Method for polymerizing and grafting polyethylene surface light-initiated controllable free radical with ultrahigh molecular weight

An ultra-high molecular weight, polyethylene technology, applied in the field of surface chemical modification of high molecular polymer materials, can solve the problems of difficult continuity treatment, easy attenuation of fiber surface bonding properties, and many side reactions, so as to improve the hydrophilicity. The effect of high adhesion and adhesion properties, low UV intensity, and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

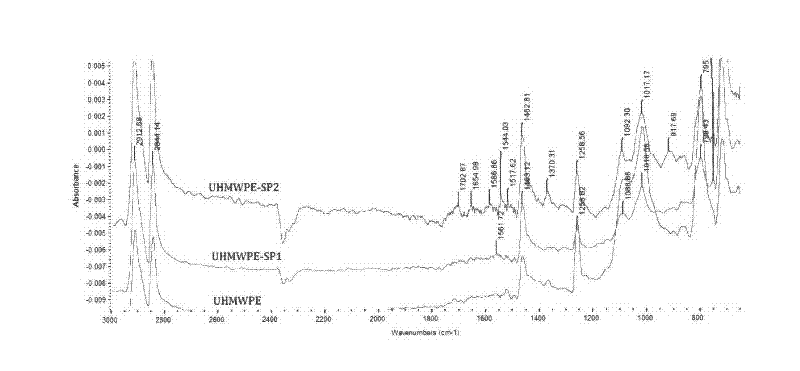

[0048] Under the protection of nitrogen, the ultra-high molecular weight polyethylene film was swelled in n-heptane for 6 hours, and then extracted with acetone for 6 hours to obtain a pretreated ultra-high molecular weight polyethylene film. The pretreated film was soaked in diphenyl Methanone (concentration 1%) in the acetone / n-heptane (acetone / n-heptane weight ratio 1: 4) solution 2h, then be placed in the quartz tube and react 20min under nitrogen atmosphere, the sample infrared spectrum after reaction is as follows figure 1 As shown, after ultraviolet irradiation, the absorption peaks of benzene ring appeared at 1654, 1586 and 752nm.

Embodiment 2

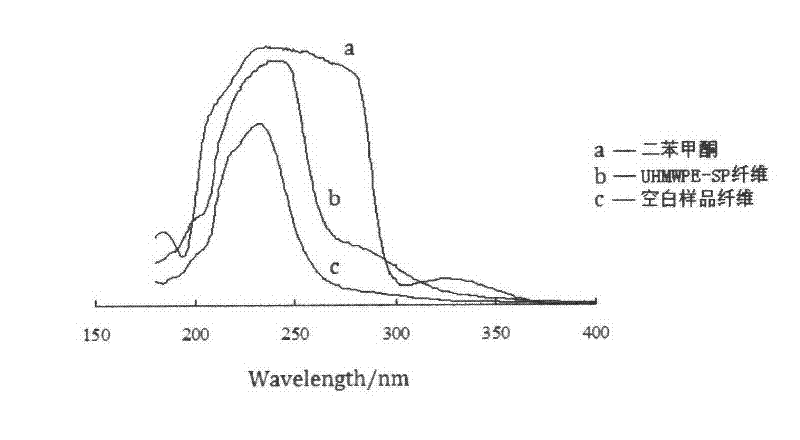

[0050] Under the protection of nitrogen, the ultra-high molecular weight polyethylene fibers were swelled in n-heptane for 24 hours, and then extracted with acetone for 10 hours to obtain pretreated ultra-high molecular weight polyethylene fibers. The pretreated fibers were soaked in diphenyl Methanone / xanthone (benzophenone / xanthone weight ratio 4:1, concentration 10%) in acetone / n-heptane (acetone / n-heptane weight ratio 4:1) solution for 24h, then Placed in a quartz tube and reacted for 120min under a nitrogen atmosphere, the UV absorption spectrum of the reacted sample is as follows: figure 2 As shown, the UHMWPE-SP fiber has an obvious absorption peak at 280nm, but the blank fiber sample does not, and the absorption peak at 280nm is the ultraviolet absorption peak of the benzene ring.

Embodiment 3

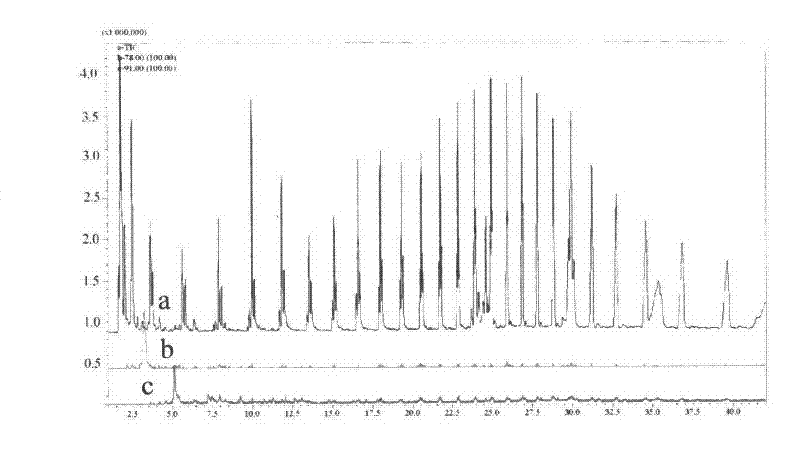

[0052] Under the protection of nitrogen, the ultra-high molecular weight polyethylene fibers were swelled in n-heptane for 12 hours, and then extracted with acetone for 8 hours to obtain pretreated ultra-high molecular weight polyethylene fibers. The pretreated fibers were soaked in diphenyl Methanone (concentration 5%) in acetone / tetrahydrofuran (acetone / tetrahydrofuran weight ratio 2: 1) solution for 12h, then placed in a quartz tube and reacted for 60min under a nitrogen atmosphere, the sample py-GC-MS spectrum after the reaction is as follows image 3 As shown, the benzene ring and toluene fragment ion flow in the Py-GC-MS spectrum is the fragment ion flow of the photosensitive group in UHMWPE-SP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com