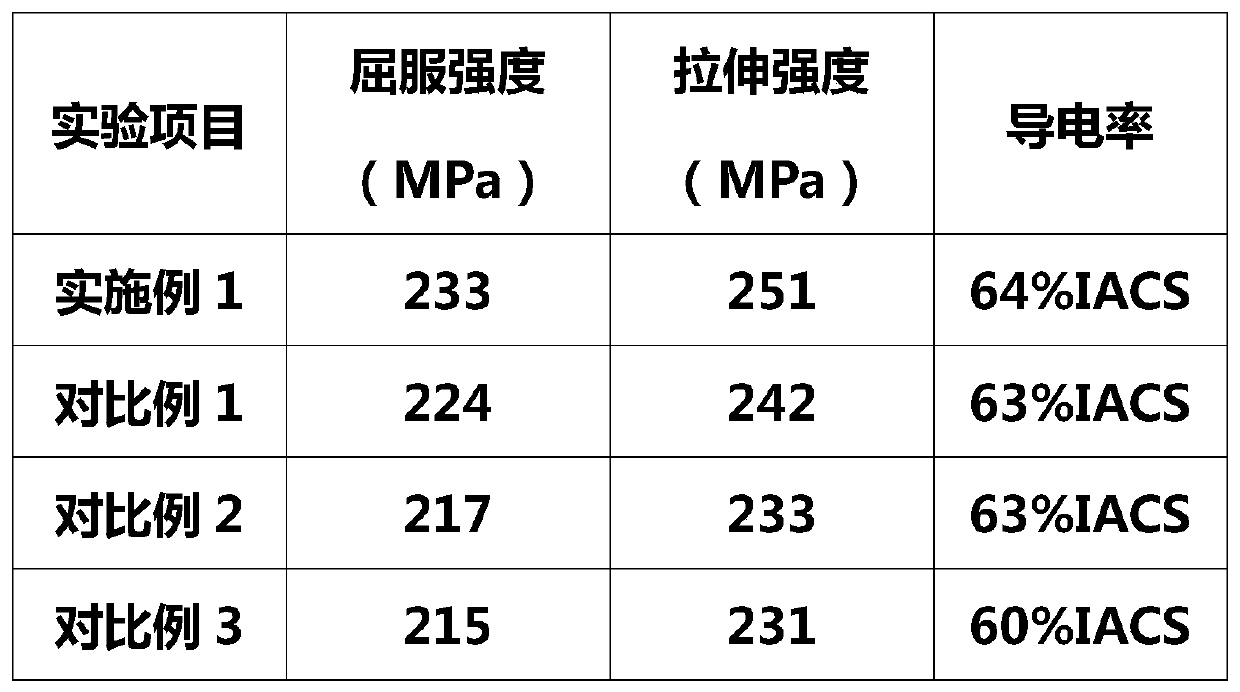

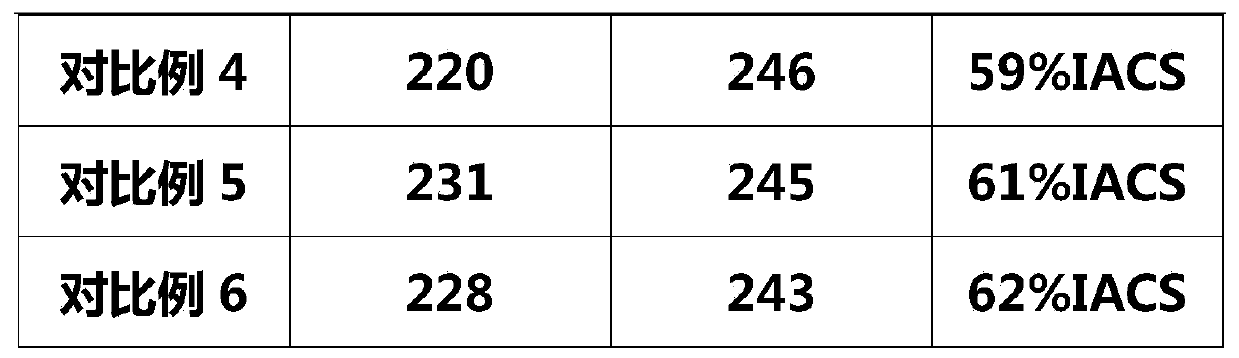

Examples

Embodiment 1

[0017] A highly conductive aluminum alloy comprising the following components: 0.39% Si, 0.1% Fe, 0.124% Cu, 0.65% Mg, 0.04% Zn, 0.05% Cr, 0.12% other unavoidable The impurity element and the balance are Al.

[0018] The preparation method of high-conductivity aluminum alloy: (1) Add the raw materials into the melting furnace in order according to the block weight and size from large to small, then raise the temperature of the furnace gas by 20°C and keep it warm until it is completely melted, then raise the temperature of the furnace gas by 20°C After ℃, add pure zinc ingots one by one, keep warm until it is completely melted to obtain an alloy solution, reduce the temperature of the alloy melt to 730°C, add a covering refining flux, the recommended composition of the covering refining flux is (%, mass fraction): 30 %NaCl, 47% KCl, 23% cryolite, after forming a protective layer on the mirror surface of the melt, refining, refining once during the alloy melting process, the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com