Toughening modification method for bismaleimide resin

A kind of bismaleimide resin, maleimide resin technology, applied in the direction of adhesive and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

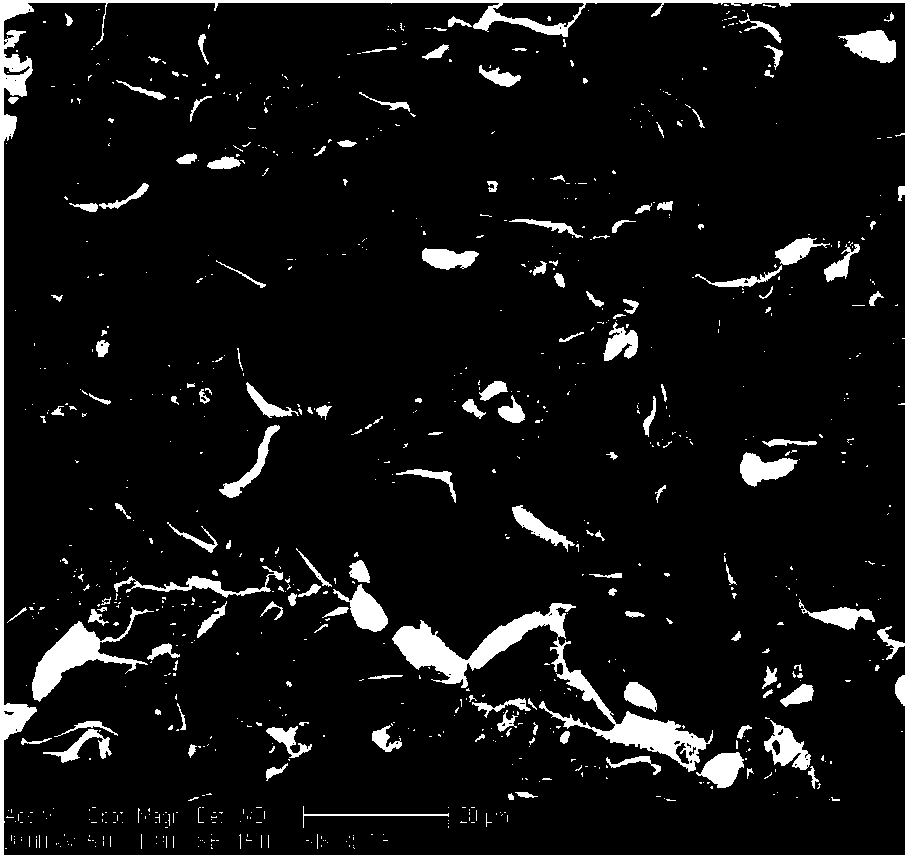

Image

Examples

specific Embodiment approach 1

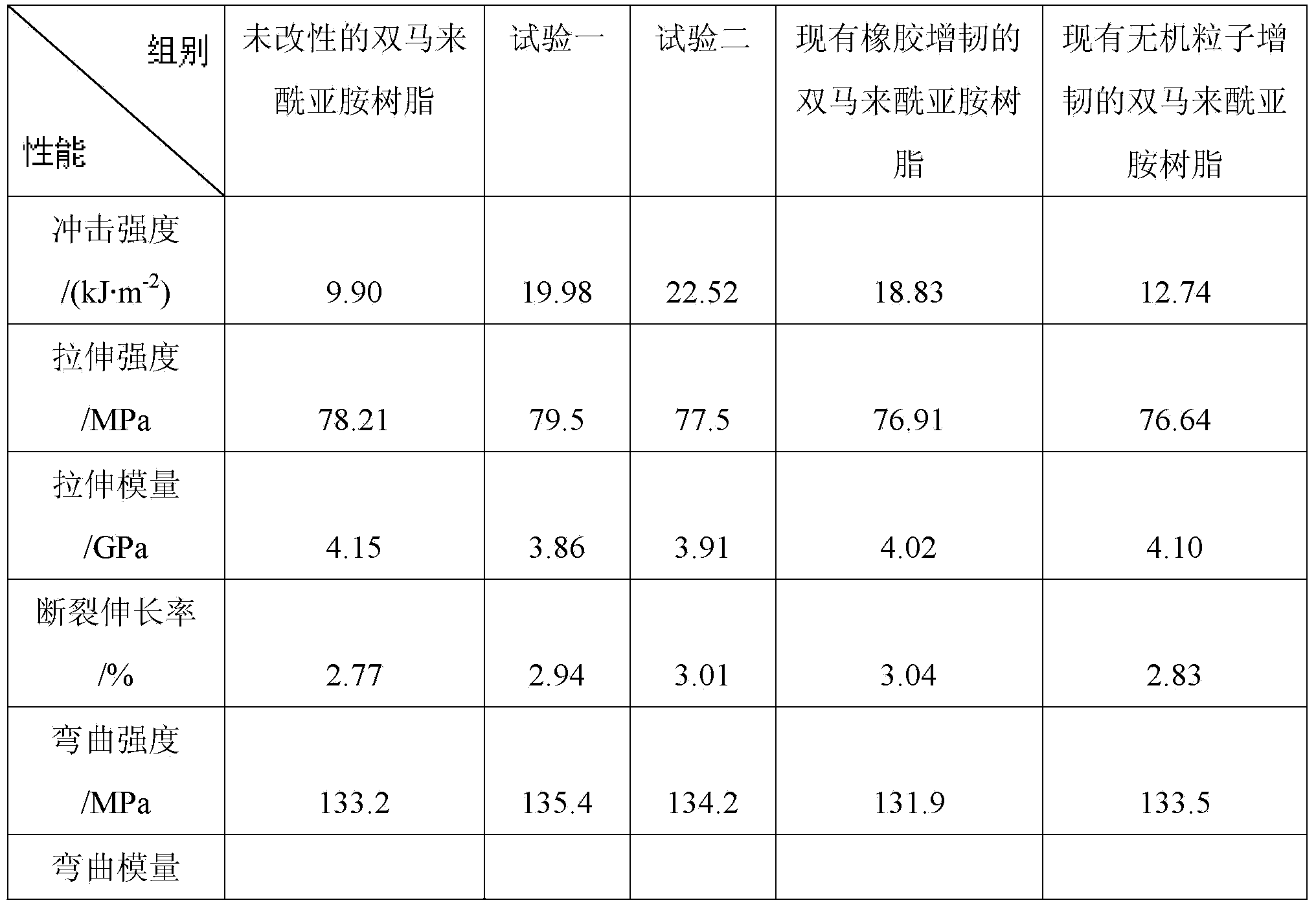

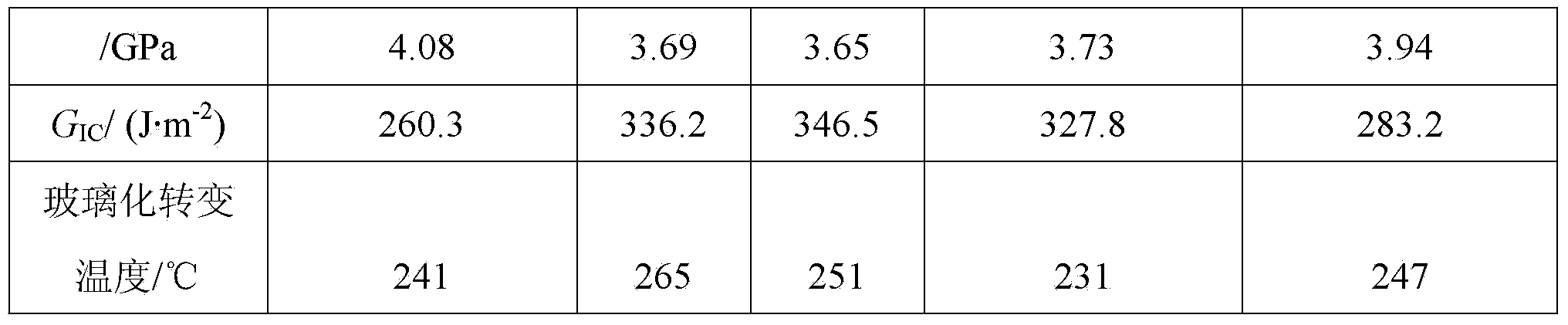

[0012] Specific embodiment one: the toughening modification method of bismaleimide resin of the present embodiment, carry out according to the following steps:

[0013] 1. Prepolymerization reaction: Stir diallyl bisphenol A, bismaleimide resin and vinyl-terminated nitrile rubber in an oil bath at a temperature of 120°C to 150°C until they are completely dissolved, and then at a temperature of 120°C ℃~150℃ under oil bath, continue to stir and react for 20min~40min to obtain prepolymer; the molar ratio of bismaleimide resin to diallyl bisphenol A is (0.9~1.9):1; The bismaleimide resin is 100phr, and the addition of the vinyl-terminated nitrile rubber is 5phr~15phr;

[0014] 2. Add silicon carbide whiskers treated with silane coupling agent to the prepolymer obtained in step 1. After stirring evenly, put it into a vacuum with a temperature of 120℃~130℃ and a vacuum degree of -0.09MPa~-0.1MPa. Perform defoaming treatment in a drying oven for 25-35 minutes, and then pour into a m...

specific Embodiment approach 2

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the bismaleimide resin described in step 1 is 4,4-diaminodiphenylmethane bismaleimide resin (BDM) and 4,4'-bis(3-maleimidophenoxy)benzophenone (EK-BMI) or a mixture of both. Others are the same as in the first embodiment.

[0021] When the bismaleimide resin described in this embodiment is a mixture, each component is mixed in any ratio.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the molar ratio of bismaleimide resin and diallyl bisphenol A described in step one is (1.0~1.8): 1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com