Halogen-free environment-friendly flame-retardant polyolefin master batch for replacing bromine-containing flame retardant and preparation method of master batch

A polyolefin and environmental protection technology, applied in the field of replacing bromine-containing flame-retardant halogen-free environmentally friendly flame-retardant polyolefin masterbatch and its preparation, can solve the problems of general defects and lack of masterbatch, and achieve no precipitation and excellent flame retardancy performance, high temperature and high humidity resistance and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

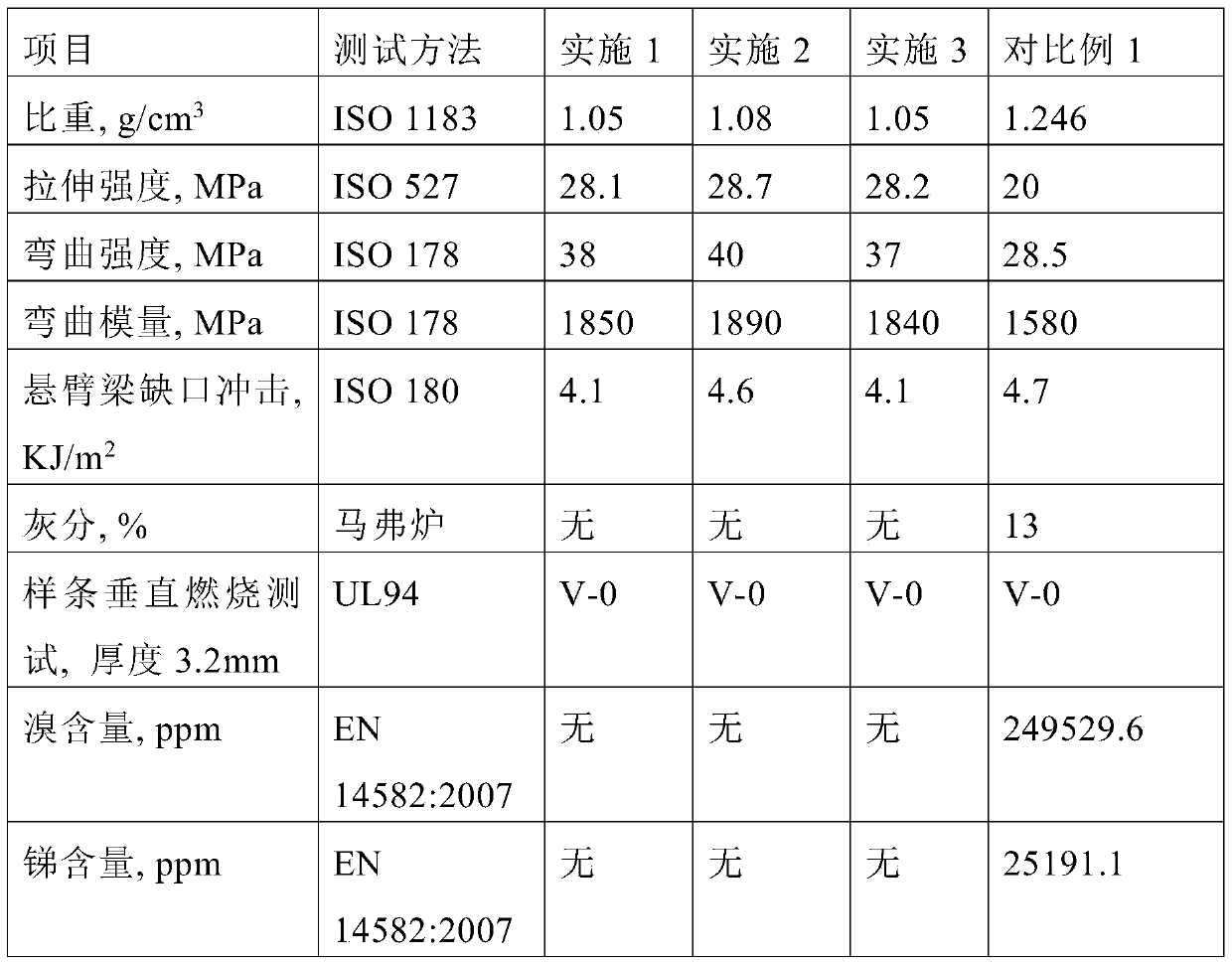

Examples

Embodiment 1

[0024] A halogen-free environment-friendly flame-retardant polyolefin masterbatch replacing bromine-containing flame-retardant and a preparation method thereof, the following steps are adopted:

[0025] The first step: prepare materials according to the following components and weight: polypropylene T30S100, condensed ammonium phosphate (polymerization degree 1600) 240, melamine cyanuric acid 100, silane coupling agent 2.5, siloxane compound 20, synthetic polyhydroxy compound 2 , Antioxidant 1680.3.

[0026] The second step: fully mix the halogen-free flame retardant polycondensed ammonium phosphate with silane coupling agent and siloxane compound in the mixer, and then pass through the high-speed mixer with the remaining components polypropylene, synergist and antioxidant Mix thoroughly and evenly, add to the co-rotating twin-screw extruder for extrusion and granulation, the temperature of each zone of the twin-screw machine is 170°C-175°C-180°C-185°C-195°C-210°C-210°C-210°C ...

Embodiment 2

[0029] A halogen-free environment-friendly flame-retardant polyolefin masterbatch replacing bromine-containing flame-retardant and a preparation method thereof, the following steps are adopted:

[0030] The first step: prepare materials according to the following components and weight: polypropylene 8002100, polyphosphate (polymerization degree 2000) 300, melamine 100, titanate coupling agent 3, silicone 20, polyhydroxy phosphate oligomer 4 , Antioxidant 10100.8.

[0031] Step 2: Fully mix the halogen-free flame retardant, titanate coupling agent, and silicone in a mixer, and then fully mix with the remaining components polypropylene, synergist, and antioxidant through a high-speed mixer , into the co-rotating twin-screw extruder for extrusion granulation, the temperature of each zone of the twin-screw machine is 170°C-175°C-180°C-185°C-195°C-210°C-210°C-210°C-220°C -220°C-220°C, twin-screw extruder with a screw length-to-diameter ratio of 46, the air-cooled grinding surface ...

Embodiment 3

[0034] A halogen-free environment-friendly flame-retardant polyolefin masterbatch replacing bromine-containing flame-retardant and a preparation method thereof, the following steps are adopted:

[0035] The first step: prepare materials according to the following components and weight: polypropylene T30S100, polyphosphate amine (polymerization degree 1200) 280, melamine hydrobromide 700, silicone oil 20, polyester hydroxyl oligomer 6, antioxidant 10100.2, Antioxidants 1680.3.

[0036] Step 2: Fully mix the halogen-free flame retardant and silicone oil in the mixer, then fully mix with the remaining components polypropylene, synergist, and antioxidant through the high-speed mixer, and add them to the co-rotating twin-screw extruder Extrusion granulation is carried out in the machine, the temperature of each zone of the twin-screw machine is 170°C-175°C-180°C-185°C-195°C-210°C-210°C-210°C-220°C-220°C-220°C, double The screw length-to-diameter ratio of the screw extruder is 42, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com